I was scrolling through Keith's awesome thread about his budget laser engraver a few weeks ago, when one sentence jumped out at me:

Keith Tanner Said:

- you can get a CNC milling machine that can carry a laser head for about $100-150 more than I paid for this thing. That would open up a lot of options for other materials and potentially adds focusing capability since it can set the Z axis. That's nearly double the cost but I think it would be a lot more flexible.

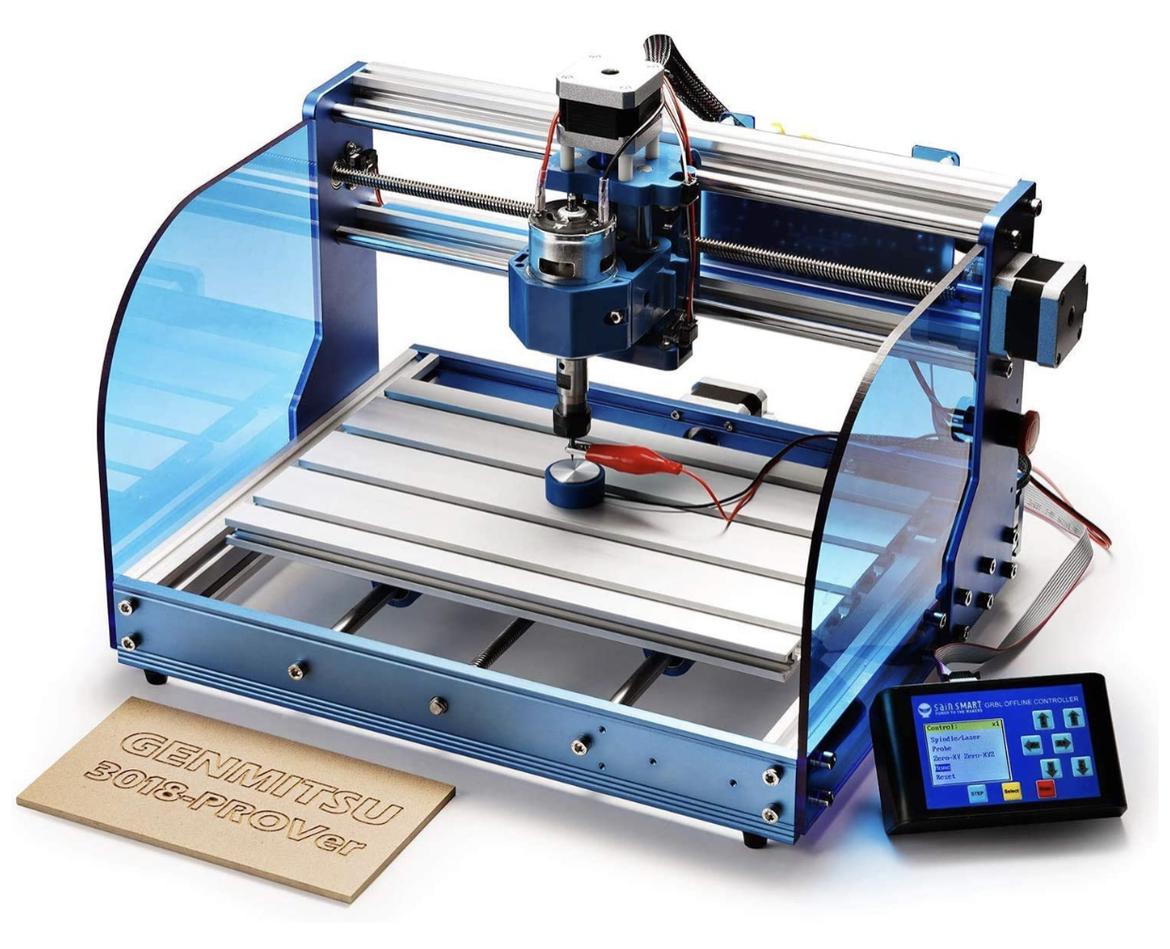

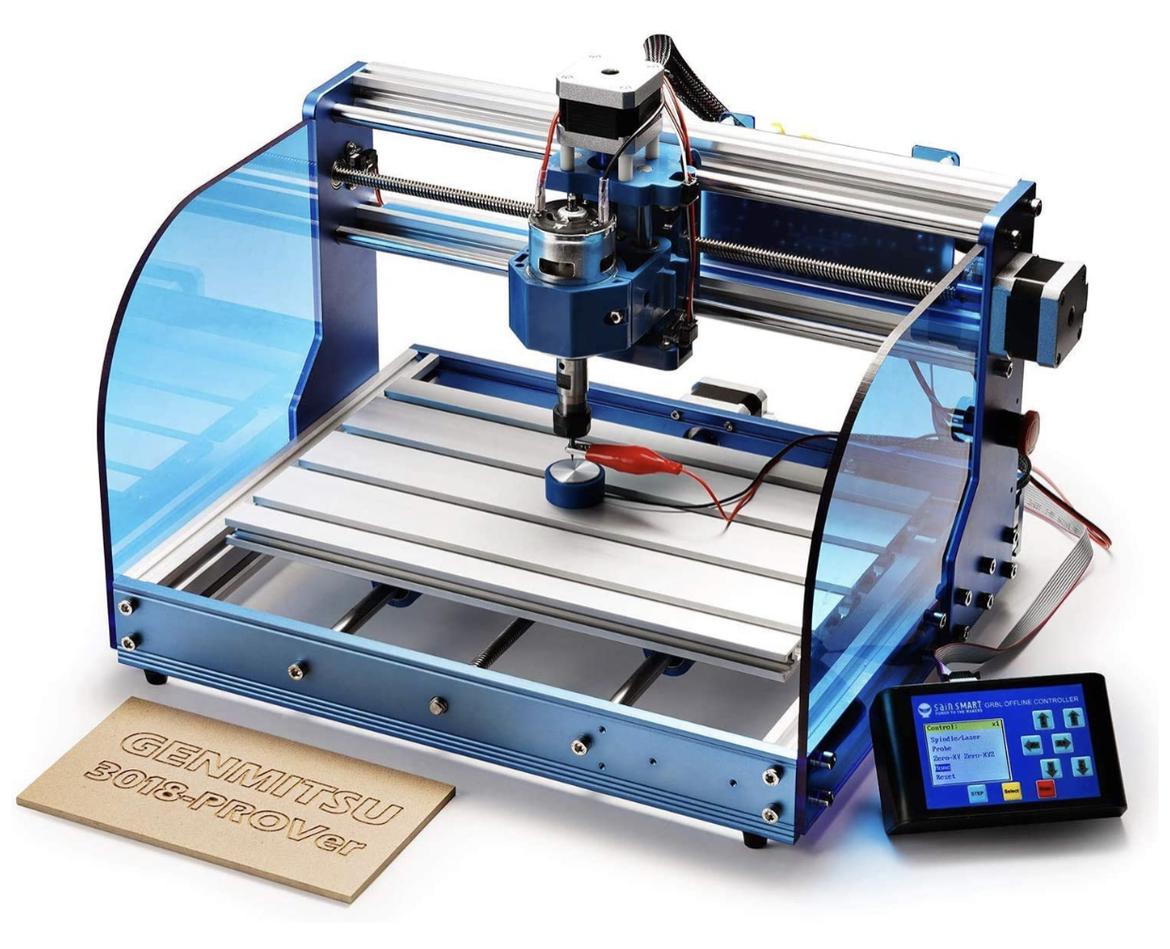

Wait, what, really?! You can get a CNC machine for that price!? No offense to lasers, but suddenly I had dreams of a magical bench-top machine that could spit out camber plates and bushings and so much else with one click of the mouse. Having that for a few hundred bucks seemed impossible, but sure enough I went down the Google rabbit hole and it does exist. Everybody, meet the 3018 CNC engraver, which is the generic name for a wide range of cheap imported engravers that all seem to have the same design. The basic version sells for about $200, while one with all the bells and whistles is $350 on Amazon.

But you know what's even cheaper than $200? Lobbying your family to get you commoditized Chinese machinery for your birthday, and I just happened to have one coming up. Thanks to some very generous parents who probably just want me to make extra parts for them, I unwrapped a Sainsmart Genmitsu 3018 PROver a few weeks ago. I figured it was worth a thread to document my experience with it, and hopefully convince everybody else to jump on the bandwagon!

