I've finally found what I hope will be an acceptable solution for the aux port actuation that I worked on in post 8 of this thread.

For new readers, I'm going to recap from the beginning. It also helps explain what my goals were with this project.

On a rotary engine the port timing is controlled by the footprint of the intake and exhaust ports. Smaller intake ports with an earlier closing time promote better idle, and larger intake ports with a later closing time improve performance (to a point, of course). In a piston engine this is normally controlled with a VVT actuator, but since there are no cams in a rotary engine, Mazda's answer to this problem are the auxiliary ports:

These ports have sleeves inside of them. Normally the sleeve is closed, which means that the engine runs only on the smaller port (closing at 40 degrees). This is helpful for idle and midrange, where the extra port area kills air velocity. Then at higher load, a set of actuators rotate the sleeves, opening the port:

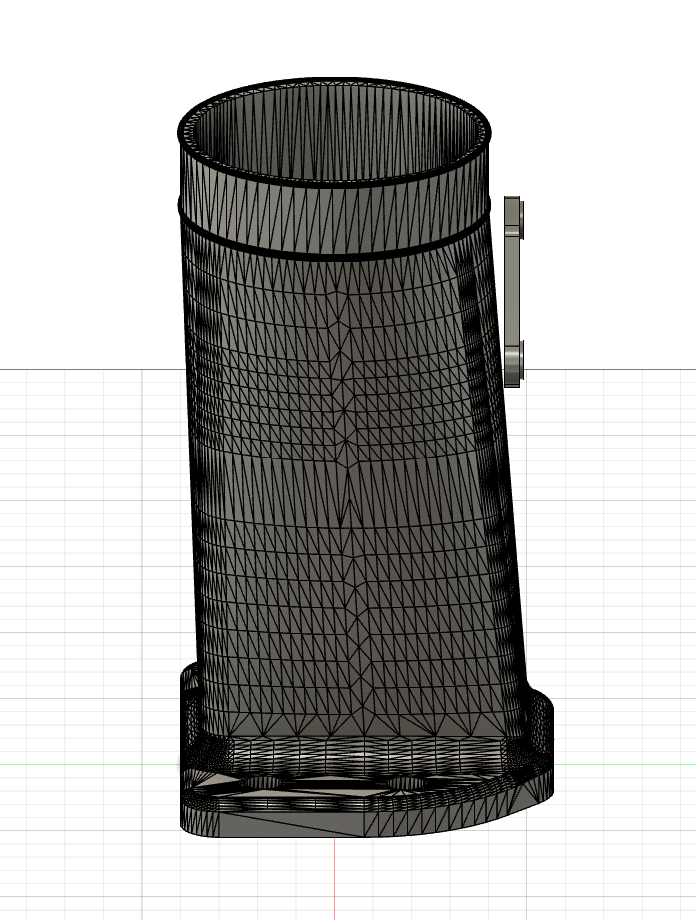

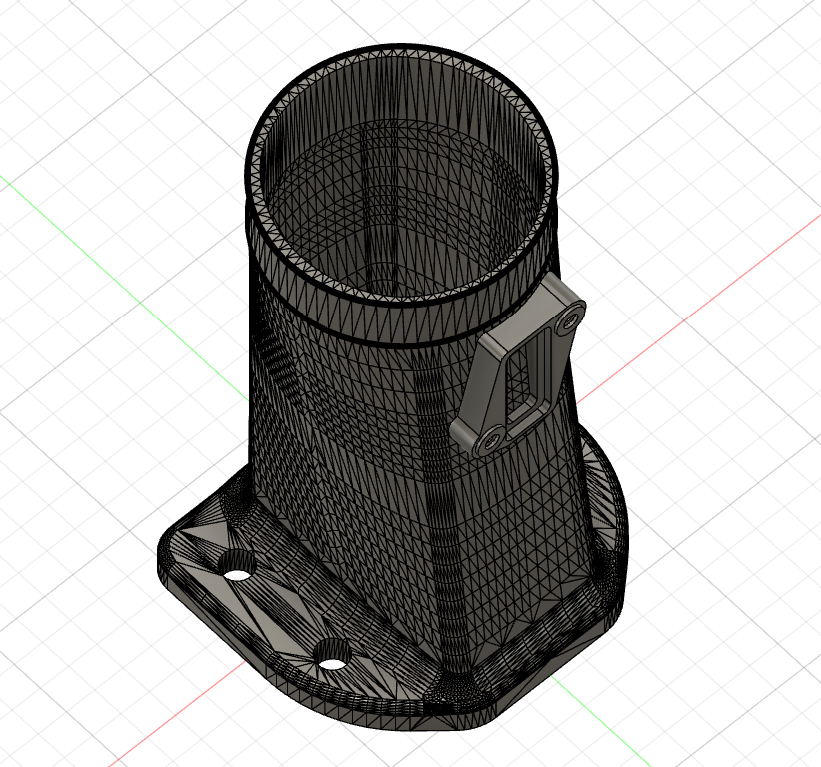

The actuator looks like this (on S4 models):

