jgrewe

New Reader

1/26/14 8:52 p.m.

Around new year I had dinner with the PO of the car and he sent me an email afterwards, "Is this what you are making?"

Click the link and a picture of a manifold pops up, "2006-13 MX5 inner manifold"

After all the searching and finding only plastic manifolds that point the wrong direction the car that is most similar is the one I should have looked at the closest.

So, not feeling the need to re-invent the wheel I found one on car-part.com for $40. I just need to make an adapter plate to hold the TB's. A hunk of aluminum and some Dykem blue fix that.

Action shots

Air passages roughed in and TB mount holes drilled.

Manifold mount hardware countersunk in.

Test fit the TB mounts

Test fit on the car

I couldn't make a part that works better. A little trimming and polishing and its done. The TB's will need a few spacers to hold them lined up with the Duratec and there is a long bolt that runs through all of them that needs to be about an inch longer. Once that is done I need to add a little metal to the tabs that transfer the throttle twist motion through the whole set. I'll post pics when I do it.

Right now I've changed my focus to the rear end. After putting stuff on the floor how it needs to be under the car I've decided to use stock Miata control arms and modify the frame to hold it all in the right spots. I've also decided to keep the Miata Torsen diff for another Spec Miata build.(I've got a '99 shell, a hard top and a diff. I'm half done!) It just looked too difficult to mount compared to others and ratios might be an issue. The "other" diffs would be a Ford 8.8 or a 7.5 IRS. There is a Lincoln Mk8 and a bunch of T-birds at the local LKQ so I have my choice. I'm leaning toward the 7.5, I just don't think I need the strength of the 8.8. I'll be checking on axles this week, that looks like it will be the only thing I can't make properly.

LorenFL

New Reader

2/1/14 8:04 p.m.

Wow! Glad I made the suggestion.

You gotta get that car on the road. I'm starting to feel really bad for hacking it up.

This is a great build. I love the sand casting for the motor mounts. No school like the old school.

Cool stuff in here! I'll follow along.

jgrewe

New Reader

2/23/14 4:14 p.m.

I've been in the research and parts gathering mode for the rear end. I have all the Miata control arms and uprights and I'd like to use them if I can. I picked up an aluminum Ford 8.8 out of a Lincoln Mk8 along with the axles and uprights with hubs.

Here is where I run in circles.

I want to use the Miata sport brakes and suspension. I've imagineered the rear frame I will build to hold all the Mazda suspension and Ford diff. That was the easy part. I'm running into all kinds of options for the uprights, hubs, and axles.

-

I can machine the Ford hub down 1mm to fit into the Miata bearing. I will then need to turn the OD of the hub to fit inside the Miata rotor and redrill to 4x100 to fit the rims I already have. This will let me use the Ford CV's in and out but I read you cant use the stock shock mount because of the CV size. Ford outer CV may be an issue shortening the axle.

-

I can see if I can install the Miata CV on the Ford axle after shortening it. That solves a lot of problems but I don't know how strong the Miata CV's are. Future plans for the car could find it over 300 hp. I know I've heard of some Miatas in that range, don't know what the next fuse in the Miata driveline is besides the stock Mazda trans. Thoughts? Any first hand experience with high hp through 1.8 axles? Also, anybody know where I can buy just an outer CV? No luck finding new ones and I don't want to rip apart a couple good 1.8 axles I have for the race cars.

-

I can use the Ford uprights and build control arms. Still need to redrill hubs. Axles may or may not be an issue to shorten. I haven't pulled one apart to see if the splines are bigger or smaller than the axle OD where it would need to be cut.

I really don't want to build control arms. I'd much rather machine stuff to make it work. The only up side of making control arms is I can make them work with the stock Spitfire frame and just add some structure to hold the upper arms and diff.

I'll buy an indexing head and tooling to cut splines before I spend $1000 on axles. Even then they will be custom because the V8 Miata ones are too long.

I saw one company making axles that use the Porsche/VW design of CV's that bolt to a stub axle going through the hub. Any info on that set up? That might give me the right bolt pattern and a hub close enough to the Miata bearing dimensions.

