Thats a nice shop ! Now, go work on your car sir ![]()

physician wrote: Thats a nice shop ! Now, go work on your car sir

Yeah...what he said. Remember this thing![]()

This is the first decent post now, in over a year. I've been building The Workshop, and it is near enough to completion that today the Firefly has moved in. Chances are it will get a whole lot more finished with light, heat, and a hoist.

Interesting dilemma in how I want to go about wiring this.

At SOME point, I will likely run Megasquirt. At THIS point, I just want stock TBI. I want to wire it in such a way that switching to MS in the future is quick and easy.

Gotta do some thought on various inputs, sensors, and emissions.

Difficult too, in that I had students strip the Firebird donor six years ago, and put everything in boxes. Found the fuel pump switch (on the motor, above the oil filter), but clearly hadn't thought about its location when I built the headers.... This, too, might need a re-think.

I have some scrap header tubes in my collection. It might be easiest/simplest to pull the header and change that offending tube. I have room to run it forward a bit.

That wasn't what I ~wanted~ to do, but nevertheless, it's what is going to happen.

Today, I took the header out to have a good look at it.

This required removing four spark plugs.

I don't know how the owner/builder of this car got plug #1 in, but no socket can get in there. #1 and #3 come out from the top. #5 and #7 come out the bottom, using the spark plug socket and a 3/4" stubby wrench - thank heavens spark plug sockets have a "hex" on the end.

This also required pulling the temperature sender. No problem since there is no coolant in it.

This also required disconnecting the steering shaft. Not difficult, but annoying.

The headers are held in by 3/8" Allan Head Cap Screws, half of which are removed with a shortened Allan key, and the others are removed with the piece I removed from the Allan key (about 3/4" long) and a 5/16" open end wrench. Good times.

Turns out I do not have enough bends in the last scrap header tube I have to make this work. And even if I did, that would render the removal of spark plug #5 impossible. Though #7 would be much easier to get to.

I removed the fuel pump switch, and plugged the hole.

That all took half the day.

I made some clearances for spark plug socket and cap screw access, and cut the flange section from between #1 and #3 so that I do not have to remove the temp sender in future.

Installation was the reverse of removal, but with more swearing at the owner/builder of this wreck. That took the other half of the day.

Also bolted the torque converter to the flex plate, installed the plastic cover, and attached and adjusted the Throttle Valve cable to the transmission.

No pictures today, because there was nothing to see here.

So, I picked up a few pipe bitties over the past couple weeks. I might be able to cobble this together into something. I wanted to try and fit it this evening, but reaching past the engine into the dashboard area, or crawling over the roll cage tubes, wasn't something my back was interested in doing.

And I can't seem to find the plug for this in the harness anywhere. The kiddies at work pulled this 6 years ago. I can't remember what happened that far back.

Adding up receipts this evening, I'm a tick over $1700CDN (that's $1300US).

Seems like one of those times when a car looks better with the grill removed. Good luck getting this project back on the road to completion!

Thanks. They do look the part. Stealthy, and yet.....

End of the semester is coming up, so I'm a bit busier at work. First group of kids trying to start their Chevy engine today.

Was chatting with a friend (teaches mechanics post-secondary) about the delightful fuel pump switch placement, and the impending T into the idiot light sender. He said the fuel pump is redundant - it is wired in parallel to the fuel pump relay, and the car should run without it.

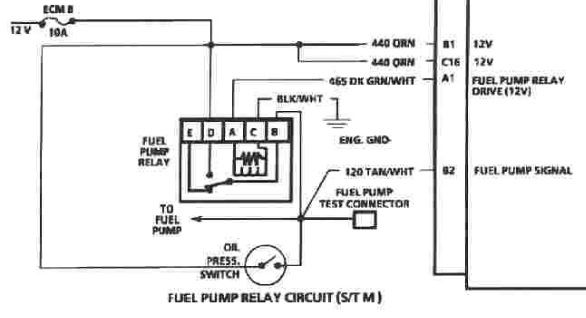

Sure enough - there it is, parallel with the relay:

So good news! I ain't even going to put it back in. Bugger that.