The little tube to the left is a pickup that connects to the exhaust. As you cross about 4000rpm, the back-pressure in the exhaust drives these actuators and the ports start to open up. This presents an obvious problem with an aftermarket exhaust - where do you get this pressure from? Most exhausts don't have the pickup for the tube, and even if you wanted to add a tube the aftermarket exhaust probably won't have as much back-pressure. There are a few solutions I've heard of (and tried):

- Use air from the air pump (with or without an RPM switch)

- Use an electric air pump and an RPM switch

- I've read of at least one person saying they used cable actuation connected to the throttle (for which I can no longer find the post)

There are problems with all of the above:

- The air pump builds pressure way too early (2000rpm) which means the ports are opening about 2500rpm earlier than they should

- Most electric air pumps are an impeller style. After testing, I was not able to find any that build enough pressure at the outlet to budge the actuators at all. I've read of people using an aquarium pump, but I have my doubts about that pump surviving a long time under the hood of a car

- Even if you did get either of the above to work, an RPM switch is the wrong approach. We want to actuate the ports based on load (in my case MAF), not RPM. At light load above 4000 rpm the ports being open is worse than them being closed. Now I know that light load above 4k is not a common situation, but my point stands.

- A throttle cable has a similar problem, which is that now it's tied to throttle-position instead of MAF. If you floor the throttle from idle, even before you leave idle the ports are already all the way open.

