Well, I should go to bed, but the no-doze, red bull, large diet Pepsi (like Coke better, but KFC was close to the exit) says that I should type up today’s events… So, without commercial interruptions (pictures), we present:

The Day that MotorGeek “Timmy” Stopped By the Dyno

(insert dark and stormy night theme music)

Left the house at 7:30am to drive 3.25 hours south to Hudson, NH.... of course, with all the construction in VT it took almost four hours.

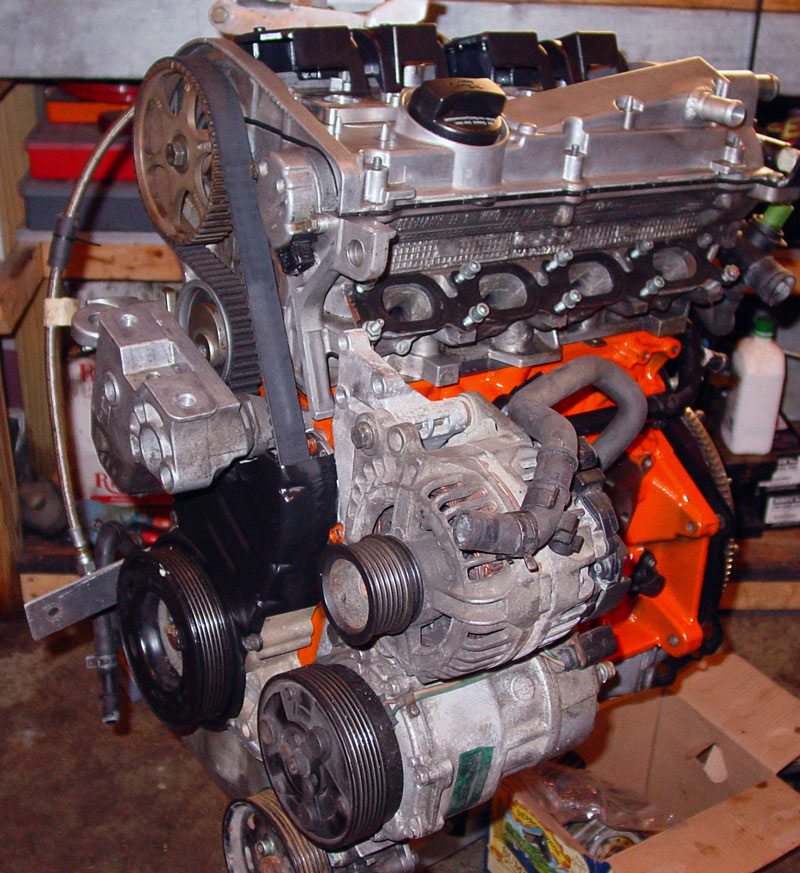

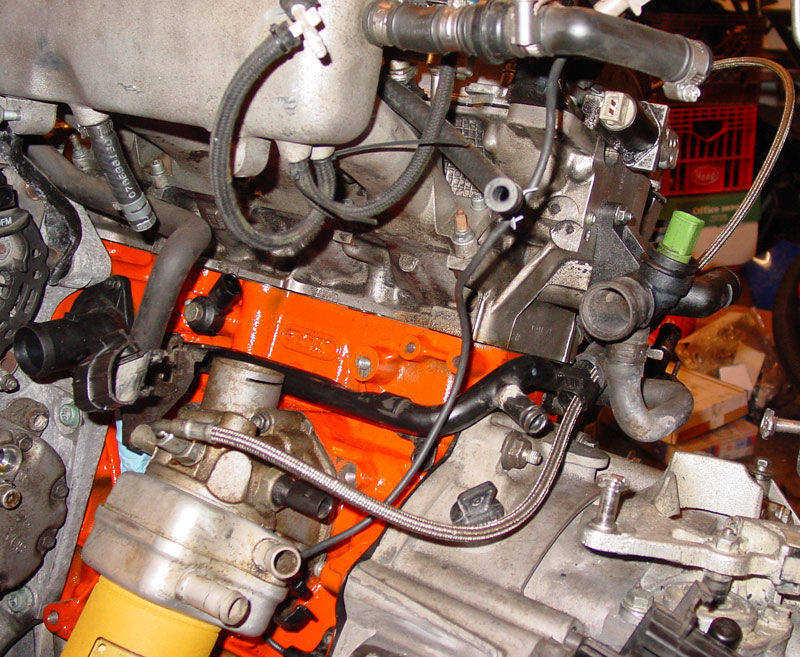

Prettier front end... still need to figure out a better way to attach the bumper skin with the skid plate bracket slightly in the way.

