Looks like I need to pull at least one of the heads (most likely both) on the Formula FST - I've got a busted spark plug thread on one of the heads and the other one has a spark plug hole that's not far behind. Yeah, race ready car...

Anyway, I'm not that experienced with VW aircooled motors (yet, I suspect) but I'm assuming I can just pull the heads, check the jugs for scoring just in case but leave them in place, get the spark plug threads helicoiled and then slap them back on with new seals on the pushrod tubes?

I hope that's all that's required to get the motor race ready again - well, that and new seals at the bottom of the oil cooler/oil filter pedestal - but I'm not holding my breath given my usual skill at buying cars.

That is about it. Don't over torque. I forget the spec. and I lost my handy pocket spec book.

Weren't there cheap good heads for the aircooled bot long ago? Its been a while, but im thinking dual port or something along those lines.

For the fst: are you allowed to hot rod it?

Just be careful you don't crunch a pushrods tube when tightening the heads. If I remember right, they liked to fall out when the engine was still in the car. We used to put the push rods in to hold them but it helped to have an extra set of hands to keep from fall out. It's been 25 years but I think they used to make clips that would hold them in place. Still sucked when you were in a rush and you would crunch an end.

Dusterbd13 wrote:

Weren't there cheap good heads for the aircooled bot long ago? Its been a while, but im thinking dual port or something along those lines.

For the fst: are you allowed to hot rod it?

The 1600 in this car is already a dual port. Not much hot rodding allowed, the rules are very restrictive compared to FV (one of the reasons I picked FST, because engine builds are much saner than FV ones). The cars are running restrictor plates anyway, so most of the ability to improve breathing is pretty limited.

Basically, the rules only allow port matching on the cylinder head, no ported heads and similar fun stuff.

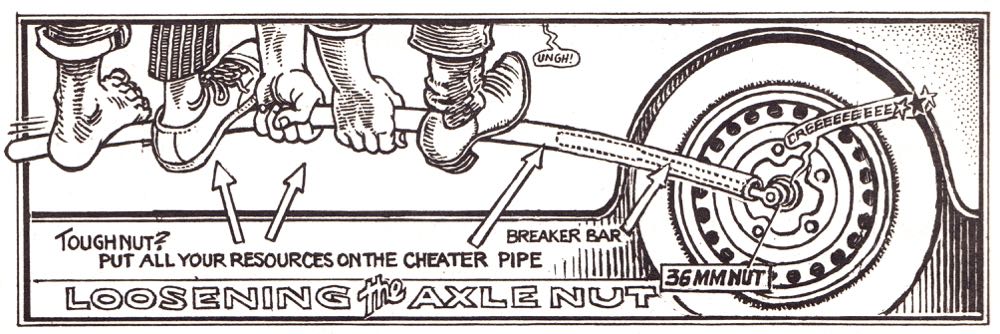

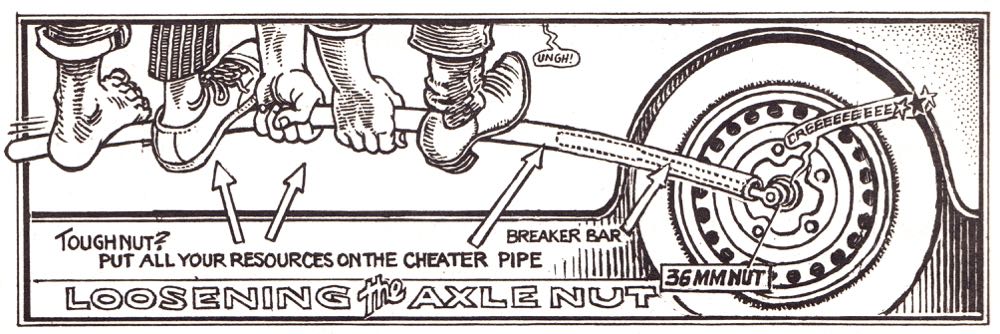

likely the best manual ever printed:

I was looking at getting this manual:

Is the John Muir one preferable? Of course I could get both and report back...

Why not just repair it without pulling the head?

Two reason actually - one, I suspect that some of the shavings from the spark plug thread may have ended up in the cylinder. Second, I found way too many inconsistently tightened or plain lose nuts and bolts on this car, including around the motor. So I want to make sure that at least some vital parts like the cylinder heads are torqued down properly.

BoxheadTim wrote:

Is the John Muir one preferable? Of course I could get both and report back...

I suppose I just have a soft spot for the John Muir manual. Great illustrations and explanations, Real world, light hearted instructions, and a fun, hippyish, almost R.Crumb vibe. I learned mechanics with this book, and ACVW's. I will never sell it, even though I doubt I'll ever own another air cooled car. I kind of doubt you need it, but it is a joy to read, even purely for entertainment.

Ordered both in the end. Let's hope at least one of them has the torque specs  .

.

