Oh dang. Fuel pump or fuel pump related.

Truck is at home in the house garage, up on jack stands in anticipation of dropping the fuel tank.

Not tomorrow though - I have physio after work, and while I usually have dreams of coming home and working on stuff, I'm usually lucky if I can even tie my shoes after the IMS and elecro-shock.

The fuel pump relay was clicking, and I tried bypassing the relay and powering the pump directly, but it wasn't working. I think it's the connection inside the tank. I remember building it going "this seems rinky-dink."

I re-did the internal connections , and it is now "robust."

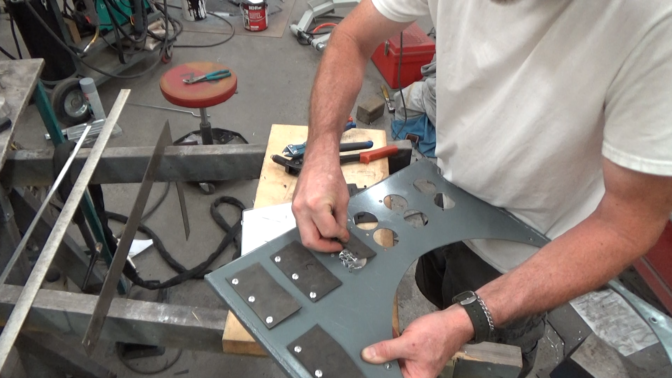

Old and busted "hot" connection for the fuel pump (I'm using a Walbro 450):

I removed that gray connector, and crimped/soldered/heat-shrunk all the wires to their respective pins, with 12ga wire to the pump. There should be no problem now.

Back up to 8psi boost now, and with all eight cylinders properly firing ... HOOO BOY!!!!

I have a smile.

Added a relay to turn on the cooling fan during AC. It's using the Trinary pressure switch off the accumulator. Not sure I'm totally happy with the result, but we will see.

You can just barely see the reorganized relays to the right of the rad.

The bottom of the front air bags are mounted to a plate, with about a 3/4" riser on it to keep the bag in a happy place whilst sitting in the spring pocket of the control arms.

Problem is, as the truck is raised off the ground on a jack or a lift, the control arm moves in an arc downward and the bag bottom wants to move outward to stay perpendicular to its upper mount.

So, I welded about a 1-1/4" section of 2" pipe to the bottom of the bag mount/riser, as far over as I could and still access the mounting bolt. Kind of like a cup within a cup. This 2" pipe fits inside the existing hole in the control arm, and restricts the movement of the bag mount when the truck is raised.

What I had been finding, is the bags were sitting more horizontal than vertical, requiring more air pressure and netting less ride height.

MUCH better now, and the bags stay in place when the truck raised on a lift.

Last staff meeting of the school year. I should have taken a picture of the entire parkinglot filled with white and black and dull. And me.

I have a new "Princess Auto" axle on it now.

Had to move the leaf perches because this trailer has them on 47" centers.

Also had to open up the bore on the Chevette wheels to 2".

Also have to replace one tire that the tow truck operator blew up unloading off the roll back. Why they didn't send a hook and boom with dollys is beyond me; I was very clear on the phone on what it is they were picking up. Might as well replace both - they're 16 years old.

Funny bit: Tow truck guy had asked me to pull it forward so they didn't have to block half the lane to load it (I was mostly in the center lane). Truck wouldn't budge the trailer at all. No gentle pull. Not even a brief freakin' hazer. Nope.

COOLING ISSUES

On the highway, it's fine, but in traffic, in the summer, at 38°C, with the AC on, it's not.

Could be because I have an intercooler in front of a transmission cooler in front of an A/C condenser AND P/S cooler all in front of the radiator. Nah.

The rad core is 22x19" in size and rated for 700hp. I have one $100 17" American Volt electric fan, zip-tied directly to the radiator. This cools ONLY a 17" circle minus the hub of the fan area, inadequate when standing still. The fan is rated at 130W, which should pull about 11Amps of current.

I ordered a $360 "Be Cool" 16" fan that is actually make by Spal, which draws 26Amps.

Excitingly, the blade and hub protrude past the mount, necessitating a raised mounting. If I'm going to raise it at all, I'm going to build a shroud. A shroud should encompass the entire core so the fan can draw air past the entire core. Which I fabricated.

On the other hand, fully shrouding a rad reduces the amount of air that can pass through the rad at speed. To fix this, I made nine 2"x4" rubber flappers from a commercial truck tube, which "flap via three (each) 3/16" pop rivets pulled NOT tight, so they can move. These each cover a pair of 1-5/8" holes in the shroud. In theory, when the fan is pulling, these flaps are sucked closed, and when the car is at speed, air pressure forces the flaps open.

And boy does the completed unit almost fit for reassembly.

The result?

So far, seems good after the first short outing....

There's also been a bit done with the 800w Mercedes fans, they're wired always hot with a pwm control signal...

Truck cools down quicker, but still overheats with AC on. We're around 38°C currently.

To save the engine, I have the AC off, the windows open, and the heater on FULL. When I turn the heater on, it will stay under 206°F in traffic just fine.

I THINK....

My stack of coolers is the problem:

INTERCOOLER/TRANS-COOLER/AC-CONDENSER/RADIATOR

With basically no air space between them.

I pulled the Trans-Cooler out, and I'm only running the rad-based trans cooler for now. If I do run another external trans cooler, I'll need to figure out where.

Not tested yet, as I'm replacing our back deck with a raised Allan Block patio with pavers and a pergola-esque top, and I need to unload the gravel out of my trailer to get the truck out of the shop. Today was placing the Sunlite Polycarbonate roofing panels in place

Also today I stepped off the ladder and onto a stray corner Allan Block, lost my footing, and landed on my face. Took a while to get back up again.

Also I seem to have landed on my wrists - I'm in the queue to see a specialist on Carpal-Tunnel already, and am already using a prescription version of Voltaren that is 5X stronger than Voltaren's "Extra Strength." Yay me.

NOHOME said:Did you look into the Volvo two speed fans that are popular with the hot rod crowd?

What model Volvo do these come off?

Racingsnake said:NOHOME said:Did you look into the Volvo two speed fans that are popular with the hot rod crowd?

What model Volvo do these come off?

I would also like to know the answer to this question...

With the trans cooler gone, I can drive with the AC on and it stays 197-199°F.

Pulling a loaded trailer, it's less happy - running about 204° a lot of the time, with a high of 217°.

I may look at ducting and sealing to keep the radiator sides well separated. And WaterWetter

Today wasn't a fair test. 30°C outside today, vs the 38°C we had on Saturday.

I added a bottle of Water Wetter, and stuffed some dense foam between the top rad/mount gap. I will fill the gap at the bottom as well, probably tomorrow.

I also reduced some of the AC pressure - it is possible it was over-charged, which, as I understand it (?) could cause the condenser to run hot.

Highest I saw was 206°F in traffic, but I had the AC on full, pulling a trailer, and it was usually 199°-201°F.

(Yes - up here in Canada we speak both Metric AND Imperial, it just depends what we're measuring.)

You'll need to log in to post.