A question came up on another less sophisticated board about eliminating frame flex for a "play truck" trying to get rid of frame flex seen while off road.

Here was my response but I'd like to see if you guys with more engineering minds agree or disagree:

My thoughts are these:

1) Suspension travel is not great on these trucks, less so with 3/4 and one-tons. I think a VERY stiff frame would be more appropriate for a very flexible suspension.

2) Recalling the Three Stooges plumbing episode, every time they diverted the water with a pipe, it just shot out somewhere else (gas stove etc.).

And similar to a powertrains weakest link, once you install badass u-joints, the axles are next in line, then maybe a ring gear. Point being is that you may just want your u-joints to remain the weakest link because the other alternatives upstream are much more expensive and a bigger PITA.

When flex is elimated successfully, that stress is going to find the next weakest point wherever that may be. It may indeed be the metal itself and cracks will develop at invisible weakpoints along the frame or perhaps a spring mount will tear off.

I'd let the frame flex as it was engineered to do and not worry much about it.

So your reasoning is to not fix something is because something else is just going to break?

I am not sure you would want to fix flex on an offroader. In many cases, I am sure frame flex is built into the suspension design

If it's not flexing a really worrying amount or causing a handling problem (probably not even worth worrying about on an offroad vehicle, there's nothing subtle or refined about the way they handle  ) I'd leave it.

) I'd leave it.

The weak point argument is a good one, this is why you should never install a rag joint eliminator for example, It just means something else breaks and you get no warning - just carry a spare rag joint I say.

Stiffening the frame typically transfers the stress to the suspension and this is typically what you want, but depending on how you do it you could focus all the stress that was previously distributed across a large area into a small area and this could lead to cracks.

DaveEstey wrote:

So your reasoning is to not fix something is because something else is just going to break?

Well what's your definition of "fix"? I'd be careful "fixing" something that was engineered into a chassis.

And to your point: yes, it is a very common practice to keep a known "fuse" in a drive train in off-road vehicles. In fact, Warn made locking hubs with an easily replaceable component that'll break before too much load can be placed on CV joints or front end u-joints. The hub would "fail" several thousand inch/lbs before the known strength of the u-joint.

Therefore having an easily field-repaired, fairly predictable failure point is a good idea. Not sure about anyone else but I wouldn't have the resourses to build the most unbreakable off-road vehicle mankind has ever seen. And since there will ALWAYS be a weak link, I'd like to be able to easily fix it.

Maybe this doesn't make sense to the street car crowd but it definately does to the off-road crowd and afterall, this was to whom the question was intitially directed.

I've changed a u-joint in the mud in about 20 minutes. Not as easy with a broken c-clip or axle or a stripped ring gear.

I remember seeing trucks with valvesprings mounted in the body mount hardware, so the frame could flex MORE without breaking anything.

SVreX

UltimaDork

4/30/12 12:05 p.m.

Your logic is good, except for the part where you said "...let the frame flex as it was engineered to do".

If you are talking about a stock chassis, they were NEVER engineered to take the stresses put on them in off-roading.

If they are really serious, they need to re-engineer the suspension to have more travel. Perhaps MUCH more.

Too much flex could lead to metal fatigue, broken welds, etc.

ebonyandivory wrote:

DaveEstey wrote:

So your reasoning is to not fix something is because something else is just going to break?

Well what's your definition of "fix"? I'd be careful "fixing" something that was engineered into a chassis.

And to your point: yes, it is a very common practice to keep a known "fuse" in a drive train in off-road vehicles. In fact, Warn made locking hubs with an easily replaceable component that'll break before too much load can be placed on CV joints or front end u-joints. The hub would "fail" several thousand inch/lbs before the known strength of the u-joint.

Therefore having an easily field-repaired, fairly predictable failure point is a good idea. Not sure about anyone else but I wouldn't have the resourses to build the most unbreakable off-road vehicle mankind has ever seen. And since there will ALWAYS be a weak link, I'd like to be able to easily fix it.

Maybe this doesn't make sense to the street car crowd but it definately does to the off-road crowd and afterall, this was to whom the question was intitially directed.

I've changed a u-joint in the mud in about 20 minutes. Not as easy with a broken c-clip or axle or a stripped ring gear.

Doesn't make sense to me. I upgrade things. If something new breaks that gets upgraded too. Eventually i'll run out of things to upgrade or I'll break something incredibly expensive. I would classify a broken frame from constant flexing and resulting metal fatigue as something incredibly expensive.

Then again, if I break I'm at the track, not out in the woods.

SVreX wrote:

If you are talking about a stock chassis, they were NEVER engineered to take the stresses put on them in off-roading.

Wait, four wheel drive truck chassis weren't engineered for off-roading?

ebonyandivory wrote:

SVreX wrote:

If you are talking about a stock chassis, they were NEVER engineered to take the stresses put on them in off-roading.

