I seriously haven't posted here since November? I'll play catch up then. I've been on mandatory 6 day work weeks (minus two weeks in Feb.) for over a year so bear with me.

Nov/Dec 2013

I went on vacation to my in-law's in Sarasota as an excuse to spectate at the challenge. Got back did Christmas, and the worst winter I've ever experienced begins.

Jan 2014

The worst winter. Ever. Spent two days at home due to snow emergency/-17 below air temps. Made the decision to attend SDAC (end of June) only if I finished the van.

Feb./Mar. 2014

Winter won't let go. I made it out there to do some minor things but didn't accomplish much.

April/May 2014

If I'm going to do this I have to do it now.

First the brakes

Measured for then bought/mounted the intercooler.

Trying to keep it at least somewhat sleeperish.

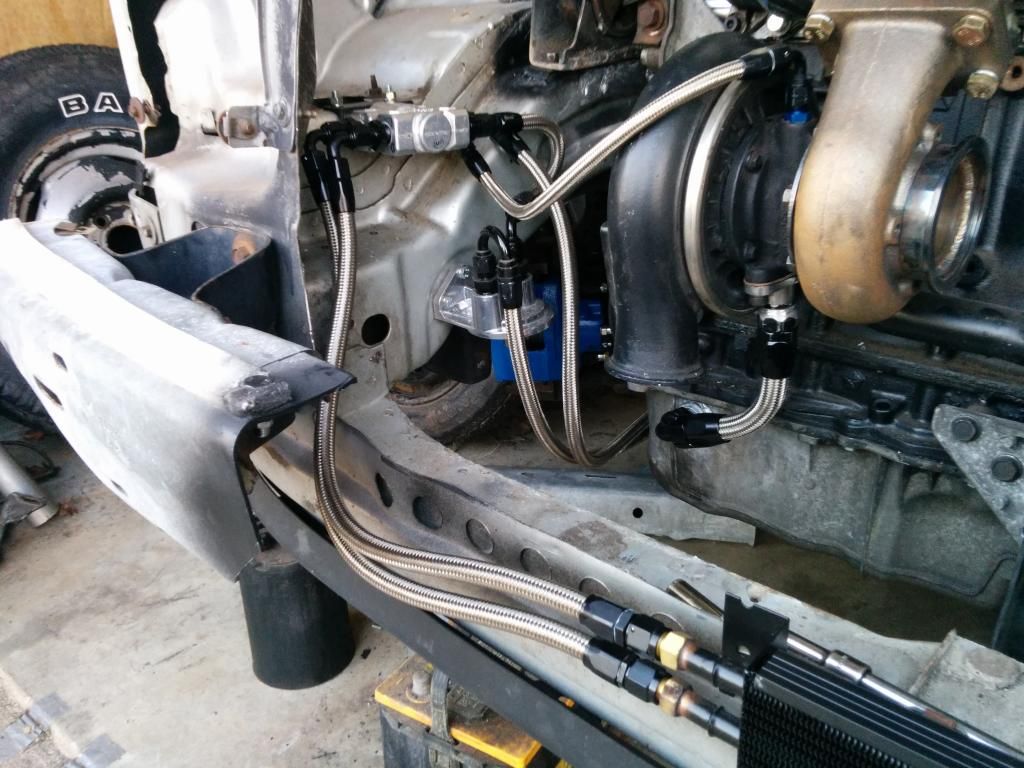

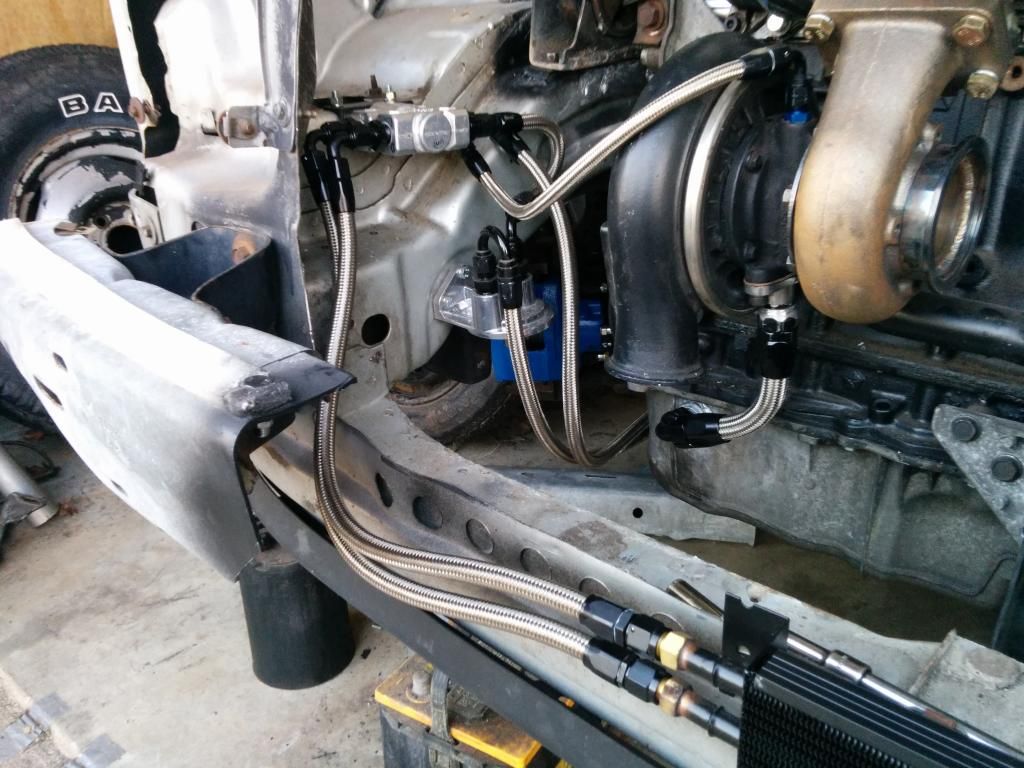

Started mocking up my oil filter/cooler/turbo lines.

May 2014

Editors note: Somewhere around this time Dakota number 1 has a catastrophic rear end failure. The decision is made to press Dakota number 2 (eventual replacement anyway) into service as the work beater. Spend several days off prepping Dakota number 2. Get back to work and 1 week later Dakota number 2 starts dropping oil pressure at hot idle and after a couple days gets a light knock. More time off replacing the rods and cleaning junk out of the pan and I throw in the towel on it and get a company van (less dollars but less broken).