What are my goals with this project? I'll be thrilled if I can use this as a tool to teach myself CAD and the basics of CNC machining. I know I'll probably never use this to make anything substantial, but if it gets me to a place where I can walk into a friend's shop and confidently use their machine, and has me designing parts on the computer with manufactuability in mind, then I'll be completely satisfied with the little 3018. And if I get some cool trinkets and the occassional race car part along the way? Perfect!

So, what's the difference between a 3018 and a 3018 PROVer? This one is a little more expensive, and comes with more goodies. You get some acrylic shields, an upgraded circuit board, a Z probe, an offline controller, limit switches, and an emergency stop switch. These are all good things to have, and I'm pretty happy to have the fancy one. How much extra is all this luxury? Right now they're listed for about $350, but I spotted prices drop as low as $250 during Cyber Week. If you shop around and wait for a coupon, you should be able to find a PROVer in that ballpark.

Let's get it unboxed!

In totally love n for more info! I have some very basic (toddler level) CAD ability (Autocad, not the cardboard kind!) and CNC experience. (MDI 2 axis millpower on a converted Bridgeport) but haven had access to a machine in over 15 years.

I need a source for ball-lead screws for my old Bridgeport.

One of the 2-350 machines would be a exelent practice start for me

congrats on the new toy!

Mr_Asa

SuperDork

12/18/20 11:16 p.m.

So is it an engraver or can it actually remove enough material to be a CNC?

Volume is a little small for anything really great, but could be promising; 6x10x1.5 ish inches.

