I'm building an Individual Throttle Body motor (E30 M20), and this prevents me from running a normal vacuum hose from the intake manifold to the valve cover.

Most of the people running this ITB setup do the catch can method with no vacuum, but that isn't convincing me that that's the right way to do it.

How important is it to have the valve cover hose under vacuum, rather than just run in to a catch-can and leave it like that? Opinions seem to be all over the place. What are my options to put it under vacuum? I've seen valves that attach to the exhaust, will that mess up the CAT? Should I put an air/oil separator in line?

I am running a plenum, should I pull vacuum from there with an air/oil separator, or will this foul the ITBs eventually?

I need suggestions with explanations. This car is used 2-3x a week as my only car, so I need the correct long-term solution.

I'd say a catch can inline between the VC and the intake plenum is the way to go. You can probably get away without the catch can, assuming the motor is tight and not producing excess blow-by. I run a line straight from the VC to the intake plenum on the dual sidedraft Weber M10 in my 2002 - that's how the tiSa and tii came from the factory, but that's in the pre-emissions days.

Does your line going to the plenum have a filter?

The motor is currently being built, so it better not have any blow-by! However, 10 years down the road it might. I would like to plan for the future with this setup.

No filter. I've thought about setting up a catch can, but I haven't gotten around to it, and there's no pressing need that I can identify. If you want to do it right the first time, set up a catch can with a drain that dumps to the dipstick guide tube (braze on a nipple and run a hose to it from the bottom of the catch can). Add some internal baffling in the can and you'll be good to go. You've got the engine out, so now's the time to do it. If you want a really neat install, you can probably rig it up directly under the ITBs.

Definitely going for a clean installation. The backing plate for the plenum is aluminum, and I'm already drilling a hole in it for the air temperature sensor, so running the vacuum line there makes a lot of sense. The feed from the valve cover points right at the plenum..

Really like the dip stick tube idea. Now I just need to find the proper catch can that won't break the bank, and will fit. Open to suggestions. Been going through the Summit website, massive amount of options.

Ok, found a Moroso catch can with a drain option, and a PCV valve with a 90* bend that should fit. Today's parts order complete.

Thanks for the help, glad I'm keeping it the way BMW would have done it.

Sounds like a plan. Let us know how it works out.

Will do. I'm hoping the ITB's produce enough vacuum, otherwise I'll be looking at an exhaust vacuum source.

You don't really need a lot of vacuum in most cases, just enough to prevent the build-up of oil fumes, cylinder blow-by, and pressure in the crankcase. Anything from partial to wide open throttle will draw enough vacuum. If you want to measure it, a slack-tube manometer is easy to build (a normal vacuum gauge will not be sensitive enough).

It's not super-important and you can absolutely get away with not having vacuum in the crankcase (just like most pre-'70s cars), but there's no reason you can't have crankcase vacuum and ITBs at the same time.

All you need is an after-throttle vacuum source. Many ITB setups have one for each throttle body teed together and going into a "vacuum box" that connects to the MAP sensor, IAC valve, etc. Do run an oil catch can to keep the oil ingestion down.

