Does anyone just make their own exhaust/turbo gaskets from a sheet of hardware store copper sheet?

I gather it’s possible. Now i’ve got to try it

off the shelf ones i have bought are usually quite thick and/or have a raised crush area around what is to be sealed

Da Boss's dad used to make his own copper head gaskets for Pontiacs since nobody made them at the time.

Made his own punching dies, too.

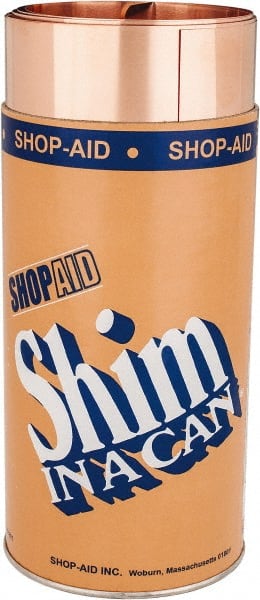

Copper shim stock is available in an annealed state from 0.001" to 0.032" thick. Using a full hard sheet of hardware store material seems like it would be problematic.

You can of course anneal copper with a torch by taking it to 800F and quenching it but it won't be flat after that.

Never tried it, but would copper flashing used for roofing be thick enough? It seems thin enough to be easily cut with scissors,shears, or whatever.

Many street guys use no gasket on their turbo setups, as they seem to blow out no matter what they do with the insane pressures. An hour with a plate of glass and some emory paper, followed by a coat of copper spray gasket gets er done for quite a few 40psi 4 bangers.

I am a NA guy, so thats all 2nd hand knowledge. I have used copper rtv for exhaust gaskets that see less pressure and need more compliance. I often make a thin layer to supplant any crush gaskets as well.

I suspect it won't work. Not because it's the wrong material, but because with a large gasket, you're trying to compress the entire sheet. As noted above, commercial copper gaskets are either small, have low surface area, or have a raised ridge. Any one of these makes it possible to compress it with the fasteners. Too much surface area and it's going to be like using a sheet of steel.

I should run no gasket from head to manifold. It must move around quite a bit because one of the holes, the locating one is the same size as the manifold stud and the others are all way bigger to allow for expansion.

I made a 90 degree elbow to move turbo with some schedule 40 and flanges but the flanges warped when I welded it all together. Hit them with sanding belt at work but still not perfect.

Glass and emery is the ticket I think.

Nothing but copper rtv on things that could use a copper gasket or never had a gasket in the first place, ie-cast iron manifold to cast iron heads.

Nugi said:Many street guys use no gasket on their turbo setups, as they seem to blow out no matter what they do with the insane pressures. An hour with a plate of glass and some emory paper, followed by a coat of copper spray gasket gets er done for quite a few 40psi 4 bangers.

I am a NA guy, so thats all 2nd hand knowledge. I have used copper rtv for exhaust gaskets that see less pressure and need more compliance. I often make a thin layer to supplant any crush gaskets as well.

The copper spray is insanely good imo. I have had that stuff hold up when nothing else does. One of my old beaters entire engine is not completely copper colored we sprayed so much of it.

You can make copper 'gaskets' out of solid copper wire. Easier to anneal a length of wire than an entire flat sheet.

Compared to flat sheet, the small cross section of the wire yields higher unit clamping pressure which will crush and deform the wire to conform to any surface irregularity on the mating faces.

Unless you have a means of melting and joining the ends, make at least two-three turns of wire to enclose the 'port' being sealed.

There will still be some minor leakage past the wire labyrinth, but not enough to worry about.

When you make it, sandwich it between two pieces of wood with screws. When you cut it on the scroll saw it wont rip and tear the edges because the wood acts as a backer. Then hit it with some copper spray and rock on.

You'll need to log in to post.