Arrived here at 11:15 with Marc (http://www.EFIexpress.com) arriving shortly thereafter..... Fashionable late (his words).

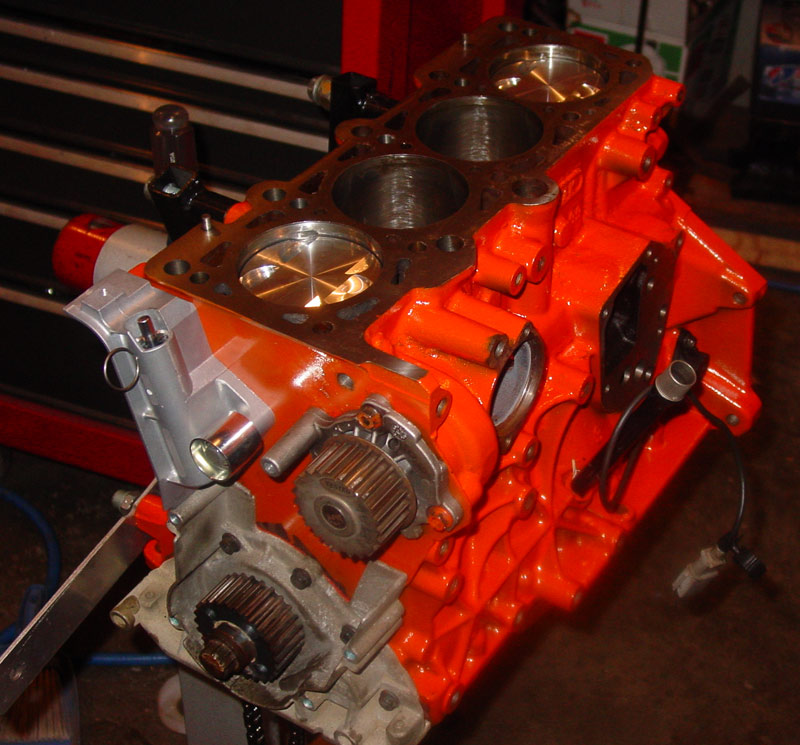

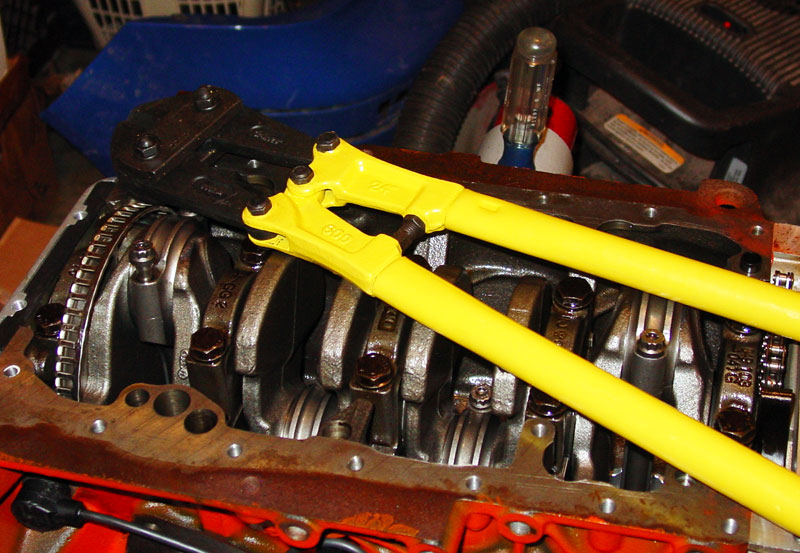

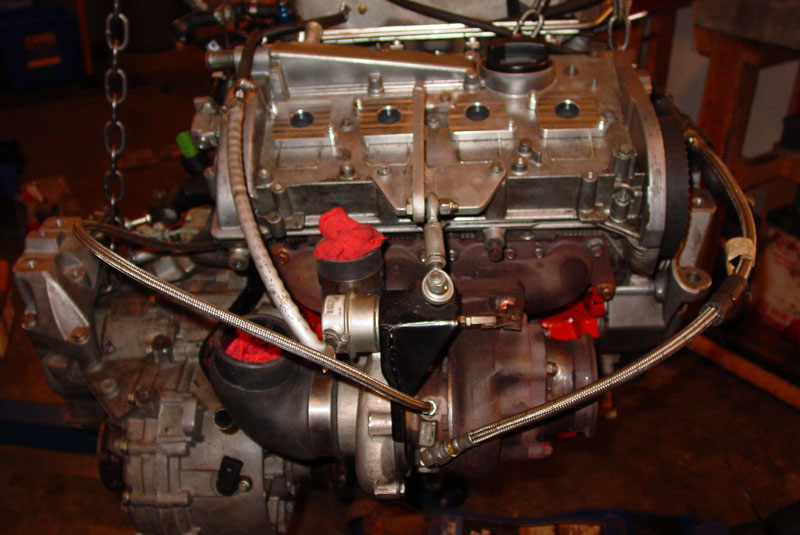

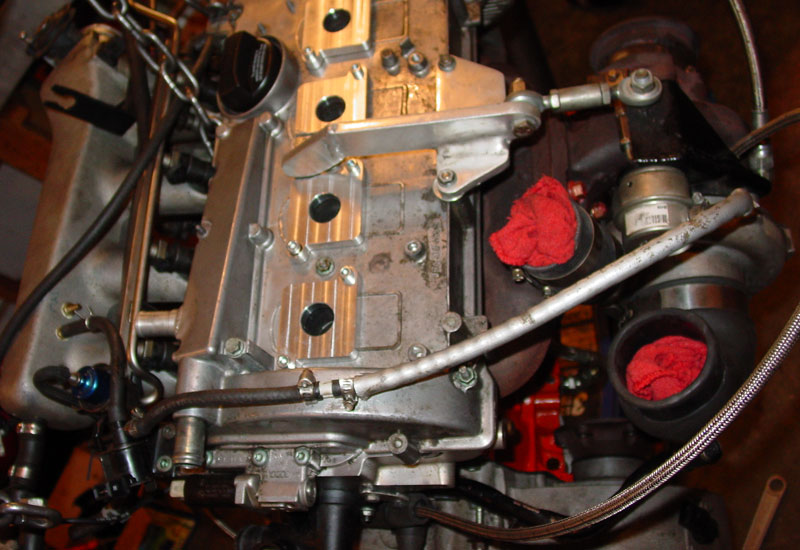

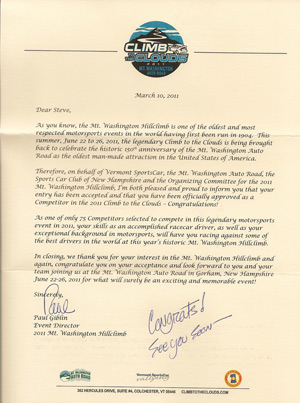

Dyno time was set for 12:00 giving us 45 minutes to talk about issues since the past tune (pistons were porous from excessive heat), talk about the exceptions for the next tune (foot to the floor for 7.5 miles up Mt. Washington, more fuel, etc.), and giving Marc time to convert the old 2D map to the new 3D map setup.