In reply to Mr_Asa :

Looks like it can actually mill away enough to function as a CNC. Video below has a complex design milled into what he calls "5mm" aluminum which would be about 1/5" thick. I wonder if it can mill through 1/8" mild plate? Presumably if you have a good cutter and it doesn't get hot. May not mill quickly...but still I can think of about a thousand projects in the 6"x10" range...

https://m.youtube.com/watch?v=YKCokjYhGCY

I have a CNC like yours but its all aluminum ,

like many things I bought it and never used it , its sitting next to the Laser and 3D printer ,

Hopefully I can get it working soon , watching you will help !

What software are you going to use ?

Thanks

Can we mill things out of wood? As much as I like my 3dprinter, I've wanted to work the other direction since I got it. Being able to play with machining wood would be huge for me.

sure it will do wood ,

look up CNC 3020 on youtube , lots of videos showing how to set up and cut ,

Mr_Asa

SuperDork

12/19/20 12:31 p.m.

I'd probably get a tupperware container to set it in and collect the chips.

Normally I'd agree, but because this is in the shop I'm used to vacuuming up chips. I just blow them onto the ground and let the Roomba handle it in the evenings.

There is a 100% chance I'll be ordering one of these. Not that I need another machine to tinker with. Thanks a lot Tom.

Oh, excellent. I've been watching these since I made that comment as well. I ended up going further down the laser route and have been making a fair bit of use of it - my productivity in the garage has dropped off because the laser is in the garage so I keep playing - but I would love to put one of these beside it. It would open up DIY circuit boards quite easily without the multiple steps of masking/burning/etching/cleaning/drilling.

One of the things I've been doing with the big laser (the little one doesn't have the horsepower) is making quilting rulers/templates. Most of them can be surface engraved easily but once in a while you want a groove that's 1mm deep and the laser is not as clean there as I'd like. One of these CNC mills would do it easily.

If it's anything like my K40 laser there is a deep pool of DIY modifications to make them better. I expect the 3018 is the same, so I look forward to the evolution!

And dammit, I suspect this thread is going to force me to dedicate another workbench to a G-code machine. I have the vinyl cutter, the two lasers, a broken and obsolete 3D printer that I may never bother bringing online and I've done some work programming for my wife's embroidery sewing machine. It's funny how all of these disparate tools are really so similar. The embroidery machine is the most complex by far, if only due to the fussiness of the mechanism.

At this point I was still using the test files that come with the machine, and I realized that my CNC machining skills were way better than my (basically nonexistent) CAD skills, so the next step was learning how to model parts on a computer.

But which software should I use? After doing lots of research and talking to my friends, I decided on Autodesk Fusion 360. It's free for non-commercial users like me, and it's what my friends with actual CNC machines were using. Plus, there are tons of tutorials on YouTube. What's the downside? Well, it's more complicated than some of the alternatives, and not really setup for artistic engraving and such, which makes it a poor fit for most of the things the 3018 is actually good at. But it's great for designing race car parts, which is my eventual goal, so I figured I should just start using the real CAD software from the start.

After a few hours on YouTube, I had simple parts figured out and could start learning how to turn stuff in the computer into stuff in real life. And that isn't as simple as it sounds. CNC machines can't look at a model and say "got it, I can make that!" Instead they're fed G-code, which is basically a list of points the machine should hit. Once I draw something in Fusion, I have to use the manufacturing section of the program to create a tool path, then export that as G-code for the 3018.

TL;DR: I draw thingy. I help Fusion figure out how to move a tool in space to remove material from stock until only the thingy is left. Fusion exports that as a list of "Move tool to X,Y,Z, then move tool to X,Y,Z, etc." I give that code to the Candle software on the laptop hooked to the machine. The laptop moves the machine through that list of coordinates, and then boom the machining is complete.

It's not that exciting, but this text was the first thing I'd ever created on a computer and then brought into the real world. Success! (Even though I accidentally told it to machine the center of the "O").

This is good stuff but bad for me personally. Curse you, Suddard.

In the laser world, cardboard is the prototyping material because it's cheap and super-fast. I'm assuming the CNC version would be some sort of foam, like your styrofoam but less coarse. Maybe that blue sheet wall insulation?

BTW, I believe a necessary rite of passage with this sort of machinery is to use the machine to make parts to improve the machine.

Oh, and we're not to this point in the story yet, but here's a spoiler to the question "can it actually mill aluminum?"

I just took this screenshot from my CNC camera:

I'll go into more detail later in the thread.

Rodan

Dork

12/19/20 2:26 p.m.

Watching with great interest!

Wow. I am going to have to look into these. Looking forward to seeing how the alum turns out.

Driven5

UltraDork

12/19/20 4:04 p.m.

Oh geeze. I already had a 3D printer on my list for this year. If this thing does aluminum with any consistency and reliability though, and depending on the size of cutters it can run in aluminum, that could quickly move one of these to the top of the list.

Obviously it doesn't have the capability to be anything other than quite slow...However, I still can't help but thinking about the ways in which some larger items might be able to be made in layers.

Mr_Asa

SuperDork

12/19/20 4:38 p.m.

Once you get into CNCing with it for real, I'd appreciate knowing how well it handles a non-level but flat surface. A couple of the things I need to make are all 90 degree surfaces, except the top has a ~7 degree angle on it; but they need to be flat enough on that surface to seal with a paper gasket.