Most of yesterday was spent in the workshop getting to know the Miata in basically the biblical sense. It was fairly uneventful to push the car into the shop thanks to the low weight and having nothing dragging or sticking in the brakes or wheels.

Once in the garage, I faced down my target and got to work:

There's definitely some external cleaning that's going to be happening here. The first thing I pulled off was the air intake tube, confirming that there's also a lot of internal cleaning that's going to need to happen:

After some wiggling, I was able to get the throttle body off (that's not what required wiggling) as well as the fuel rail. As usual, I forgot to remove the gas cap before disconnecting the fuel lines, so I played the little boy plugging his fingers into the holes in the dyke while I talked my dad through removing the gas cap to relieve the pressure.

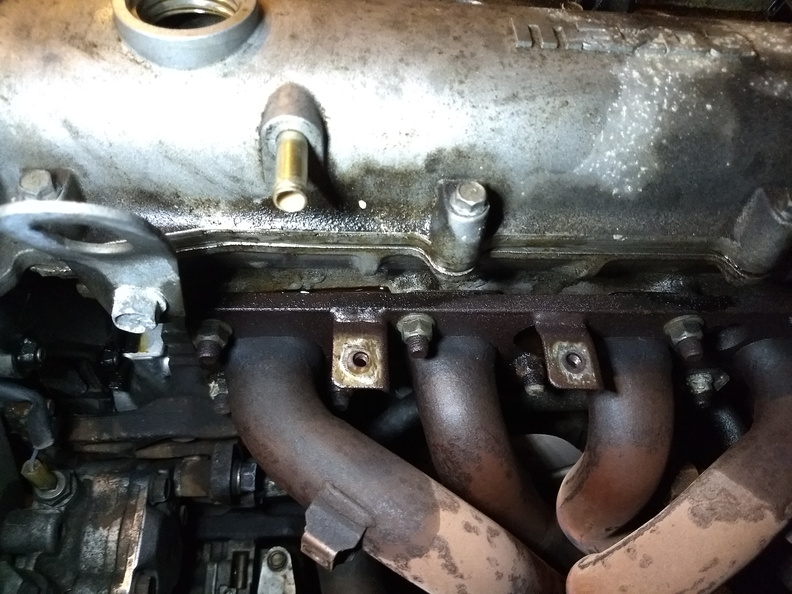

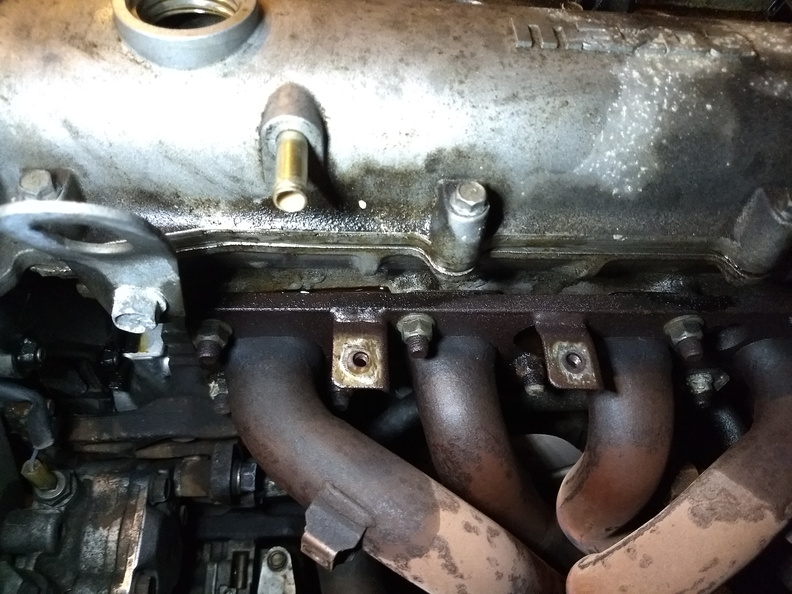

After taking off the exhaust heat shield, I was able to confirm the source of the oil that was on the left side of the engine and on the bottom of the car:

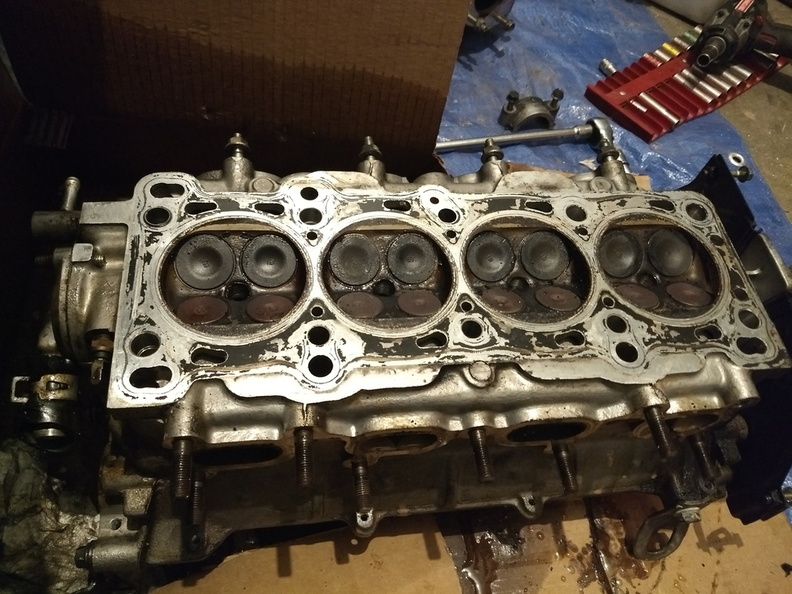

It looks like the valve cover seal is in pretty bad shape, as I suspected when I first looked at the car. I can't see the rear main because there's this transmission in the way, but the front main looks good, so I think these top-end leaks are all the points that I need to worry about -- so all the stuff I was going to do anyway. Taking the valve cover off revealed a lot of nastiness. The antifreeze/water that the camshafts have been bathed in for the last couple weeks has caused a little rust on the lobes of the cams. Since I want to do the valve seals anyway, I'll hit the lobes with a light bit of emory cloth and bathe them in a little oil to clean them up.

