Got some more stuff done in the last couple days. Flushed my brake lines and then bled them with some crappy fluid for the moment. Need to adjust the rear calipers, as i'm now wondering if this is part of the reason the pedal has never felt good on this car. It feels pretty decent now just to start, but i think they could be better.

However, in getting ready to adjust the rear calipers, i was hooking up the parking brake cables, and they're totally hosed. Sigh. Another $50 down the drain for new ones.

Clutch pedal feels good. Nice positive engagement from the 100% self-contained system now, no rubber lines. The South Bend TZ clutch is going to be more streetable than i thought it would, so that's good.

So, as we can see.... i finally have all three pedals!!!

Had a few more setbacks yesterday, unfortunately. Was under the car taking measurements to make a new flywheel dust shield (Lost mine), and noticed that the 4 point tie brace was hitting the Y-pipe. Not much i can do about it. I could shim the back part of the brace down far enough that it would clear, but only by about 1/8", and i don't like the amount of shims necessary for that. Turns out this brace was actually the prototype and the design had since been changed because it didn't clear the exhaust on 1.9 cars, either. Cleared my 1.8 just fine, but not the 2.5. Le sigh.

I'm going to run it anyways for now and swap out for a new one in Spring.

Then i figured that while i was down there, i'd take care of the binding issue that was going on with the passenger suspension. What a nightmare. Not that this was HARD work, just a brain teaser and really repetitive.

The front tubular arms that i have, have rodends in the portion that go into the subframe for adjustment. This adjustment is to correct the geometry/binding issues that happen with this suspension when it's lowered too far. Basically bringing the rodend farther OUT, brings the back "post" of the arm farther "inboard," and vice versa. The only goal here is to adjust the rodend to the point that the "post" on the back of the arm passes through the rear bushing at a perfect 90 degree angle to prevent any sort of binding and reduce/eliminate all stiction.

Easy peasy. In theory.

However, this is a BEAT chassis, and looking underneath it, i don't know how it has a clear title.  It's got some frame damage, and the floor right in front of the passenger seat has buckled upwards a good 2". I'm going keep my eyes open for another chassis to fall in my lap, but not really actively look.

It's got some frame damage, and the floor right in front of the passenger seat has buckled upwards a good 2". I'm going keep my eyes open for another chassis to fall in my lap, but not really actively look.

I ended up having 5 threads difference between left and right on the rodends, AND had to to shim the passenger arm to directly couple the arm and the bushing about 1/16". Ugh.

The good news: Both sides now move up and down like butter. I've never seen/felt anything like this. The resistance seems to be exactly the same as when i was just pushing on the struts themselves with no springs or anything else attached, outside of the car.

The Bad News: Broke the captive nut on the driver's side of the subframe that holds the through-bolt that attaches the rodend portion of the arm. Just like the passenger side. Sigh.

Pictures!!!

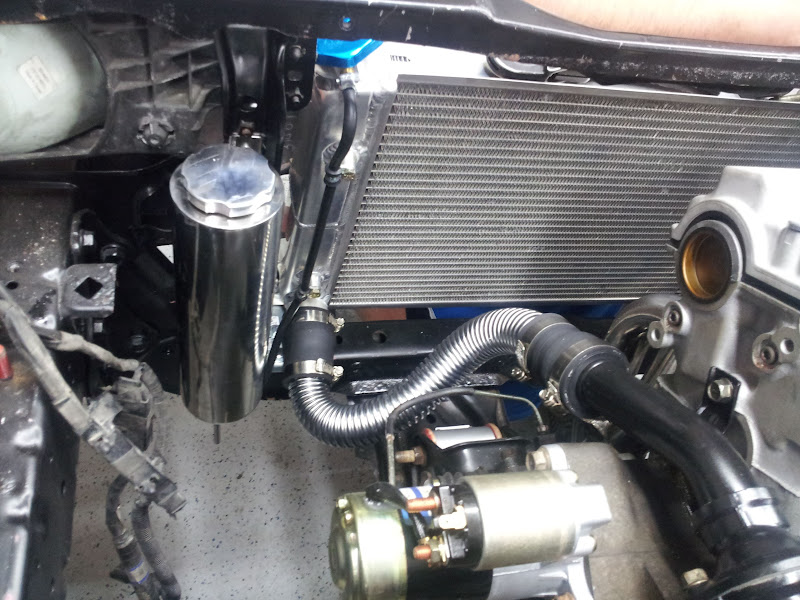

Where the magic happens:

This is uhhh.... full droop. Seriously.

These wheels make my brakes look huge!!!