What does the collective think?

jgrewe

New Reader

2/24/14 3:20 p.m.

crickets

OK, today I was able bust apart the differential end of one of the Ford axles. I didn't pull off the part of the CV that is on the splines but a rough measurement tells me the splines are a few thousandths smaller than the rest of the axle. This means the shortened Ford axles with Ford hubs turned down to fit the Miata bearings is in the lead.

I stopped by one of my local machinery re-sellers looking for a dividing head. The one that was perfect for my application was already sold, missed it by a day. I have a few more places to check this week.

jgrewe

New Reader

3/20/14 7:54 a.m.

I think I've solve the $1000 axle problem. I found RCV Performance on the web, they say they can make axle shafts for about $225 each. They just need length and what CV's I plan to plug them into.

The rear end has been an interesting engineering exercise. Fitting all the stock Miata suspension along with the 8.8 diff under the car has required extensive use of my NAD program (Napkin Aided Design). I think I'm up over 7 napkins from the first version to what I've ended up building.

I first put everything in a pile on the floor in the rough locations things will end up and it looked like it was going to be close. I had to figure out how to handle the new load paths with coil over shocks, upper and lower control arms, and the diff munts. I didn't want to deal with the moving the fuel tank so I have a hard ceiling.

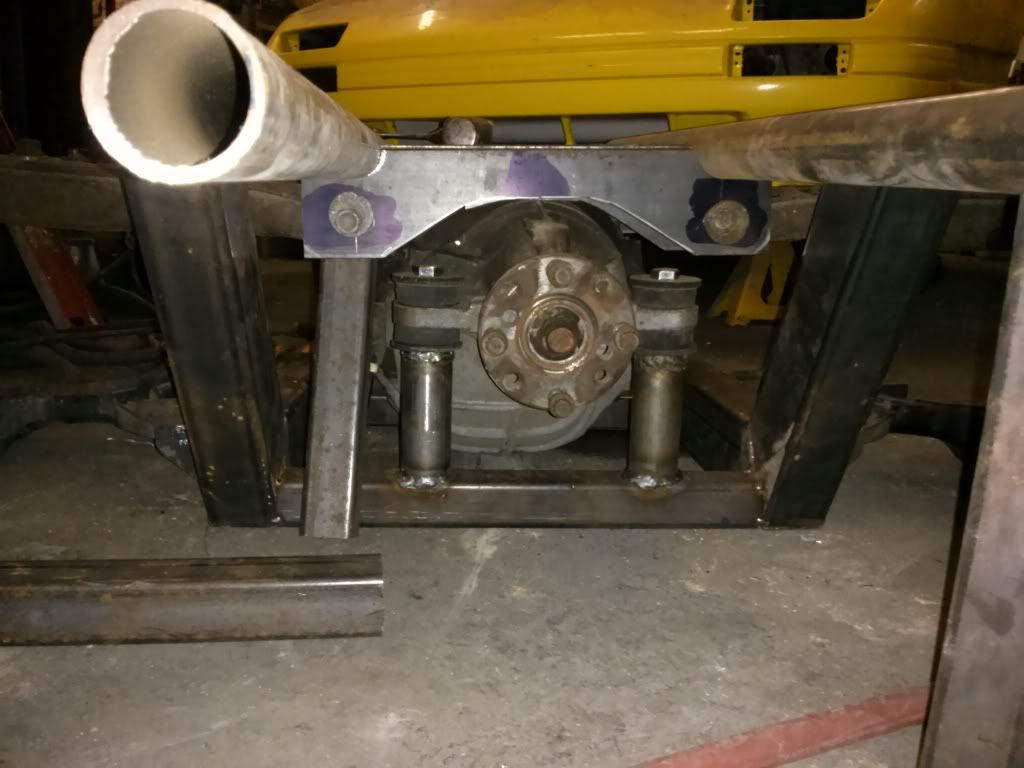

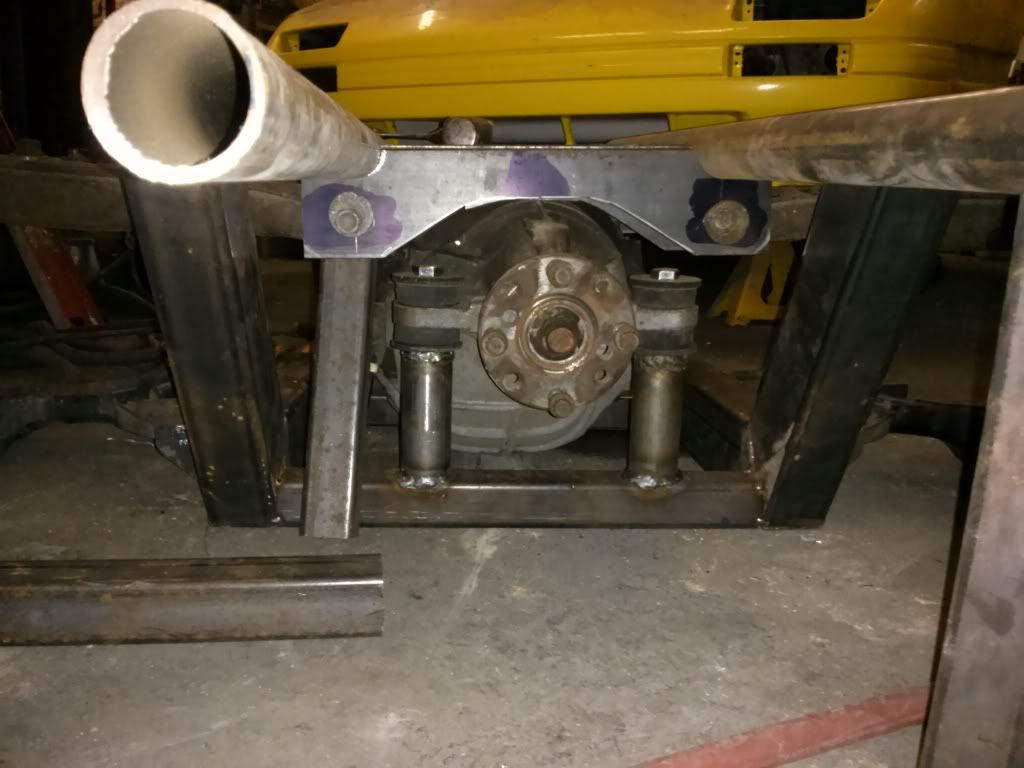

