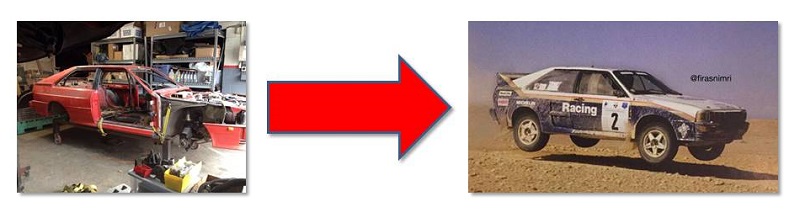

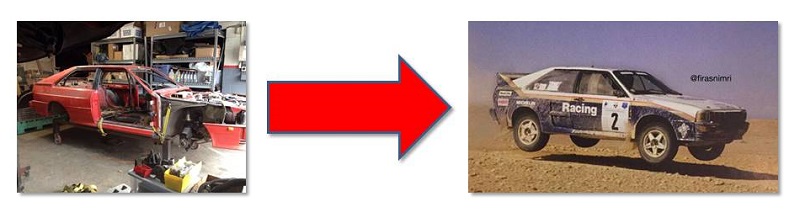

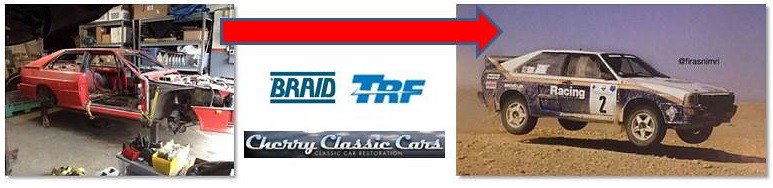

As our 85 UR quattro (http://teamilluminata.com/pages/85-ur-quattro) is getting to the point of being on the road again I'd like to introduce our latest project which we plan to start almost immediately. A 1983 UR qauttro, currently in such a sorry state that it's only viable future is as a RALLY CAR!

The shell is pretty solid and the car "ran when parked". We will be rebuilding the engine and transmission and it does have this hole in the rocker panel.

We picked up the car about a year ago quite locally as it happens. The previous owner had driven it for about five years then decided to put a cage in it and use it as a more dedicated track toy. He stripped a lot of the interior out, bought some go fast bits, put a rudimentary cage in it and then got distracted for about twelve years. That's when we cam along and "saved" it.

It came to us in the stripped out condition you see but with some interesting bits; some attached, some not.

Koni based custom coil overs:

Rally rear spolier.

Fiberglass front fenders

NOS kit!

Audio

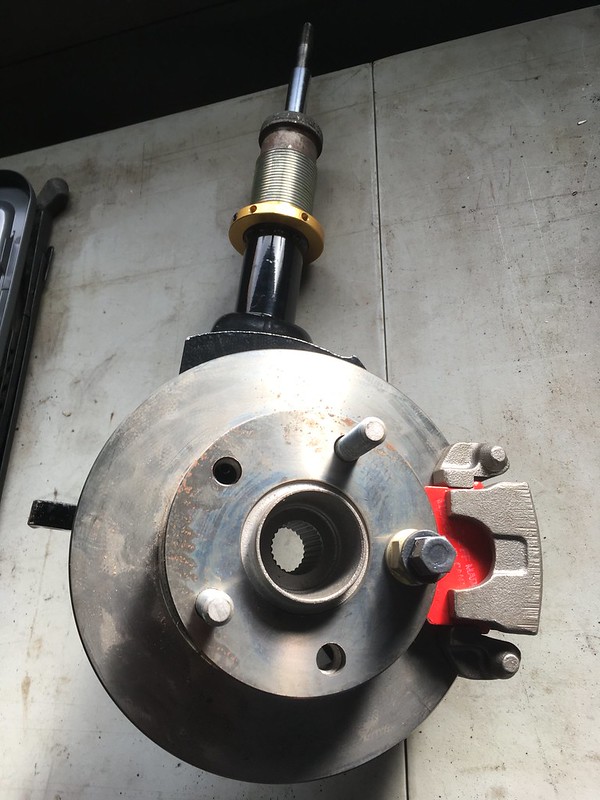

Refurbished brake calipers with new discs

Fiberglass S1 (short wheel base) hood

and all the parts that came off it in a trailer!

