A couple updates from the last few weeks.

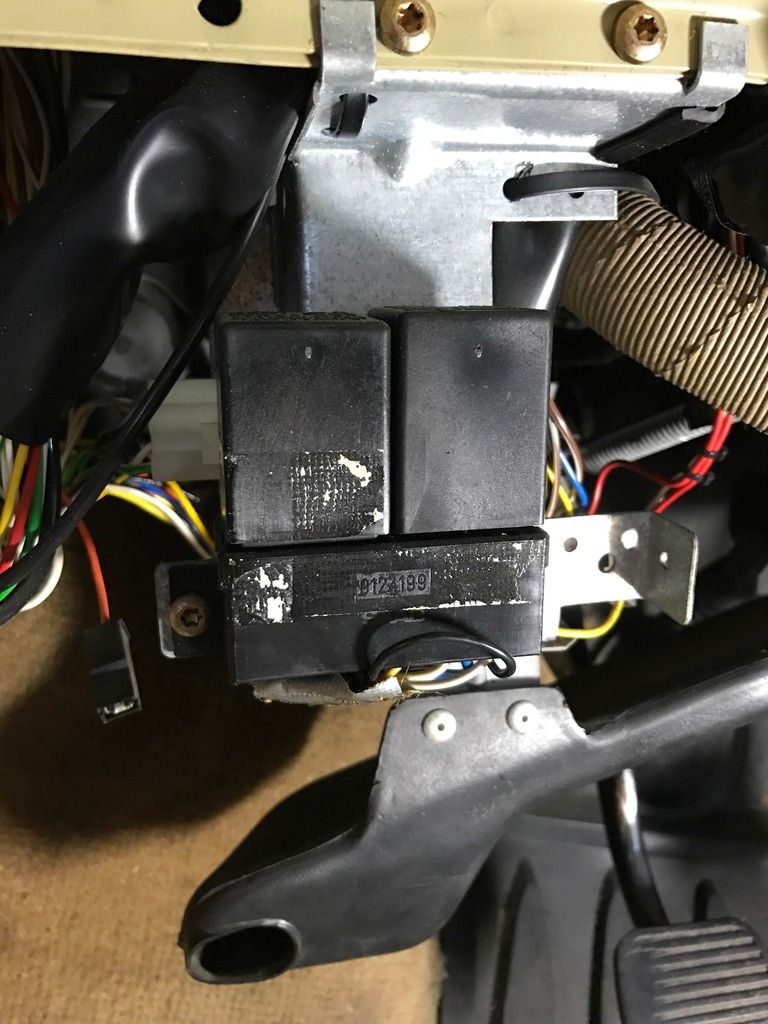

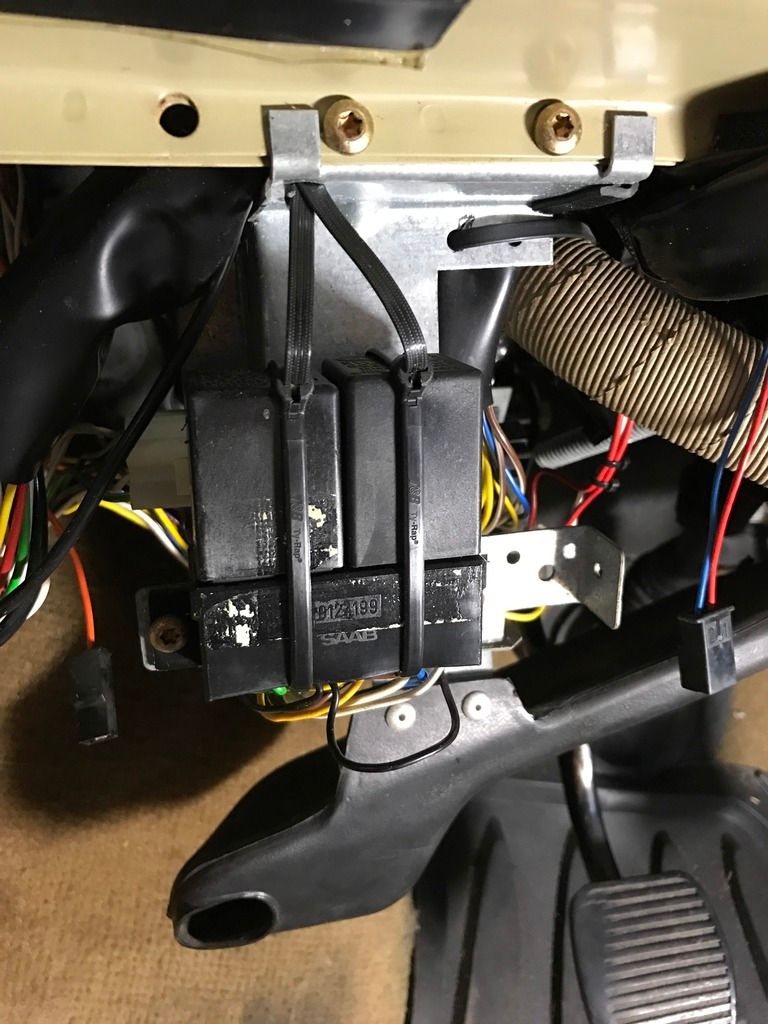

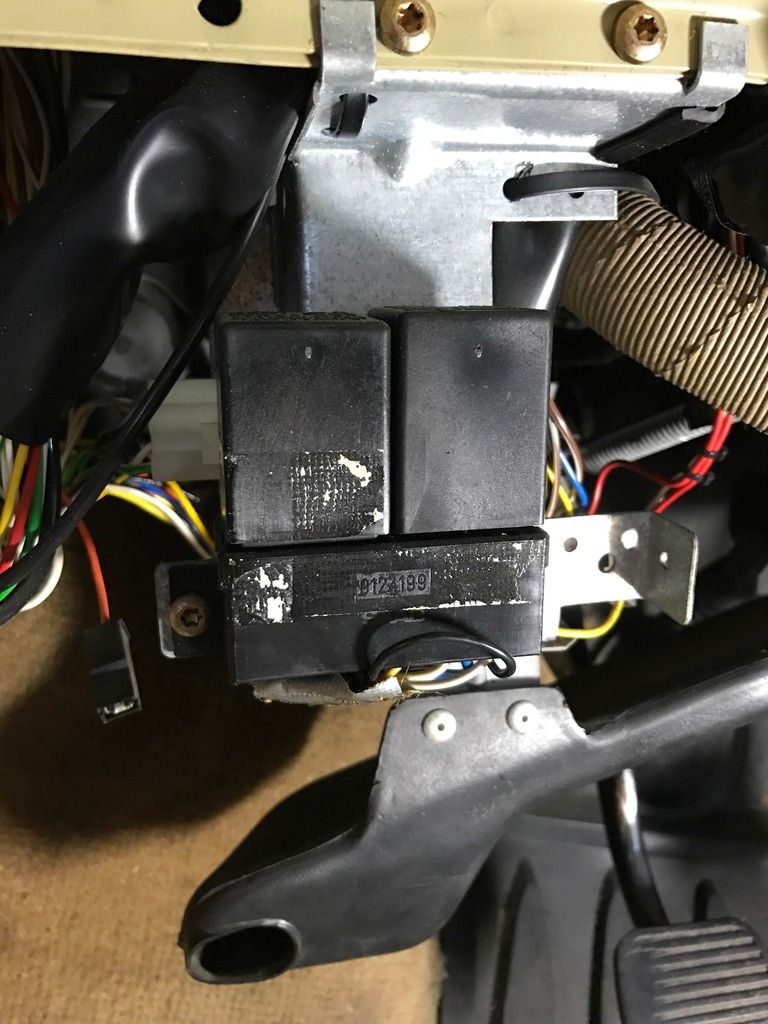

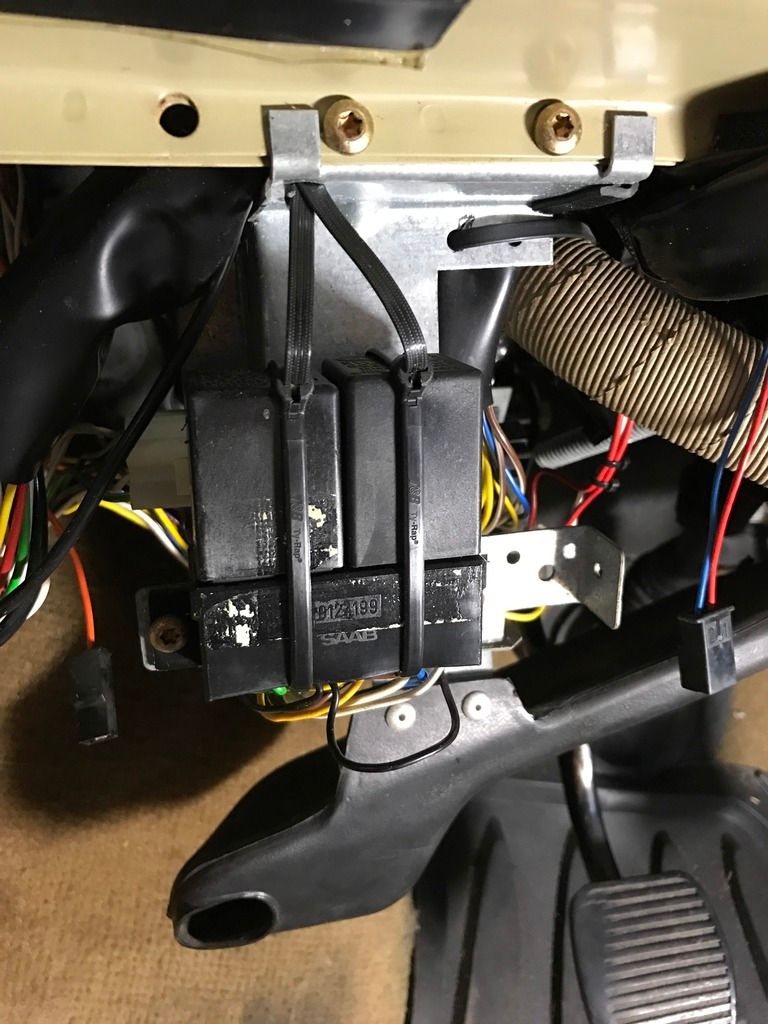

While I was under the dash replacing the brake light switch, I found these relays with some old, not so stock looking duct tape holding them in their sockets.

Threw some cable ties on them and kept on trucking...

The dash went back together pretty easily. Two of the four long screws went back in, the other two did not (see above). But I'm not the first person to have done this, so who knows exactly what's going on in there. It needs attention, but more than I have time for right now.

On to the exhaust (sigh).

When it fell off last summer, the guy that welded it back together said it looked like some supports were missing. So I had three new stock style rubber supports to shore things up.

For the tail pipe:

And the muffler:

These did make things less boingy than the couple doughnut style rubber supports that were on there.

This image pretty much sums up the whole exhaust system:

Several welded in band-aids rather than replacing any whole parts. And I think there is still a leak in there somewhere around where the catalytic converter should be, as I still hear a bit of a backfire when I shift from higher RPMs. But the gobbed together mess seems pretty solid when I pull on it. So I will probably let this situation ride and see what happens during the rallycross. If it falls off again, well, I won't be too surprised. And I'll pack ear plugs for the ride home, just in case.

Now to the Walfart battery. The stock mounting system is still solid, and with it tightened down I can't move the thing no matter how hard I try. And I added a space age positive terminal cover. Hopefully this will pass tech. Once again, I will be packing some ratchet straps and ty-wraps just in case...

The fuel filler neck. Last season my kids brought the fuel filler door in to me and reported it fell right off the car, they had no idea how  I came out to find a plastic filler neck with no plastic left for the mounting screws to hold on to. Ok, so it's an old plastic part. $50 on Ebay yielded a pretty good looking used filler neck delivered to my house. But being used, I figured it would be a bit brittle as well, so I cut some fiberglass fabric and epoxied it on to try to strengthen it and keep this one from cracking.

I came out to find a plastic filler neck with no plastic left for the mounting screws to hold on to. Ok, so it's an old plastic part. $50 on Ebay yielded a pretty good looking used filler neck delivered to my house. But being used, I figured it would be a bit brittle as well, so I cut some fiberglass fabric and epoxied it on to try to strengthen it and keep this one from cracking.

I let it dry for a few days and trimmed off the excess with a razor knife. Today I drilled out the epoxied clearance holes and attached the door to it, and took half of the trunk apart (again, layers) to install it. Before I had the first screw tight that motherberkeleyer cracked! So much for that idea.

Anyway, it's on and certainly better than what I had before.

And while I was putting the trunk back together my oldest son snuck out to the driveway and opened and slammed the filler door shut about 15 times in as many seconds. Kids.

The next update should be wheels and snow tires!