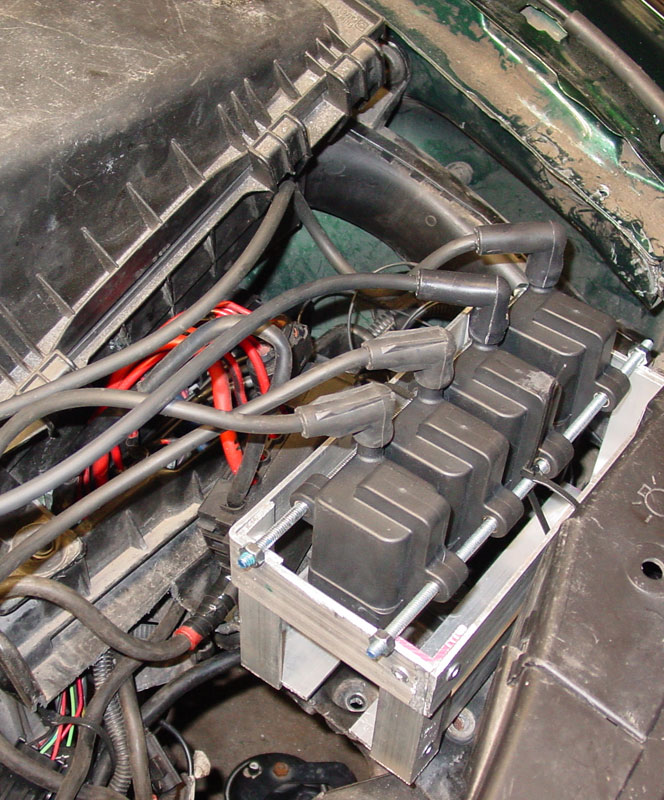

We started the car and things didn't sound right.... I had thought it was because of the new ECU (updated firmware and 4 bar MAP sensor) wherein not all variables were set so it was running funny. Turns out that the car had been running on three cylinders since I put it together… it was actually pretty peppy for three cylinders. It turns out there was an issue with the 034 wiring harness that we fixed after the “incident”; problem corrected and the car was finally strapped down by 1:30. Ugg… Behind schedule. Another car was supposed to come in at 3:00 so we had to be quick. Soooo, we did want normal people would do during crunch time… We went next door to the Dairy Queen and had lunch. Great shakes!

Meanwhile, back at the ranch…

We got situated in the car with Marc in the passenger seat and me in the driver’s seat… this is a first, I would be doing the driving on the Dynojet dyno instead of the dyno owner. Even better, the owner handed Marc the controls, explained how to use it (get roller started in 1st, go through 2nd, and then 3rd up to 2000 RPM, then push the green button, floor the car up to 5000 RPM (the limit we set for the first pull to determine a baseline), let off the gas/push in the clutch, and FOR THE LOVE OF GOD DON’T TOUCH THE BRAKES!.... and then push the red button (dyno brakes). Oh, and two hands on the wheel. Pretty easy… lots of pulls. Because I was driving, I couldn’t take pictures so go search the internet for a rabbit with a pancake on its head and call it a day.

Well, the next two hours were a real learning experience.

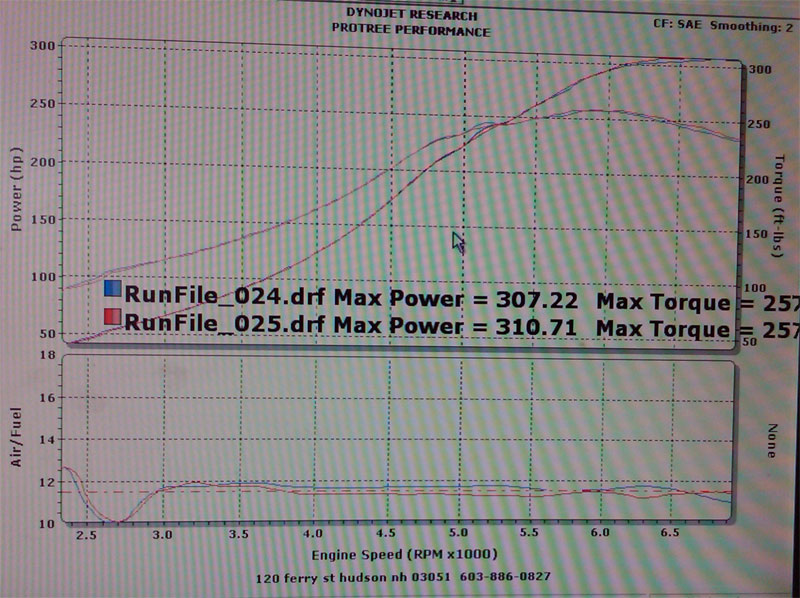

First mild pull was 305 wHP; this shows us that the Dynojet dyno shows higher numbers than the KTR dyno from last summer… this was expected. Regardless, this is not a game of the highest wHP numbers win the game and gets to bring home some giant pink elephant that will sit in the basement until a suitable time to sell it at a yard sale for 25-cents. The intent of the dyno is to have something consistent, repeatable, and provide a load so that we can get the best performance out of the engine. No kidding, huh. (Well, you should have seen the look I got last summer when I was talking to a guy with the Honda with the big wing about wheel HP vs. crank HP. Yes, VTEC came up in the conversation many times)

The plot thickens…

The stock redline is somewhere around 6800 (either 6750 or 6850; I don’t recall); I had the redline set at 6500 since day one because I wasn’t sure what all the components could take for horsepower before things started failing. You know, like 5-speed gearboxes. Since I have the stronger 6-speed in there and DriveShaft Shop axles (that was a saga), we turned the redline up to 7000. Yes, I know we can turn it up more, but I’m okay with 7000 for now. Everything worked up to the old redline… no problems.

