I am working on some custom control arms for the front of a ~2200 pound street/track car and am up against a tough set of space constraints, but want to make sure the parts I use are strong enough. The geometry is non-stock, and so are the big brakes. Moving the rotor/caliper outboard hits the inside of the wheel, and moving them inboard hits the LCA. Going to a smaller diameter rotor requires going from a hat/rotor arrangement to a one-piece, which I don't want. I am chasing a minimal bump steer, minimal scrub radius setup, so I am hoping to find space without changing geometry. The current setup is a press-in balljoint and the stamped arm around the outer edge of the balljoint is the part that interferes with the brake rotor. I was doing some Google images searches for ball joints to get some ideas and spotted the Miata bits that may be promising. I have never owned one of these cars, but am hopeful the bolt-in design may be the answer for me. In case someone brings it up, yes, I did a lot of searching on locostusa.com and found tons of info on upper front ball joints.

Dimensions I need:

-Diameter of the top/bottom of the taper.

-Height of the taper

-Ballpark O.D. of the bottom round portion of the ball joint...I realize that this isn't a precision machined part.

-Width of the "tube" the crosswise balljoint->control arm bolt passes through.

If it easy for someone to measure that would be great. If not, I can find one at a local parts store to buy, measure, and return....and then order from a GRM advertiser like Flyin' Miata if it works.

New wheels would be nice, but A) I'm heavily invested in several sets of rare 15" wheels, and B) I'm not aware of much out there available in lightweight, 4x114.3, around 4.25" back spacing in a 7" width, 4.75" or so in an 8".

Front hub redrilling isn't a problem, but rear axles are scarce and have two huge holes between two of the four studs. I'm not thrilled about wheel spacers either.

I considered 16" wheels, but wheel selection isn't any better than 15", and tire selection is a joke. 17" are going to really heavy compared to light 15s, and trying to keep tire height in the 23" ballpark means 35 series or maybe 40 series with some rubbing.

I know, picky, picky....

I'm just trying to think outside the box and keep a car I've had and loved for 15 years alive and relevant. I used to encounter occasional brake fade with stock brakes, not a problem in most circumstances, but could happen towards the end of a 20 or 30 min session at a fast track. My new rebuild will have somewhere around 50% more power, so returning to stock (with slotted rotors, braided lines, good pads) is a last resort.

Think I have one in the basement, I can get you some measurements tonight if you don't find them before then.

ae86andkp61 wrote:

-Diameter of the top/bottom of the taper.

16mm/18mm

-Height of the taper

22mm

-Ballpark O.D. of the bottom round portion of the ball joint...I realize that this isn't a precision machined part.

48mm on the one I have

-Width of the "tube" the crosswise balljoint->control arm bolt passes through.

59.5mm

I had a new one in my toolbox

Awesome...thanks, guys! I will post an update once I do some mockup/more measuring.

If you haven't seen it, there's also an extended version if stock geometry isn't to your liking

I'm pretty sure the Locost guys have the dimensions you're looking for. I don't have them handy.

Thanks again for all the help! I ordered the extended ones and they look really promising. I loaned out my welder, but once it returns next weekend I can tackle the minor fab work on the control arms, really the last thing keeping me from getting this AE86 rolling!

Maybe too late but look into Volkswagen A4 chassis ball joints ('98?-??). They are taper fit and three bolts to the control arm.

Pontiac Lemans/Daewoo Lanos/Opel Kadett ball joints are also taper, but 2 bolt fit like Mazda FC/Protege.

Finally getting around to finishing this project. I decided to fab an outboard section of control arm to accept the Miata balljoint, and then weld this section onto the outside of a cut-down stock control arm.

It still needs hardware for the bolt in the other axis, but things are moving along!

Rough cut and initial fit. Hard to see, but at this point the side of the rectangular tube is still pretty far off from the not-totally-straight shape of the side of the stock LCA. In this mockup, the LCA is not well aligned and shifted too close to the camera. Getting the two closer took more effort than the rest of the fitment work.

A little trim here, a little light bending on both sides, and the fit us better. I beveled the edges of the butt section on the bias to improve weld penetration. My thought on the overlapping top part was more area to stitch weld, increasing the margin for error and strength.

The stock stamped channel arms can be difficult not to bend while pressing bushings, so I found some tube ends that were reasonably thick wall (0.083) and a nearly perfect I.D. I trimmed to the right width, drilled a drain hole (AKA future spider habitat) and split them to help with install. I flexed the channel sides out slightly and flexed the tube open slightly to slip it over the press-in-lip, and then rotated it around. I will clamp both parts inward for a snug fit while welding.

View of the underside. The fish mouth gives access to install the sway bar end link (big hole) and maximizes weldable area, and if my hazy engineering concepts are in the right ballpark, should help minimize stress risers. Just barely visible beyond the end link mount is one of two tension rod mounts (small hole) which I prepped to receive captive nuts which I will weld on before welding the control arm halves together. There is probably room to fish a nut in there, but why not minimize the headaches?

Almost ready to weld. Another detail still to work out is the third bolt for the ball joint...I want get the tension rod and sway bar end link hardware mocked up before getting into the fabrication, but I have some ideas.

Never thought I would say this about a control arm but that's sexy.

Thanks, Stampie!

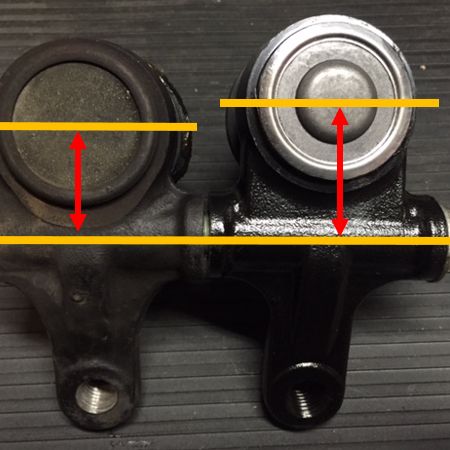

Just for reference, here's what I had before, with the ball joint pressed-out.

You can see that I ground all of the lip away from the outside edge, and was still having hard interference with the brake rotor. Without the press-in metal around the new balljoint, clearance should be much better!

Alright, finished the other side, welded in some captive nuts for the balljoint and the tension rod mount, added an access hole, and rounded off the ends.

The welding isn't the prettiest, but it gave me more practice, and should be strong enough. I've never tried DIY powdercoating, but might give it a go on these. If the results aren't the smoothest, they will be black and under the car, so no big deal.

And the money shot all mocked up. This shows the backside of the brake rotor clearing the balljoint at full lock, and you can see where the rotor was scored by the old arms just pushing it into and out of the shop once!

I decided to try my hand at powdercoating, something I've thought about playing with for a long time, but just never made the time to dive in.

I'm pretty happy with the results! I used the Eastwood Hot Coat kit, hung up some sheet plastic to keep the excess powder in a somewhat contained area, and cured it in an old electric range we keep around the shop for heating and curing.  It feels really gratiftying to know that all the little bits of surface rust that were starting to form here and there on the original arms are now gone, and the new coating should be more durable than my usual rattle-can finishes.

It feels really gratiftying to know that all the little bits of surface rust that were starting to form here and there on the original arms are now gone, and the new coating should be more durable than my usual rattle-can finishes.

Ahhh...back on the ground!

I also got a trip permit today, so I am an interior install (plus a couple minor details) away from doing some Megasquirt tuning in earnest!

![]()

![]()