Ok somthing went compleetly wonky with this post.

Original post deleted? I guess you checked the capacities of compressed air tanks vs. how much air an engine sucks in.

Something like KERS using compressed air could make sense.

Are you then running into a problem with the drag or hp it takes to run a compressor?

Or maybe use an old York a/c to charge a tank then use it in 1/4 mile increments?

ebonyandivory wrote: Are you then running into a problem with the drag or hp it takes to run a compressor?

Well my idea is that, like KERS, it would charge on deceleration so it doesn't cost you any power to run.

In reply to motomoron:

At what psi then? Were talking high volume, low pressure vs. high pressure storage then regulated to correct psi?

I was first thinking of if you could use some sort of tank that would give a very short boost period say 2-4 seconds for off the line acceleration but then i did the math and realised it would not relly be practical. Then I got thinking about using compressed air to assist in spooling up a turbo off idle. I think I have seen this discussed before but again not sure on if it was actually practical. I was editing my post and things went weird. I did not mean to delete it but. .. . Probibly did. The main computer in my home died and I am on an old laptop so things are kind of slow and waht not I bet I clicked before it loaded compleetly.

Then I

What am I missing about highly compressed air spooling up a big turbo like a high-stall converter. With enough storage, could be good for 2-3 minutes without the heat removal issues.

Still have to add fuel though...

Preheat the air going to the turbine so you don't get thermal shock from hot turbo + extremely cold air, then cooled turbo + hot exhaust?

GameboyRMH wrote: What is it that compels people to run compressed air through PVC pipe?

It's cheap and they haven't seen the shrapnel from a PVC explosion yet?

Late GRMer, swarfalot, was trying to get something working, using an air amplifier.

motomoron wrote:GameboyRMH wrote: What is it that compels people to run compressed air through PVC pipe?Oh come on. It was at something under 20 psi in pipe rated for 400 psi which has safety factor beyond that.

PVC is not rated for pressure applications. OSHA specifically bans it's use in pressure situations due it's danger of explosion.

ABS pipe is rated for pressure applications.

Never use PVC for positive pressure situations. It's not worth the cost savings.

motomoron wrote:Fueled by Caffeine wrote:For less than 20 motherberkeleying psi, I'm absolutely going to override a blanket OSHA spec if I was looking to plumb some 2" air lines from my engine bay to the 2 huge, freakin' wound-fiberglass pressure vessels in the back on my 80's Dodge Daytona. But I was referencing ~someone else's car~ and ~what they had done~. If you said "I'm planning on running air lines in my garage/shop. Can I use PVC?" I'd say: "No! It's not appropriate for long continuous pressure applications and has exhibited a tendency to catastrophic failure. The best thing to use is black iron pipe, and put a drip leg every place there's a drop, and slop it back to the compressor" and "If you have lots of money the Parker stuff is even batter" But If you asked "I need to pipe a LOT of air at no greater than 20 psi, and it's got to be challenge priced" I'd say PVC in a heartbeat. Period.motomoron wrote:PVC is not rated for pressure applications. OSHA specifically bans it's use in pressure situations due it's danger of explosion. ABS pipe is rated for pressure applications. Never use PVC for positive pressure situations. It's not worth the cost savings.GameboyRMH wrote: What is it that compels people to run compressed air through PVC pipe?Oh come on. It was at something under 20 psi in pipe rated for 400 psi which has safety factor beyond that.

http://www.wave3.com/story/17113807/explosion-at-fairdale-factory-injuries-reported

Fueled by Caffeine wrote:motomoron wrote:PVC is not rated for pressure applications. OSHA specifically bans it's use in pressure situations due it's danger of explosion. ABS pipe is rated for pressure applications. Never use PVC for positive pressure situations. It's not worth the cost savings.GameboyRMH wrote: What is it that compels people to run compressed air through PVC pipe?Oh come on. It was at something under 20 psi in pipe rated for 400 psi which has safety factor beyond that.

I don't know about OSHA, but I can tell you that PVC piping is used extensively in pressure application in the water treatment world. Heck, a few years ago, I worked on a local municipal water treatment plant where absolutly all the piping was PVC with pressures up to about 120 psi.