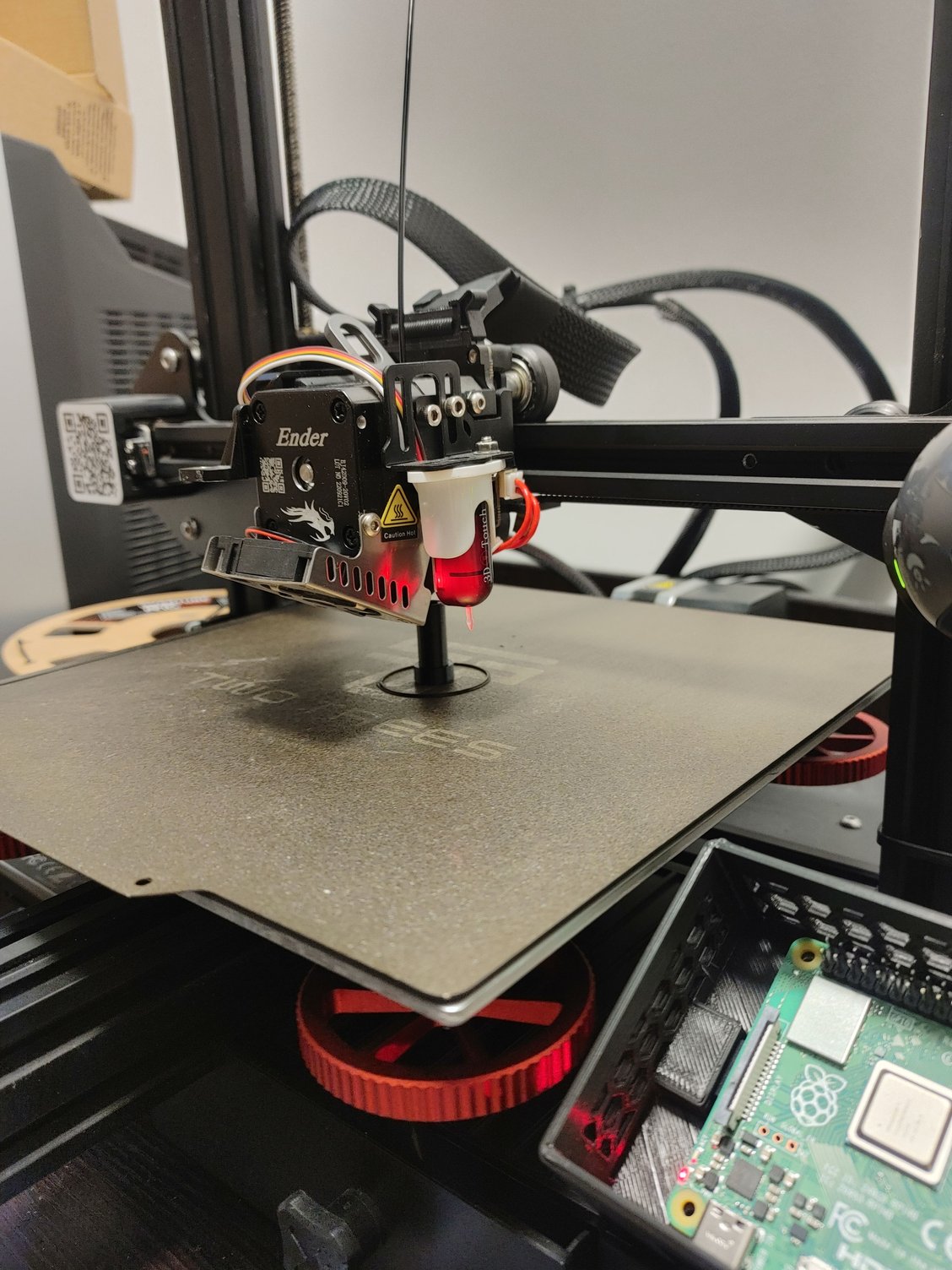

I experimented awhile ago (see page 8) with using air pumps, MAC valves driven via PWM, etc to try and have the ECU control the ports based on MAF. But there wasn't any solution that I was happy with.

Recently I decided to pick this project back up. Here were my goals:

1. The ports should open at the appropriate time, consistently (I could never get this to happen with the air pump options).

2. I should be able to control them with the ECU, and adjust the opening time.

3. They should be controllable based on MAF

4. The solution should be reliable

5. (Nice to have, but not 100% required) I should have infinite control over the port position, not just simple open / closed control.

