A little late to be asking this question because I just picked up my new shaft yesterday. Through this whole driveshaft making process, I've been questioning my thought process, so I'm here for a reality check. Engine trans combo is a modified LS3 with the Tremec TR6060 out of a 2010 Camaro. Rear end is a narrowed Ford Explorer 8.8 stick axle(not the later independent). The Camaro has an independent rear end and it uses a 2 piece driveshaft with a rubber guibo on each end. The way I had the shaft made utilizes the guibo at the front with the front flange from the Camaro shaft, then tube, then a slider yoke with a U joint, and a new flange just like you would find on a standard Explorer shaft. Driveshaft guy said he knew of no direct mount flange he could use to go directly to the output flange on the transmission. For the record, this is the first shaft he made to go behind this Camaro 6 speed. Do the Mustang and Dodge vehicles that run this same tranny use a two piece shaft and an independent rear end? So what say the hive? Does this sound like the best way to go? Anybody know of a better way? What are the Miata guys with this combo running? If need be, I'l toss this shaft and build another one. This one was only $330. I was expecting much more based on some of the prices I've seen on line for Miata conversion shafts. My concern is that there is only one u joint and a flex guibo at the other end. Shaft is only 30.5" long. Whats going to happen as the rear end moves up and down? Guibos usually run between a fixed trans and a fixed independent rear center section. The slider will take care of the change in length caused by the rear end moving, but without two universals????????

Titan4

New Reader

12/28/17 7:31 a.m.

I thought you had to use pairs of u-joints. A single u-joint causes variations in the rotational speed of the two shafts as they rotate (gets worse the greater the angle). A second u-joint in phase with the first will cancel out the variation (assuming the first and third shafts are parallel). Will a giubo cancel out the rotational speed variation caused by the u-joint? If not, then it seems like this set-up would lead to a lot of problems.

44Dwarf

UltraDork

12/28/17 8:17 a.m.

Sounds like a recipe for danger / new floor boards and a hip replacement. I would not use it. You need two u-joint to cancell the rotational speed change due to the angles the Giubos will not take that amount of flexing long and will blow out.

Your best bet if you can't find a U-joint yoke for the trans is to take the Giubo yoke have it machined to take a bolt on u joint flange like whats at the rear axle. you'll need a pilot register and a bolt pattern.

Try South Shore Bearing (Quincy Ma.) or Mitchel driveline. It's been years but South Shore used to do a bunch of custom stuff for me and some of the shops i worked at. Browns up in Manchester NH is good to but me get moody the older he gets on custom stuff...

44

Pretty sure with the Guibo you have to have the other end of the shaft fixed. In your case that probably means guibo to hanger bearing to splined shaft, then conventional fixed length driveshaft with two ujoints that slides onto the splines with a yoke and then has another ujoint bolted to the axle.

So a two piece driveshaft. But those two pieces are going to be short to fit in your application.

NOHOME

UltimaDork

12/28/17 9:59 a.m.

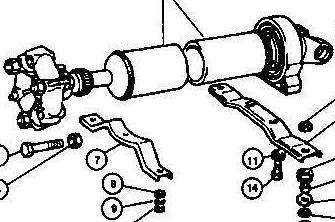

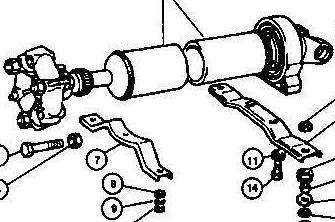

The way I had the shaft made utilizes the guibo at the front with the front flange from the Camaro shaft, then tube, then a slider yoke with a U joint, and a new flange just like you would find on a standard Explorer shaft.

I cant convert these words into any kind of a mental image, but I have a bad history with a guibo that tried to kill me.

Back when I was young and even stupider, I stuffed a Fiat 124 enigne and gearbox into an MG Midget. Since I was ignorant, I tried to reduce the two part shaft shown to a single shaft. While test drivign the results on axle stands, somewhere around 5000 rpm or so, the guibo abandoned ship. The driveshaft proceeded to eat the passenger side of the transmission tunnel and I exited the car like a jack in the box.

I don't know if any of this applies to your build, but Guibos are like clown to me...scare the E36 M3 out of me when I see one.

Pete

edit. The Guibo stayed in the end...I fixed the problem by going back to a two piece driveshaft with a hanger bearing in the middle. They were some short shafts!