Does anyone know if it's possible to DIY your own harmonic damper pulley?

My Civics' 1.2L engine never came with one but with the planned addition of rpms and stroke I'd like to have a little bit of reassurance against shaking things to bits.

Does anyone know if it's possible to DIY your own harmonic damper pulley?

My Civics' 1.2L engine never came with one but with the planned addition of rpms and stroke I'd like to have a little bit of reassurance against shaking things to bits.

Other than just adding mass to the rotating assembly, I don't know how an individual would do it. Does your civic's engine have balance shafts or something like that already? For the duratec/mzr 4 cylinders, Cosworth design a "balance shaft" delete kit... just take that as an FYI.

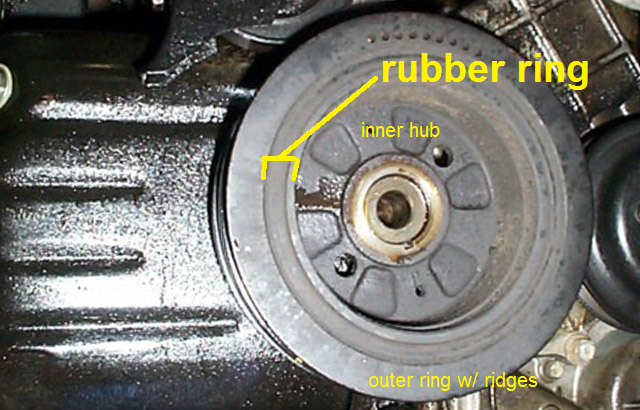

After working on the crank pulley in my 1.4 liter '95 Corolla, I did a little investigation The crank pulley is comprised of an inner hub, a maybe 3/16" thick rubber ring to dampen vibrations, and the outer ring with the grooves for the belts.

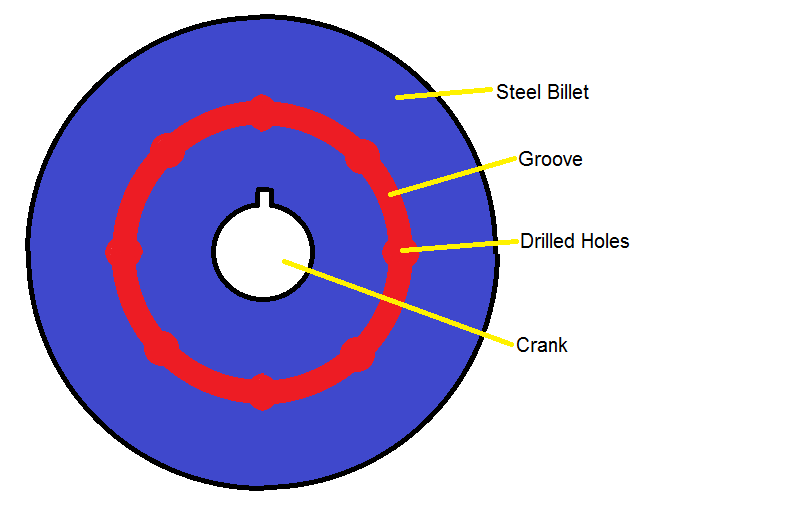

So, having never actually done this, heres what I would do:

start with a billet disc of steel the thickness you want, but a bit larger diameter than you would need. Chuck it up in a lathe. Bore your crank hole, and cut the grooves in the outer circumference for the belts to ride on. About 1/2 way out from the center in the radius, cut a 3/16" groove nearly all the way through the thickness of the billet, but not quite all the way. Place the billet in a drill press, and drill several 5/16 holes centered on the groove you just cut so that you have 1/16" of hole on either side of the cut. Fill this cut and the holes with some 70a urethane. Once its cured, flip the billet over, and cut the rest of the grove, separating the inner hub from the outer ring. Fill in the remaining gap with more urethane.

quick and dirty paint sketch

Basically, the flaw in the 'yota part is that eventually the rubber wears out a little, and the outer ring starts to slip over the rubber, and you lose accessory power and you shred belts. The drilled holes give the rubber something to hold on to, especially if youre going to start to add power.

Also, probably not a bad idea to drill out a series of holes in the hub part of your new pulley, to reduce weight.

Hope all that makes sense...patent not pending, image not subject to copyright, your mileage may vary, offer void in Rhode Island.

In reply to sobe_death:

This not something you should try building, due to safety concerns. I've seen one fall apart on a drag car and nearly hit me in the head on the sidelines over 100' away. There's a reason there are certification standards for harmonic dampers used in competition. If you want to add one, take the existing main pulley and take measurements. Most of them also provide the surface for the front main seal so pay attention to that. Now take it down to the parts store and see if you can find one to match. Another alternative would be to look at aftermarket brands like TCI, ATI, etc for 4-cylinder applications. Many of those are made with a big hole in the middle where engine specific adapters are bolted in. If you can find one that's built for a 4 cylinder engine, you can take it to a machine shop and have an adaptor made for your engine. Some balancers are counterweighted and some are neutral so make sure your pay attention to that as well. Happy Hunting!

Are you sure it doesn't have one? They don't necessarily look like much.

Is there another Honda engine that shares the same crank nose design? Engines tend to be built in families, of course. You can cheat a little bit by looking at the part numbers for "underdrive" crank pulleys and see what other engines share the same.

There are so many different ways to do this and type that have been made in the past but like the above post said its not really something you should try. One of those basic questions were if you have to ask how you shouldn't try. But like others have said look for common fit parts. Beware that each type has different absorbing frequencies so it may or may not help you. Common types used are the bonded inertia ring as above. Inertia ring floating in liquid (common on diesel engines and fluid damper brand) Heavy metal damper (mercury filled capsules hung from crank throws ala Dusenberg and Stutz) roller type (TCI Rattler) bar stock slugs in holes fly outward at high rpm and are noisy down low)

Well, I was thinking more along the lines of taking one from another engine and machining the crank snout area to fit. It's an EB3 engine from a '79 Civic, and the pulley is a very thin, almost stamped-looking steel pulley that drives the water pump and alternator.

I'm more worried about finding one with the right frequency so it's actually doing something instead of just hanging there adding mass to the rotating assembly...

You'll need to log in to post.