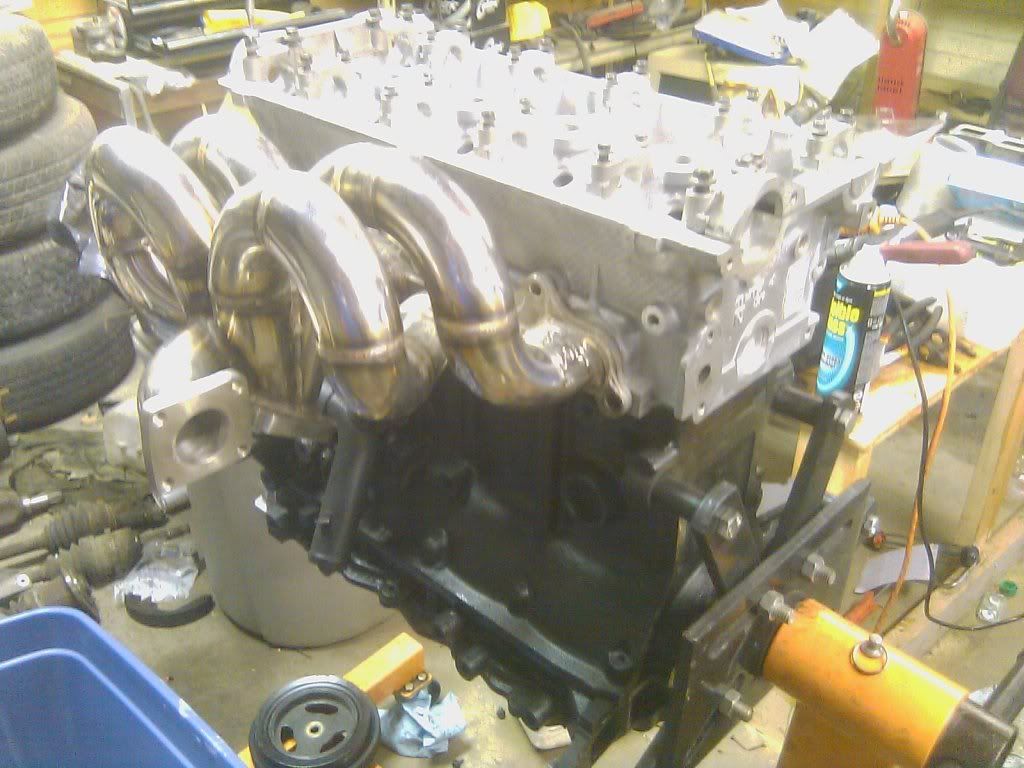

This is a "how-to" post I made about making your 80s 5 speed turbo-dodge AWD capable:

Ok so how to make a AWD diff fit your 523. I'm sure the process is similar for a 520 but I can't confirm this.

First let me start by saying this was much easier than I expected. I assumed this would be one of the harder parts of the project but it was all pretty much straightforward.