Moved on to the Fuel cell. I had internal debate on using the 12 gal summit racing cell I already had or springing for a used atl or the like to make sure I was NASA legal (you know for.... well reasons). Time and money won out and I decided to make it NHRA legal for now and deal with NASA compliance later. I then decided just to bolt it to the floor and deal with the rule books later since I needed to break in all the new parts (planned trip to SDAC would cover the miles for break-in).

(placeholder for pictures)

The list of items doesn't get smaller. For everything I check off 1-2 more things are added. The stress of 6 days weeks and spending any available time on the van, and realizing I won't have enough $$ to get everything I need in time, wears on me. I canceled the trip to SDAC and instead took a weekend off in Cincinnati. If you follow me on IG (you do follow me right) you'll see pics from the Carew Tower and other sites.

Early July

Been over a year of 6 day weeks now. Then on the 3rd my mom goes to the hospital with a brain hemorrhage. Spent the next month dealing with ICUs hospitals and rehab centers.

Now

Mom is home but still off work. Took a big hit in the wallet taking a good chunk of July off. I have most of the stuff to finish the fuel system and probably get it fired up for the first time. Project creep (AKA scope creep- see image below) keeps telling me I should just go MegaSquirt and ditch the factory ECU since I can't run a VSS and I wouldn't need the funky dizzy adaptor since I could use 2.4 cam/crank sensors. Money will probably keep that from happening so it will just evolve to that point later. Still need to get a few odds and ends done for the rear axle and driveshaft also before it can come off the stands, finally.

Long post is long.

TL;DR still not done, making excuses.

image below: