When I first installed the Megasquirt (and a bit later on) I mentioned some issues with sync loss. I was able to mitigate the issues by adjusting the VR pots and re-gapping the pickups, but every so often I would get a couple of lost syncs on the datalog with no apparent reason. Then the other day I noticed that sometimes at high RPM it would lose sync and then have trouble re-establishing it for a few seconds at a time.

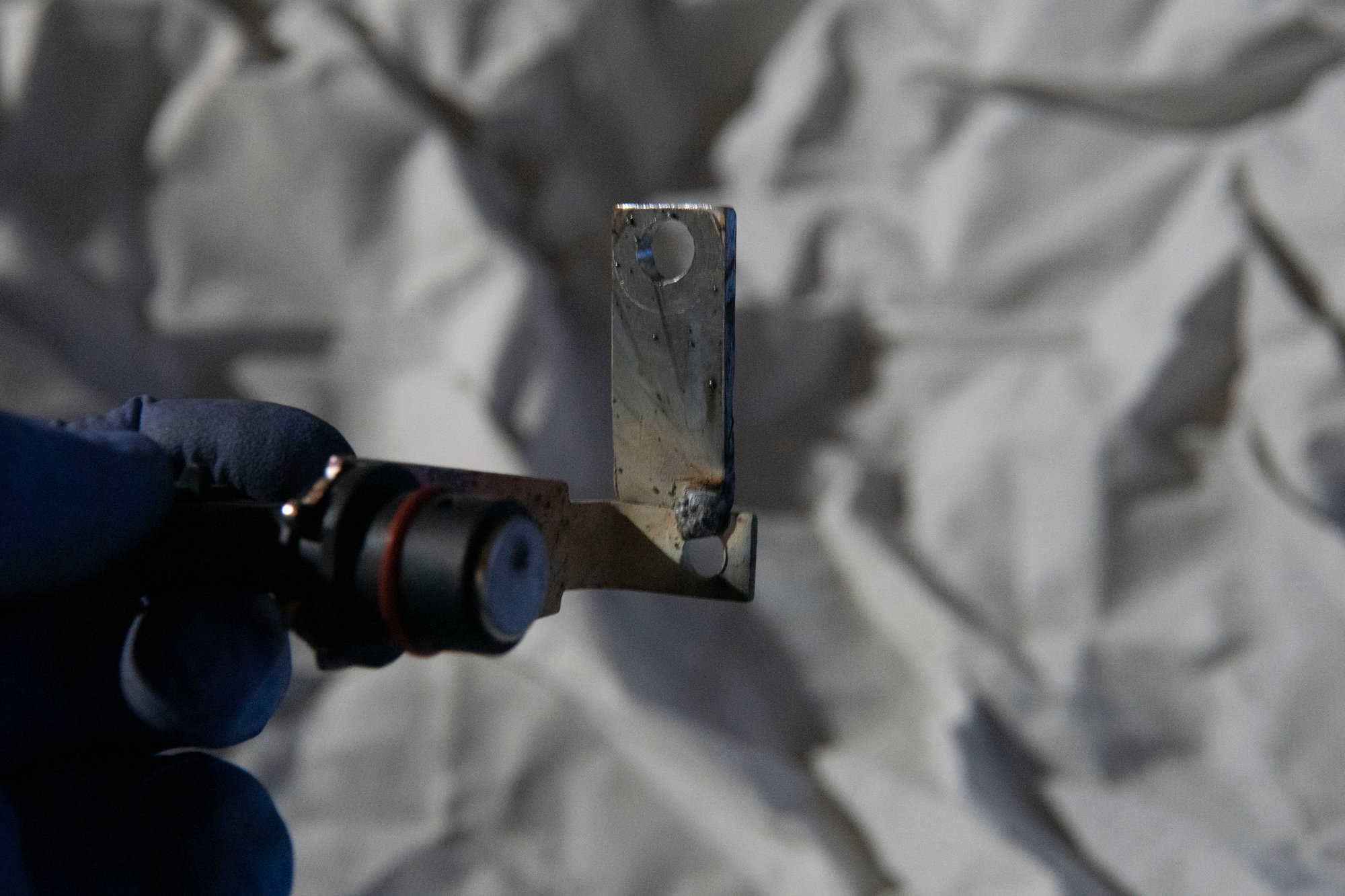

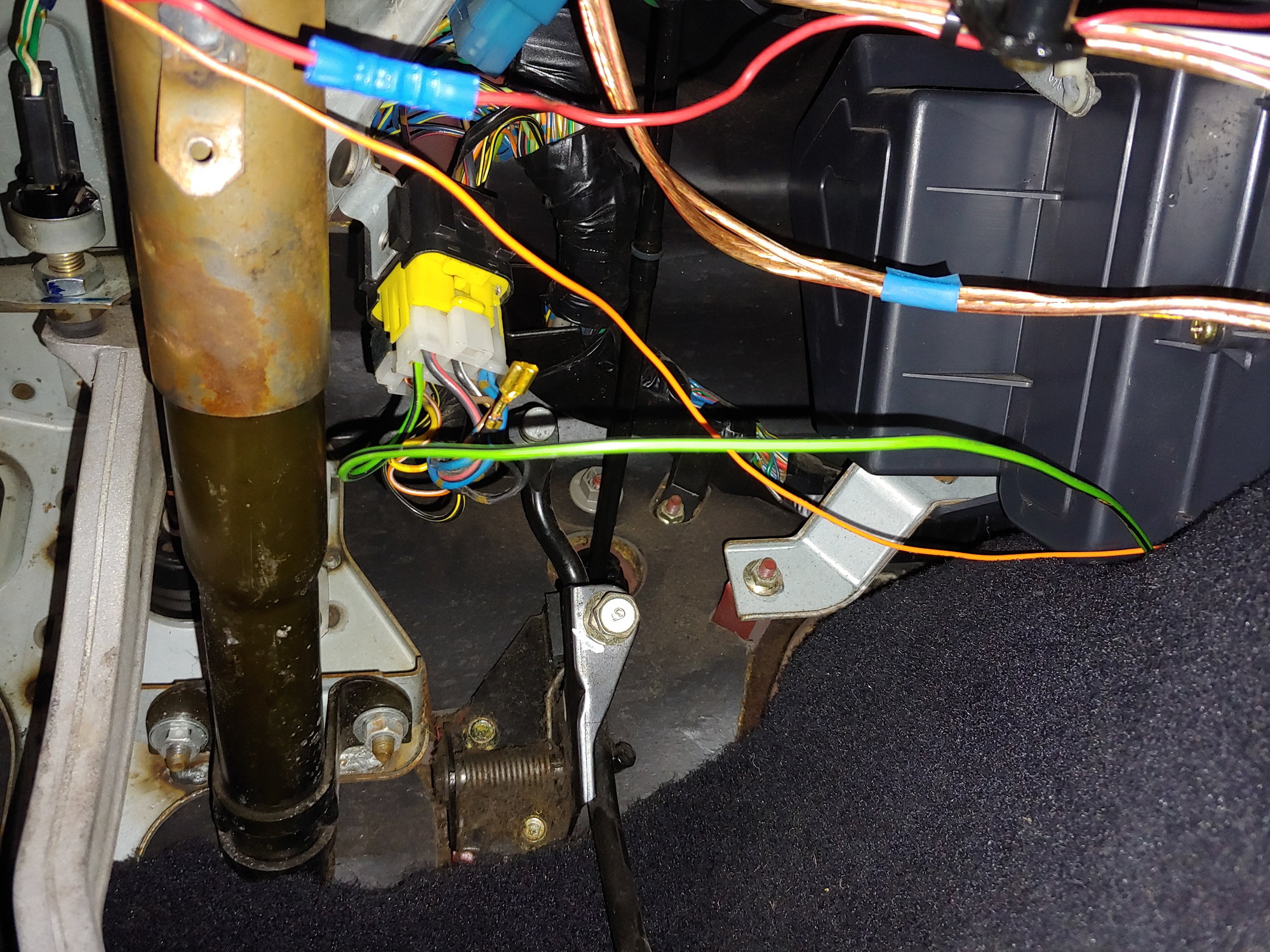

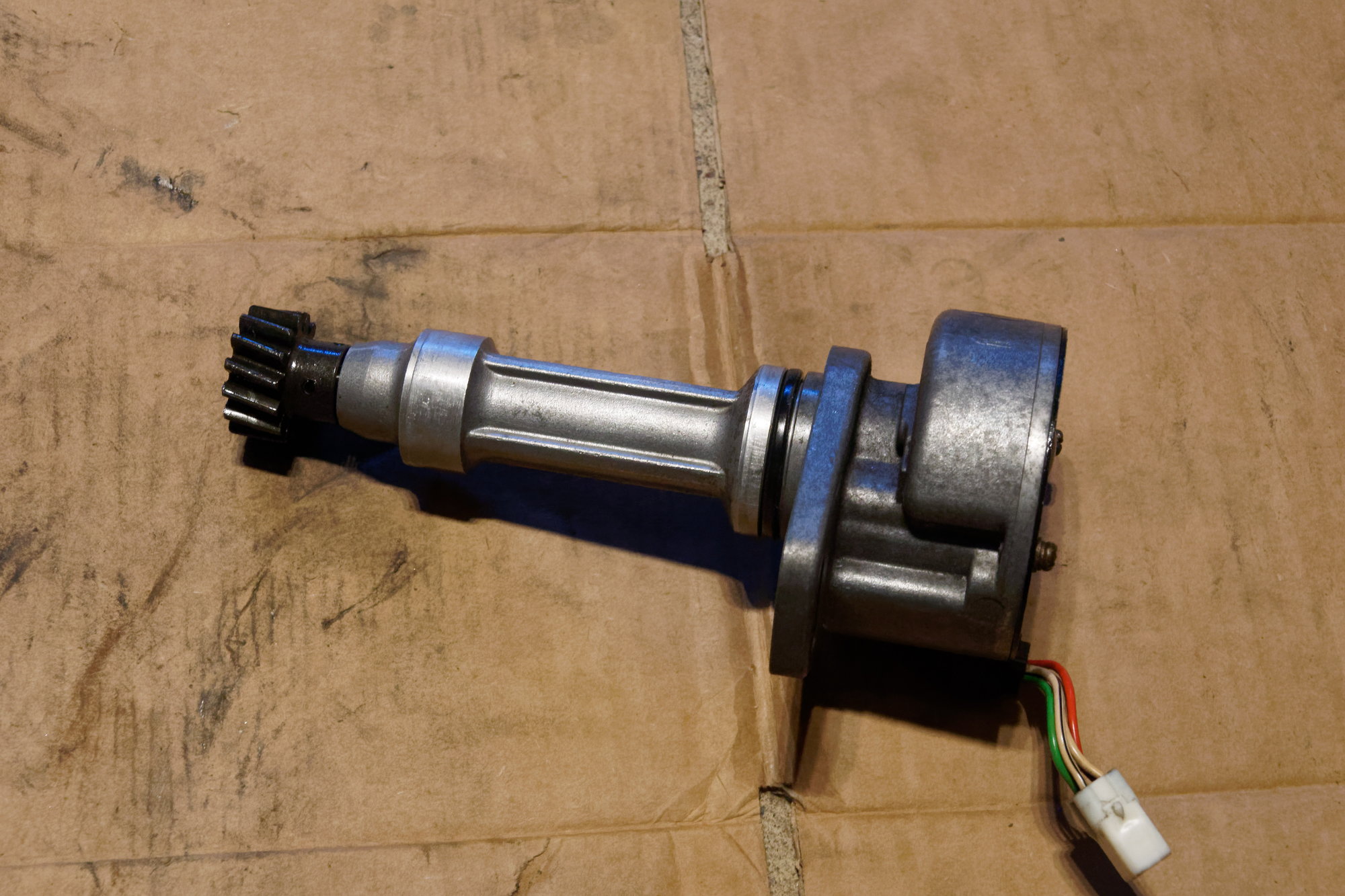

Here's the stock CAS:

