So far this has been a week of great success and big (painful) failure. Getting the driver's door just about finished was hugely exciting and really put me on a Healey high, itching to get moving on the other side. Christmas with half my family came and brought goodies for the shop and vehicles - the most immediately exciting were four linkable overhead LED shop lights. I went over yesterday and got them all hooked up.

Before - two light bulbs over the one-car section and two florescent fixtures in the back over the two-car area.

It's hard to really tell how dark it was in there. The shadow on this side of the car cover gives the idea. More often than not, I blocked the light I needed with my body/head and needed to use the auxiliary work lights I have.

I decided the more important area to have light was the back section where the Healey is. Three of the new lights would go back there and one on the "truck" side. After much time up and down the ladder and screwing in hooks, here is what I ended up with.

It's still much darker over the truck but I'm really happy for now. I also became a grown-up and hung a real wheel rack and got four more dollies (this is a precursor to the painful failure of today).

So that covers the successes of the weeks so far. 'Tell me, Andrew, what was this big failure?'. Glad you asked.

I had these grand visions of welding jackstands to the wheel dollies so the Healey would be easily scooted around the garage to access different sides/angles/etc. I also intended to secure the frame of the Healey to the jackstands.

This morning, I got the Healey up in the air on all four jackstands and dollies. I decided to do this before welding as a sort of proof of concept. As I was getting prepared to join the stands to the dollies, I decided it was a good idea to give the Healey a little test scoot. First I did the rear (moved it about 0.5") - great, this is going to work! Then I tried the front - the jackstand and dollie aparatuses moved about 0.25" and the car moved the the other 0.25". OK, I thought, I'll just reposition the car. After doing that, I tried scooting it again - DISASTER. I obviously was missing some brain power this morning. Why did I even test scoot? Why didn't I first secure the car to the stands? We'll never know.

The jackstands and the dollies stayed put and the car fell off the stands. I tried (to no avail) to catch the front of the car where I was standing. I pulled my back really bad, something stabbed me pretty deep in the ankle (still not sure what) and the Healey is showing some battle scars.