After a series of 2000 to 5000 RPM pulls to setup the fuel tables, we went for the gold and tried a 2000 to redline (using the rev limiter at 7000) pull. After the pull, Marc was reported as saying “Steve, why did you let off at 6500?”…. a meek response of “I didn’t…”

(insert picture of two very confused people…. One person probably had a better idea what could have happened and while the other was daydreaming about having another DQ milkshake because it was hot as hell in the dyno room; naturally, Marc still had his shake)

Looking at the numbers, the boost kpa went from 220 to 70 (something like that)… you know, manifold pressure… even with the throttle at 100%. Hmm, we must have blown a boost hose.

Non-DQ guy got out to check the intercooler hoses… nope, they are all intact.

Intermission: Dyno owner tells us the 3:00 cancelled so we have until 5:30. Whew!

Dyno 2000 to redline again just in case it was a fluke. Same thing.

Dyno 2000 to redline with Marc staring at the blow off valve… nope, that did not open prematurely.

Dyno 2000 to redline with Marc staring at the armature of the wastegate... nope, didn’t move.

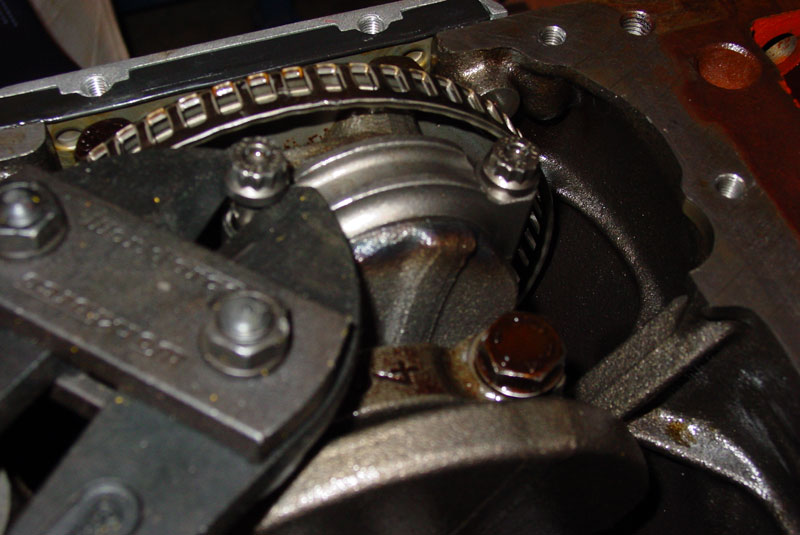

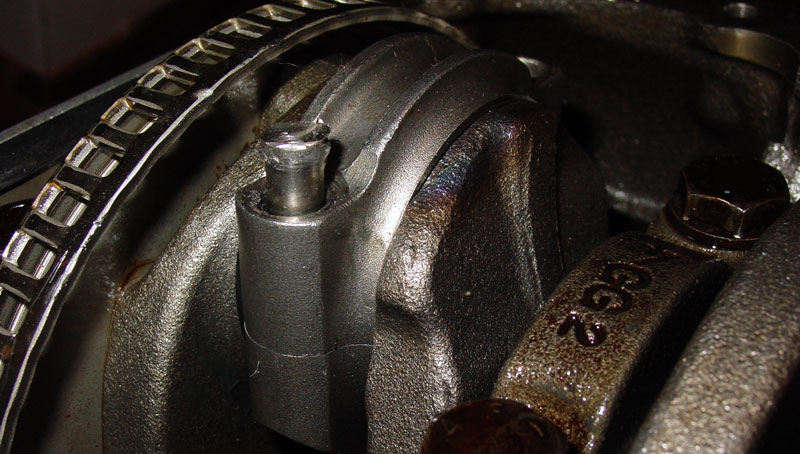

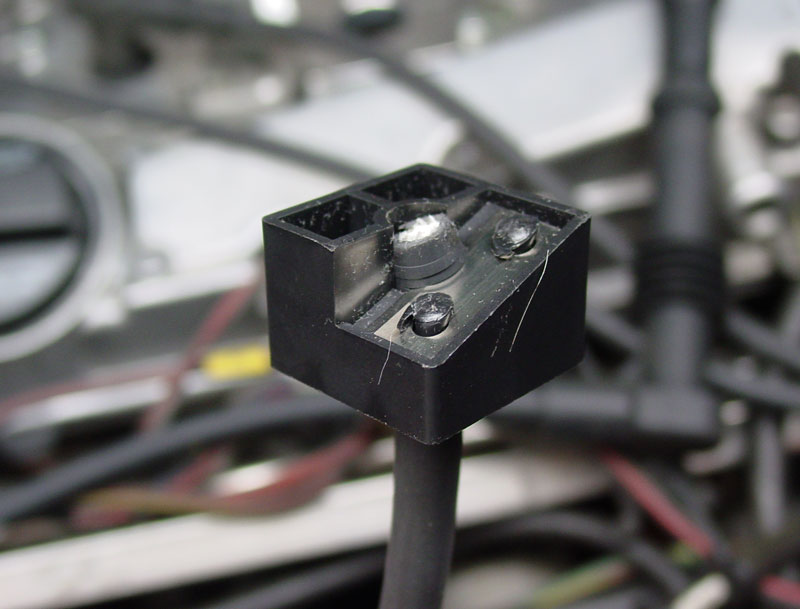

Must be something with the intake/airbox with something plugging the air from going in. Removed the stock airbox and it seemed to work. But…. Dum dum dum duuuuuuum…. We found problem #1.