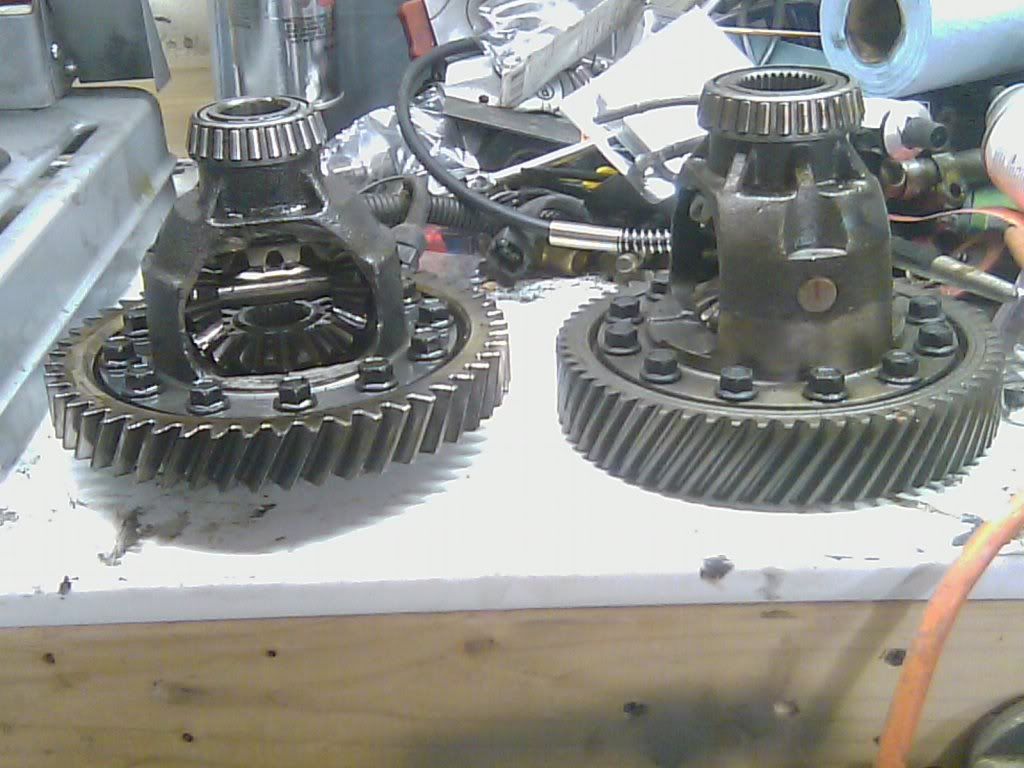

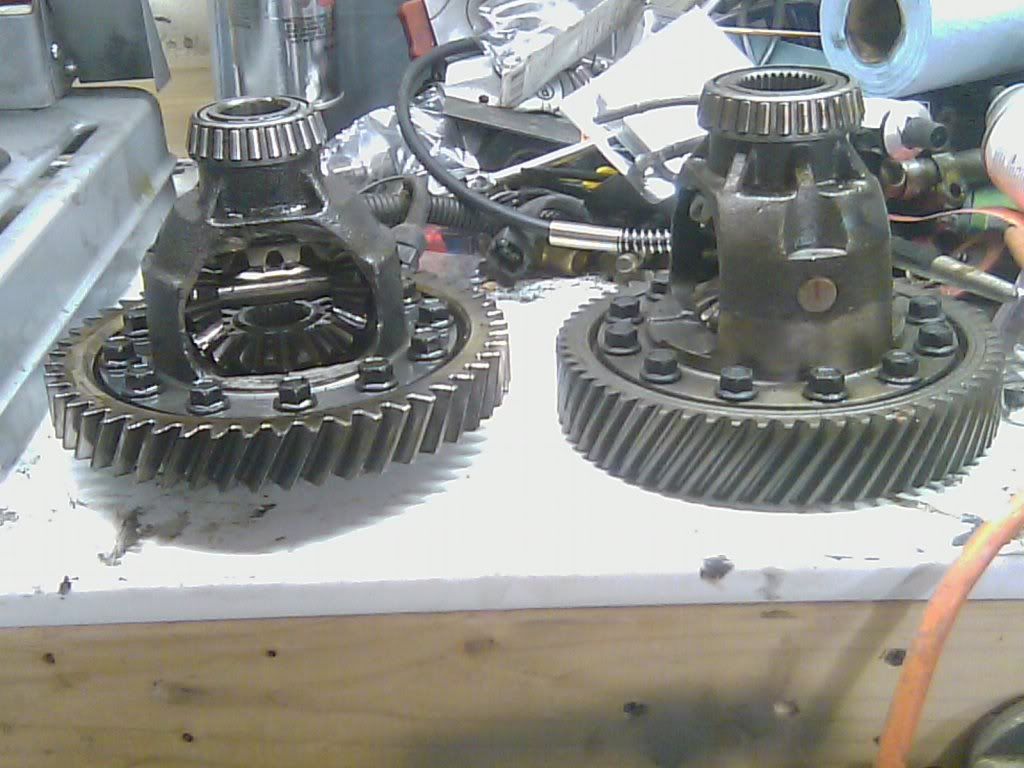

Here are the two diffs side by side.

