My LS-powered MG project is starting to move again. Slowly. I've decided to start work on the rear end, and start by pulling the axles so I can alter the bolt pattern.

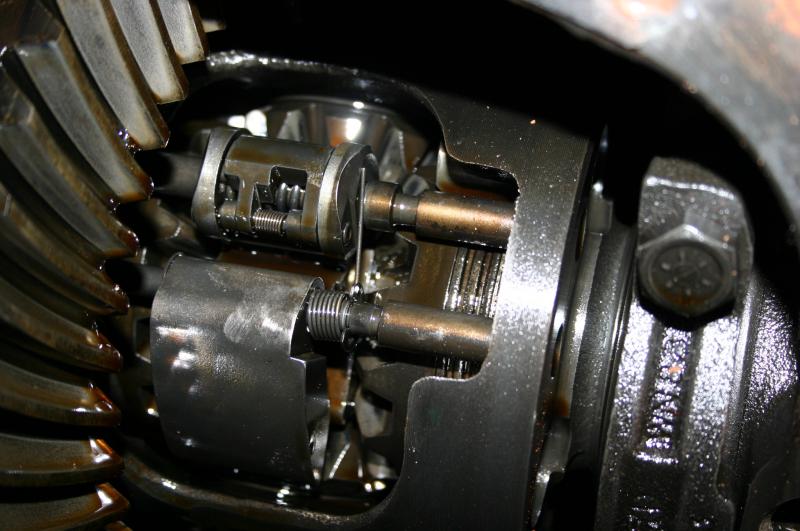

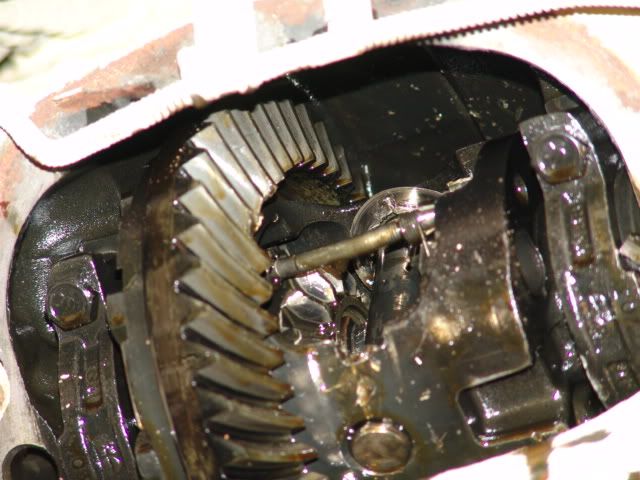

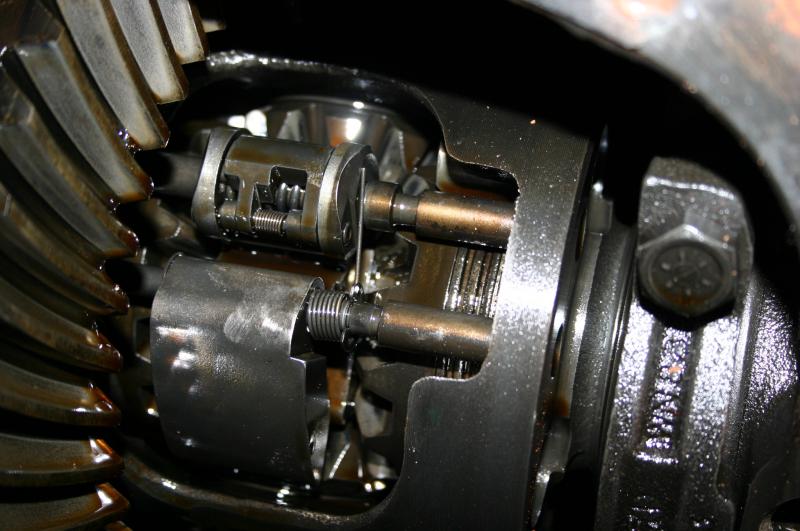

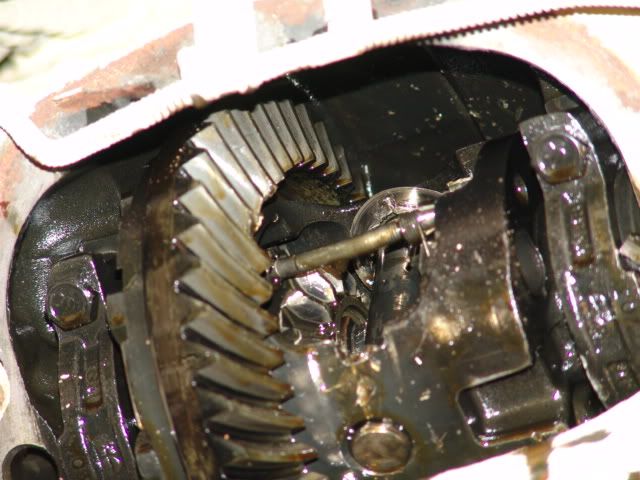

This rear is from a 2000 S10 Blazer with 4WD. By doing the usual "turn one wheel and see what the other one does" test, it acts open. But check it out - it's a little more complex. There looks to be a clutch pack in there, and an interesting little mechanism.

