so much awesome in this thread very nicely done sir

Maybe rubber mounts for the engine and trans, leave the cab alone?

Worth a shot. All the rubber in this truck was gone. The good thing about poly is you likely won't ever replace them again.

A friend had an '81 4wd many moons ago. All stock. He had poly cab mounts for a week, then yanked them and put rubber back in. Said he couldn't stand feeling every pebble.

You know what would help your emm pee gees tremendously? A 700R4.

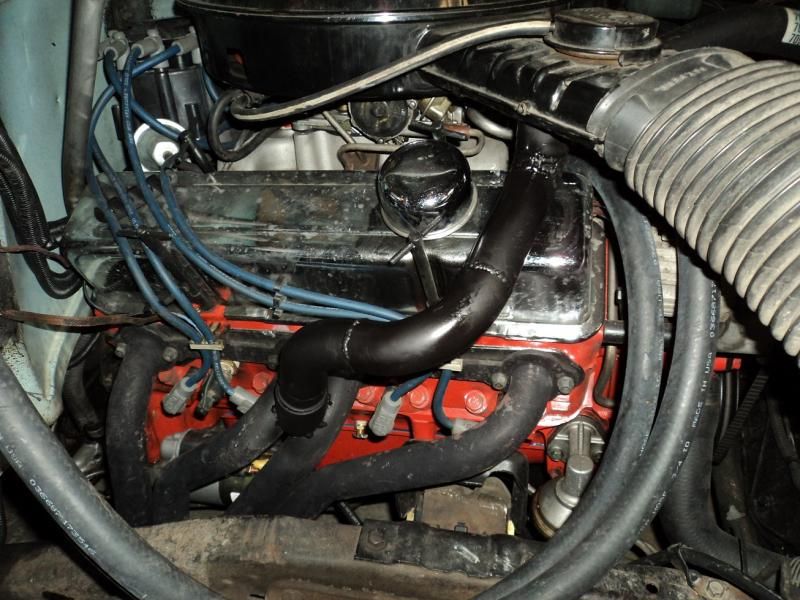

I have a 700R4 on a shelf waiting for a rebuild. For now I'm just enjoying the potato-potato-potato. If I'm cruising much under 2000rpm, the cam isn't going to be efficient (108° lobe separation sounds wicked!). So I need to eventually decide if I want to cam it down and do Vortec heads, or do the 700R4 and get a 5.3L (I will probably do that, and put the hot rod 350 in the V8 Firefly).

Dropping a 5.3L will be easy and cheap with a 700R4, especially if I get the 350 Megasquirted - the wiring would be there by then.

I'm up to 14.7mpg (Imperial, mixed) at the moment, which I think is pretty good considering what it is.

~15mpg isn't bad for a cammed, carb'd 350 with a loose TH350. But a 5.3/4L65E would be absolutely bad ass in that thing.

Still tweaking the APT on the Rochester Q-Jet. Latest fill up was 15.4 (Imp) MPG. I'm pretty pleased.

Not much of an update.

I gave up trying to chase ATF leaks, so I took it to a friend's shop. Swapped my older John Bean alignment machine (newer than his, and I wasn't enjoying the machine) for parts and labour for them to pull the TH350, pull the pump, replace the pump bushing and pump o-ring and gasket. Tranny doen leak no mo.

Picked up a Holley TBI unit, but it has the wrong injectors. It fits my adapter beautifully. Pulled the MSII out of the Lethal Locost for an MSI unit so I can use it on the Chevy and run a stepper motor IAC. Haven't done much more with that. Still rocking the Rochester.

Today I dropped the pan and replaced the rear main with a Felpro 2912 Flouroelastomer jobbie, and a one-piece pan gasket. The cheap-o gaskets I built the engine with are less than exemplary. I like Felpro.

Also replaced a junk-yard sourced tank selector valve with a brand new one, so I should now be able to get two weeks of commuting per fillup.

When I got the truck, I was surprised that the windshield washer pump still worked - those used to always die. Now that the pump had made the appearance, it died. So that will be replaced this weekend.

Also modified a hot air tube to fit the headers and the tall valve covers to help out with winter driving.

And then I finally got around to dealing with a water pump gasket leak. P/S pump was in the way of the lower bolt on the driver's side, and I was reluctant to get in there and fix it. Finally did. Three bolts, eight minutes and done.

Also picked up a book on rebuilding the 700R4 that is calling my name....

Updates.... Breached the headgaskets.