So the plan is to strip the shell, fix the rust, install a cage, install a Group B body kit, and rebuild it as a Rothmans tribute to match our Porsche 911 Carrera RX (https://teamilluminata.com/pages/84-911-carrera) and Mercedes RALIVAN (https://teamilluminata.com/pages/ralivan). Stay tuned.

INTRODUCING THE TEAM

We’ve teamed up with a small group of Engineering students from Oakland University to assist with the project and contribute to the education of a few future automotive experts in some small way. These guys are so keen they’ve already given themselves a name. They call themselves the “Qauttro Sqaud”.

So who are the Quattro Squad? Well we have Amanda, Nathan, Matt and Aaron. All students at Oakland University and all way younger than this car! They vary in age from Sophomore to graduate student and most have worked on OU’s Formula SAE car to some degree. They have never worked on restoring a car, building a street based race car or, for the most part worked on modifying any street car, though Nathan did install mud flaps on his Dodge Dart. This is truly going to be a new experience for all of them, as it is for us and we are excited to be able to help broaden their experience as they progress with their engineering careers.

We plan to work on the car as a team one evening a week and maybe some weekends. Last Wednesday was our first such gathering. So what did we accomplish? Well job one is to strip the shell so it can go off to our fabricators: Thompson Racing Fabrication (www.thompsonracingfabrication.com), for a proper shell and then paint. All the team were very eager to jump in and not shy to put wrench to car. Fortunately one of them seem too overly aggressive so much of what comes off should survive the process and as we discussed, most parts should get bagged, labeled, organized and photographed as we disassemble everything in a logical and methodical way. These are engineers and future engineers after all. I myself being a recovering engineer ;)

We assigned people to different areas of the car but they spontaneously teamed up when needed. Nathan and Aaron attacked the interior but that soon turned into stripping the trunk as they had to to get the rear belts out. Typical Audi.

Amanda took over trunk duty as she was also working on interior wiring and much of that terminates in the trunk.

Matt removed what he could from the front suspension then went after the front body work: bumper and spoiler mostly.

It seemed as if everybody was involved in removing the dash.

Next time we will continue stripping the shell before we figure out how to get it off the rolling platform so we can drop the rear sub-frame then front sub-frame/engine/transmission. Should really test the engineer’s skills that one.

Second evening for the "Qauttro Squaud". We were a little light on numbers last night due to unforeseen testing of the Formula SAE car. Still, we made some progress.

We stripped the trunk lid of its lights, spoiler, trimmings and wires.

We also got the rear lights out but forgot to photograph that.

Matt continued with the interior and managed to relieve the car of the dash panel and the blower housing though that is hardwired into the harness as far as we can make out. Good one Audi. Sorry, we had to cut the dash as the current cage goes through it. It was already cut up and cracked anyway.

Next week we hope to remove the headlining, pedal box, fuel tank and the rest of the interior wiring harness. And we think we have a plan to get it off the table and onto the lift so we can remove the engine, transmission and sub-frames. Stay tuned.

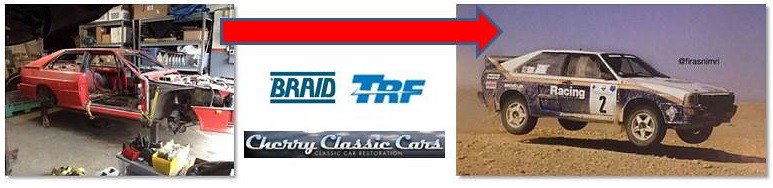

So this is an unusual experience for us, being a parts supplier we are often asked for donations to people's projects. Now we are now the recipient of donations ourselves! So we'd like to introduce a couple of project sponsors:

Firstly, Thompson Racing Fabrication (www.thompsonracingfabrication.com/) will be doing our cage and other fabrication. We have helped them with a couple of their project cars in the past and almost always use them for any fabrication needs we have such as the custom radiator and exhaust for our Subaru Rally Wagon and the custom harness bar and skid plates they made for our Porsche 911 RX.

