Alright folks. So maybe you've seen that I got a kinda good, kinda bad rollback. Maybe you didn't. The AL bed is a bit messed up to put it nicely. I've gotten a lot of thoughts and quotes for getting the al bed repaired and I'm going with option WTF. I want to build a steel tilter bed with pin on ramps. ... duh?

I have a plan. A rollback has a subframe that sits on top of the chassis. This chassis is a tilting 3"x6" boxed steel square. I will build the bed directly on top. I will extend the subframe rails to be ~19feet total. 2feet off the back, ~5feet off the front. This leaves me enough room to use the wheel lift still (the wheel lift has a ball hitch mount as well). I've done the geometry and off the shelf pin 8' pin on ramps will have an angle of 11* with the trucks stands grounded. That's less aggressive than the rollback was originally, technically I could go with longer ramps and ease the angle further, but 8 is about as big as I want to go.

Having pin-on ramps means that I can instead put on a rudimentary tailgate when I remove the ramps via the pin. If I weld on stake side bed pockets this could be a neat little super-light duty dump truck - at max angle it's pretty steep.

BUT, first let's design it.

Questions:

What wall thickness should I get the 3"x6" frame extensions (beige)?

What wall thickness should I get the 2"x4" rails (purple)?

How much of a gap should I put between the 2x4 rails?

What thickness should I get the deck plate steel?

Is 11* too steep of an angle for race cars? What's ideal?