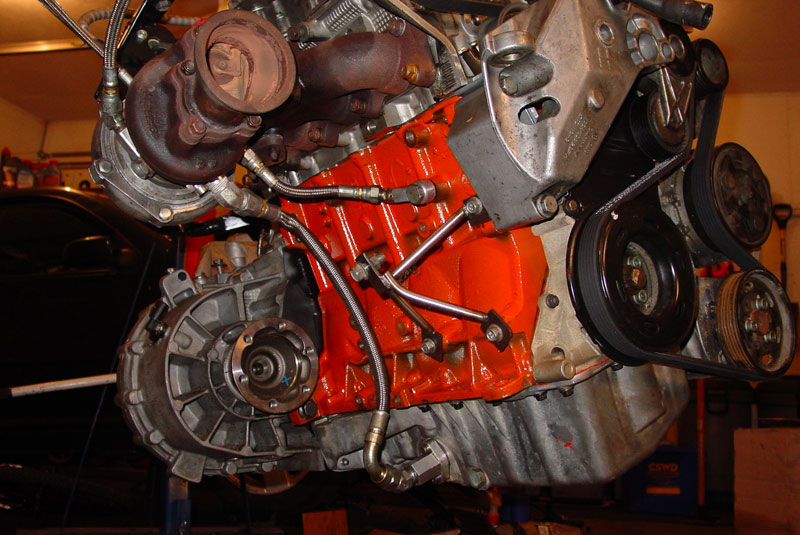

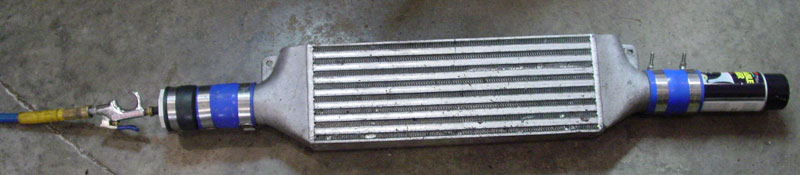

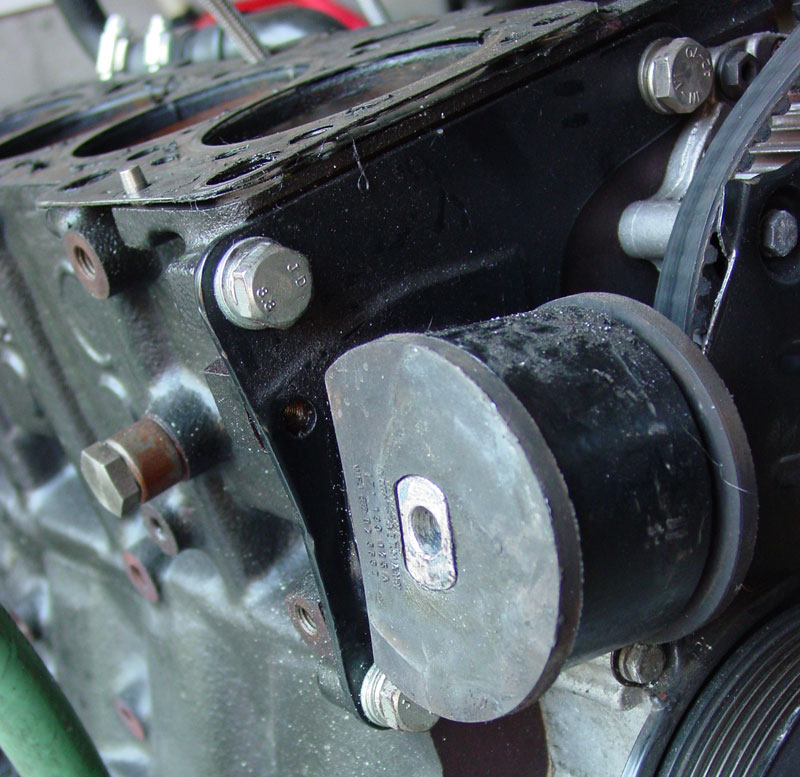

Issue #1: The rubber elbow mounted on the turbo inlet was very soft and was collapsing, thereby, cutting off the airflow. In the words of Dr. Roof (Robin Williams), “Damn straight, baby. You can’t make butter with a toothpick!” That would have to be replaced. Marc said he could compensate for the restriction at higher RPMs by adding more fuel (the compensation would be needed for after I replaced the elbow with something that didn’t collapse). By leaving the airbox off the setup, the elbow did not collapse a lot so we were able to continue as we were able to get up to the 7000 RPM redline.

Because of some anomalies (thanks, Geordi La Forge) in the air/fuel numbers (lean condition) we increased the baseline fuel pressure from 50 to 60 psi (or perhaps it was 40-50; whatever, it went up 10 psi) via the FPR. (gotta love those TLAs..... three letter acronyms)