Then we have BRAID wheels USA (www.braidusa.com) who are going to provide a set of wheels for the car once we settle on a design. We are currently contemplating their Serie 6 three piece design but with hidden spokes as it looks very reminiscent of the Speedlines the factory used to run in tarmac trim. Probably will be 16x9 with 245/45-16 tires.

Lastly (for now) Cherry Classic Cars (http://www.cherryclassiccars.com) will be helping us restore and paint the shell and body panels. These guys do fantastic work and are TRF's primary source for bodywork and paint so we will be in good hands.

Thanks guys. Now we wonder who else can help...............

On Wednesday the Quattro Squad continued to turn the 83 quattro inside out.

Matt relieved it of its sunroof

Then we decapitated the halo cage.

https://youtu.be/14Wx6dqrCdg

https://www.youtube.com/embed/14Wx6dqrCdg

so we could extricate the headliner.

We also removed the trunk lid

and the gas tank

We are producing quite a pile of parts

Not much action to report this week as we took the Quattro Squad on field trip. We managed to get our 85 quattro running again for thew first time in 2.5 years to to celebrate we took three of the students in it to visit a friend's shop and quattro heaven.

Werner owns a 85 from Switzerland and an 83 that he rescued. His 85 is for all intents and purpose a restored example but, because he is a perfectionist, will undergo a full engine rebuild this winter.His 83 is a rescued project that for now is just sitting. We believe the squad were suitably impressed.

Perhaps inspired by their experience the guys removed the rear bumper when they returned to the shop. Though it put up some resistance.

Now the hoist is free perhaps we can take the engine and transmission out.

Not a lot of progress these last two weeks. We didn't meet last week as we were at Lake Superior Performance Rally posing about with a bunch of other old rally cars.

However, progress was made "off" the car while we were away. The Quattro Squad came up with a logo and created a Facebook Page that already has over 140 likes. https://www.facebook.com/QuattroSquad/

We did accomplish some stuff Wednesday night though, mostly in the engine bay in preparation for removing the engine and transmission.

We managed to pull the radiator

The distributor and hydraulic "bomb".

Nathan and Josh struggled almost all night to remove the fuel distributor.

But when they got it free they were very happy; disturbingly so.

We are a little concerned about how they will react once we drop the actual engine. Stay tuned for that one and like the Quatro Squad on facebook

If I died and could redo the free-time part of my life, I'd be part of this crew!

Two weeks of progress to report! We didn't get much accomplished last week as we had a very special visitor in the form of Paul Ritchie, former head of Porsche Motorsport and Porsche Engineering. Needless to say there was much conversation and much left over pizza as everyone was too bust talking to chew.

We did discover that 12 year old gasoline will dissolve a plastic cup!

This week we continued to remove as much weight from the front of the car

and stuff as much weight in the back of the car

in anticipation of moving the car from the table where it has sat for the last twelve years to the host. I tricky endeavor as the hoist has a center post so we couldn't just wheel it over the hoist and lift it up. We settled on jacking the front just off the table and sitting the sub-frames on jack stands then moving the jacks to the rear to jack that end off the table.

Once it was elevated we carefully rolled the table out from under the car and smartly brought the hoist pads into contact with the jacking points and BOOM! The car was on the hoist!

Our goal now is to remove everything from the underside of the car starting with the front sub-frame, engine and transmission as it is rather nose heavy at the moment. This is the first time we have really been able to get a good look at the underside of the car. The body looks to be remarkably rust free except for two spots but the fuel supply components have not fared so well. All to be replaced anyway so no concern. Just hope all the fasteners cooperate.

We don't think we should put it back on here. It's just too long and gets in the way of the suspension.

Excited by the leap forward Matt decided he wanted to get a lift too. I think we'll call him Jack.