Here is my roughed in frame. It will be two pieces, one that will replace the back of the stock frame and hold the UCA's, front diff mount, shock, and body mounts. A lower subframe will attach to it and hold the LCA's and rear diff mount.

Spy photos! Here it is during the first trial to double check track and camber. The stock Miata method of camber adjustment will be used. Turn your computer over if you want to see it right side up.

More later after I weld some stuff together and clean up the square corners. I still need to add the body and shock mounts and figure out the rear diff mount and how the subframe will attach.

love the spitfire 1500 and Mark IV nice project

LorenFL

New Reader

4/8/14 12:55 a.m.

Can I drive it yet, John?

RossD

PowerDork

4/8/14 7:44 a.m.

Awesome build thread! I would sell the Type 9 and Q4R bell and grab a NC Miata 5 speed. Check car-parts.com you will probably make money if you sell the old stuff.

When I worked at a foundry pattern shop, the core molds always had an area that located the cores with respect to the part. I would also guess that they would built half of the pattern on one side of a plywood board and the other half on the other side. It makes pulling the cope and drag apart a lot easier. Or make a multiple piece pattern that allows you to remove parts to maintain the sand (if that makes sense). Then make a core box with a 'keyed' area that fits into a 'keyed' area in the pattern.

Notice the small dowels that form a Tee in the box and the larger stub that exists on both the pattern and the core box. When you put the core of sand into the sand, it will be held in place perfectly, well as perfectly as one can make the two parts...

jgrewe

New Reader

4/8/14 11:17 a.m.