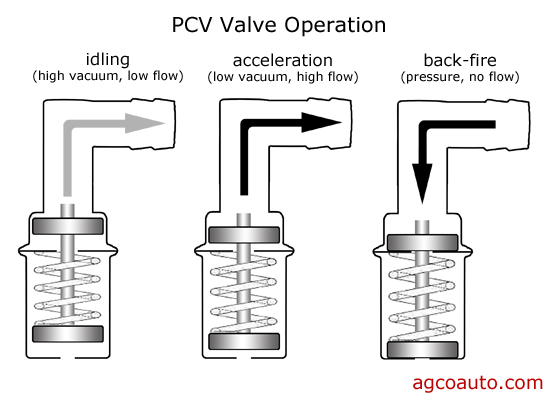

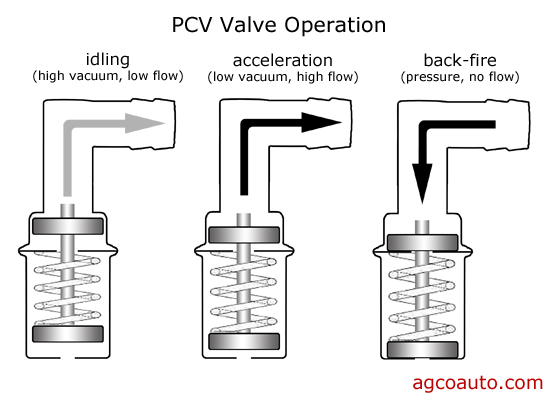

Also you're better off having a direct open line from the valve cover than a PCV, if you can only have one of the two. A PCV valve is more like a safety blowoff valve for your crankcase. It's better to have an actual vacuum in your crankcase whenever possible - it helps contaminants evaporate (keeping the oil cleaner) and helps oil flow back to the sump more easily.

In reply to GameboyRMH:

I was going to say the same thing- my Alfa has a vent going into the air cleaner- works well enough- the crank is at least cleared out of pressure, so that the seals don't break.

Also- put it to the intake- it's a better place than the exhaust if you have a catalyst. The crank is mostly air and un-burnt hydrocarbons- which burn really well in the exhaust. A little too well.... Better for the air to be fed into the combustion chamber to be burnt again.

Run PCV and change your oil every 5000 miles. Don't run PCV and change the viscous emulsified acidic paste in your oil pan every 2500 miles.

PCV is a big deal for oil health. Use one.

Crankcase vacuum is a very good idea and I would set it up if possible.

The more airtight you can make the motor the better, and I'm not sure what effect the separator drain into the dipstick would have.

But it's a new motor and you're not afraid of popping the hood so I'd just put a little valve on the bottom of the separator and manually drain it when/if ever it collects oil.

The best way to run it, imho, is to have vacuum on the top and bottom of the motor. I'd run those lines into one or two separators and either to a vacuum pump or to the plenum.

In a perfect system, you'd never see oil in the intake because the separator would separate :)

I've seen a number of vintage racecars running an open filter (like a mini K&N cone filter) on the valve cover, plus an oil catch can.

These were all engines running on side-draught carbs. Any reason that wouldn't work in the M20? Not sure if ITBs are different from triple Weber DCOEs.

You don't want pressure building in the motor, top or bottom. So venting to atmosphere is fine. But it's bad for environment and can be very messy.

The environment part may or may not be a big deal and may or may not bother you.

The messy part would, and the solution is to put a good separator or two in the system. The other end of the separator can go to atmosphere or can be attached to a vacuum source which will help make more power. If the source is the intake and the separator doesn't do it's job it would make for a messy intake and maybe less power.

If it is "clean" (ish) air, it will probably be a net gain.

Look at the big power drag racers - they run separate vacuum pumps to put a vacuum on the motor because it helps make more power

Ian F

MegaDork

3/8/17 10:31 a.m.

I would run it. Especially if the motor has some age on it and there may be some blow-by past the rings. When I first installed SU carbs my ex's Spitfire, I replaced the PCV with a simple breather filter off the valve cover. Because of the engine age (and general British-ness), pressure in the crankcase built up to the point where it was spewing oil out of every possible orifice (and made some new ones). Even the dip stick tube. I rigged up a OE style PCV system (which also connects the gas tank vent) and the engine went back to normal LBC leaking.

I ran an M20B23 with Weber 3236 for a while. It was a really old motor, over 150K. Compression was still pretty good and it was peppy enough for HPDE fun, though not Miata-fast like a freshened M20B25 is. Anyway, it came set up with a VC breather hose and no valve. That spewed a lot of oil out the end of the breather hose, even at idle. Just nasty on the engine bay and even the underbody.