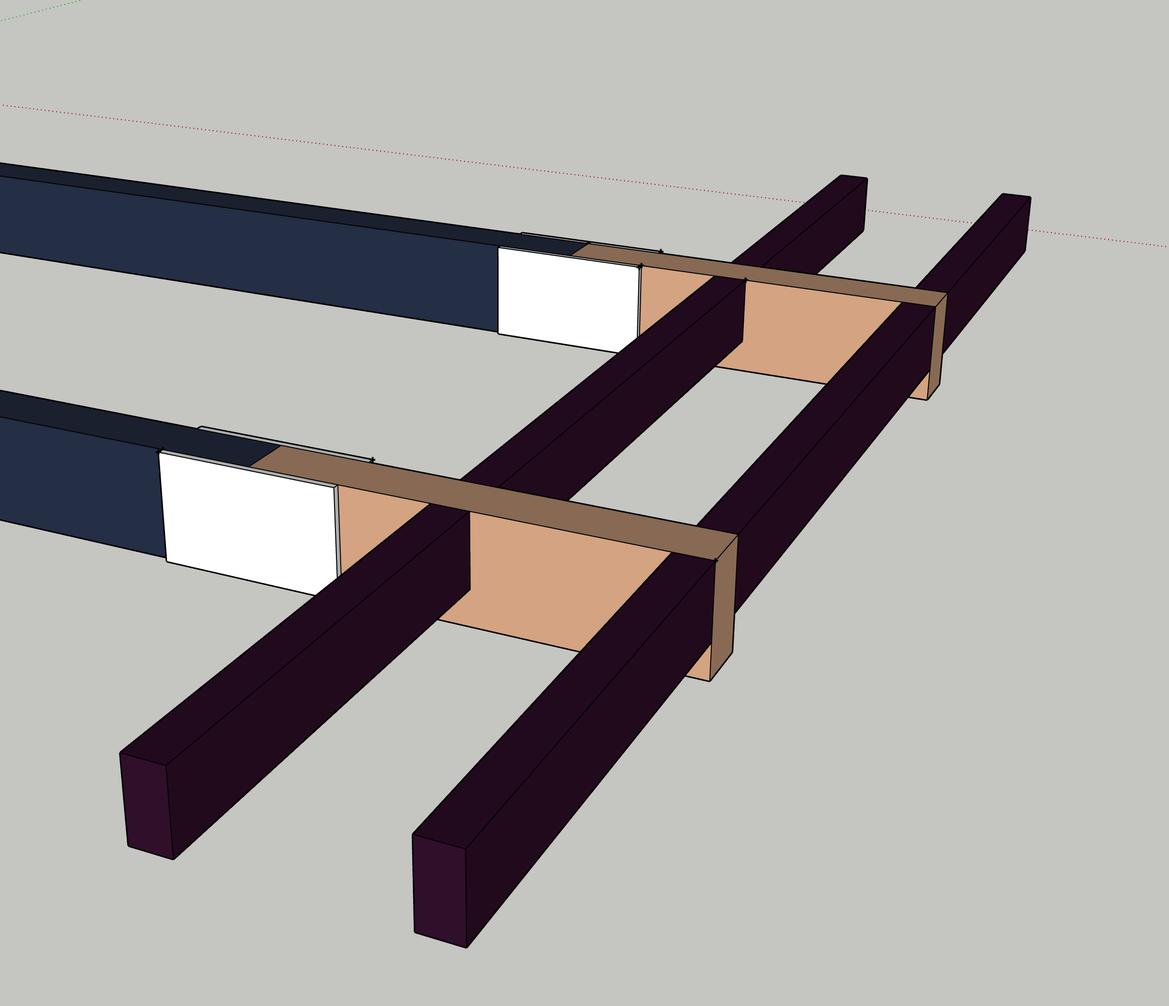

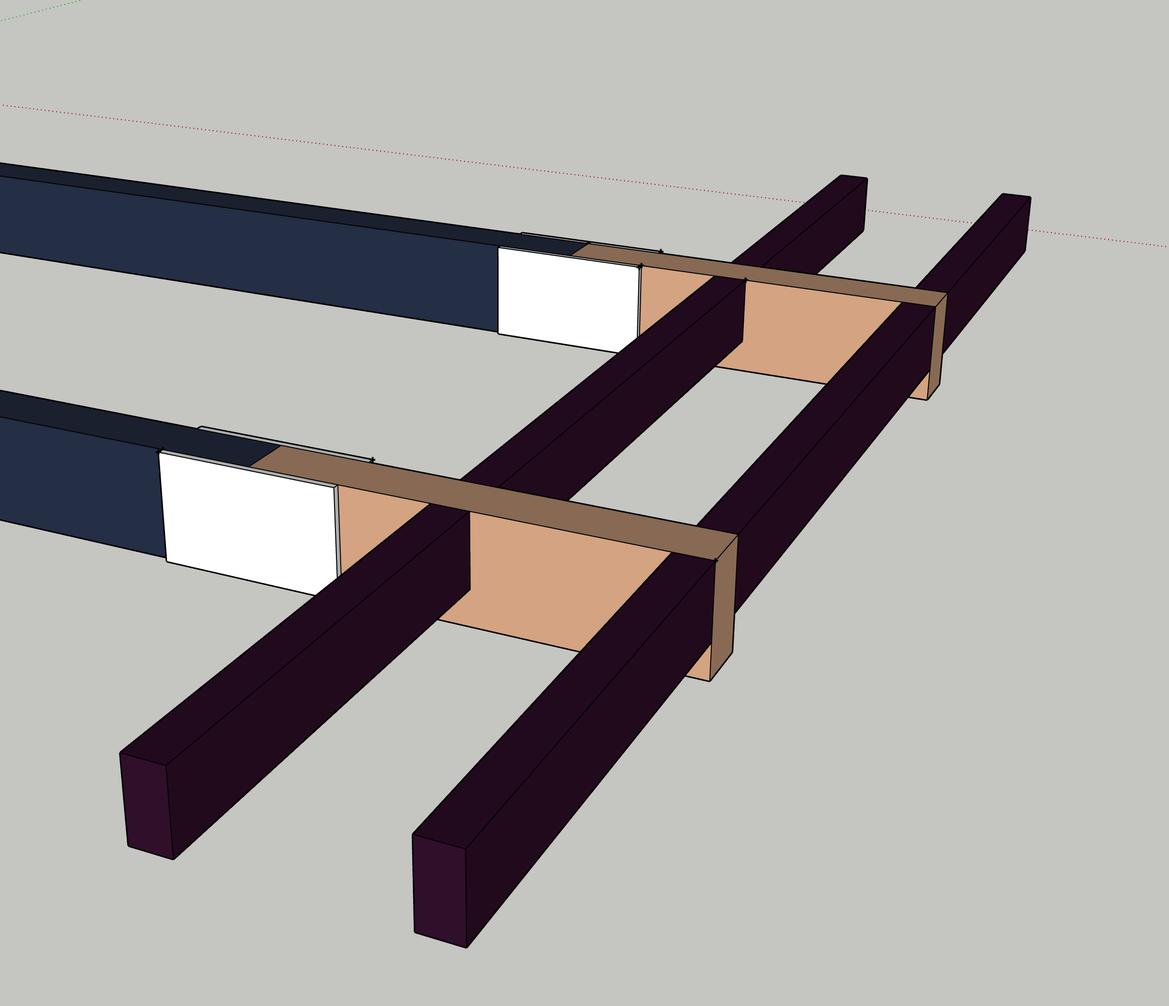

It looks like this:

The basic plan:

Blue is the original 3x6 frame rails

Purple 2x4 frame rails

beige 3x6 extensions

white plates

Note: I'll have a spare set of hydraulic lines because of the ram being removed. Can anyone think of anything nifty I could do with that....?

I've seen lots of rollbacks in scrap yards/junk yards. With the price of steel nowadays(all-time high), I would look for a bed and adapt it to fit before I set out purchasing steel and welding one together. I just purchased 180' of DOM tubing for 2 rollcages that I have to do and it was ridiculous!!! Nearly $1000 for 180' !!!

Would it make any sense to go back to your original plan and convert this into a ramp truck with a fixed ramp bed?

Yep, I've started pricing steel. I could adapt a bed, but this is cooler I think. Are you guys saying I shouldn't make a tow truck/dump truck/super diesel?! ;)

Anyone have hints or thoughts on thickness or spacing? I think I'll just try to dig up some car trailer blueprints I guess?

Shooting from the hip I would think 1/4" steel if you want something really beefy. Otherwise 3/16". When I built my car trailer it was all 3/16" but some people go down to 1/8" in most areas. How beefy do you want this thing to be?

Deck thickness largely depends on the spacing of your framework. In my opinion, 1/4" is way too thick. I'd be looking at standardish (1/8"?) diamond plate.

I'd do 3/16" thick on the 3x6 but would consider what the existing frame rails is and maybe go with that.

Same on the fish plates. 3/16" Maybe look at how 'they' splice frames. Some people don't like a vertical slice and prefer an angle.

2x4 would be 11ga probably, but somewhat dependent on what the floor is going to be.

Steel prices couldn't be higher (well they can and might be).

I was paying .38 cents/lb 6 months ago for plate. Now it's 1.03/lb.

I might consider 4" channel instead of 2x4 tube. Weight will be similar, it will be cheaper. It won't rust from the inside out.

If well supported I'd use 11ga treadplate for the floor. You could also consider heavier where the wheels roll and/or thinner in the center. (or removable panels down the center.

Your gonna do a build thread, Right? I know where a '68 Chevy one ton is that I think would make a cool ramp truck.

Totally derailing the thread for a minute:

Are you eliminating the slide function and keeping the tilt function?

I can think of a dandy use for the spare cylinder. I want to build a deck-over box trailer that lifts to dock height. Take an old equipment trailer or a high-boy RV frame and drop a 26' box from a box truck on it with a ram to lift the tail to dock height.

Take this:

Add this:

and make it do this

In reply to Curtis73 (Forum Supporter) :

Indeed - I'm probably going to "delete" the giant slide ram. I wish I could think of something clever to do with the control, maybe a hydraulic arm?

In reply to jamscal :

Solid advice, I really like the channel idea.

For spacing on the channel I might try and dig through some trailer blueprints or check spacing on other trucks - I'm just unsure of what's overkill, especially considering those two center rails are BEEFY so I think a lot of the strength will be in those.....

accordionfolder said:

In reply to Curtis73 (Forum Supporter) :

Indeed - I'm probably going to "delete" the giant slide ram. I wish I could think of something clever to do with the control, maybe a hydraulic arm?

World's largest log splitter?

Four-corner stablizer jacks?

Nope... I got it... DIY GRM Cyclone:

In reply to Curtis73 (Forum Supporter) :

Lol, no I meant what I could do with the now "open" controls on the truck. Like I have a hydraulic channel with nothing hooked up to it so I could technically add another winch or maybe an arm?

Curtis73 (Forum Supporter) said:

accordionfolder said:

In reply to Curtis73 (Forum Supporter) :

Indeed - I'm probably going to "delete" the giant slide ram. I wish I could think of something clever to do with the control, maybe a hydraulic arm?