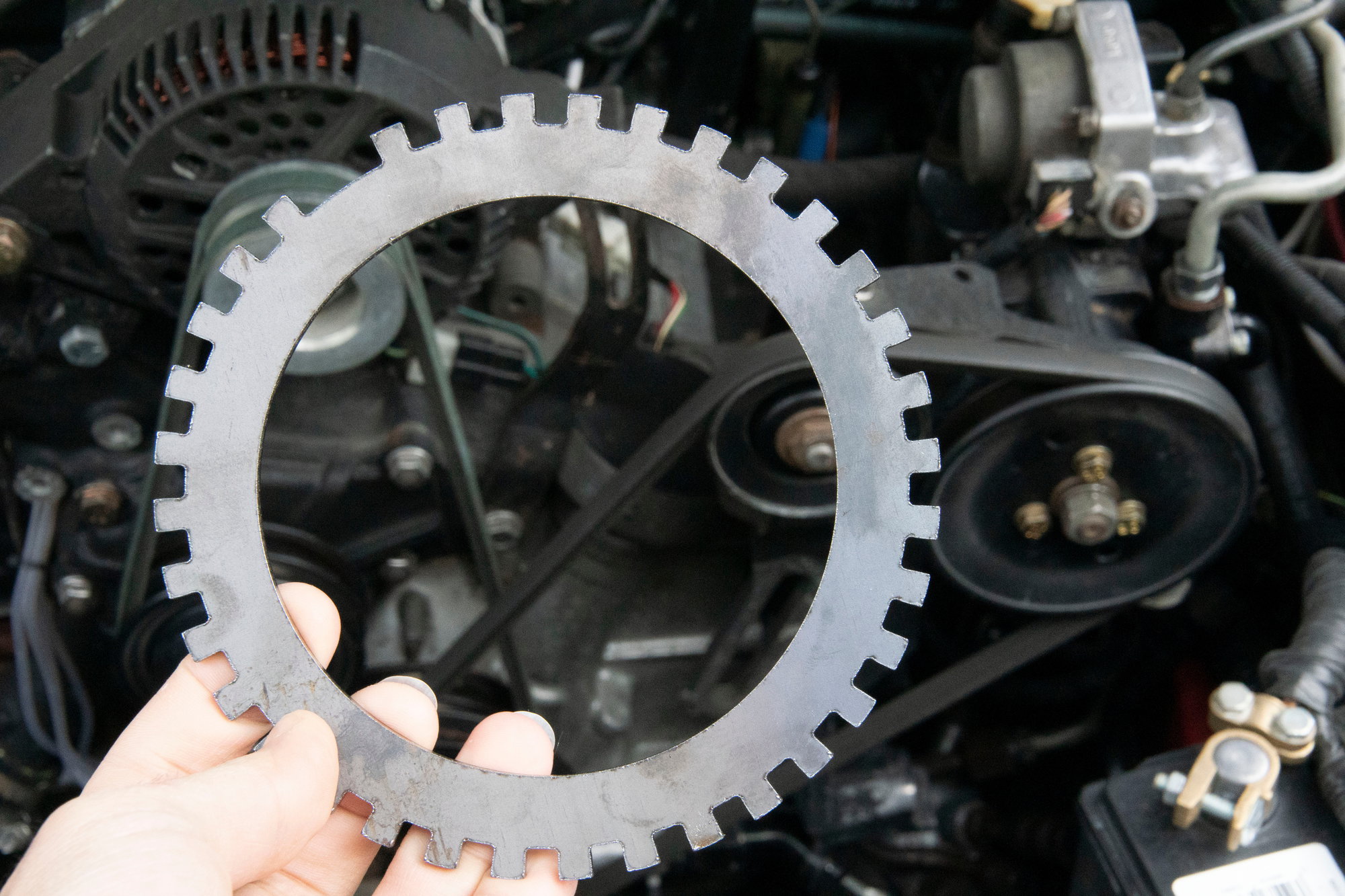

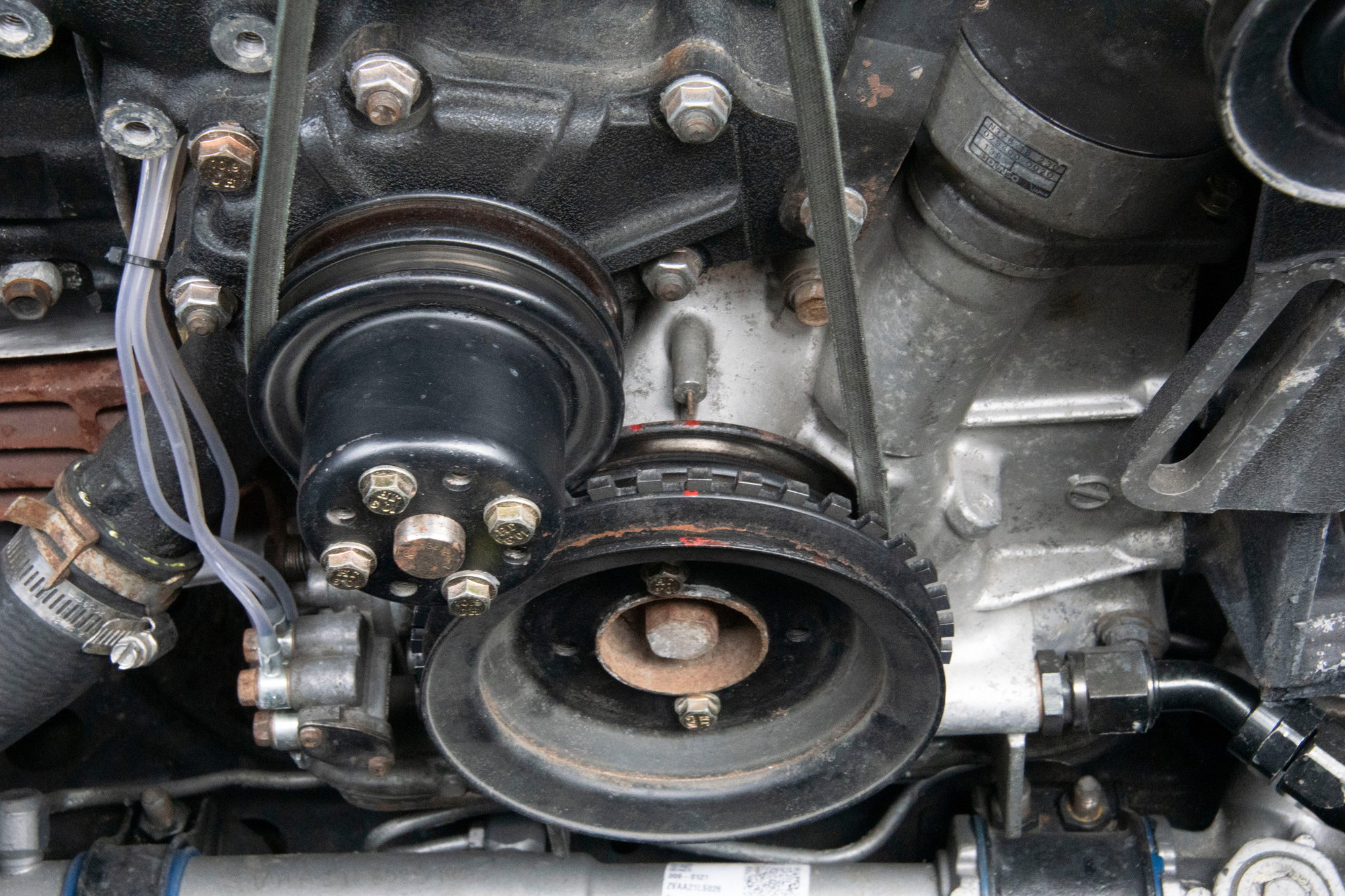

The wheel I was losing sync on is the upper "cam" wheel. I wasn't able to determine the reason, and despite some fiddling with the pickup gap I wasn't able to completely eliminate the issue. I ordered a small 36-1 wheel and hall sensor with the idea that I could mount them in the CAS itself and avoid modifying the front pulleys, but then when I was asking about it in the Rx7Club's Megasquirt section, member Nosferatu had some really helpful advice. Apparently you can just modify the CAS into a 24-2 wheel and avoid using the upper wheel entirely.

So that's exactly what I did. I found several posts about it, but most were relating to the MS1 and didn't have very clear instructions. It turned out to be pretty straightforward though.

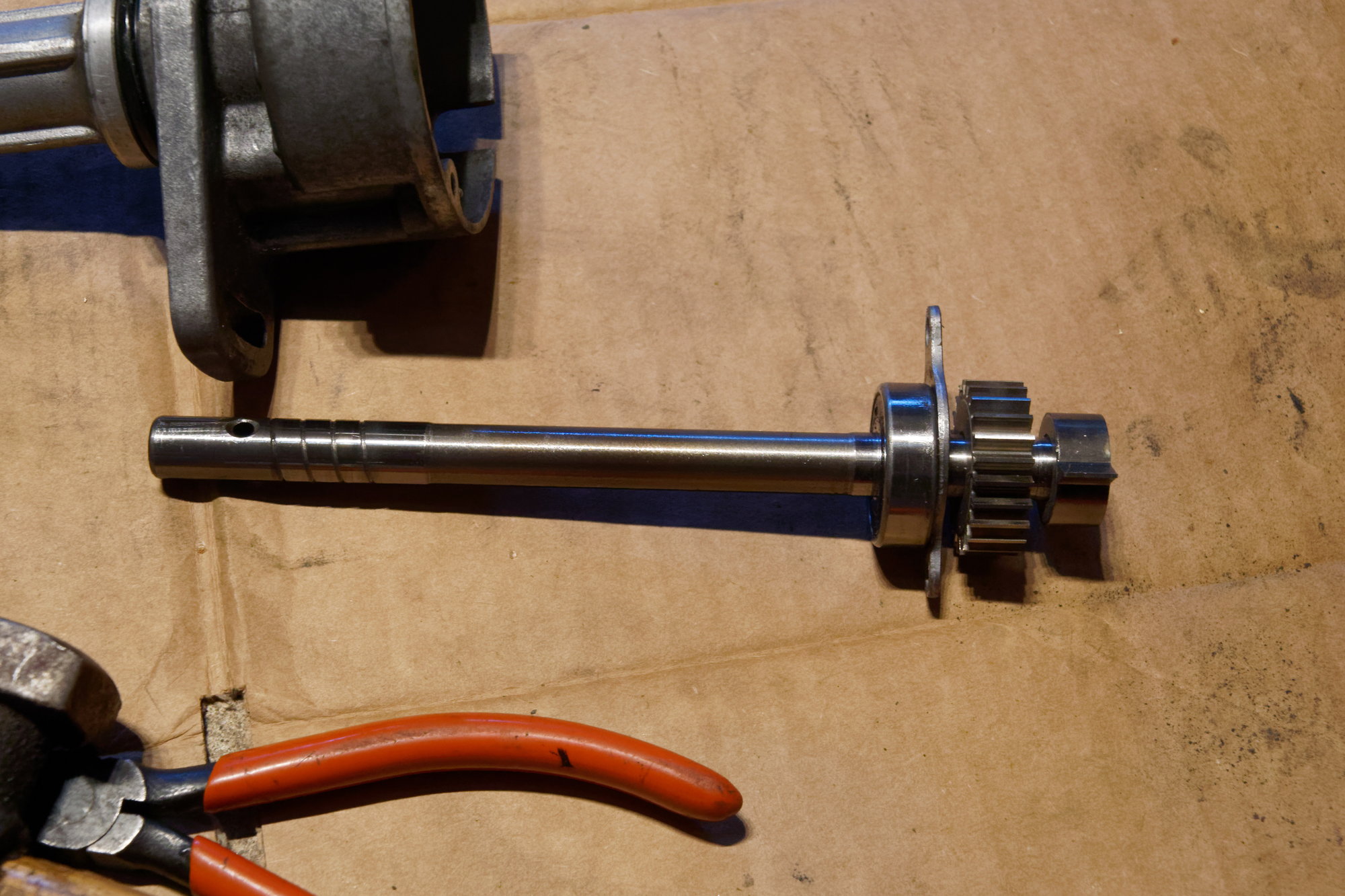

Remove the roll-pin and drive gear:

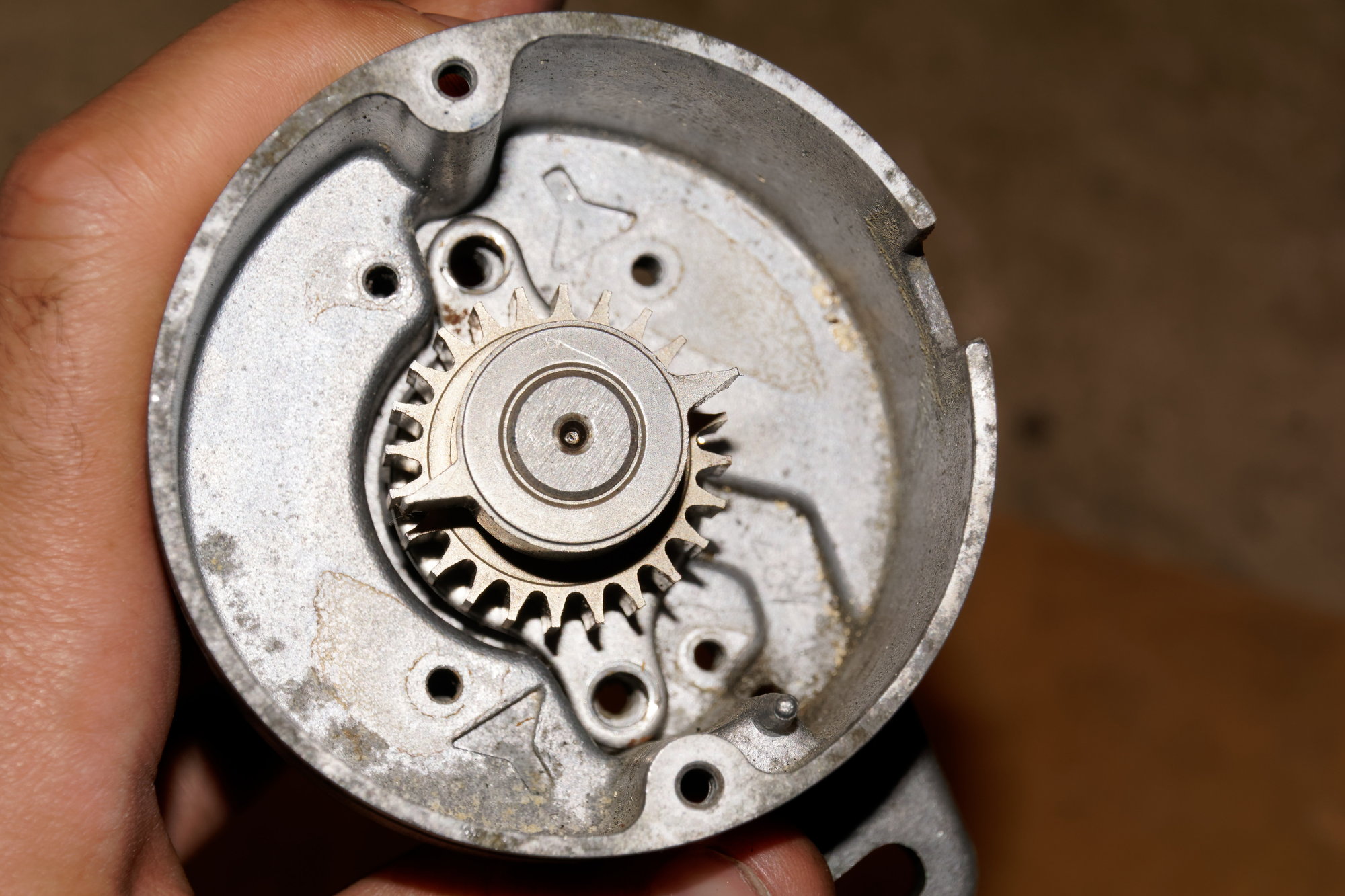

Take out the pickups, and the screws that hold the rotating assembly:

Pop out the shaft:

Removing the two-tooth wheel is optional, but this ball-joint puller made it a 2 minute job, so why not:

Then grind out two opposing teeth. I read first that it "didn't matter" which teeth you grind out as long as they are opposing. This is technically true, but the best way is to count back from the two-tooth wheel three teeth. There are instructions on this particular step if you search. The only consequence of my choosing the teeth at random is that I had to grind out the adjustment channel on the CAS body a bit to time the engine. Since I've already gone and modified this CAS, I'm not worried about it.