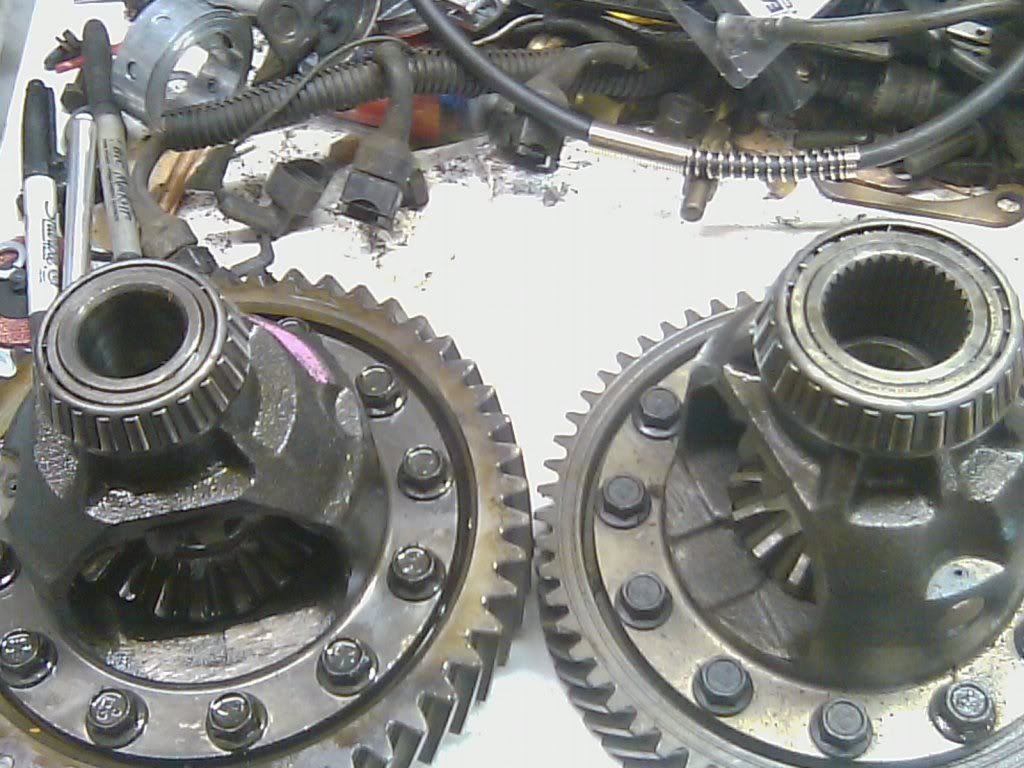

The 523 is on the left and the AWD is on the right. Here is more detail on the pass. side bearing.

