Yep, I'm not looking for a "Most Power" motor, I'm looking for a solid, dependable motor with good mid-range, say 1500-6500 rpm range. The car currently has a 4.56 rear, but I'm looking to change that to something taller, like a 3.73. Going to put in a Tremec 6 speed, 2.97/2.10/1.46/1.00/0.74/0.50 ratios, and I like a 275/40/17 for a rear tire. I figure those ratios will make for great acceleration, as well as sedate cruising. 2000 rpm at 80mph in 6th gear, but I also want to make sure I've got the power where I need it to make that happen without lugging it down.

In todays world, why bother building a smallblock Chevy?

Go to the junkyard and buy an LS engine, they can be had for less than the rebuild will cost you. If you buy it right, it comes with a manual transmission.

Spray said LS motor until it pops.

Repeat.

I'd like the experience of doing it myself, and I want something that shouldn't lay down on me unexpectedly. I'm at the age where I want to do it once, do it right, and be done with it. No worrying about wiring, setting up a fuel injection system, etc., just throw it in, build it, go. Add gas, change oil, not worry about it breaking when I get into it, just giggle like a little school girl and have some pride in what I did.

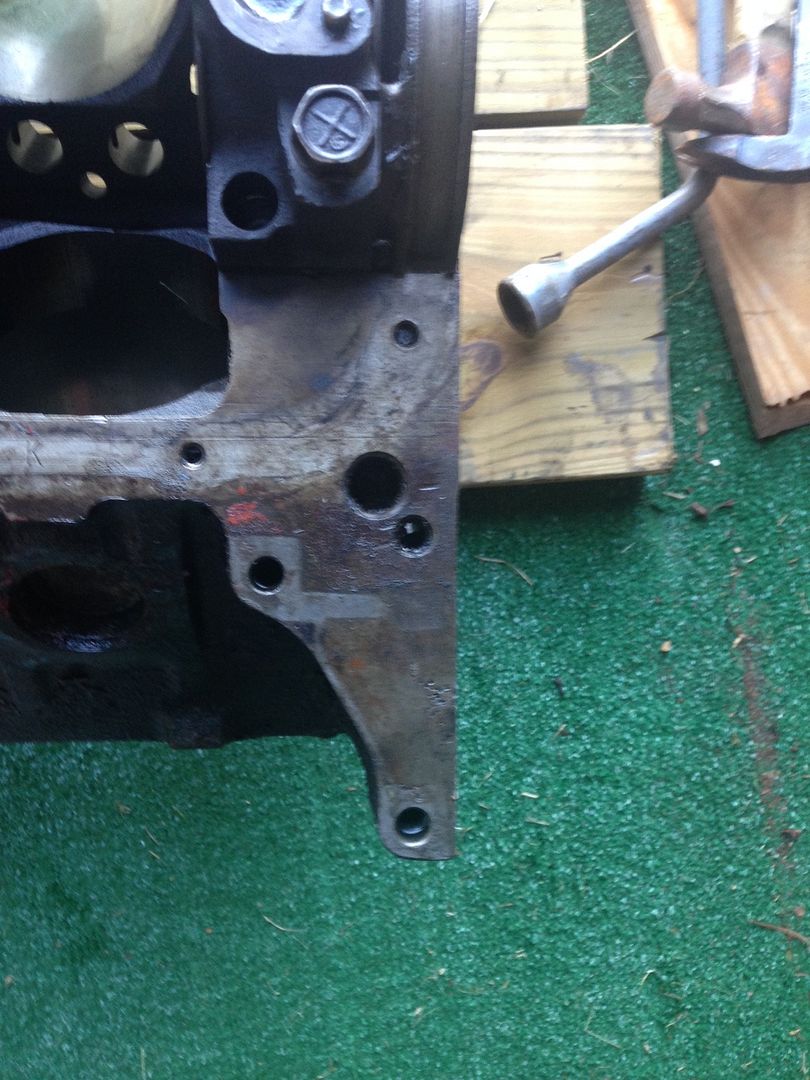

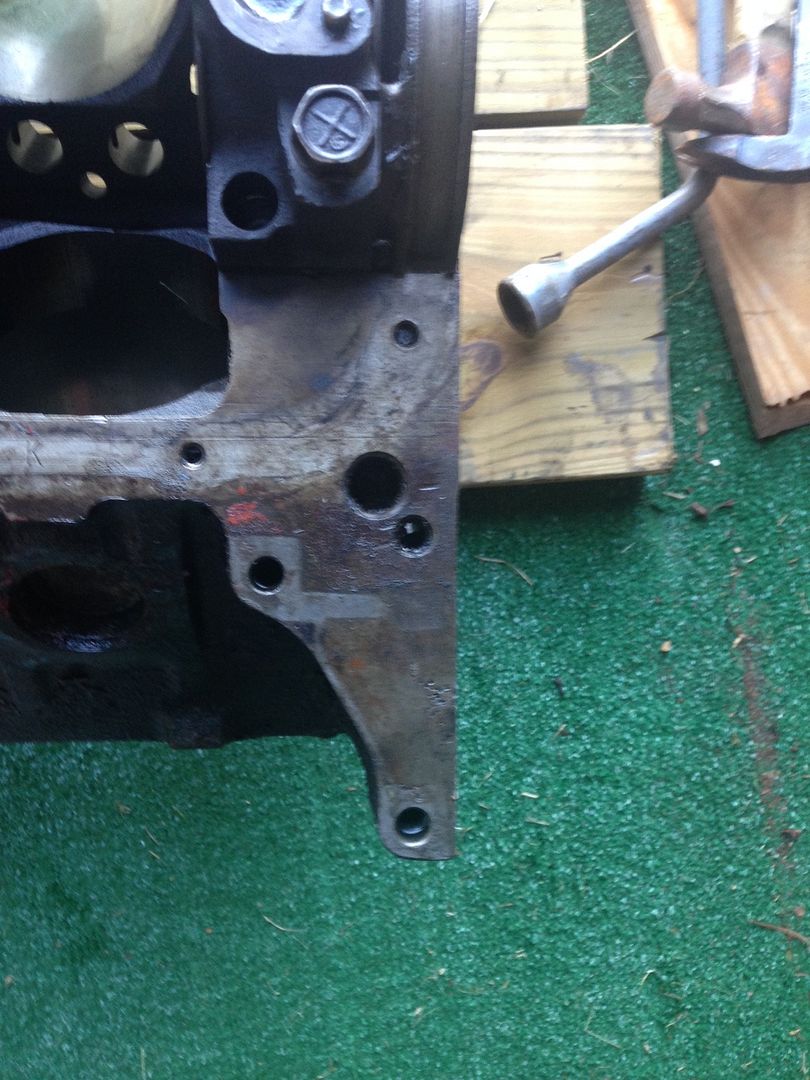

Ok, I'm getting ready to order a flywheel, needing to make sure on getting the proper one. I've got the 2 piece rear main seal (Yay!  ) and I'm trying to figure out the starter since there wasn't one. Here is a pic of the mounting pad

) and I'm trying to figure out the starter since there wasn't one. Here is a pic of the mounting pad

I've read that the 153 tooth starter is a straight across bolt pattern, and the 168 is a diagonal bolt pattern. This looks to me like it could go either way. Any experienced folks want to educate and guide me?

I've read that the 153 tooth starter is a straight across bolt pattern, and the 168 is a diagonal bolt pattern. This looks to me like it could go either way. Any experienced folks want to educate and guide me?

Also, I'm planning on getting the rotating assembly balanced, so should I get a flywheel for an internally balanced engine? And which harmonic balancer should I get to go with that? Or do I need to get an externally balanced flywheel with the same weight balance as the harmonic balancer?