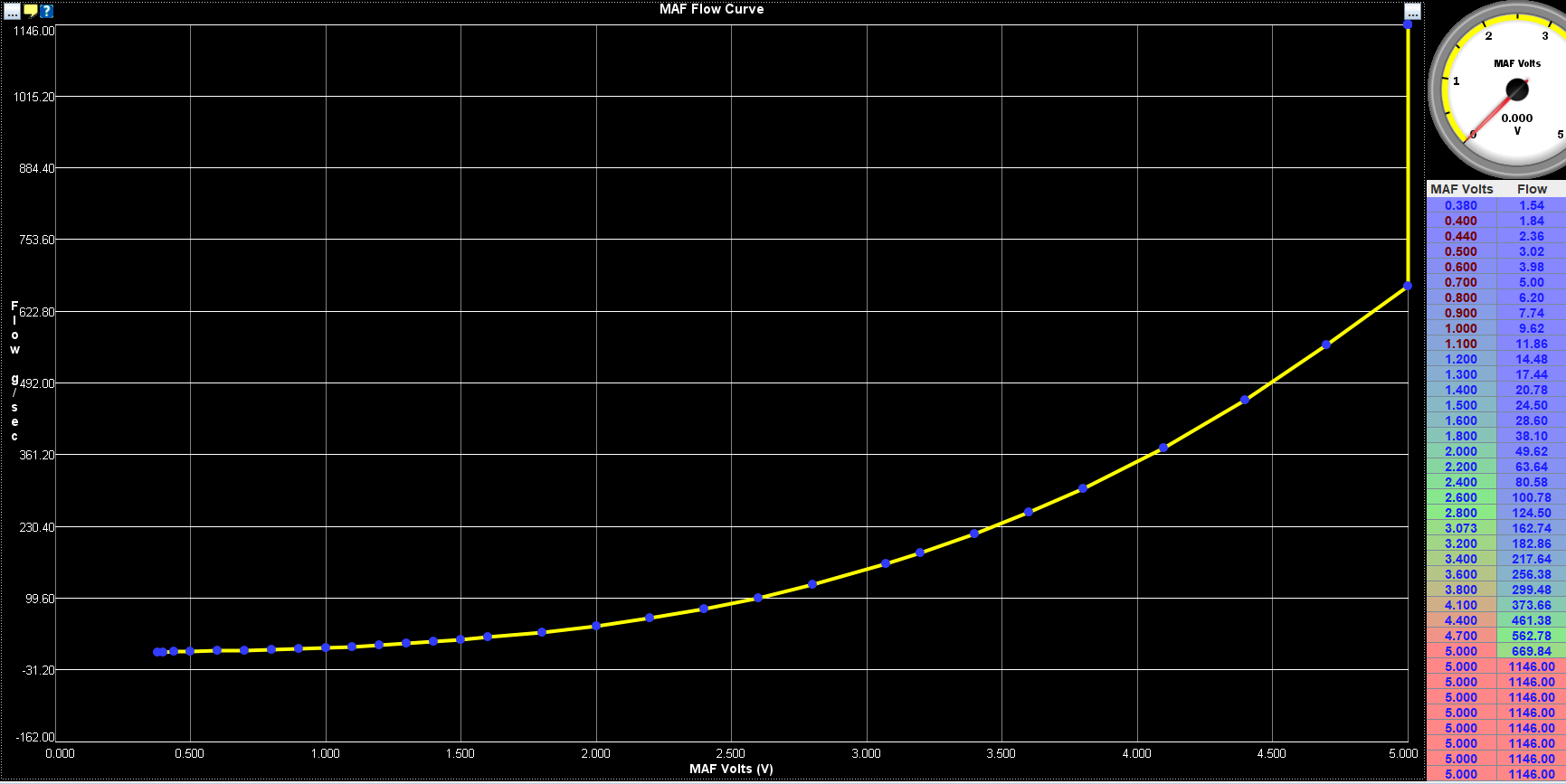

Why did I want number 5? Well, one thing I noticed when testing with the air pump and a MAC valve is that it's not difficult to get the ports to open, but it's difficult to get them to stay part of the way open. I wanted a way to have the ports not just be open or closed (40 degrees vs. 80 degrees closing time) but to be able to hold them at say 60 degrees closing time. This would maximize the area under the curve in the powerband. Speaking of which, here is some data I took from a log:

It's a bit crude since I'm using MAF as a proxy for power, but since I don't have a dyno this will have to do. The first thing to notice is that the closed ports flow a lot more until about 4250 rpm, and then the gap starts to narrow. At about 5250 rpm the open ports surpass the closed ports in terms of airflow, and after that there's no contest. I think the weird dip at 6250rpm was tune related, but this was several months ago so I don't recall the exact cause.

Anyways, this begs the question - if 80 degrees close time is flowing more at 5250 rpm than 40 degrees close time, is 50 degrees close-time outflowing both 40 and 80 at 5250 rpm? Ideally, I should be able to start opening the ports at around 4250 rpm and open them smoothly until they reach full open at say 5750 or 6000 rpm. More testing would be required to determine the exact transition points.

I'd seen a photo online of someone using solenoids to pull the ports open, but I originally scrapped that idea for a few reasons. Mostly that it required mounting some return springs (with no good OEM location to mount them to) and also that I was concerned with reliability because of the short duty cycle and the fact that the solenoids would sit above the exhaust manifold.

But then I saw these on Amazon and I did some more thinking:

They have an integrated return spring, so that simplifies the bracketry. They have 60N of force which should be much more than required to open the ports. They fit in the available space, and they also had a clevis that looked like it might fit the stock linkages. And at 3A each, they could hypothetically be PWM driven by my Megasquirt. So I ordered a set for about $40 and did some testing:

The first thing I tried was powering it for awhile and seeing how hot it got. The answer is "not very". It has more than enough strength to pull the ports open, and the "3 seconds 80 degrees temperature rise" in the description didn't seem to occur. It definitely got warm, but not that hot (even after 10 seconds). I didn't end up pushing it because at some point I would burn out the solenoid. Even with the added exhaust heat I'm confident that these will last a good long while. Besides, how often am I above 6000 rpm with the pedal flat-out for more than a few seconds? Every time I shift it will drop back down below the threshold anyways.

Worst case scenario, these are pretty cheap. I can always replace it if I burn one out.

You can also see the mounting plate and linkage. That linkage is for testing only, since I was in the middle of fixing my 3D printer at the time. The linkage is required not only because of the fact the sleeve is rotating, but also because the actuator is positioned somewhere in the center of this rotation. So when the actuator starts moving the linkage ends up pivoting from one side to the other. I'm probably not describing that well, but suffice it to say the linkage is required. Here is a mock-up with a drill bit since I didn't have an appropriately sized screw and some M8 nuts used as washers:

I tested it and confirmed that it absolutely had enough power to pull the ports open. The return spring was a bit too weak, so I removed the circlip and stretched it taller before putting it back and that fixed the issue.