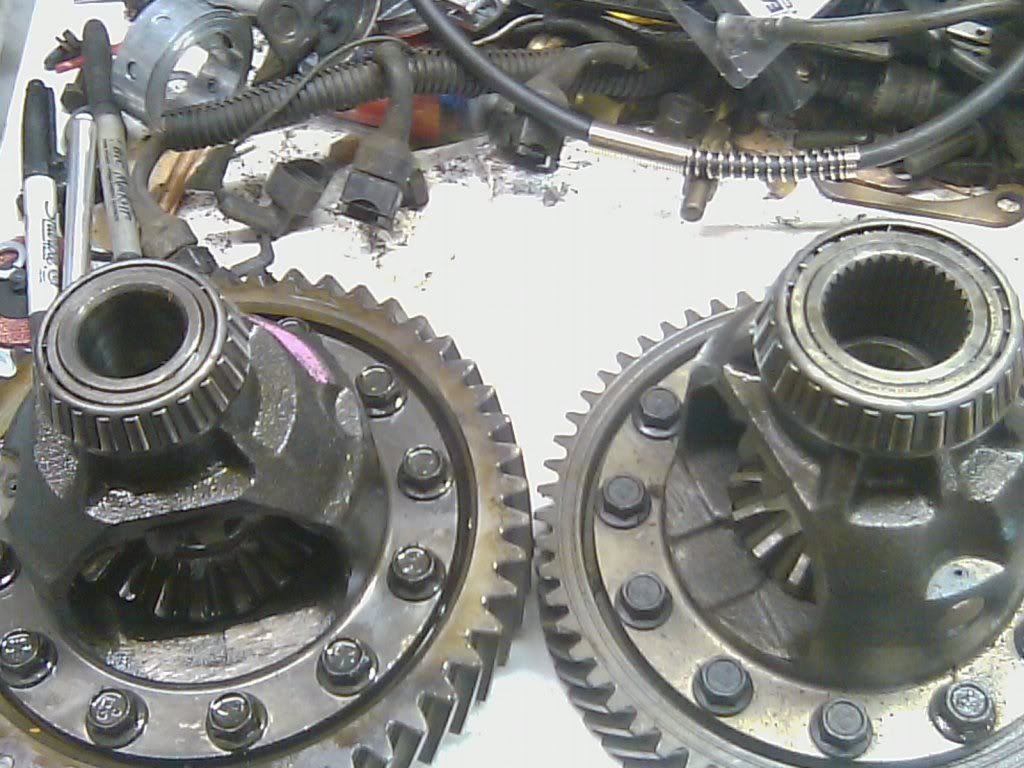

The AWD uses a different bearing because the diff housing is larger and is splined to accommodate the PTU. Here is a better shot of just the AWD diff.

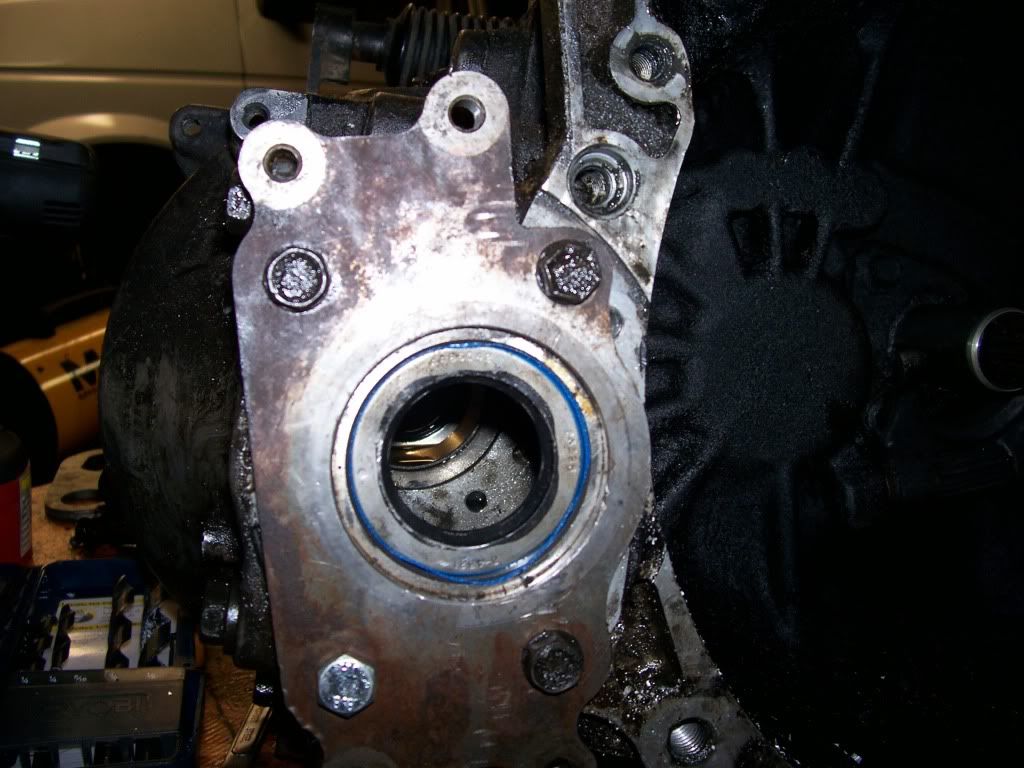

You need to use the pass. side bearing housing off of the 41AE the diff came out of so that A) the bearing will fit and B) the PTU will bolt up.