I'm confused what the point of the pressure switch is then. Looking at that diagram I would think the relay is only being used to prime the system at key on and run the pump at startup and then it disengages and hands control over to the oil pressure switch, so if it loses oil pressure it kills the fuel to protect the engine.

Or am I misunderstanding the purpose of the switch? Like rather than a protection thing, it's only there to keep the car limping along (with lonngggg crank times) if the relay/relay driver that normally controls the pump full time craps out? That does sound like the sort of stupid GM is famous for.

I did some mad tyte Google-Foo and came up with a number of sites that confirmed, including a TSB posted as below:

*** UPDATED BY TSB 893206E, DATED OCTOBER 90

When the key is first turned ON, without the engine running, the control module will turn the fuel pump relay ON for two seconds. This builds up the fuel pressure to normal operating pressure. If the engine is not started within two seconds, the control module will shut the fuel pump OFF and wait until ignition reference pulses are present. As soon as the engine is cranked, the control module turns the relay ON, which powers the fuel pump. The control module continues to power the fuel pump during engine operation. If the fuel pump relay fails, it is backed up by the oil pressure switch, which continues to operate the fuel pump as long as oil pressure remains above 28.0 kPa (4 psi).

I always thought that switch would kill the pump if you lost oil pressure, but I guess it's a "it'll still get you home if that relay fails" kind of thing.

I think you're right on the GM Engineering. Not surprising, really.

So I knackered my back on Dec. 30th, and after three visits to the Chiropractor, one visit to Physio, and an entire bottle of Robaxacet, I am finally a lot more mobile, and on Tylenol a reluctant twice a day now. This is good.

I put a thermometer in my shop to see what the temperature was. I had the heater at full OFF, and it was staying at 10°C. I did a bit of research on the thermostat I had bought, and apparently it is supposed to sit at 5°C minimum (we've been between -10° and 0°C (freezing, to you 'Muricans) for some time now). I disassembled the thermostat, found the calibration screw, and reset it so that when it's turned to 15°C (comfortable working temp), it actually ~IS~ 15°C

I took the dashboard out to make it easier to wire. This is going to be a challenge.

Also, I have relented and decided to run a heater and defroster, but I this will be another challenge, because the defrost ducts and heater guts have to go where engine currently is. This will take some thought. So far, my thinking is some PVC tube with holes drilled to blow through the defrost openings, fed on one end and capped on the other.

So, I let that simmer in the back of my head, along with the placement of the ECU, and any suspected future changes of wheel well size (danged bigger tires).

I cut a hole in the firewall for the engine harness bulkhead connection thingie from the Firebird, and started wiring up the engine. Lots of shortening and routing, and I ran out of heat-shrink.

Conveniently, the Firebird had this bracket that held the cooling fan relay, fuel pump relay, ignition module, and MAP sensor. So I mounted that to the inner fender. Overall, I ~think~ I am happy with my results.

I toyed with the idea of hiding all the electricals and make it look all bling, but the logical side questioned how fun this thing is going to be to service as it is.

I think I have a solution for the heater core. This is NOT fun to place, but I have no options. I will be adding some kind of fan and ducting to this to blow air to the new defrost ducts. The original cowl inlet is paneled over, since engine fumes would otherwise get into the passenger compartment.

The past year and a half of building the shop had me venturing back into the "obsessive" end of things - I feel myself slipping back down to a more productive "git'er dun" mode. This isn't as thoroughly well thought out as I'd like, but I'm mostly sure the end result will work. Went to look at a '65 C10 step side that popped up locally. I want one to replace The Crusty Chevy. Turns out when he said "yes it has BC registration," what he meant was "no I don't have BC registration." Which means a vehicle inspection, which means I have to build it once to pass, then disassemble it to molest it properly. I didn't even open a door or pop the hood, just "thanks for your time" and walked away. There are more fish in the sea.

You'll need to log in to post.