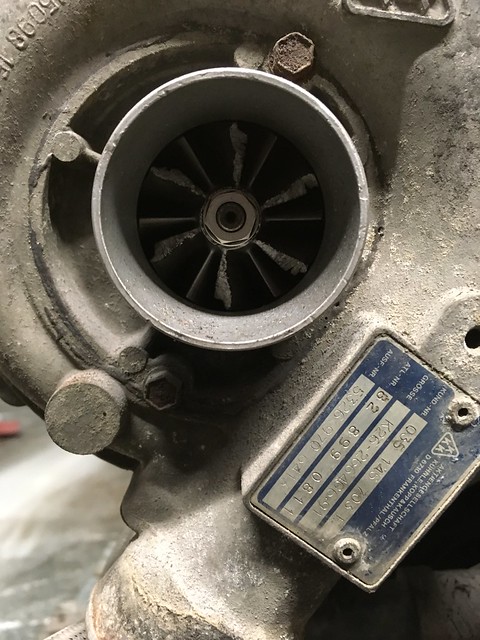

Yesterday the Quattro Squad accidentally took the engine and transmission out! Well, it wasn't a proper accident; just that it wasn't part of the evening's plan. Being a little light on peeps and wanting to have an early night we only planned to prep for engine removal. Instead it just sorta happened as we were on a roll and we still got out of there by 8:455pm. Not a bad night's work.

Being a Quattro it comes out of the bottom with the sub-frame and transmission. Being a Quattro it doesn't just drop straight down but instead has to be quided past several obstacles on the way down. This is not a Porsche 911.

Nice job gentlemen.

Toothless grin

The right side engine mount fell apart; as they do.

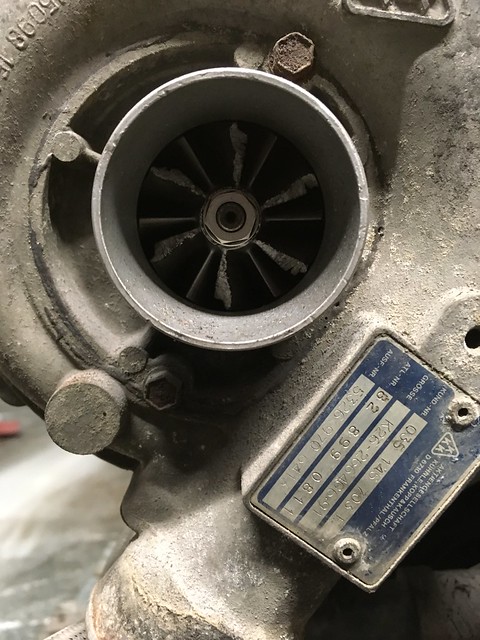

And this doesn't look exactly pristine.

Next week: the rear sub-frame and diff. Look out below!!!

This past Wednesday we reached a big milestone with this project: we finished stripping the shell! The biggest chunk that came off was the rear sub-frame and diff then the steering rack and drive shaft. We also introduced video to our arsenal so you have been warned.

https://www.youtube.com/embed/FYtrTu_pz1o

We also visited a local rally prepped quattro that's up for sale to get some ideas and, in the process acquired a windshield for our car.

We also took delivery of our tires. Bridgestone Potenza RE11 in 245/45-16. A little ahead of ourselves here but they are hard to find and we already had two. We now need to finish the car before they age out.

Next task is to get it off the hoist and back onto the table then onto the trailer so we can haul it up to our cage builder Thompson Racing Fabrication . That won't happen till the first full week in December as we are off to Barcelona to see how BRAID wheels are made and then to Stuttgart to visit the Porsche museum.

Almost a month since the last update. Boy does time fly when your'e having fun. In this case the fun was a visit to the BRAID factory in Barcelona including a few laps around the F1 track there in BRAID's Ligier LMP3 car.

Album here if you're interested.

We also went to Germany and visited the Porsche museum in Stuttgart. https://flic.kr/s/aHskQ2wchj

So you see, we have a couple of good excuses. We have been busy on the quattro though. In fact we managed to get it onto the trailer and drag it up to Thompson Racing Fabrication to get caged, restored and painted! It took a bit of engineering to get it off the lift but we managed alright. One more pair of hands and we could have just lifted it but this method worked quite well too.

https://www.youtube.com/embed/wk1IgaIdSeA

Looks good on the trailer

It's going to be in good company up here.

New temporary home

So maybe it will be caged early January then Cherry Classic Cars can work their magic fixing the rust and prepping it for paint. There are many other fabrication tasks to take care of, some of which require body panels etc. but we are not ready for those yet so the shell may be up north for some time. Still, there's plenty to do back at the shop, like sorting out all the parts we took off and deciding what to keep and what to sell. Stay tuned.

Thompson Racing Fabrication have begun work on or quattro shell. They began by removing and patching the old cage then removing all the sound deadening and various bits and bobs that we (hope) we don't need.