World's largest log splitter?

Four-corner stablizer jacks?

Nope... I got it... DIY GRM Cyclone:

This, but with NA Miatas.

I'm beginning to suspect we've lost the plot here

In reply to accordionfolder :

Have you considered a mod to a roll off?

I've not looked into the design/work involved by my brother and I talk about it every now and then. I have seen a lifted pickup that had a box that would roll back and drop to the ground for loading things into. This strikes me a ideal for a low race car with aero as the deck thickness is how high off the ground it would be. Deck sits flat or very near flat on the ground for only a 6" rise or so to load a car. Strap it down and the hit the hydraulics to raise and pull the deck back up onto the truck. Roll off dumpster bin truck type mechanism would probably work.

Edit:

This looks to be the simplest design I can find pics of: Southland Hooklift RollOff Trailer | Tait Trailers

accordionfolder said:

In reply to Curtis73 (Forum Supporter) :

Lol, no I meant what I could do with the now "open" controls on the truck. Like I have a hydraulic channel with nothing hooked up to it so I could technically add another winch or maybe an arm?

Maybe a hydraulic lifting crane to get heavy stuff on and off the deck?

In reply to stafford1500 :

That's what I was thinking of - might be kinda nifty...

In reply to asphalt_gundam :

I think that's probably more moving parts than I want to get into, but a pretty fun idea.

So on the note of fish plates and frame joining - it's covered somewhat on "body builder" frame truck manuals like so:

https://www.ramtrucks.com/BodyBuilder/service/Image?imageId=MtQrP%2FFqLY5r%2Fest8MtGjGgHzAHGUTU0WB3rWuqSY7YmQ2vEhuBWBHwE0oZie3eN%0A

https://www.ramtrucks.com/assets/bbg/pdf/2016/van/docs/vf/far.pdf

https://www.gmupfitter.com/pages/best-practice-manuals

https://www.gmupfitter.com/files/media/photo/843/2018_Chassis_BstPrac_093017.pdf

Which I found from the last post of this thread:

https://www.ford-trucks.com/forums/1608787-1991-ford-f450-fsuper-duty-frame-repair-plan-with-hd-illustration.html

I think the good news is I'm not doing this to a "floating" truck frame. It's largely just resting on the stock truck frame except in the relatively rare event of loading/unloading (since this is personal use vs professional).

Fish plates we do at work (big industrial stuff) tend to be full width of material, same thickness, and have pointed ends (radiused) after the "box" section. Kinda like <=> if the equal sign matched up to the ends of the vees. On some others its the opposite with >=< kinda thing going on with the equal sign at full height to the tips of vees.

In reply to asphalt_gundam :

That aligns with I've read. I've read in various places that welding the very leading edge leads to stress risers that will crack and that it should be made out of the same wall or thinner to avoid being stronger than the frame itself (which also leads to cracks).

I really want to get an engineer to go over my plans ... are they on fiver? ;)

Here's what to do with your extra ram.

In reply to Robbie (Forum Supporter) :

lol, I'm down for the engineering side/neat side, but that does seem like an expensive and complicated way to avoid ramps on a vehicle with no overhang.....

The irony of my last statement is NOT lost on me.

Can anyone find a close up picture of how a stake-side bed pocket looks on a truck like this??? I'm honestly having a tough time finding anything, ha.

I thought I'd make pockets roughly in lumbar 2x4 sizes(i.e. 1.5x3.5 or whatever it is), but that looks like some kind of square lumbar? Are bed stakes usually some other size?

https://www.etrailer.com/Tie-Down-Anchors/etrailer/HW03-080.html

THIS is what I'm going for roughly when in "truck" mode, but then I can pin on long ramps on for "car" mode.

accordionfolder said:

In reply to Curtis73 (Forum Supporter) :

Lol, no I meant what I could do with the now "open" controls on the truck. Like I have a hydraulic channel with nothing hooked up to it so I could technically add another winch or maybe an arm?

My selfish brain is still going toward... "hmmm, he may have a used cylinder for sale"

Does the truck have onboard air? You could rig up a hydraulic motor to a compressor/tank. Handy for a dugga-dugga and inflating tires. Kinda expensive and complex when you could hang a York off the belt drive.