Loren, not quite yet! I've been trying to clean the shop of little stupid projects and focus on the 5 cars  It looks like I'm going to end up with the other EP RX7 by doing a little horse trading with the Spec Miata. That means I've been working on the RX2 to get it ready for the driveline out of the RX7. I'm going to try to get the RX2 ready for a trip to Watkins Glen or Mid Ohio this fall. I need to get a hold of my Alfa buddies to see who is going to what event.

It looks like I'm going to end up with the other EP RX7 by doing a little horse trading with the Spec Miata. That means I've been working on the RX2 to get it ready for the driveline out of the RX7. I'm going to try to get the RX2 ready for a trip to Watkins Glen or Mid Ohio this fall. I need to get a hold of my Alfa buddies to see who is going to what event.

RossD, cool pics of cores, models and parts! The whole alignment thing for the manifold was going to be careful placement of the cores into the wedge shape of the manifold, and hope...

As I get a little better on the design side of things, and maybe make something that I may need more than one of, I'll need to work on that kind of stuff. I had just gotten to the point that I had the cope and drag parts of the casting box designed to line up perfectly. What is the red stuff on the model and core box? Or is that the actual material they are made of?

The MX5 box is still an option. The big concern is the size compared the T9. The PO's idea was to try to do as surgical an install as possible and the T9 fits in the stock tunnel cover. With the extra hacking I've done and will do in the future it may turn into a better option. The flywheel to work with the T9 is probably a bigger reason to look at the MX5 set up. Very limited options, either really heavy stock or really light expensive.

jgrewe

New Reader

4/15/14 11:31 p.m.

A little bit of staring, a little bit of welding, a lot of thinking.

I have the whole rear frame put together, probably about 80% welded. The rear diff mount is the last thing that needs to be figured out. After measuring I'm going to wait until the frame is up under the car to finish the mount. I could put it on the top of the lower sub frame but I figured out I wouldn't be able to get the bolt out. I'm about a 1/4" from the body where the small tubes come down to support the subframe.

The upper frame piece behind the diff will be removable and you can see the bolt/spacer combo sitting on the left side frame rail. They will bolt through the rail and into a threaded plug in the end of the cross member.

Those lower rails are the same level as the dip in the stock frame.

With everything welded up the moment of truth was upon me. Track was within 1/8" of what I was shooting for and camber was even but not zero. I ended up with 0.3 neg on both sides. I think I can live with that. If I had made the slots for the lower control arms about 1/16 longer to the inside I'd have my target track and zero camber. I'd rather be lucky than good sometimes.

beans

Dork

4/16/14 12:15 a.m.

Crap, why didn't I see this last year. That Honda head looks like the non-vtec version of the VTEC head(both stamped PAA) for the 98-02 Accords. It's from the F23A5 and I think the only difference is in the intake rockers.

Oh well, the rest of this build is pretty awesome!

LorenFL

New Reader

4/25/14 1:47 a.m.

I need to come over to the shop and check this out. Looks pretty damned cool!

A Spitfire with proper rear suspension... I'm having trouble wrapping my head around the whole notion.

Ian F

UltimaDork

4/25/14 4:48 a.m.

Looks nice!

Umm... maybe a stupid question... but can you get the diff out of the sub-frame the way everything is constructed?

jgrewe

New Reader

4/25/14 8:12 a.m.

At this moment, no. It's designed to have the rear upper cross member come out along with the "V" supports, lower cross member, and all the stuff that holds the lower control arms. Right now the upper cross member is still tacked in to keep things easy during fab work. If you look at the pics closer you can see a bolt laying on top of the frame opposite my digital level and a spacer shoved into the end of the frame rail. The spacer will be lined up with the cross member and keep the frame from collapsing when the bolt is tightened up.

I've turned some plugs that will be welded into the ends of the upper cross member, I just need to tap them before it all comes back together.

jgrewe

Reader

9/7/14 11:37 p.m.

I had to go back 11 pages to dig this up, that is depressing.