They both do, but the Muir book is better than "how stuff works" for explaining things in an easy to read format. I've loaned or gifted one of my copies of that book several times to people who wanted to get into cars but had no background, and only one of them ever had an ACVW. I know for a fact two friends in the past were loaned that book, eventually turned onto cars, and then they purchased their own copies even though they didn't have VWs; it's that good.

Making sue the pushrod tubes are installed correctly is probably the trickiest part of installing the head. Patience is needed. Be sure to use new seals. we used to install spark plug inserts in the car without removing the head. Small chips would be soft material so no problems. At the time, Champion spark plugs were prone to seize.

Interesting dilemma. I have some basic air-cooled VW experience, but that was a long time ago, in a galaxy far , far away. While I have heard of ACVWs stripping spark plug threads, the only time I personally ran into a problem is when someone installed long reach plugs into an air-cooled Beetle. Carbon had built up on the threads and I broke one plug off trying to remove them. I had replaced both heads on that engine, with the engine removed from the car. 35 years later I wonder why the pistons did not hit the plugs... Sorry there is really nothing here to help you. Just stretch the pushrod tubes to the pre-install length and be careful on the install.

This looks more like Ook The Shop Gorilla made a plug fit if it wanted or not. I've never seen a plug that had the front half of the thread stripped...

IIRC the plug on #3 cylinder commonly strips out the threads in the head. I had at least one helicoil on my '71, and I'm pretty sure it was #3. Something about airflow and that area running hot.

1988RedT2 wrote:

IIRC the plug on #3 cylinder commonly strips out the threads in the head. I had at least one helicoil on my '71, and I'm pretty sure it was #3. Something about airflow and that area running hot.

The really early ones actually had the #3 plug nipple on the distributor cap shifted to retard timing on that cylinder because the air for it was heated by the oil cooler.

I have a friend who shall now be known as Ook The Shop Gorilla.

In reply to 1988RedT2:

The one with the busted thread is #2, and #4 is also very stiff when trying to both insert and undo the plug. Not quite sure why it's both rear cylinders...

The oil cooler is mounted differently on this engine (vertical with an adapter block) so it doesn't obstruct airflow to any of the cylinders.

One other little trick I learned on the push rod tubes. Expand the accordion on both ends by a swipe of the hand. Not much, helps press the seals.

Heads are off, after studying both books and deciding that it appears to be a pretty easy job. Heads look mostly OK, no cracks and the main work that needs to be done is helicoil the spark plug threads that haven't been helicoiled already. I don't think that motor has been together for that long (it was of "unknown provenance" as the PO had to find a used race motor after blowing up the first motor) as everything came apart really easy - the heads came of with a timid tuck (which of course also loosened the barrels. I don't think they've been glued in with silicone like you find so often...

Anyway, today's achievement:

I haven't turned the motor over with the heads removed to check the condition of all bores, but unfortunately I found this in cylinder 3:

Annoyingly, I can feel the big scratch at about 8 o'clock with my finger. So the question is - do I slap the heads back on as is and run the last couple of events of the season under the assumption that it'll use a bit of oil, then pull the engine and go through it, or do I at least pull the barrels and find out what caused the scratch? It's not like standard pistons and barrels are expensive, but I suspect that if I go this far I might as well go all the way down to the crank and build it up again. That might be a bad idea given that I've got to have the car ready for the last race of the season by mid-October.

With the way they are balanced, as long as you don't have an ac compressor belt pulling the crankshaft to one side the bottom end can go a long time without issue. I'd pull at least the one jug and check the ring gap.

No belts at all, not even a generator/alternator  .

.

I think you're right, I should at least pull the jug with the damage and see if I can find out what caused it.

Pulled off the barrel with the scratch to inspect the piston and it looks like the piston has no damage, nor do the rings show any damage. Pretty weird, unless someone changed out the piston and decided that the barrel was "good enough". The are some weird corrosion marks (like white powder type aluminium corroson) on the piston though, but non seem big enough to warrant this sort of damage.

Anyway, I better go back to reading the rules to find out what the restrictions on the replacement barrels and pistons are - I have to buy a set anyway so I'm beginning to debate just changing out all of them and then quickly buttoning up the motor before while-we're-in-there-itis sets in.

BoxheadTim wrote:

Pulled off the barrel with the scratch to inspect the piston and it looks like the piston has no damage, nor do the rings show any damage. Pretty weird, unless someone changed out the piston and decided that the barrel was "good enough". The are some weird corrosion marks (like white powder type aluminium corroson) on the piston though, but non seem big enough to warrant this sort of damage.

Anyway, I better go back to reading the rules to find out what the restrictions on the replacement barrels and pistons are - I have to buy a set anyway so I'm beginning to debate just changing out all of them and then quickly buttoning up the motor before while-we're-in-there-itis sets in.

Could the white powder "corrosion" be from race gas? I have used leaded race fuel and left a white powdery residue in the combustion chamber with c16.