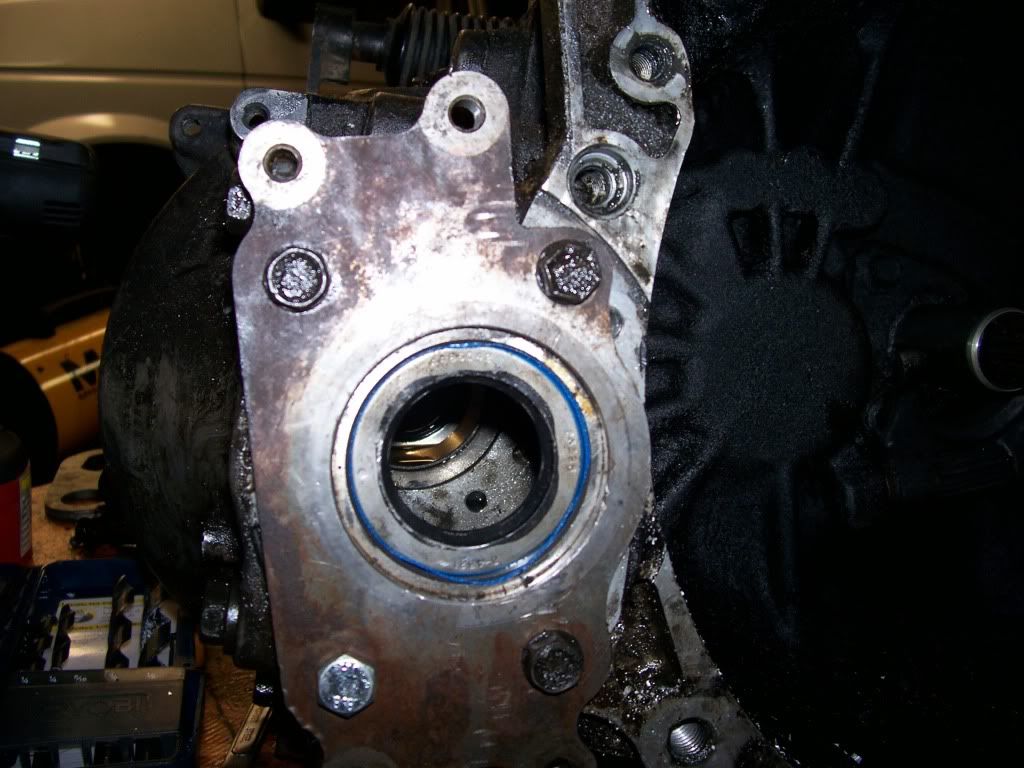

As you can see the top right bolt that the extension housing uses will line up, the others need to be drilled and tapped for M8x1.25 threads. Be careful as you will drill through the upper diff housing bolt hole with the top left, and each one of the lower holes will drill through the lower diff housing bolt hole. You'll have to use shorter bolts than what the extension housing uses. Remember that the case is aluminum so it will strip out easily.

One that is done all you need to do is put the 523 ring gear on the AWD diff. To do this you will need to flip the gear over and mount it to the opposite side of the diff than the stock AWD ring gear uses.

I unfortunately don't have many pictures of this but I'll explain as best as possible. The 523 ring gear's flange is offset. The "inside" of the ring gear flange usually bolts to the drivers side of the diff flange, the ring gear is threaded. The AWD diff and ring gear have a different offset so they won't readily interchange. If you flip the 523 ring gear and bolt the "inside" flange that originally mated to the drivers side, onto the passenger side of the AWD diff, this will get you almost perfectly back to the stock ring gear location.

If you mount the diff in the trans this way you'll notice two things, first is the ring gear doesn't sit exactly where it did with the original diff. I made a mark on the case before removing the diff, and again with the ring gear bolted to the AWD diff and it was "around" .035 off. I say "around" because others measured it as .030 and I was using a rather unscientific method (dial calipers and two sharpie lines). I decided to go with .030 as I figured that other people probably did a less ghetto measuring job and if it was a couple thousandths off it wouldn't wear the gear too badly. I ended up finding a transmission shop that took care of the machining, and in my excitement to remount the ring gear I didn't take pics of the machined surface. Put loctite on the bolts and torque them to spec, and you'll end up with this

The other thing you'll notice is that the ring gear bolt heads, which now stick out the drivers side of the diff, hit the gear that slightly protrudes into the pinion area. The only answer is to remove enough material off the bolt heads to clear. I haven't done this step yet but it is pretty straightforward.

After the diff is in then you can bolt the diff housing and etc. back up.

REMEMBER, this is just a guide, YMMV. I accept no responsibility for what you do to your vehicle.

![]()