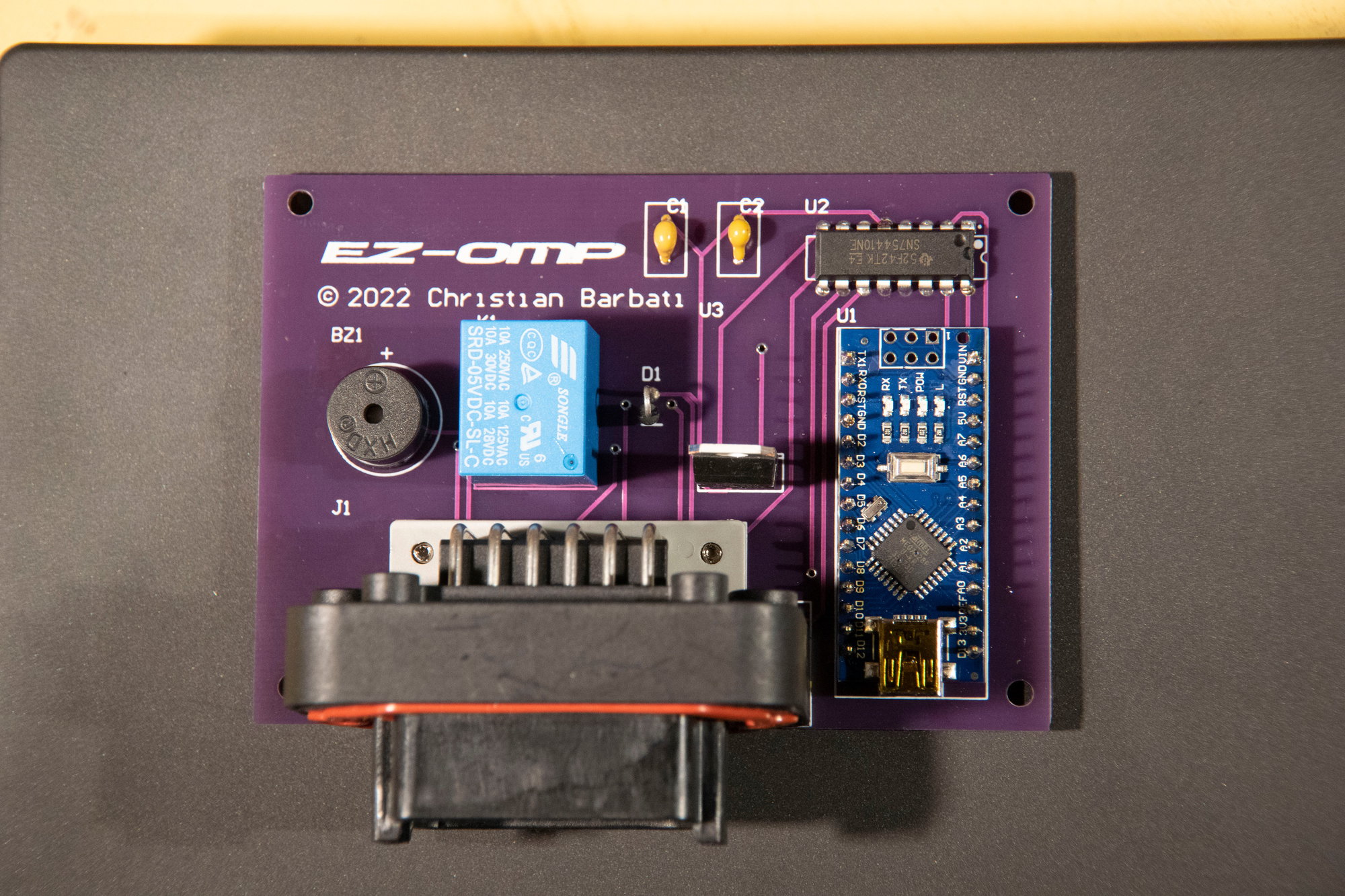

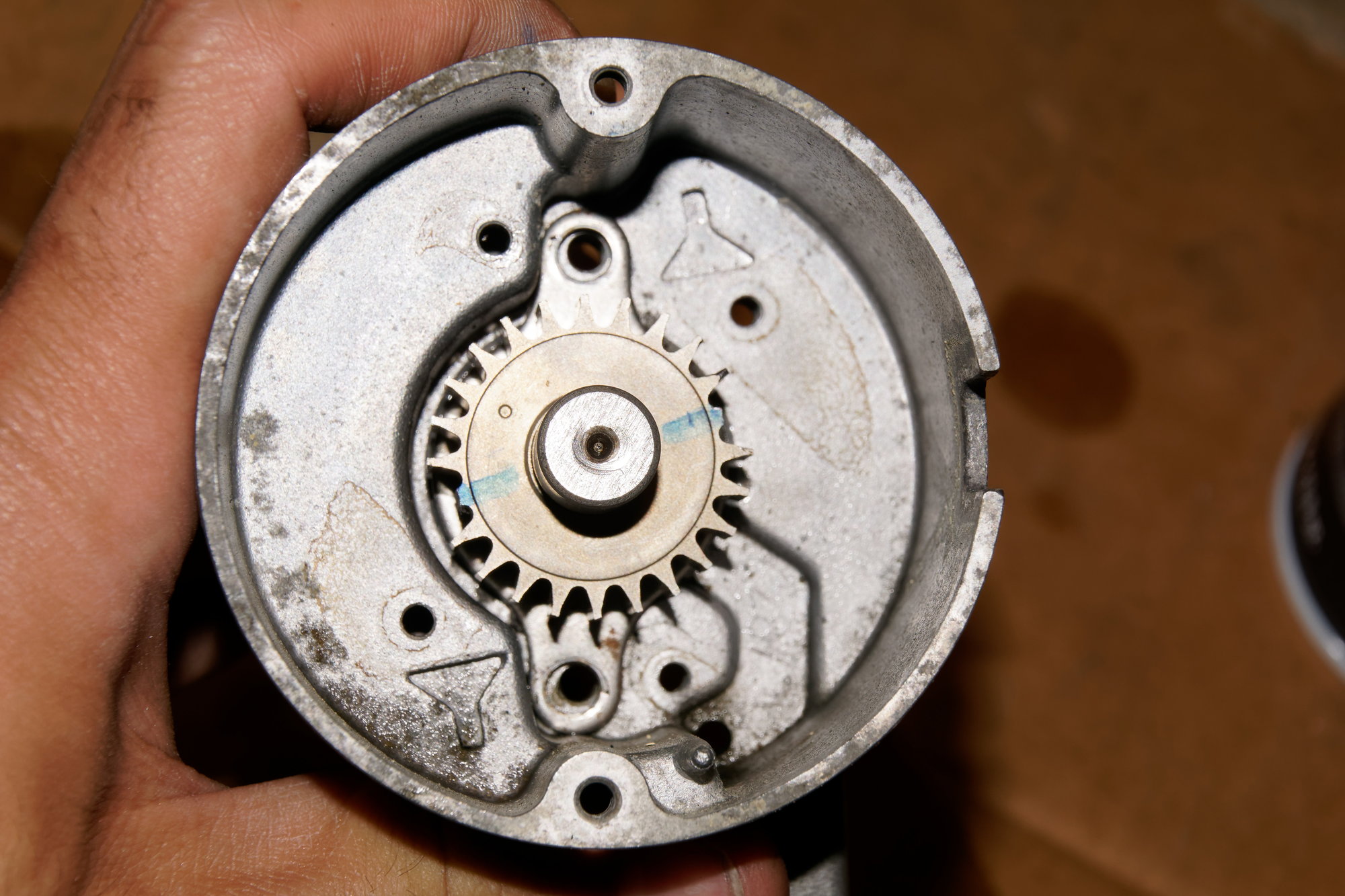

Time to put the CAS back together with its new 24-2 wheel:

I did accidentally kiss the next tooth over with the carbide burr, but it hasn't caused any issues in operation since it's a minor mark. Be careful though, if too much damage is done the tooth won't read anymore.

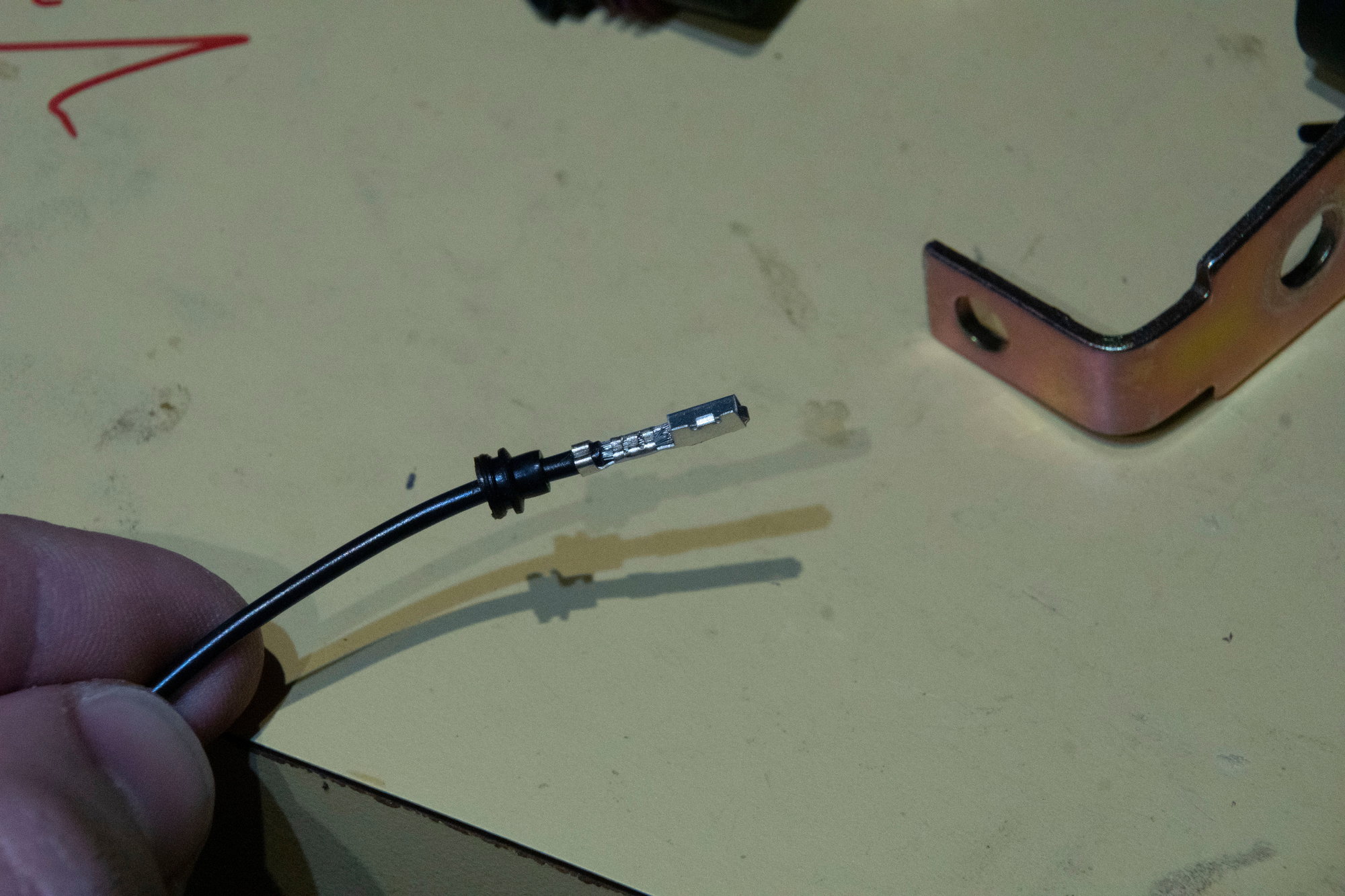

I technically don't need the extra pickup anymore, but couldn't think of a better place to store it than in the CAS. If I need a spare, I'll know exactly where to find it. I also added a dab of red paint to the third tooth back, since that's how the engine is timed now:

Then I put the engine at TDC, lined up the gears, and installed the CAS. Altering my sensor settings in Tunerstudio took a few tries, but I got it working and timed. After a test drive and re-gapping the pickup to .011", perfect sync. No loss during cranking, no loss at high rpm, no loss when the fan turns on.