Now I mentioned wanting to have infinite control of the position of the ports, so I rigged up a simple system to PWM the solenoids with a microcontroller and see what PWM duty corresponded to what port position. But I noticed something interesting which is that any duty sufficient to move the solenoid would open the ports all the way. I could slow the opening a bit but I couldn't halt it at say 50% open. I realized there was something I hadn't considered with the solenoids, which is that the power required to pull them inwards decreases as the rod enters the coil. This makes perfect sense and I'm not sure why I didn't think of it before. It's possible there is some sort of solution involving a progressive spring for the shaft that increases spring tension as the shaft moves inwards, but for now I'll have to shelve that particular goal.

I also noticed something interesting, which is that the stock actuators don't open the ports all the way. Before the actuator rod hits the inner stop, the actuator itself runs out of travel. You can see how far they open in the second photo of this post. Meanwhile the solenoids have travel to spare, so the actuator rod hits the inner stop and the sleeve opens further:

This is about 2-3mm more open than stock. I could probably get it to open further by filing down the inner stop. That will be a project for another day.

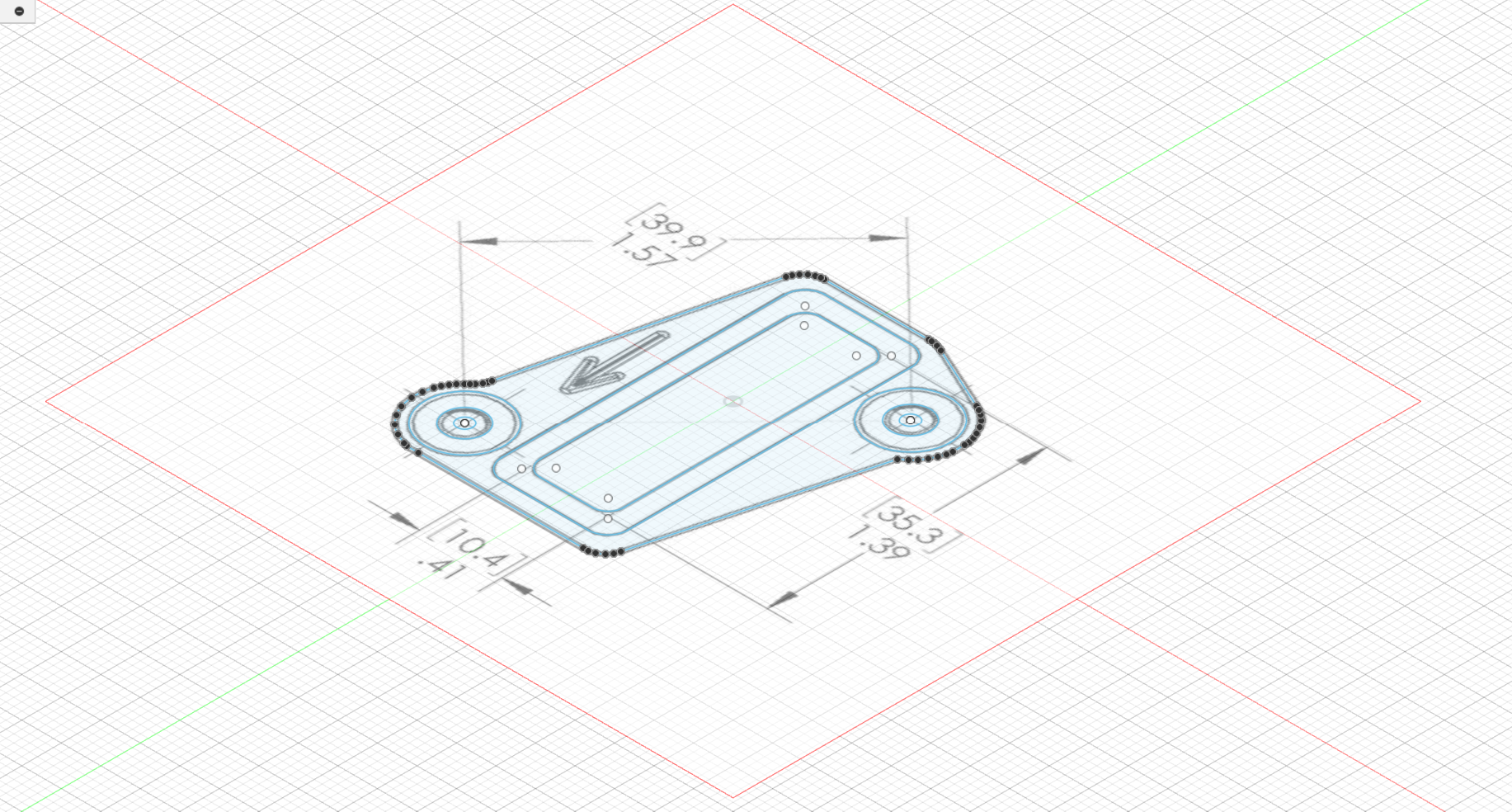

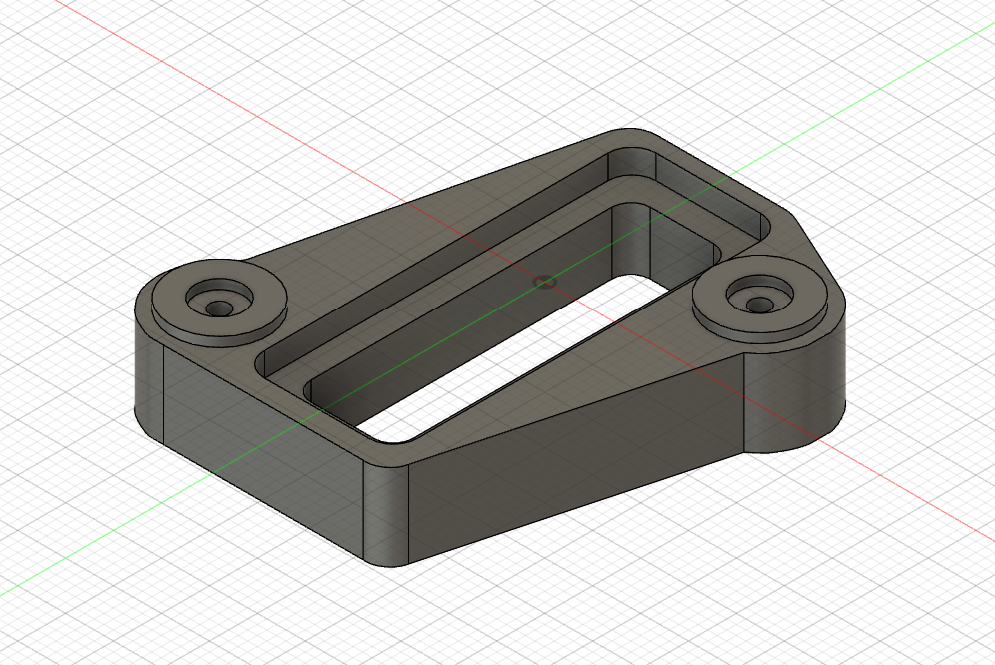

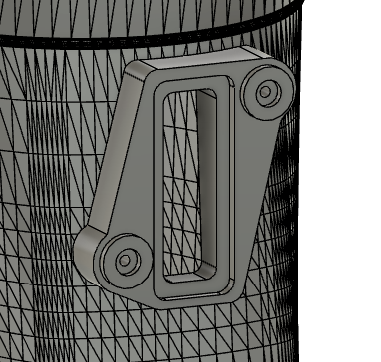

With my 3D printer fixed I made a replacement for the linkage:

In testing I found that flat linkages tended to try and slip off the actuator rod pawl if the solenoid shaft rotated a bit in either direction. So this design fits neatly into the solenoid clevis and has about 10mm of sleeve engagement on the actuator shaft. With some silicone grease everything is nice and smooth.