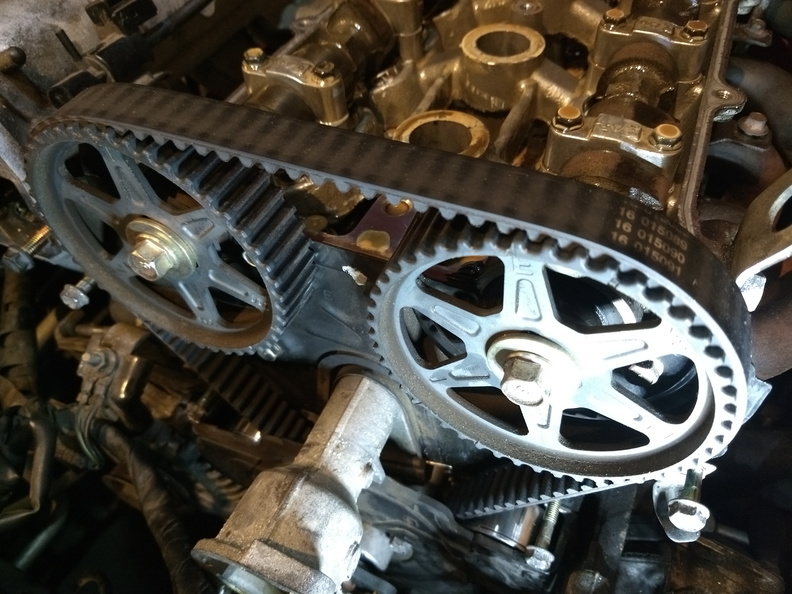

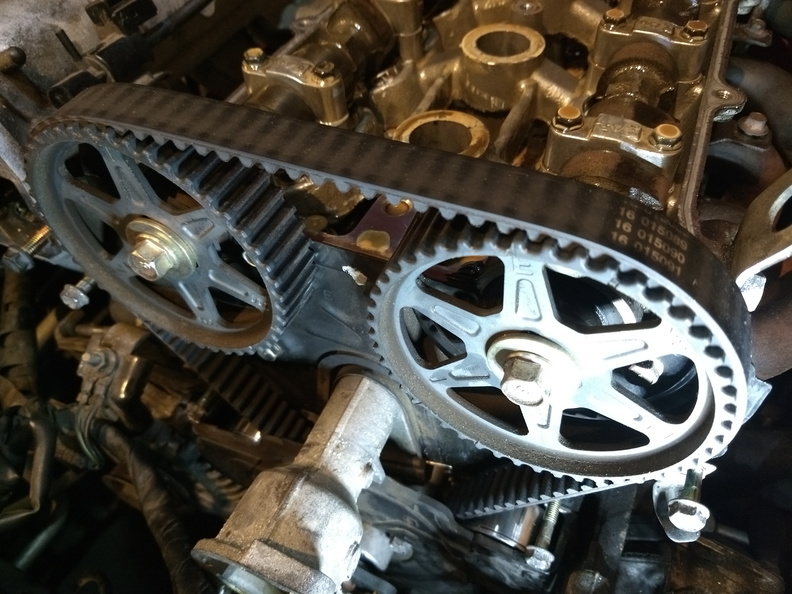

If memory serves, the timing belt replacement interval is somewhere around 105k. The car has 105824 on the clock, and this picture kind of confirms to me that the belt service has not been done, so I'm glad I got the full kit. I was a little bit concerned that I was going to spend a bunch of money to replace parts that had just been replaced, but that doesn't appear to be the case!

Next steps were to pull the timing covers off, get the pulleys removed, and disconnect everything that was holding the intake manifold to the car. Since I'm going to replace the radiator anyway, I went ahead and pulled it to get a little more clearance for these jobs.

I also pulled out the plugs. Ugh, just nasty.

Timing covers all off, and ready to take the timing belt off.

What were they thinking putting this swaybar here!? I can't get a socket on the 21mm crank bolt. I guess I need to go get a 21mm regular-depth socket to be able to take that off so I can remove the timing belt from the bottom pulley. Even then, I'm not sure I can get my impact in there with the A/C condenser in the way, and I'm not entirely sure how to best hold the crank in place to to turn that with a breaker bar. That's a problem for later, though.

With that problem successfully pushed off to later, I went ahead and started pulling the head bolts. One of them (#6 in the tightening sequence) was on much, much tighter than the others and also had no washer. It was on so tight that this happened to my H-F extension:

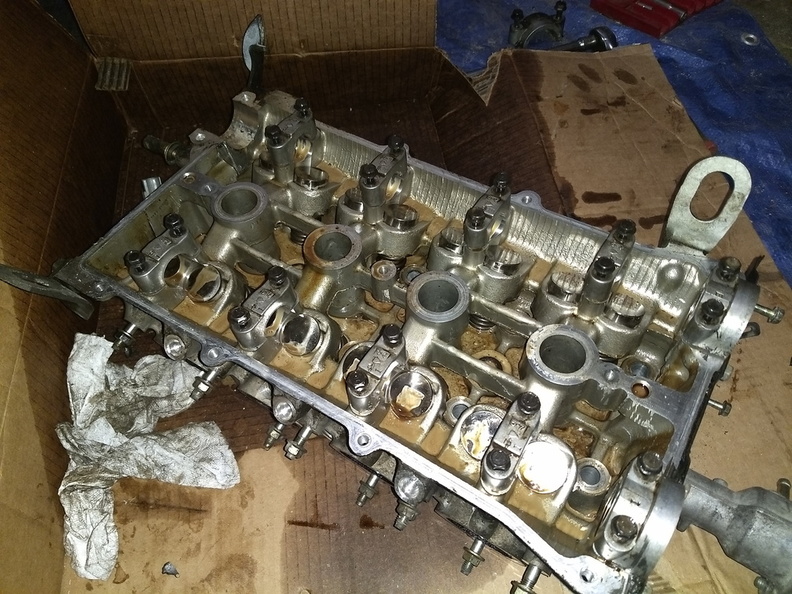

It did come off, though, and after some finageling:

The head (and intake manifold) are off! That's a real mess down in there, too.

That's going to take some work to clean up. I didn't see any real obvious breaks or anything in the head gasket, but the various layers came off one at a time instead of as a unit. By the time I had the head lifted off, it was after 2200 so I popped the intake off the head, dropped the head into a cardboard box, and cleaned up my tools for the night. I think I found the cause of the initial overheat, though: one of the heater hoses was split right at the back of the head.

Next big steps:

- Swap water pump

- Swap timing tensioners

- Pull crank pulley to swap timing belt

- Clean up the block and check the bores

- Clean up the head

- Swap valve seals

- Clean up the intake manifold

- Get an exhaust pipe gasket and swap that

- Clean up the valve cover

- Clean up the engine and engine bay

- Get new hoses other than the upper and lower radiator

- Do the other things I forgot about

- Reinstall everything