A couple more pulls wherein the anomalies were still present…. It was like the increased fuel pressure did not improve the A/F numbers at the higher RPMs. Checked the injectors and they were running at 90%... they are still big enough for the HP numbers I want.

“Timmy” popped in to talk about super secret turbo stuff, talked for a while, helped stare at the wastegate to see if it opened prematurely… it didn’t. Premature wastegate opening is embarrassing at any age… but she will understand. She’ll read a book while you stare at the ceiling trying to figure out what happened.

Last run of the day and enter…. The Show Stopper

(damn… I hope the caffeine wears off soon)

Let’s stare at the fuel gauge while running it 2000 to redline. With a 1:1 relationship with boost to fuel pressure, the expectations were for the boost and fuel psi to mirror each other. As we got closer to 6500 (the old redline where we did not have any issues), the fuel hit 80 psi and the boost was 20 psi (something like that) on its way to 25 psi and then… fuel pressure dropped to 60 psi. I let off the gas. Oh oh...

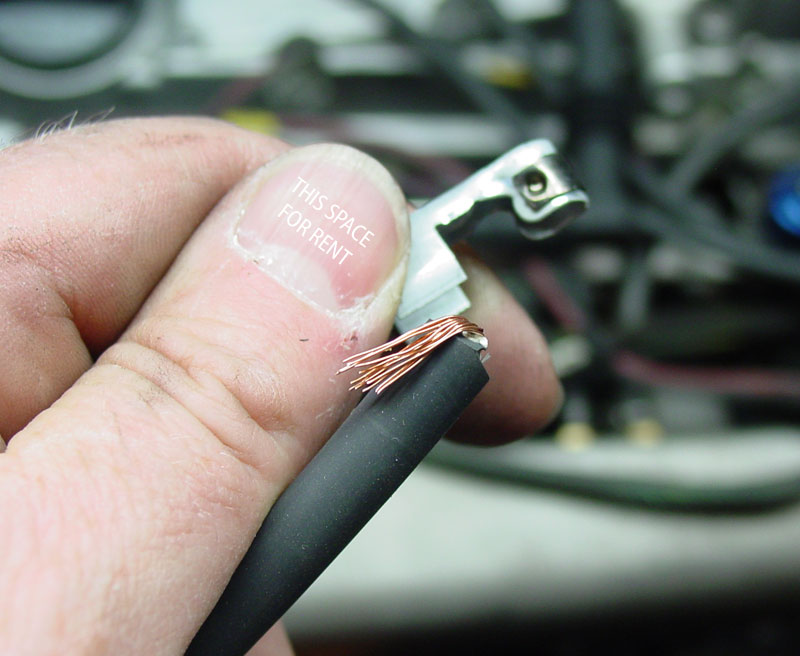

Issue #2: The #$%#$@#& Walbro 255 pump was not up to the task. This explains the porous pistons.

