SkinnyG

UltraDork

9/13/19 8:22 p.m.

Yeah, but I'm a tinkerer, and this thread covers five years of ownership(tinkerage). That, and some parts are low quality.

They are a nice looking truck. If I could make recommendations:

- Fix all the rust, then alter the sheet metal drains so it's less likely to rust again.

- LS. This will actually solve a LOT of issues.

The current holdouts of annoyance:

- Oil leaks at valve covers. Someday I'll get in there with Permatex.

- Transmission oil leaks. I give up. I pour a half liter in about every 6 months.

- Driveline vibration. I'm almost ready to give up.

If you love these trucks enough, you'll find a way to make it work for you. I'm just hoping my '61 isn't going to become as annoyingly high maintenance as this one.

SkinnyG

UltraDork

10/3/19 10:41 p.m.

*sigh*

Still chasing driveline vibrations. My butt is too fussy.

Tonight, I am still running the 2° shim under the axle, maintaining a 1° down angle (pinion pointing down at front).

I have now raised the tail of the transmission to within a rabid unicorn monkey fart of touching the floor of the truck.

The vibration -seems- to be the lowest it has ever been. It's still there, but it is very faint. It used to get very nasty above 60mph, and now it's pretty decent.

ShawnG

PowerDork

10/3/19 11:01 p.m.

Silly question but did they somehow get the yokes 90 degrees to each other when they built the shaft?

A universal jointed shaft will move back and forth a tiny bit as it goes around. Having the yokes in the same plane lets it go back and forth but having them 90 degrees to each other will make the shaft try to grow and shrink and will certainly cause a vibration.

I've seen this in Ford TTB front axles that have been put back together wrong.

SkinnyG

UltraDork

10/3/19 11:06 p.m.

Both driveshafts I have had made are made correctly. For neither shop is this their first rodeo.

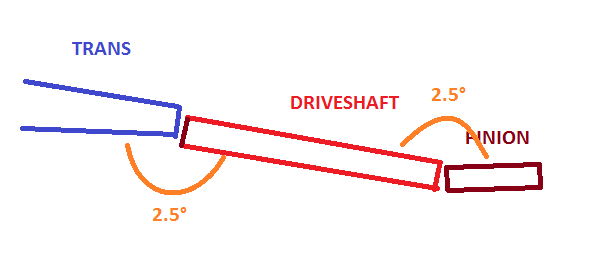

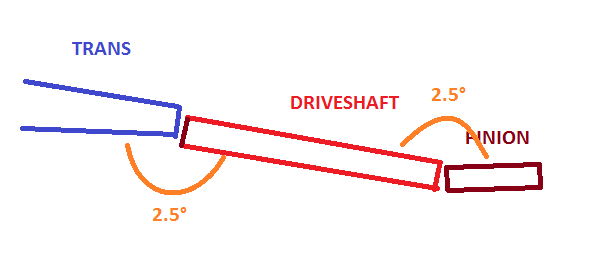

I think the operating angle is the biggest culprit, with this truck lowered around 6" or 7" in the rear, the driveline is not following the typical Trans.down/driveshaft.down/pinion.matches ( \ \ \ ), instead I have trans.down/driveshaft.level.pinion.opposite ( \ - / ). When the axle is higher than the trans output, the "equal-and-opposite" rule is out the window. Worse so on leaf springs.

I haven't measured final angles now, but I will soon and post back.

SkinnyG

UltraDork

10/31/19 9:41 p.m.

For some drunken reason, the tailpipes have been getting caught in the leafs when the truck was raised on a lift. No idea why it started now, and didn't happen before....

I got tired of fighting it, and lopped the tailpipes off, running some turn-downs angled slightly to the outside. Surprisingly, it really only drones just off idle, but nowhere on cruise at all.

Gtholen

New Reader

11/7/19 8:35 a.m.

SkinnyG,

I just read through this whole thread. That's a cool truck but I hate that you have had vibration issues for so long. I like your other truck as well.

SkinnyG

UltraDork

3/31/20 6:13 p.m.

Wow.

Runs a while lot better with new plugs (1 year old), and new cap and rotor (both 6+ years old).

Wow.

Cool! Are you getting to enjoy the truck? I don't recall if/how you are using it.

SkinnyG

UltraDork

4/4/20 11:38 a.m.

It's my daily driver, in all its 10mpg glory.

New winter tires on.