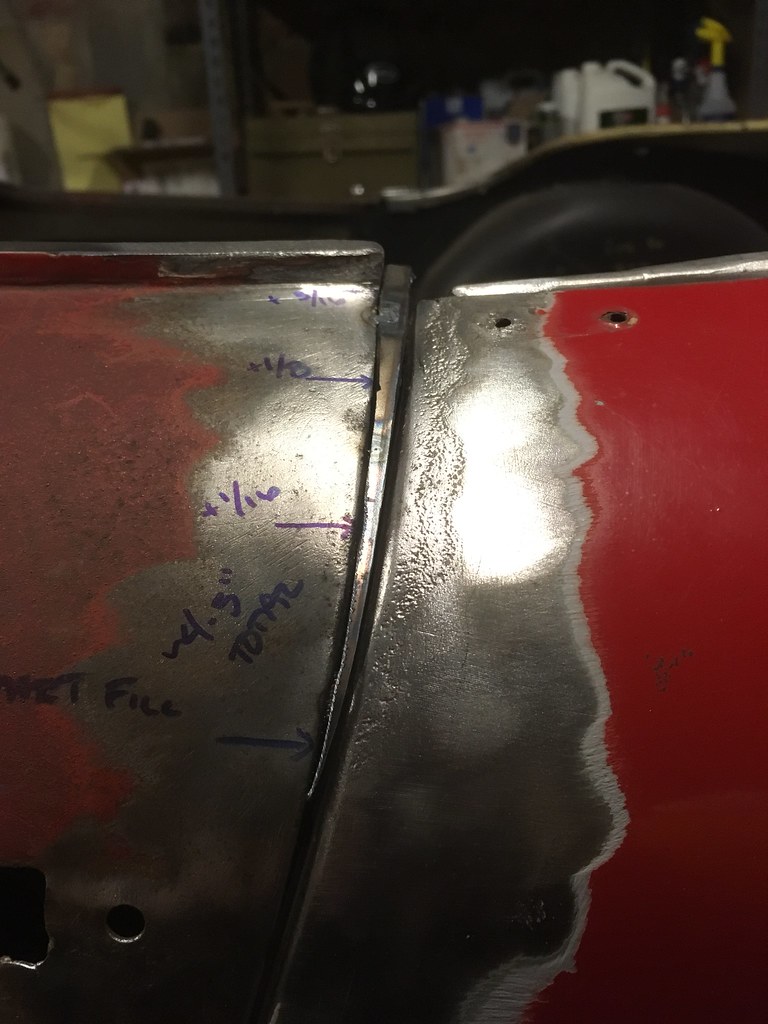

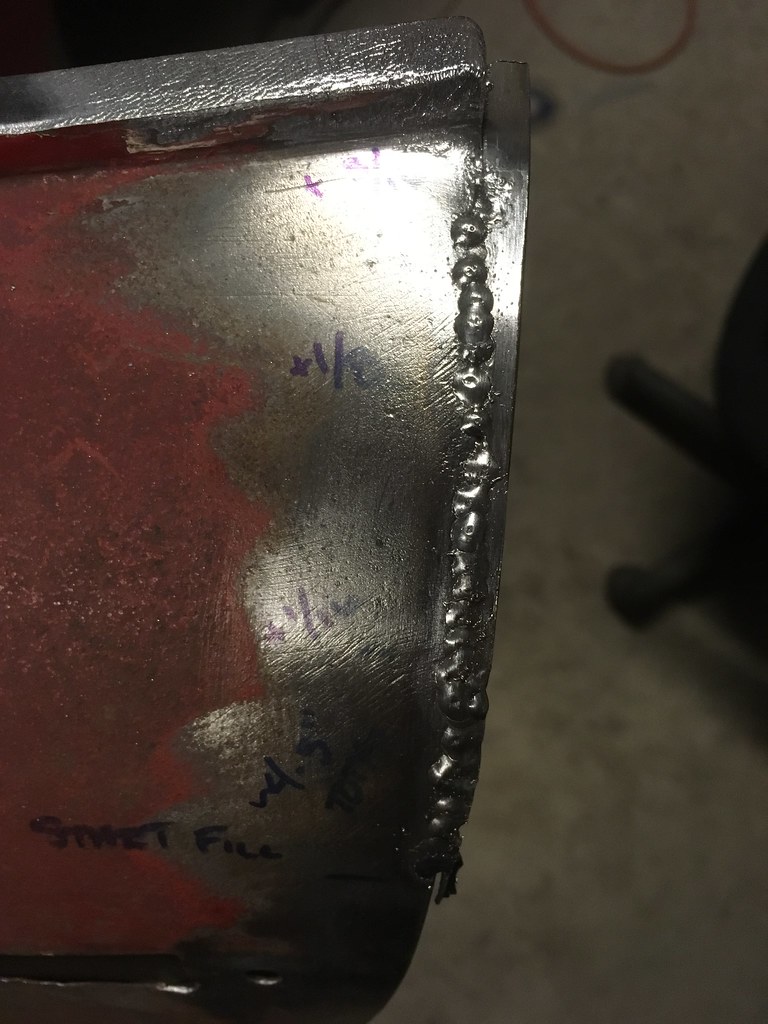

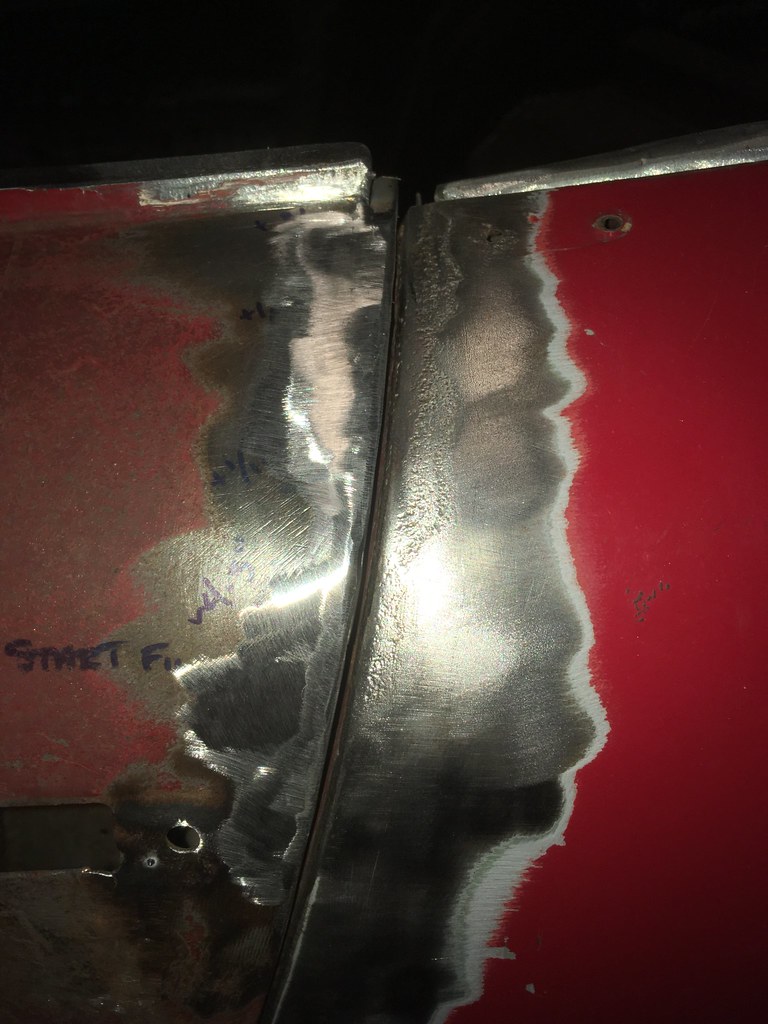

This was pretty upsetting but after a quick look, nothing seemed too bad. The shroud really didn't move much other than that dent and I was able to get it back into place. Later, I sat down in my chair in front of the Healey for a snack and something about the front crossmember caught my eye. After crawling under, I found this...

Now, the top edge of the crossmember is nowhere near as bent as it appears to be in these pictures. I think that's an illusion caused by the crank dampener and the curved support piece. That being said, it does have a bit of a hump but some of that was definitely there before. Now I get to repair a spot I already repaired and figure out how badly other things moved.

I knew this was all going too smoothly! I stuck it out for a while and made some progress on the passenger door but then my back and ankle really needed a break so I put my tail between my legs and went home. Luckily (?) I have plenty of time to dedicate to the shop tomorrow so I'll be able to further assess the damage and make more passenger door progress.

Now for a hot shower and some latkes with the other side of the fam.