Interestingly, when I was researching fuel pumps for the Cabriolet last month (same engine as the Golf, but a slightly smaller turbo), I ended up with the Bosch 044 because of the warnings on 034’s site that there was no warranty on the Walbro pumps because even the manufacturer did not stand behind them. Marc even said that the pumps were known for failure… why wasn’t I aware of this years ago when I was building this car?!

Well, the good news… my fuel mileage on the way home was a lot better than on the way down.

The bad news… this is because I left the car at Marc’s shop instead of bring it home; great news would be that everything on the car worked perfectly today, the car was ready for the Burke hillclimb, and I could somehow explain the dead hookers in the trunk.

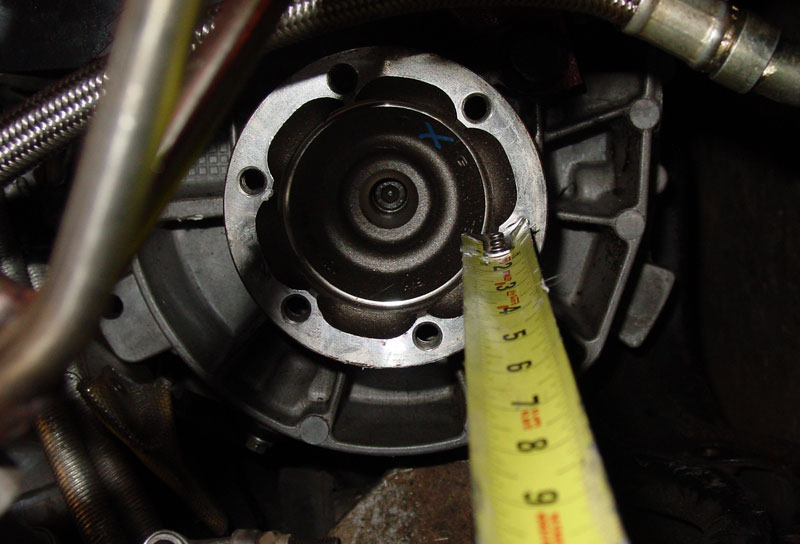

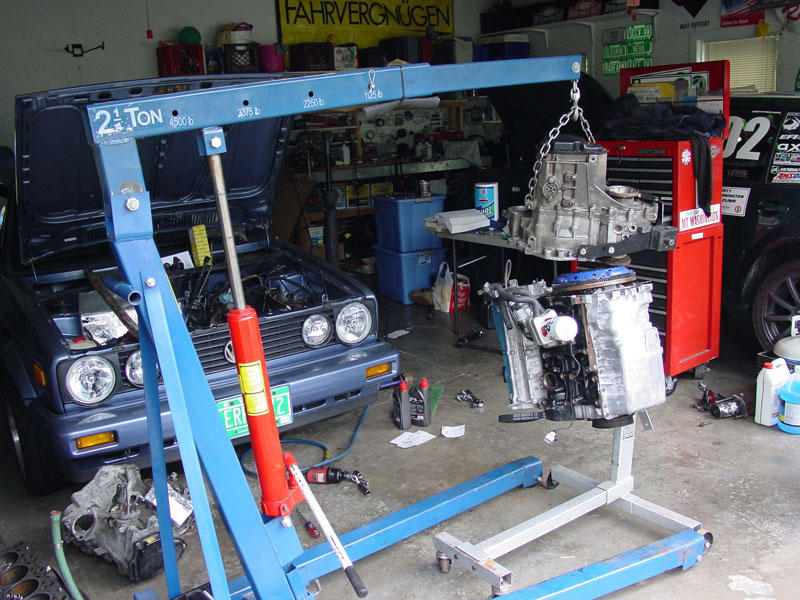

Marc is researching pumps (something mounted in the tank), will install the pump, install a new elbow, make some changes to the coil wiring harness, and tune it.

This means that I will miss the Burke hillclimb this weekend (as a driver).

The really great news is that we discovered the issues today on the dyno as opposed to on the hill. This is a much cheaper alternative. The 313 wHP number with no fuel above 6500 was pretty good.

I should be tired, but I feel like going for a bike ride, cleaning the house, putting the engine in the Cabriolet, catching up on some old movies, ripping all my CDs to MP3s, and...

Posting this story.