Wait, four wheel drive truck chassis weren't engineered for off-roading?

Haha most weren't, considering most SUVs fit that definition

No but seriously, very few trucks were engineered from the factory to take a serious offroad beating, the only American trucks that were are the Willys GP, Wranglers and the Ford Raptor.

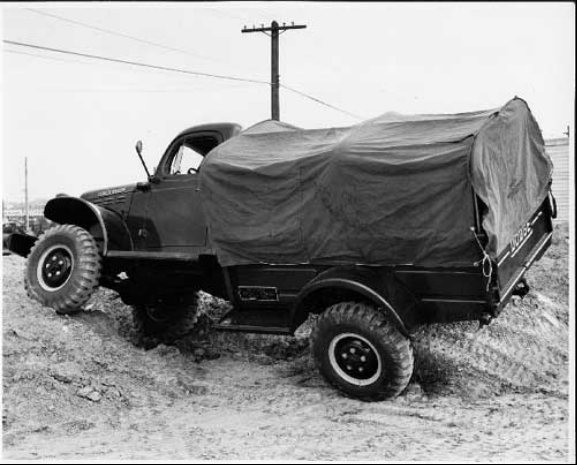

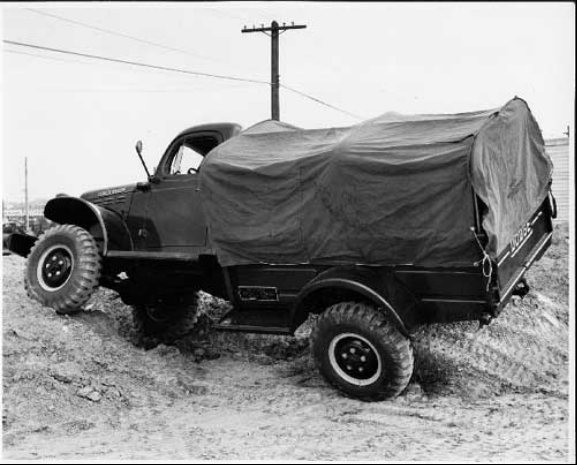

Edit: And also that badass-looking old Willys/Jeep pickup that I can't remember the name of.

DaveEstey wrote:

Doesn't make sense to me. I upgrade things. If something new breaks that gets upgraded too. Eventually i'll run out of things to upgrade or I'll break something incredibly expensive. I would classify a broken frame from constant flexing and resulting metal fatigue as something incredibly expensive.

Then again, if I break I'm at the track, not out in the woods.

In the example of the front axle of a 4x4 above, you'd need to upgrade a $20, 10 minute hub part then upgrade a $30, 1-2 hour part, up to a more expensive stub shaft, to an even more expensive and time-consuming axle shaft and possible ring gear if you're not lucky enough to blow a lowly driveshaft u-joint.

Of course with limitless money and time and tools, you could build anything but I don't have any of those.

But the original point was about elimination of frame flex and if was detrimental/worth the effort and where all that stress will end up because we know it doesn't just dissappear. To paraphrase Dr. Ian Malcolm in Jurrasic Park: "Stress finds a way!"

SVreX

UltimaDork

5/1/12 6:54 a.m.

ebonyandivory wrote:

Wait, four wheel drive truck chassis weren't engineered for off-roading?

That might depend on what we call off-roading.

SVreX wrote:

Your logic is good, except for the part where you said "...let the frame flex as it was engineered to do".

If you are talking about a stock chassis, they were NEVER engineered to take the stresses put on them in off-roading.

Don't be too sure. Older trucks WERE designed to use frame flex as part of the suspension. Newer trucks aren't, because they are engineered for suburban cowboys who want the looks of a wheelbarrow but the feel of a Lexus.

Too much flex could lead to metal fatigue, broken welds, etc.

So the frame is a maintenance part. So be it.

It's a ladder frame, it's always going to flex (bow and twist). You can reduce it, some, but you cannot eliminate it.

I have my doubts about the frame being designed to flex. Rather I suspect it's simply allowed to flex. Within design tolerances.

Rock crawlers and different from the baja racers, which are different from farmers and hunters.

Frame flex is going to happen and I too am in the 'let it flex' camp. That's because if something can't bend it's very likely to break.

Now, if it's imperative that the frame be stiffer, number 1: most of them are riveted together. The rivets will allow some movement. So add welds at those points, yeah I know that welding could change the base metal's properties and lead to more severe cracking. I think that's why they are riveted together in the first place.

Next, add braces. It's going to be difficult to improve on what was the product of many hours of computer design time, but some incremental improvement is sure to be there.

Best of all, add a properly designed roll cage. If correct attention is paid to lad paths etc it's possible to build a very rigid cage/frame without an enormous weight penalty.

Chassis is less likely to flex if the suspension is set up to flex.