I bought some Cooper Evolution tires. There's pretty slim pickings in 235/75R15 out there, and what I really want is a 245/60R15 in a winter, which doesn't exist. I ran Michelin X-Ice radials for the past five winters or so, and while they kicked buttox on ice, they were certainly more lax in snow. The X-Ice were the only tires to get me stuck, in all my cars, ever, and both times 100' from my driveway. The Coopers look like they will do better in snow, but less good in ice.

Also,

My rad started leaking. It's been getting worse and worse. It's one I had re-cored a year or two (or three? or four?) ago, for a pretty penny. Now failed.

I -thought- I had the larger core rad. I measured it, I was sure it was 19". I ordered the 19" rad from Rock Auto, and sure enough, I apparently have the 17" rad. Except today, I now needed a jug of coolant to get home. So I swapped rads, and had to fabricate a new upper rad mount to fit the taller rad. Grrrr. Thankful I have a wack of tools to do this.

It ain't pretty, but it holds.

solfly

Dork

10/30/20 5:58 a.m.

Good upgrade even if unintentional.

With that much extra area do you need to blank off part of it to prevent over cooling in cooler weather?

I have clipped a fender cover over the grill with the old rad, but usually only below -15°C. If I feel it's taking too long to heat up, I'll cover it. Usually it's not an issue.

So, this was odd. Or maybe I'm just looking at "science" and not recognizing it correctly.

New rad in, no leaks, working dandy.

Today it's snowing on the way home, so we're around feezing. Truck is running just fine.

Arrive in my garage, and there is a lot of steam coming out of the grill. I have to look.

Steam, yes. Lots of water condensing off the rad support metal, but no visible leaks from the rad. I huffed a lot of the vapour, and NONE of it smells at all like coolant, it just smells like.... steam. I taste the condensation from a number of places, and surprisingly - it's just water. Not coolant.

Let the truck sit over supper, and water collects on the ground under the rad area. Looks like water. Feels like water. Tastes like water. No coolant. Coolant level not low.

I've never noticed so much steam before. I'm not even sure why it happened. Just the right temperature humid air, with rad heat? Steam, to me, is worrisome.

Is it just science kicking my butt??

Well, it's only happened once again, and I haven't noticed it since. Coolant level is not going down. I chose to ignore it.