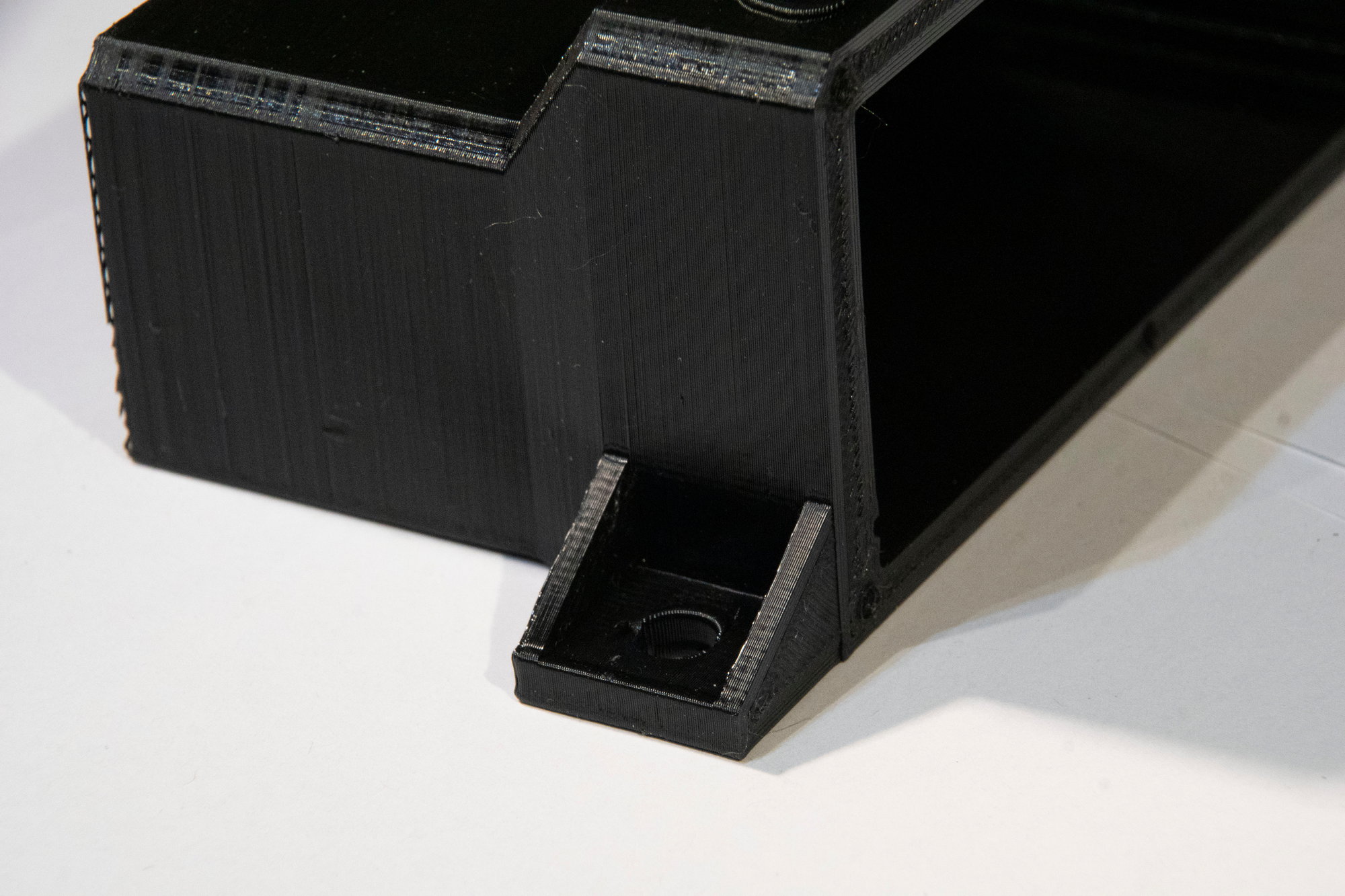

So I'm very happy with the modified CAS. What I'm not happy with however, is my own carelessness:

After work on Saturday I went to fill up the tank, and I scraped the curb entering the parking lot. I could go on about how the curb there is unusually tall and it protrudes out a weird angle, but at the end of the day this is my fault. It's fixable, but it still sucks to know that I did that. I can pick up a can of colour match paint from a local shop I know and bang this back into shape using the inner sill for access. I also have a few PDR tools that may help pull that crease back out. I'm going to get it as close as I possibly can, then paint it and call it good. Then add it to the growing list of things that a body shop will need to look at when I get the car painted. Including that bubble on the door.

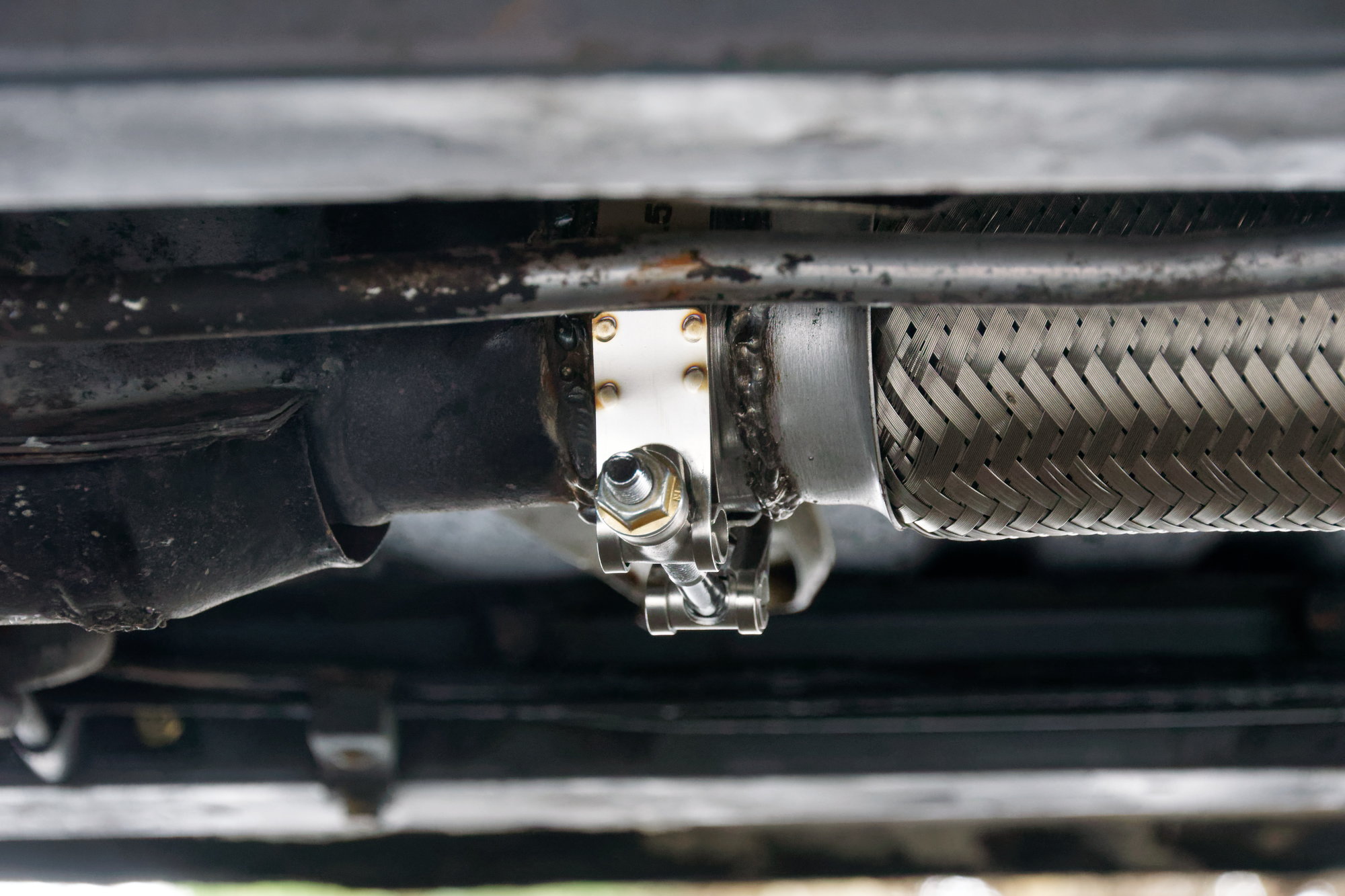

On the drive home from the gas station, I felt a weird drag on the car. Then I heard a thumping noise and smelled Jiffy Pop. That is my cue to know that a brake caliper has seized. Randomly, for no apparent reason, the caliper on the OTHER side of the car decided to seize up. I pulled over and it was immediately apparent due to the heat radiating off the wheel.