US telescoping bumper mounts; GONE

Seat mounts; GONE

Rear parcel shelf and firewall; GONE

Main cage hoop is now in and it's nice and tight to the roof!

They also received the dash kit from Bufkin Engineering

Which they couldn't resist playing with.

Happy Holidays!!!

de80q

Reader

12/28/16 7:03 p.m.

I'm sure you have ready seen this, but now that it's done, figured it might give you and your crew some motivation. Rally resto

While Ryan at Thompson Racing Fabrication was busy putting the finishing touches to our cage we were engaged in the less glamorous, but never the less critical task of sorting through all the parts we took off the car. i.e. everything. It doesn't make riveting viewing but here is what we faced:

and here's what's left to deal with:

and here's where it all went:

By the way there is an identical shelf behind the camera and a complete interior in the parts trailer. (more on that later)

Our filing philosophy was to retrieve everything we need or might need for the build and then decide what to do with the rest. This all went into one of two piles: if it might serve as a spare part for our 85 quattro it went in the KEEP pile. If not it went in the SELL pile. There is a lot in the KEEP pile; probably way too much but how do you know what you won't need one day? More importantly, how do you know what you have? Well, being super-nerds we created a spreadsheet with all the KEEP and SELL parts listed along with their part numbers and a photograph. I think we are still going to have too much stuff!

Meanwhile, at TRF, Automotive Journalist Tara Turbo-Hurlin was busy documenting Ryan's handy work for a soon to be published article. Check out her photos:

Stay tuned for more spreadsheet action!

Progress both up and down the state of Michigan this week.

We and the Quattro Squad "filed" the last of the pile of parts "we" took off the car.

Then proceeded to fill the floor with all the parts the previous owner took off the car that have been resting in the parts trailer for 13 years. Some good stuff in here: two sets of wheel, full interior, all the glass. Some of this we need, some will make good spares for our 85 and some we can get rid of.

Meanwhile, up north at Thompson Racing Fabrication they wer keeping warm by welding on our cage and installing the new aluminium (it's German) rear bulkhead.

You can see all their handy work here:

Now the shell rests while we order body panels but work will soon commence on refurbishing all the other parts necessary to reassamble the car as a Grop B monster. Subscribed and stay tuned.

With the cage complete the shell is now in storage up north awaiting the wide body kit so we thought "what should we do next?" We'll, we ordered a carbon/kevlar wide body kit of course: Should arrive from Europe in 6-8 weeks.

Of course we do have lots of parts to refurbish so we started to look at those and figure out how to go about things. First we pulled out our collection of Hella 2000 lights.

we have about 10 lights in various conditions, beams finishes and levels of completeness and we need 6 pristine black ones, preferabley two spots, two driving and two fogs. Then we'll need some brackets to mount them. Like these ideally:

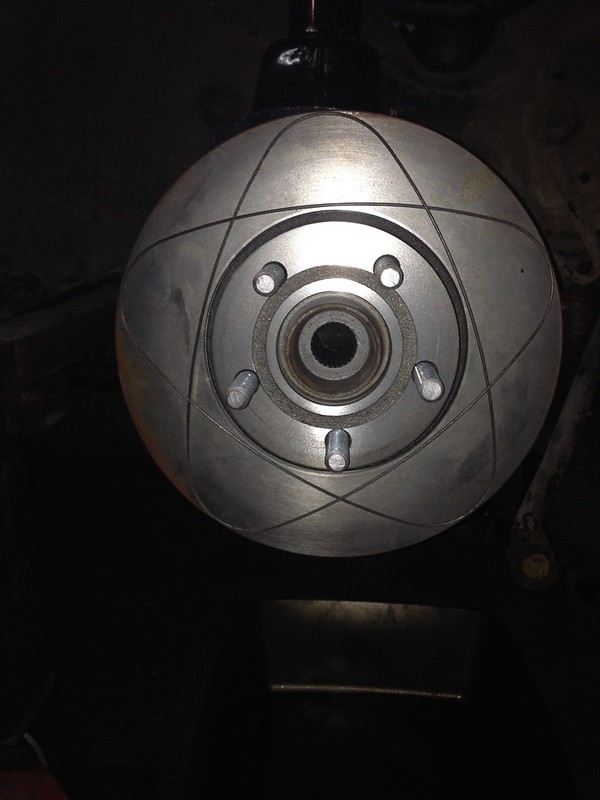

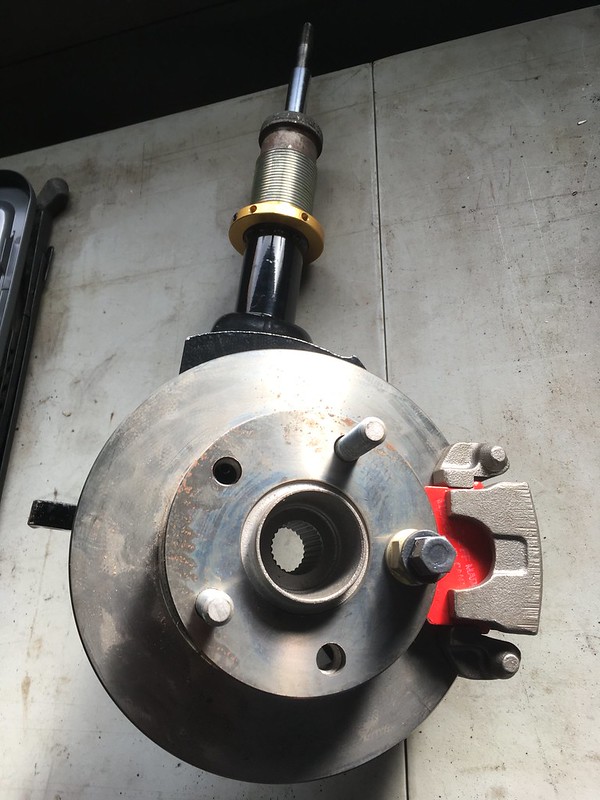

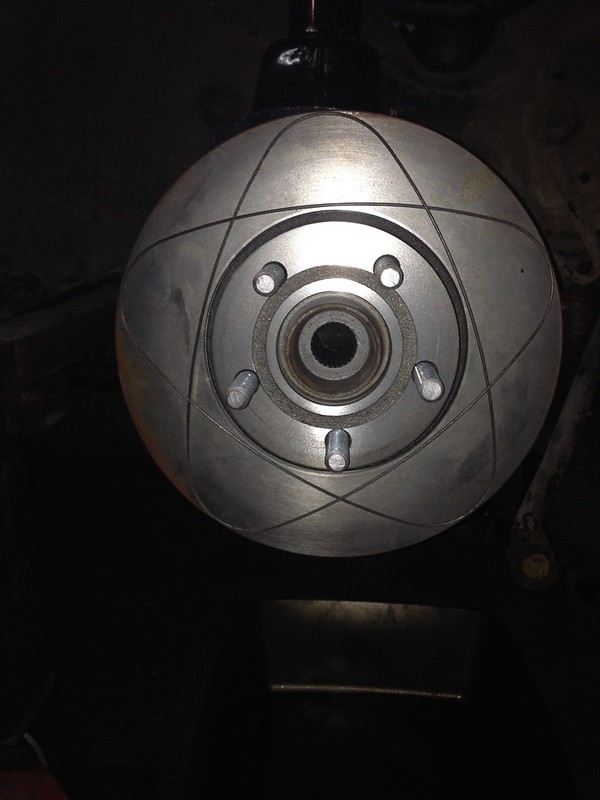

We also pulled out the brake parts we got with the project: Refurbished G60 twin piston calipers. ATE brake discs and refurbished stock rear calipers. We also got new rear rubber lines and front stainless lines. We still need to source front caliper brackets and probably some better pads. There's also a theory that our brake discs might be a little big for the G60 calipers. Once we figure it all out we'll send them off for plating or powder coating.