Having had a PVC piping explode in my face, I know it's not fun, but it exploded from a machining experimentation, and it did so because the piping had been exposed to UV rays. UV exposition is what makes PVC shatter. In its as extruded form, its resilience is very good. Similar to cast iron pipes.

this thread make me reconsider my choice to make a air cannon out of PCV a few years back that we charged to 150 psi and held on our side... ![]()

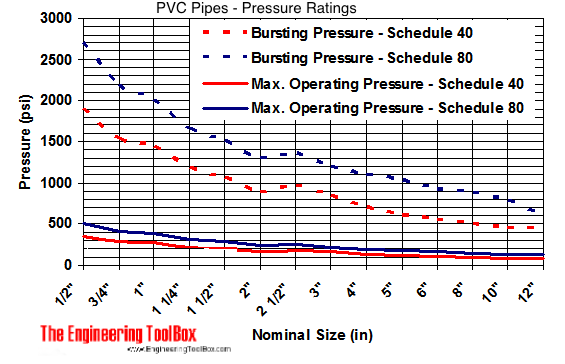

Here is your pressure chart for PVC pipe. Not sure what the mechanics of the failure are, but if it bursts containing liquid it splits and the liquid sprays out. If it bursts while containing air or a gas it shatters and pieces go everywhere. You can see by the chart that there is a 3 time safety factor, but the problem (I think) is that PVC, especially white colored pipe exposed to sunlight gets brittle and the burst point goes way down. And of course, if an object strikes a brittle piece of pipe in, say a shop, it would be like a fragmentation grenade being set off. I once connected an air hose to a rusty quick coupler which snapped off. I had rust flakes embedded in my hand for months.

Here is your pressure chart for PVC pipe. Not sure what the mechanics of the failure are, but if it bursts containing liquid it splits and the liquid sprays out. If it bursts while containing air or a gas it shatters and pieces go everywhere. You can see by the chart that there is a 3 time safety factor, but the problem (I think) is that PVC, especially white colored pipe exposed to sunlight gets brittle and the burst point goes way down. And of course, if an object strikes a brittle piece of pipe in, say a shop, it would be like a fragmentation grenade being set off. I once connected an air hose to a rusty quick coupler which snapped off. I had rust flakes embedded in my hand for months.

Trying again to speak specifically to the original poster's concept. I have a decent understanding of ram air on the basis of many years of road racing Japanese inline 4 motorcycles, and more recently, 3 seasons of road racing a car which incorporates a ram air snorkel which in theory pressurizes the airbox on the I-4 motorcycle engine which powers the car.

In both cases these are normally aspirated applications, but the challenge is materially similar to that proposed at the beginning of this thread: During times of low boost - or in my case, low vehicle speed - would it be practical to to use the release of compressed air to simulate/substitute boost - in my case ram air.

There are dynos for ram air sport bikes with 150mph airspeed fans which will provide a reasonable simulation of real-world performance. I use a piggyback ecu on my race car which we map at the track so the aerodynamics affecting flow around the snorkel are in play. If you point a leaf blower at the snorkel but don't have 100-145mph air entering the side ducts and extracting engine bay air out the back of the body between the rear body lip and diffuser, you're likely getting better pressurization than you do in real world use.

Having seen a turbocharged car that had a fairly elaborate and well-developed "boost continuation" system, it's evident that to accomplish this with air stored at boost pressure - the only way to accomplish this without expending additional energy at some point in the process...

(and please, before shouting me down that a a giant compressor will provide infinite air at infinite pressure, it require energy to compress that air. I'm attempting to speak to a real-world solution, not theory)

Is to furnish a reservoir of sufficient volume to supply your needs for X flow multiplied by the necessary duration. I'm not aware of how the matter of dumping a large volume of compressed air into the intake track was accomplished. Perhaps the stored volume was plumbed in parallel with the pressurized side of the turbo piping. I'm not a turbo plumbing expert.

But on a dedicated autocross car, it seemed to always be putting down solid power with no lag.

If one's requirements couldn't include simply adding volume to the pressurized size of the intake tract, one would need a lot of air.

Working in imperial because that's where I generally spend my days:

Let's say 2 liter engine at 5000 rpm - that's 353 cu/ft/minute at atmospheric pressure. As a comparative measure I have a medium-big home shop compressor, a 240v, 5hp, 4 cylinder, 2-stage, 60 gallon unit. In real world use it can keep up w/ close to 20 cfm at 120 psi. I have an Echo leaf blower powered by a 23cc 2-stroke engine - it blows an advertised 135 mph and 441 cfm.

Speaking from my profession as mechanical designer, "engineer", machinist fabricator for R&D, where I solve kooky stuff like this every day and with the best likelihood for success - the leaf blower is much closer to what you're trying to do - again, real world - than a compressor.

If this is a ~theoretical~ application and the objective is to supply short term pressurized air to a forced-induction engine while it's in low boost state, any supply that meets the calculated volume and duration requirement will do.

My point is the criteria for the selection of the type of pump best suited to the application.

Also - Here's a short clip of a compressed air potato cannon that'll fire a frozen core of potato through 1/2" plywood, or most likely into a geosynchronous orbit if you aim it normal to the earth's surface.

We've been shooting it for ages. I'll probably put an eye out.

You'll need to log in to post.