I'm pretty sure all Chevy blocks have both patterns. As a side note, you can see where the 168 tooth starter shim pack was sitting on the block, you'll need starter shims for whatever starter you chose to run in order to set the gear mesh correctly, you rarely get away with just slapping that part together. You also need the special knurled shank starter bolts or it won't line up right.

On external/internal balance, you need to know what crank you're running, again, I think everything was neutral/internal balance on the 2 piece blocks except the 400/383.

I dont think I would describe 1500-6000 rpm as mid-range but more full-range :)

I'm with you as far as the experience and using what you have. Is the ls a better motor? Sure. But a sbc can run to the moon and back with not much attn.

Yeah, no huge advantage going LS for a budget build that only needs to make 400 HP.

Thanks BrokenYugo! It looked like it had been using a 168 tooth starter, but I don't like to assume on an unfamiliar project. I think for budget I'm going to stick with the stock 350 crank. Thanks for the heads up on the knurled shank bolts.

Yep, it is more full range, but like I said, not looking for an ultimate power engine. I want to make sure I don't sacrifice bottom end in an effort to build an all out screamer, but I also want to make sure that if I want to zip it over 6000 occasionally while telling someone to hold my beer and watch this  it's not going to fall apart in a flaming heap.

it's not going to fall apart in a flaming heap.

It should be noted that making a SBC reliably scream costs cubic dollars (mostly in valvetrain parts). I think 6000-6500 is generally considered to be a good redline, no need to spin 5.7 liters of engine very fast when you're only trying to make like 80hp/L.

Ok, got the flywheel & clutch kit coming in so I can take everything to the machine shop to balance and check out. He told me to bring the harmonic balancer as well. I'm clueless on harmonic balancers. There is so much freaking noise out there on this sucks/this rocks, I'm getting a headache. So, that means I'm back here looking for input/advice/suggestions. Thanks!

I've read that the 153 tooth starter is a straight across bolt pattern, and the 168 is a diagonal bolt pattern. This looks to me like it could go either way. Any experienced folks want to educate and guide me?

I've read that the 153 tooth starter is a straight across bolt pattern, and the 168 is a diagonal bolt pattern. This looks to me like it could go either way. Any experienced folks want to educate and guide me?