I installed a good, 4-baffle catch can on the breather hose with 3/4" line. I didn't mess with a PCV-valve tee or anything, and I routed the catch-can vent to the open. I didn't have to empty it much, and this setup stopped blowing oil vapor out the vent hose. I didn't need to empty the can very much, and most of what I got was condensate.

Car ran fine but throttle lift at high RPMs = vacuum goes low to high = cloud of oil smoke out the exhaust big time, and oily plugs, though the valve seals were probably tired too. I changed the oil a lot so I never gave it a chance to show signs of early death, or not.

I talked to some M10 and early M20 guys who had used Milodon Vac-U-Pan ports on the exhaust manifold, and a mid-line T to a PCV valve as well. They said the Mildon worked fine even with mufflers, though it had a reputation for being no good with them. Another guy told me instead of a T to a PCV valve, he had a T to a baffled catch can with no PCV on the can vent. I think you can still get the Milodon parts at Summit Racing for $50.

I replaced the motor with a Motronic M20B25 before I had a chance to try any of that stuff though.

84FSP

Dork

3/8/17 12:34 p.m.

At my first trackday I found out the hard way that the airbox routed oil breather on my VW MKI becomes an air/oil pump at sustained RPMs. Rerouted to a simple catch can setup and no problems since. It only cost me a motor to implement a $30 solution.

GameboyRMH wrote:

Also you're better off having a direct open line from the valve cover than a PCV, if you can only have one of the two. A PCV valve is more like a safety blowoff valve for your crankcase. It's better to have an actual vacuum in your crankcase whenever possible - it helps contaminants evaporate (keeping the oil cleaner) and helps oil flow back to the sump more easily.

More of a controlled leak/check valve.

I'm not sure its presence actually makes much difference if you're running a vacuum down the case configuration rather than the usual OE arrangement with an unrestricted clean air source on one end of the engine and the PCV on the other to generate airflow through the engine. Which reminds me, why do they do it that way?

OEMs build the setup they way they do because it pulls air through via the PCV to ventilate the crankcase, the other side lets fresh air into avoid building up a vacuum and potentially sucking dirt in past aging seals. And the other side also lets flow out at WOT when there's not much vacuum if the PCV can't flow enough on its own.

a small amount of power is gained by having a vacuum in the crankcase. Less windage.

As far as fumes being drawn into the intake. Upper cylinder lube.

Most throttle bodies do have a port for synchronization you can simply use 4 or however many pcv valve one per body and plumb the hoses to one port in the valve cover or use 4 small check valves and gang the inlet sides to the one stock pcv

Im just running an open air catch can on my motor with ITBs, with ITBs any thottle opening larger than 30% will be at atmospheric pressure or very close to it, meaning there will be no vacuum to pull. remember PCV systems dont work at WOT

GameboyRMH wrote:

It's not super-important and you can absolutely get away with not having vacuum in the crankcase (just like most pre-'70s cars), but *there's no reason you can't have crankcase vacuum and ITBs at the same time.*

All you need is an after-throttle vacuum source. Many ITB setups have one for each throttle body teed together and going into a "vacuum box" that connects to the MAP sensor, IAC valve, etc. Do run an oil catch can to keep the oil ingestion down.

Also you're better off having a direct open line from the valve cover than a PCV, if you can only have one of the two. A PCV valve is more like a safety blowoff valve for your crankcase. It's better to have an actual vacuum in your crankcase whenever possible - it helps contaminants evaporate (keeping the oil cleaner) and helps oil flow back to the sump more easily.

This guy right here gets it. ^^^

The easiest way to plumb this is going to use a vacuum source before the throttle plate. You aren't going to get a lot of vacuum, but you don't need a lot either. Just run from the VC through the (baffled) catch can to the filter housing and call it done. Add the drain to the dipstick guide tube if you wish; not only will it remove the need to check and drain the catch can, but it also helps to draw vapors out of the bottom half of the motor. There is no need for PCV valves in this arrangement. All of this should fit easily under the ITBs on the M20.