Still trying to inventory all the left over parts for USE, SELL or SAPRES:

Stay tuned

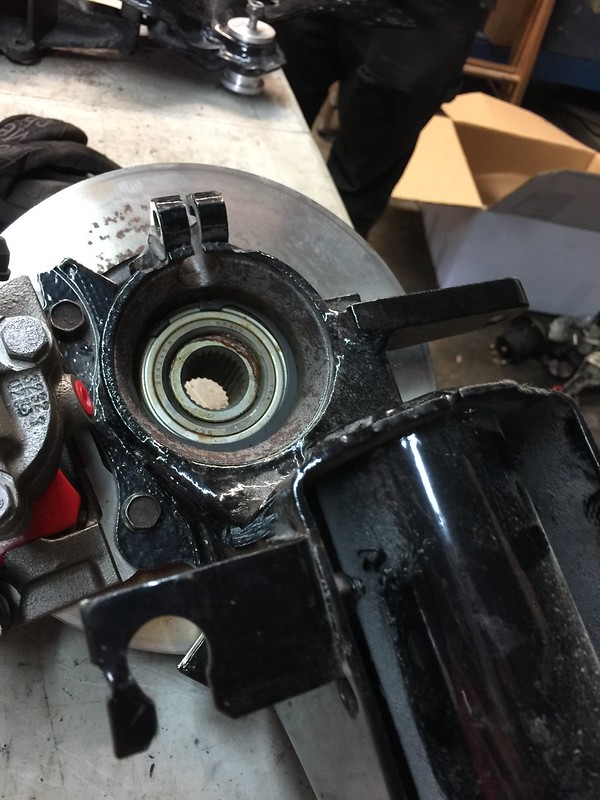

This week at Quattro Squad we started to get our head around the refurbishment projects and allocated some to a couple of the students. Matt took on the struts and brake calipers. The struts are almost complete as the previous owner installed new bearings and Koni dampers, had them powder coated and sourced a coilover kit. More on that later. He also provided varoius remanufactured brake calipers as noted earlier. We are missing caliper calipers for the front twin piston calipers so our friend Werner lent us a set he has in his parts stash to test fit. Now we know what we need and that our pads and dicss will all work together.

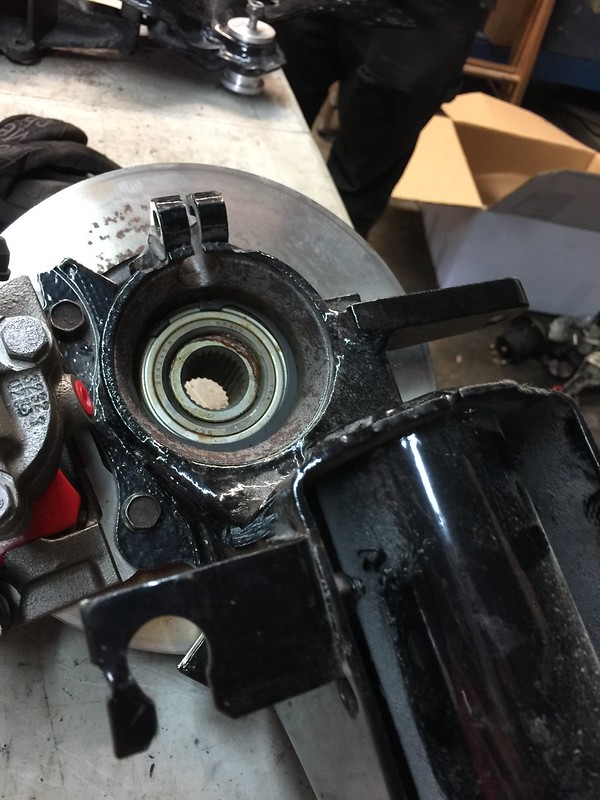

Unfortunately it seems our remanufactured rear calipers are not correct as the handbrake cable and brake line connection will both interfere with the axle. We think they are off a 4000 or similar but fortunately remanufacturd Quattro calipers seem to be still available.

Josh started pulling the various OE parts we need to retain some sort of ventilation and heating system in the car. Apparantyl we need the patr of the dash pad adjacent to the windscreen and the heater box to do this. We spent a good 2 hours of time trying to figure out what part was missing that would connect the defrost air outlet in the heater to the defrost air inlet in the bottom of the dash pad.

We couldn't find anything in any parts diagrams nor a stray bit of plastic in our parts bins that seemd to do the job. We were stumped until we stumbled upon this picture from earlier in the build:

in it you can clearly see that the dash pad mates to the hole in the body work and the heater box mounts below. We couldn't find a missing piece because we weren't missing a piece. DOH!

and then today our seats arrived form Corbeau USA. in regular and wide sizes.