After a trip to Ohio in June I came back home and started catching up with work. I have rental property for my "real job" and I had a couple apartments that needed gone through. People think I collect large old tube TV's I guess because they leave them for me all the time. I throw them in my truck and take them to the recycling place the county has for electronics. I grab a 32"er, head for the truck and hear a SNAP! Along with the snap I lose about 80% of the strength in my left arm.

Ruptured bicep tendon. My ortho told me I'm not 25 anymore and it is a common injury for guys in their 40's.

I'm about to start PT after having surgery at the end of July.

I've managed to get a little done with one good arm and a ton of time to think about things. I cut the back of the car all up and fit the frame up in the car.

Here is the stock frame peeled open with the new frame shoved inside it. Those frame flaps were trimmed and hammered back against the new rails and welded up.

The lower subframe was then bolted in to see how I close I am in the rear. I had a little more room than I figured. The front edge of the trunk isn't a straight line.

The front tubes of the lower subframe will be trimmed and bent up toward the stock frame and attached with some through bolts. There were too many variables to do a final design with the frame on the floor and the car on the lift.

The bottom of the tubes is about 1/2" lower than the stock frame rail dip. I may have room to snake the exhaust through the diff area and under the CV axle on the driver's side. Not sure yet. I should have about 4 3/4" of ground clearance under those tubes with the new suspension at the correct height.

The next project will be shock/spring perches. I picked up a pair of Bilstein shocks made for a Toyota van that are short enough. I'll revalve them with a Miata shim stack to start as a baseline. I figure compression will be darn close since all the parts that move are Miata. Rebound will be where I'm going to have to play a bit. Lighter car but similar spring rate to a Miata because I'm looking for a firmer ride.

jgrewe

Reader

9/10/14 11:48 p.m.

Well, Doc said I don't need physical therapy for my arm. I've gotten about 98% of my motion back, still no heavy lifting till December though.

Good thing I build small cars.

I worked out how to attach the front of the lower sub frame to the chassis. A couple bends and a couple plates along with some DOM spacers to keep the frame from collapsing. I just put the front bolts in real quick to see how things will work. The rear ones are going to be an issue. The body has a cross member that will keep me from gaining access to the top of the frame to hold a nut. I'll weld a nut in place

when I pop the body off later.

Time to test fit the suspension bits. A little bit more cutting with the sawzall to clear the top arm and things are looking good.

The moment of truth.

I don't know why but the wheel looks like it is too close in the front of the wheel opening. I triple checked the wheel base and it is dead on the published numbers. It could be the fact the car is above my head on the lift, could be the tire is about twice as wide as the OE unit and fills the wheel well more. We'll see when it is back at ground level if it still bugs me. Not much I can do about it anyway. I could probably pick up 1/4" by modifying the bushing centers on the control arms and put spacers in front of all the pivot points.

Camber goes from just about zero to 2.7 neg.

In reply to jgrewe:

Your build is very similar to mine, awesome work so far! I'm building a '67 GT6 with a duratec 2.3L, M50D-R1 5 speed, and independent rear suspension sorta like yours. I've attached a few pics.

http://i.imgur.com/mKBM0xt.jpg

http://i.imgur.com/8g1qvhp.jpg

http://i.imgur.com/hLlAuHA.jpg

jgrewe

Reader

9/15/14 3:45 p.m.

Looking at your design with the reversed suspension arms would solve the problem I'm having right now. My spring perch is trying to occupy the same space as the corner of my fuel tank. With the arms flipped around it looks like it sits just in front of tank. Oh well....next time.

With the arms flipped around it looks like it sits just in front of tank. Oh well....next time.

I'm just going to build them the way they need to be and worry about fitting the tank back in later. I may be able to just dent the corners in, if not, I'll get a cell or mount the tank in the trunk further.

Love your project too

LorenFL

New Reader

9/15/14 4:10 p.m.

Your axle placement is correct. The OD of the Miata tire is probably 1/4" larger than stock. Here's a photo with 155/75-13's on stock wheels. (stock tires are 145/80, so even the 155's were slightly taller than stock)

jgrewe

Reader

9/15/14 7:14 p.m.

Hey, that car looks familiar!