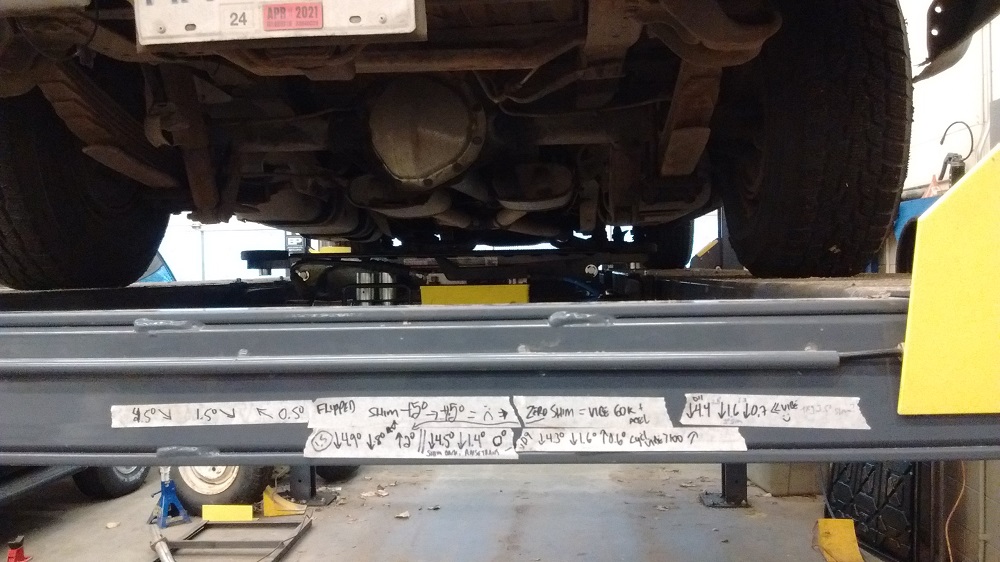

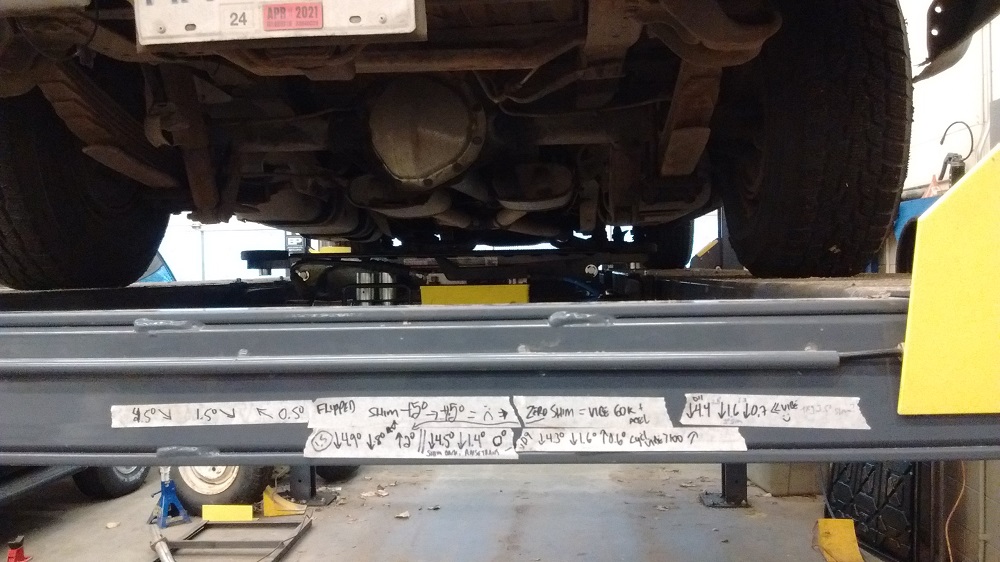

In other news, I've been spending the last month or so playing with pinion angles to try and get rid of driveline vibration.

One of the things I did was to raise the transmission as high as I could go (it's now 1/8" away from the floor). Marginal improvement.

I guarantee you, matching the pinion with the transmission was NOT a good move. Horrible vibration, probably because it makes the driveshaft angle up to the pinion, making for an awful operating angle for that u-joint, made worse under acceleration.

So I started moving the pinion the other way.

And, following the factory GM driveline NVH procedure, I ended up trying to focus on making the u-joint operating angles the same as priority #1.

Having machined a 3.5° shop to drop the pinion down, I ended up with this, and have the lowest amount of vibration ever.

I kept notes as I mucked with it:

Well, this was unexpected.

Explains the "drunk steering" on the way to Home Depot this morning.

Rist belt. Don't miss that E36 M3 AT ALL.

Not failure due to rust - the shank on this fastener is completely intact in size and everything. I'm not in the rust belt, either. It's a clean shear break. Not sure how, exactly.

Ok, thats just odd!

And i want to make sure I understand, they don't use salt and slag in Canada like they did in nw pa?

Where I am, it's nothing like the East Coast. I once bought an Ontario car - I had never seen an oil pan rust through before.

Here they use sand, but not salt, to my knowledge. Though I believe they have some weird spray on the roads before a freezing risk, but it ain't like the East Coast at all here.

Can't speak for other parts of Canada. Only ever lived in BC (though I did a year in AB, got off on good behaviour).

I had machined another pinion shim, this time at 4° which has the trans tail down at 4.4°, and the pinion nose down at 1.2°. Even less vibrations than with the previously aforementioned 3.5° shim. I may try a 5° shim next just to see.

This is totally NOT matching and parallel. Just so you know. Interwebs be darned all to heck. Matching and parallel was A.W.F.U.L.

Rust is coming though en force in the rockers and cab corners....

SkinnyG (Forum Supporter) said:

Where I am, it's nothing like the East Coast. I once bought an Ontario car - I had never seen an oil pan rust through before....

Just experienced this this week, one of the techs went to break the drain plug loose on an ISX and the entire welded bung area ripped out of the pan. Of course the customer said that was our fault right?

I've loved watching this trucks life with you. Keep up the good work

Frickin' crane operator hit my truck.

I did not ask for the crane operator to use his magnet. I am perfectly fine unloading $45 of scrap metal by myself. Except now I need to get this dealt with. It's possible ICBC might write it off as a total loss. NOT impressed.

NOOOOOOOOOOOOOOOOO!!!!!may his POS be consumed with copious amounts of lack of respect to one's property.....like iffen it craps out uh.........too Freekin bad butt munch.....lifes's a bitch and than YU DIE!!!!!