Recent Quattro Squad gatherings have looked more like meetings of the Mono Squad what with exams and scheduling conflicts. Still, we have made some progress.

We got the bushings pressed out of the front subframe. We had to burn them first as the bolts were seized in place. Fortunately the front subframe was prepped and powder coated by the previous owner and already has solid bushings.

Our aircraft grade top mount bearings arrived too and with the help of the Epicenter Design adapter pieces we managed to assemble a strut.

and we received a picture of our completed grill from Cool Wheels this week so that's quite exciting.

Next time we update we hope to have four fully assembled struts complete with brakes and maybe a resealed diff!

The 83 quattro squad rally build keeps inching forward. A few days ago we received these beautiful G60 brake caliper brackets from a very generous chap on the Motorgeek forum. Thanks Dave, they will be put to good use.

We offered them up to our struts and calipers and they fit perfectly.

Only question now is how to finish these and the calipers for best effect. Options are:

- Red powder coat

- Black powder coat

- Yellow dichromate like OE (gold)

Feel free to weigh in.

Here's an interesting aspect to the project. We found this 1:18 die-cast model on eBay. Quite cheap; probably because it is quite plain.

We thought it would be a good idea to refinish it in the same livery we are planning to finish the car in. That is, our version of Rothmans with BRAID and TIM logos.

So first we had to strip it:

We are not sure how to proceed from here however. Damn, another bloody Quattro project! Stay tuned.

I think the yellow dichromate would look best when new but the powder coat would hold up longer.

With the caliper brackets fitting well we took the opportunity to muck up a front strut before sending the calipers off to be refinished. We are still not sure what color to refinish them. Options include black or red powder coating or gold zinc dichromate like they were from the factory.

We started in on the model's livery. Tried some blue vinyl but we are not sure it is really suited to cars this small as it won't mold into the crevices well.

We did one side with the factory droop to the front bumper, which we have never liked, and the other with a full straight line to the back of the headlight. Which do you prefer?

We then added some BRAID decals

Our BRAID wheels came in from Europe. We love 'em.

They are three piece with hidden screws and reminiscent of the factory Speedlines. Specs are 16x9, et12. We could resist throwing one on our 85 but, of course, they are way too wide for this car.

As part of our quest to prep as many parts that are going to need refinishing as possible we pressed out the bushings from the lower control arms.

and disassembled some Hella 2000 lights as we have some chrome ones that need to be black.

This is the pile so far. The parts in front still need disassembling.

Quattro Squad

Scattered progress since our last update but progress non-the-less.

We started to attack the drive shaft last week. The CV joints seem a bit stiff so we are going to clean them out and see if we can save them. If not we think we can replace them. The universal joint in the center seems fine but we might have to destroy it removing the center support bearing which is also fine but whose rubber bushing is decidedly squishy.

We also started refurbishing the fuel tanks. Initial inspection revealed only surface rust so we cleaned it out with some dish washer detergent.

We had a visit from the guys who run DIYAUTO.com last week, Nick and Steve Balistreri. DIYAUTO.com’s goal is to collate all the cool information in the various forum build threads on the web so the information is easy to search and the knowledge is not lost to us auto enthusiasts. We are proud they have both our quattro builds and our 911 build on their site.

We continued to dismantle parts that are being sent out for refinishing. This week it was the turn of the suspension components. These did not want to come apart and the students learnt a great deal about persistence and the use of heat wrenches.

We’re not even sure we can get replacement ball joints and bushings for this stuff and may have to fabricate our own.

We optimistically mocked up the rear calipers again to see if we can make them work. Both the handbrake cable and the brake fluid line want to go through the rear axles but as we intend using a hydraulic handbrake we wanted to see if we could make a banjo fitting attach. Think not:

Next update we hope to share some news about the shell. Stay tuned.

Been working on a few things but nothing too exciting. we finally found some proper UR quattro rear brake calipers

You can see how the handbrake cable and brake line come in from the back instead of the side therefor avoiding the axle.

Amanda made some more incremental progress on the model. She says she's going to paint the stripes next.

Then we started on resealing the rear differential.

No wear groove on the input flange :)