On Sunday I drove my Celica to work and back. Wouldn't you believe it, I pull into the driveway and hear a thumping noise and smell Jiffy Pop again. You guessed it, BOTH my cars have seized brake calipers in less than 24 hours.

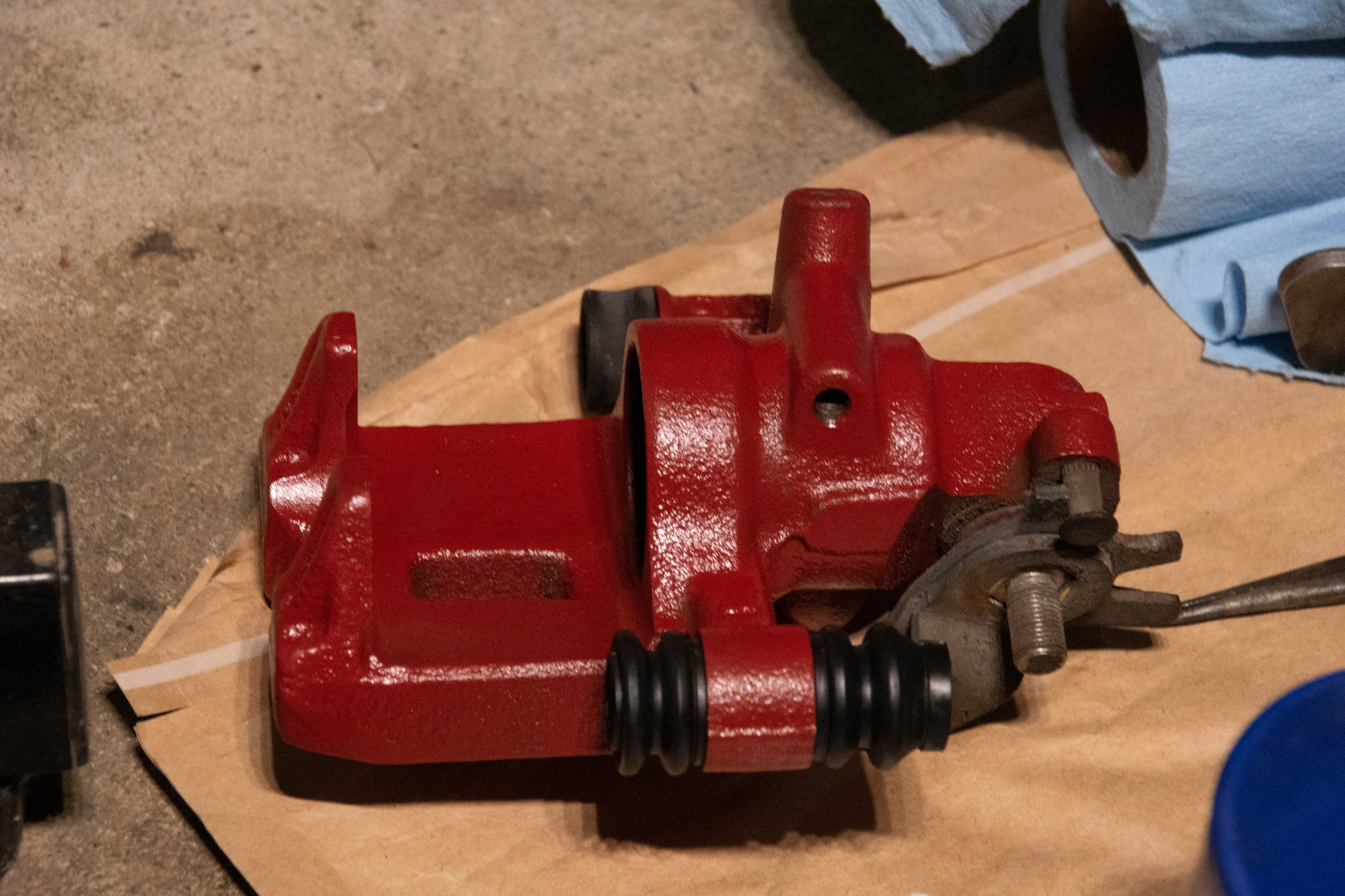

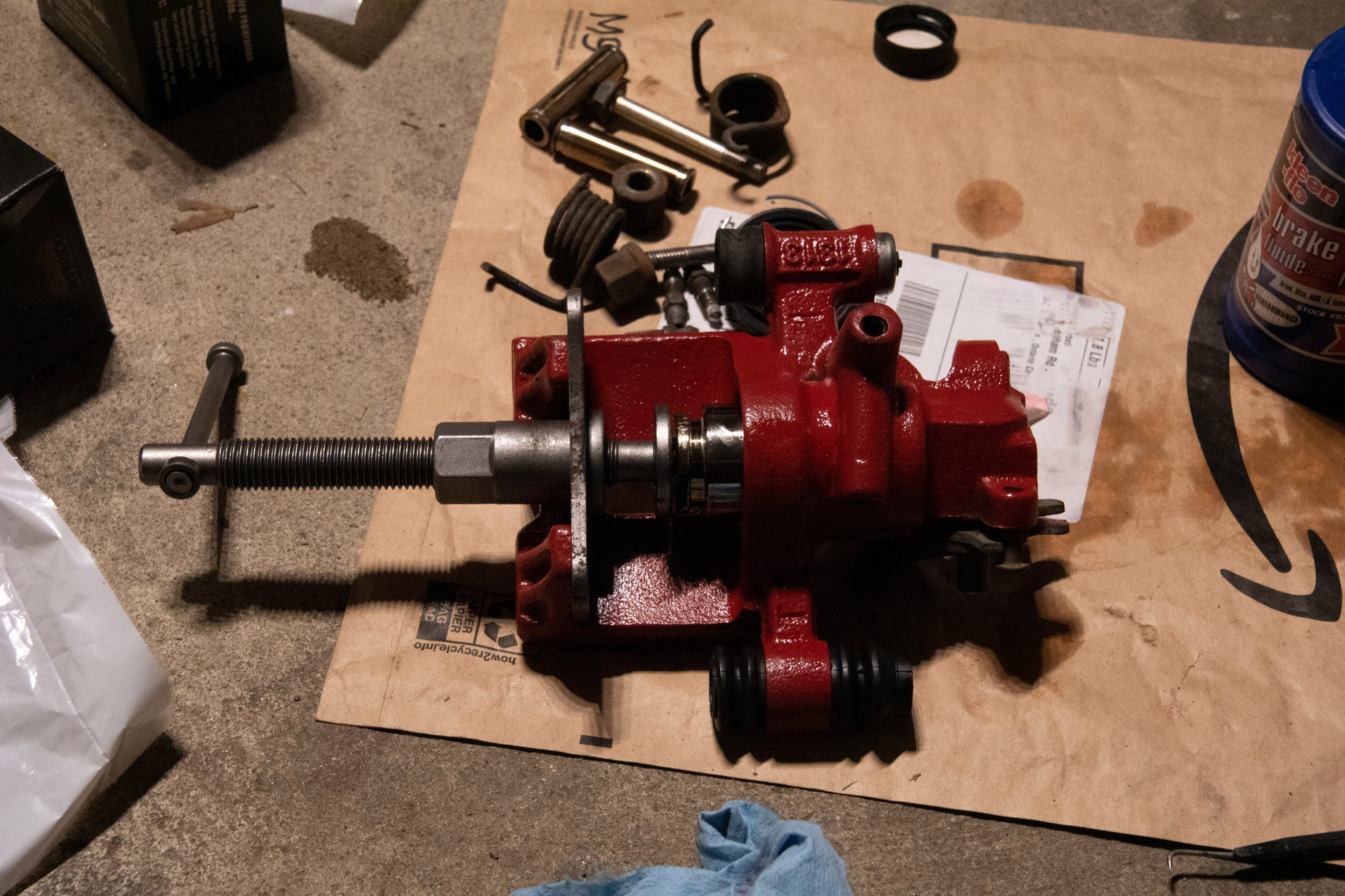

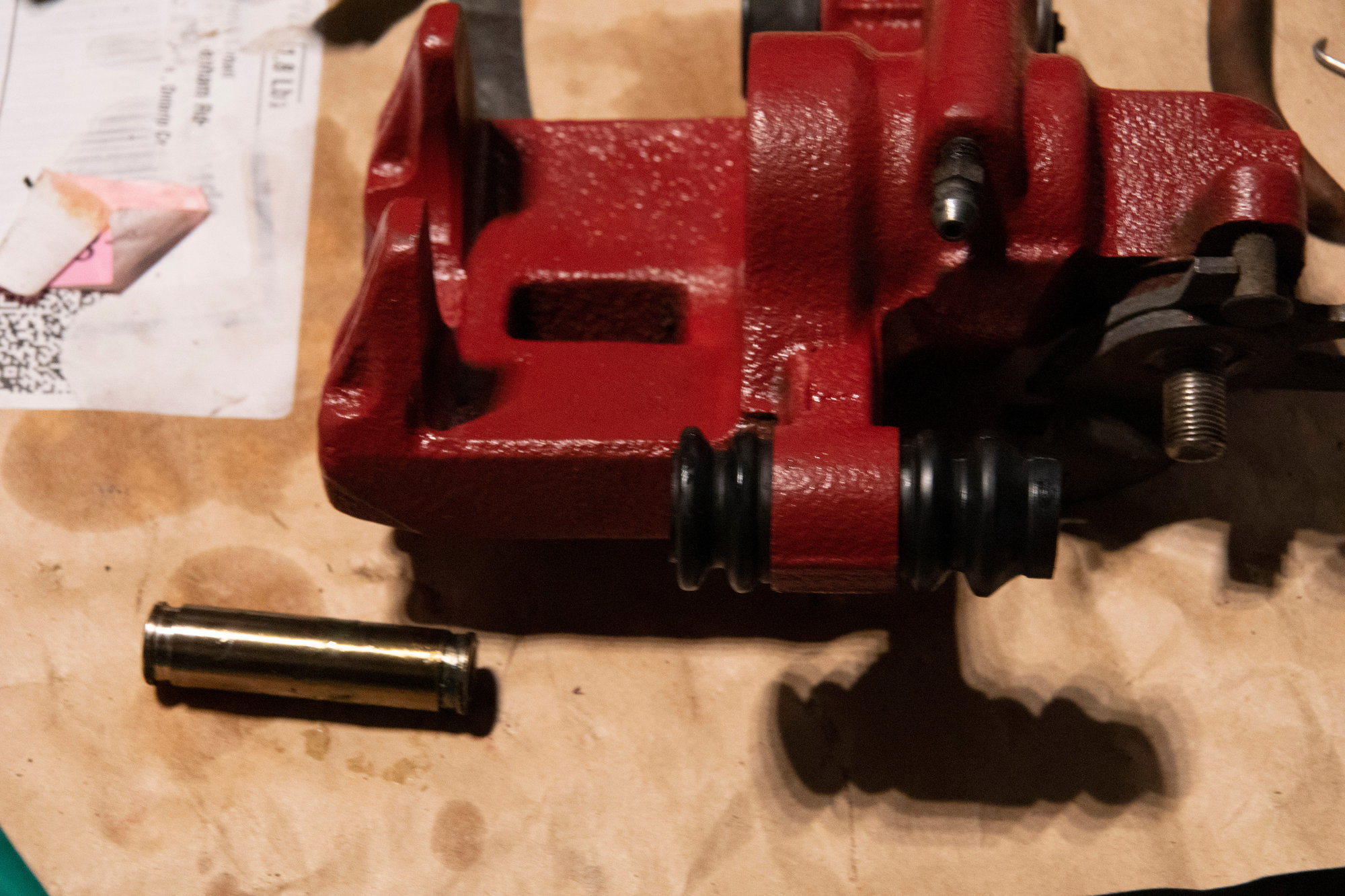

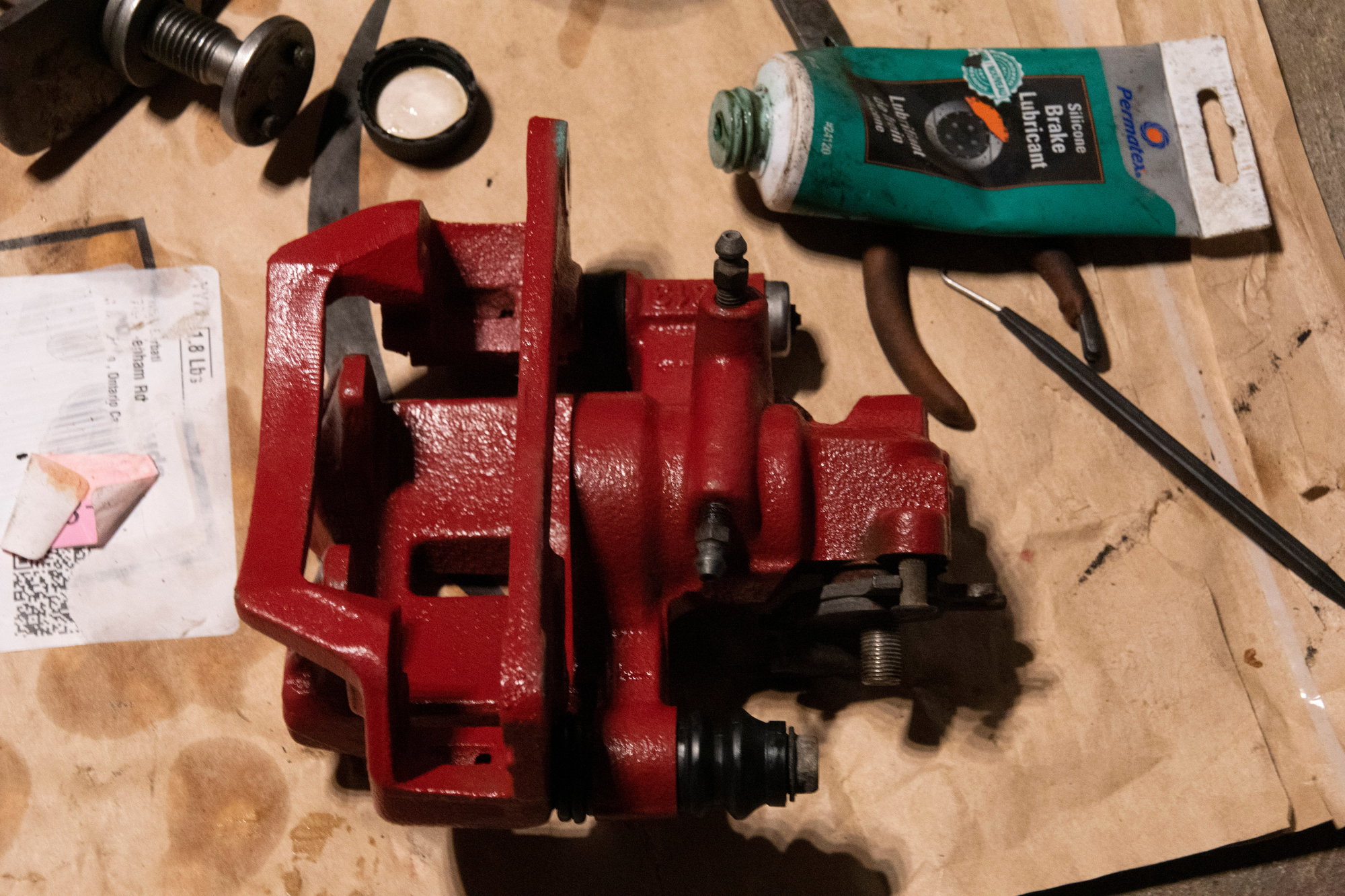

Rear calipers for the Rx7 are tough to find, so luckily I kept that free set I got from the parts yard. I tossed one on and bled it in less than an hour, but it turns out that one is even more seized then my original. So rebuild kits are on order for all the offending calipers.

Both cars are back in their natural habitat:

So for now, that's that. I start classes on Wednesday and between work and school I'm looking at 55 hour weeks. I'm going to do the required maintenance so I can continue to enjoy my Rx7, but any major jobs (like the Turbo swap) will be waiting, most likely until spring since I don't have garage access during the winter. The rebuild kits should arrive in a few days and then hopefully I'm good to go.

Until next time :)