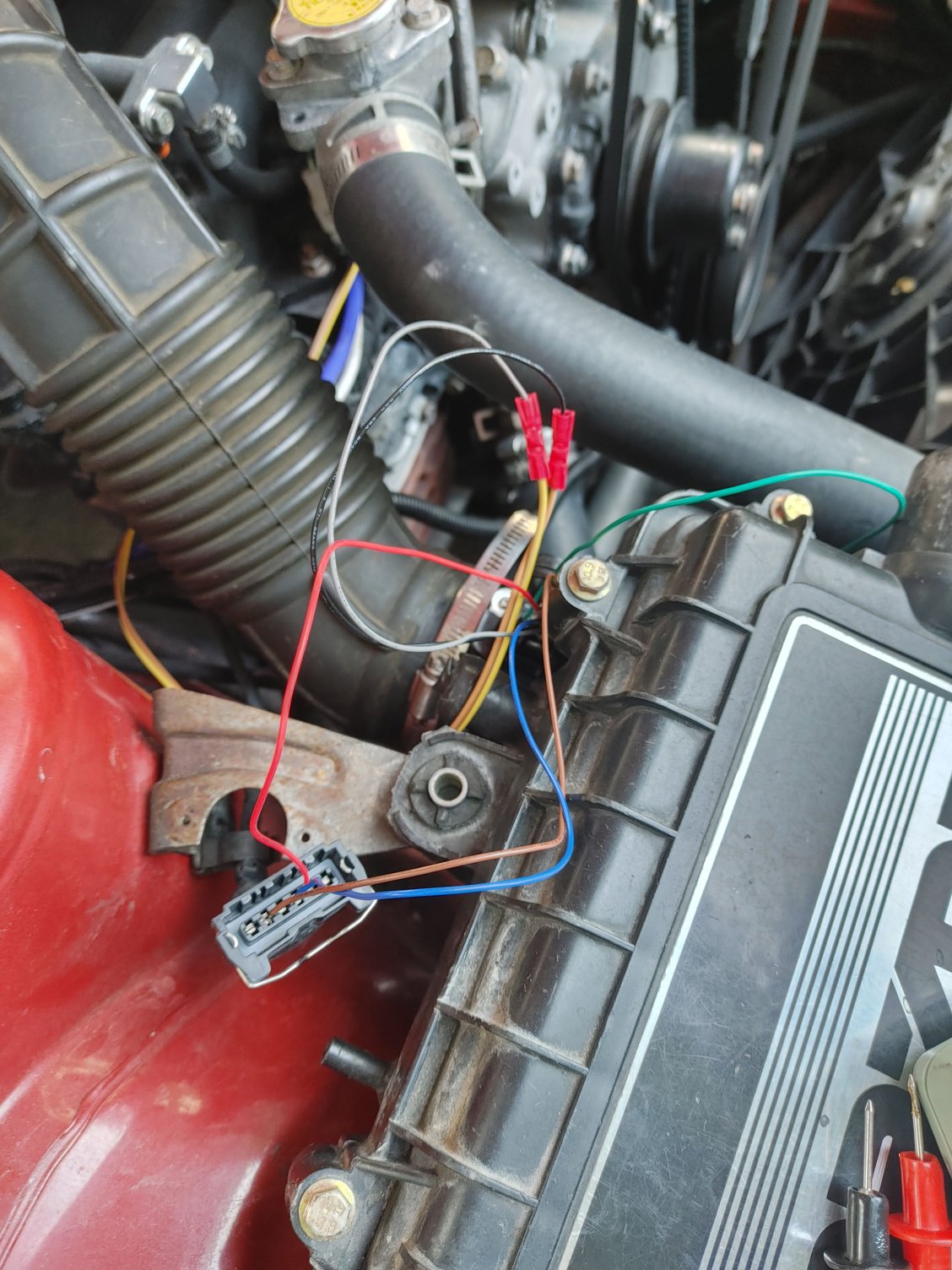

Since PWM won't help me on this project, I elected to run a relay so there is less load on the Megasquirt. It mounts to the passenger shock tower. Here's some night photography of the solenoids installed:

I still need to loom up the wiring, but otherwise it's done.

And the results? Well, it works. I can use the Megasquirt to open and close the ports when I want, and there is a way to reference it to MAF so it will do what I need. They also open slowly enough that I think if I start opening them at 100 g/sec of airflow they will take enough time to open that it smooths the transition and (mostly) achieves the effect I was looking for regarding infinite control. It's not as good as real infinite control, but it's what I have for now.

Idle and off-idle is also noticeably better with these ports open. Once the weather warms up enough for me to actually drive the car, I'll report back with the results vis-a-vis power and in the summer I'll have to test them on a hot day to see what reliability is like. Fingers-crossed that this pans out and I don't need to go back to the drawing board, because at some point it just makes more sense to focus that effort on swapping in the Turbo II engine I've been sitting on for three years.

Until next time