Or, they never actually sealed properly. Or coolant leak didn't go noticed soon enough, before the engine overheated and compromised the head gaskets.

Engine got stripped down after dinner, reassembled with new gaskets (couldn't find any cracks on the heads) and running by 4am. Ran a Heavy Duty Block Sealer through the cooling system and it's doing great now.

Then recently, as I parked pointing uphill, a stream of ATF out the back of the truck. I am HATING chasing these damn leaks. Pulled the driveshaft and brazed the damn hole closed. I ~had~ a new o-ring inside there....

I had carefully disassembled the u-joint to do this, but knackered it when one of the needle bearings fell out of place on the assembly (I should have just packed the cups with grease to hold the needles in there....).

Went and bought a new u-joint, but then discovered the driveshaft was made with a conversion joint, so I just swapped the smaller cups. U-joint was only 6-months old anyway, it'll be fine.

Today I removed the windshield washer squirters, re-soldered their brackets back on, and cleaned and re-directed them. Original pump had cacked, so I had wired in a generic Trico pump sexily zap-strapped to the wiper motor. Because truck.

Had about a foot to a foot-and-a-half of snow yesterday. Cleared the driveway three times, and then salt did its dastardly deed on the driveway overnight.

Grandpa's 1973 Ariens has been awesome. Though difficult to start. Though it's almost my vintage, and I have a hard time getting going in the mornings too...

Led Zeppelin decal makes the truck complete. The last photo, the truck still looks great... How's is the paint holding up?

There are some spots of rust coming through in a few places, likely inadequate prep on my part. Paint isn't flaking off yet, but winter isn't over. I haven't washed it yet.

The cut half-ton coil springs are too low and too soft, especially with the HD leafs in the back. I installed Moog 6454 1-ton coils, with one coil cut off. And made a short 2-minute "how-to" video outlining the entire procedure. Because Mad Tyte ADHD, and highschool kids can't pay attent.......

A while back, I pulled the driveshaft and brazed the breather hole closed on the yolk.

Turns out I must have mucked up the sheet metal cap that contains the hole, because it was leaking too. So, out it came, and a lovely syrup of Permatex Cold Weld went over it. We'll see if THAT stops leaking.

Oh, and though I had already replaced the 12-bolt pinion seal, the gear oil was seeping past the splines and exiting from behind the washer. So, out it came, and a lovely syrop of Permatex Ultra Blue when all over the place. We'll see if THAT stops leaking.

And then a while back, when I replaced the head gaskets, the fancy-schmancy Felpro valve cover gaskets were leaking. Again. So, out they came, and the surfaces all cleaned up again, the valve covers straightened again, the spreaders tweaked again, and the whole thing put back together. We'll see if THAT stops leaking.

I'm sensing a trend here.

And the coolant overflow bottle seems to be leaking....

I am a chevy guy. My truck is a GMC.

GM has never made a decent rear end, and pretty much every older chevy truck I've seen has the telltale splatter on the bed underside from the pinion leaking and spraying everywhere.

Sorry man, let me know if you find a way to stop them

Update: The DIY "flip kit" may have sucked.

I had been chasing a nasty sound like sheet-metal-jamming-itself-into-the-driveshaft. Interestingly, I could not find ANYTHING making contact ANYWHERE.

Symptoms:

I barked up a lot of trees trying to solve this. I even bought new U-bolts (I was re-using the originals, generally a no-no). Finally I began suspecting the flip kit not anchoring the axle securely enough.

I picked up a pair of Leaf Spring Saddles from the local Dodge dealer (#P4120074, $11.27, cheaper than Summit Racing, and no hideous shipping & handling), milled a 5/8" hole 1" forward.

Then I drilled another 5/8" hole forward on the u-bolt plate, since there was some evidence of movement against the center bolt. This also makes the u-bolts clamp more vertically.

Marks from the center-bolt making contact

I matched the angle of the original perch, welded the perches on, sprayed with boxliner (my favourite paint) and assembled. I'll let you know if this fixes it.

If you can feel it in the steering, kinda wondering if one of the rear wheels is lifting the body more than the other. That tries to make the car tripod which sucks under cornering and might be making your sound (from unloading/loading).

Have you done a measurement from wheel centerline to the fender opening on each side to make sure the ride height is generally consistent?

The ride height is generally consistent. Truck sits reasonably level, and rides like a truck should.

I will post my results once I take it out for a spin tomorrow or whenever.

You'll need to log in to post.