That upper cylinder spins when I turn one wheel. It can open up and is spring loaded - so I'm guessing that when it spins faster than a certain speed it locks the bigger pawl and brings the clutch pack into play. Is that what I'm looking at here, a clutch pack that only activates when there's more than a certain level of one tire fire?

Also, who knows the magic secret to removing the axles on a GM 10-bolt?

Looks like a locker to me.

Here's GM's take on it--

Locking Differential Description and Operation

The locking differential consists of the following components:

• Differential Carrier

• Locking Differential Spider

• 2 Clutch Disc Sets

• Locking Differential Side Gear

• Locking Differential Clutch Disc Guide

• Differential Side Gear Shim

• Locking Differential Governor

• Latching Bracket

• Cam Plate

The locking differential allows for normal differential function as indicated in the standard rear axle description. Additionally, the locking differential uses multi-disc clutch packs and a speed sensitive engagement mechanism that locks both wheels together if one wheel spins excessively during slow vehicle operation. Under light loads, the clutch plates alone tend to lock the axle shafts to the differential case, and therefore locking to each other. This is due primarily to the gear separating the load developed on the right clutch pack. This induced clutch torque capacity resists motion between the side gear and the axle differential case. The differential allows the wheels to turn at different speeds while the axle shafts continue to transmit the driving force. Heavier throttle application will cause an axle speed difference. This action starts the full-lock feature of the unit. You can accomplish full-lock through the use of a heavyweight governor mechanism, a cam system and a multi-disc pack. The flyweights on the governor mechanism move outward in order to engage a latching bracket whenever the wheel-to-wheel speed varies by approximately 100 RPM or more. This action retards a cam, which, in turn, compresses the multi-disc clutch packs, locking both of the side gears to the case. The 100 RPM wheel-to-wheel speed allows for cornering with the differential lockup. At vehicle speeds above approximately 32 km/h (20 mph), the latching bracket overcomes a spring preload and swings away from the flyweights. At this vehicle speed or greater, the differential is designed not to lock since added traction is generally not needed. The axle parts of the vehicles equipped with the locking differential are interchangeable with those equipped with the conventional differential, except for the case assembly.

As for removal, look at the rod holding your two outer spider gears in place. You'll find a bolt at one end, remove that bolt, the rod slides out.

With the center rod removed, you can slide the axle shafts inboard ~1/2 inch and remove the c-clips that are retaining them.

Its easy once you spot what you're looking for.

Looks like the Eaton limited slip to my eyes. Interesting units those! They are an open unit until the speed difference gets too high, then they engage the clutch pack.

I rather like the design and functionality. I've got one in my Volvo 740, maybe.

Dashpot

New Reader

5/28/09 6:04 a.m.

foxtrapper wrote:

Looks like the Eaton limited slip to my eyes. Interesting units those! They are an open unit until the speed difference gets too high, then they engage the clutch pack.

I rather like the design and functionality. I've got one in my Volvo 740, maybe.

I put a lot of miles on Blazers with those things back in the 80's. As I recall, they do act like a locker and the clutch pack barely dampens the slam of the pawl engagement. Pretty crude. I wouldn't think they would be a very friendly companion on a road course.

RobL

Reader

5/28/09 9:11 a.m.

I had one. They suck in all conditions.

Imagine this: You are stuck in the snow. You give it some gas to get moving and the one wheel drive starts spinning a little. It engages the other wheel with a thump and now both wheels are spinning and you are sliding down the crown in the road. You let off the gas so that the wheels catch again. Rinse. Repeat.

The problem is that you need to spin a wheel for it to engage so it is useless on tarmac.

Tom Heath

Production Editor

5/28/09 9:29 a.m.

I know that unit, blizazer has it pretty much dead on. Should be stamped with "AAM" on the third member, probably assembled in Buffalo, but possibly at 1840 Holbrook Avenue in Detroit. Should be plenty durable and even quiet unless you break the marriage of the ring and pinion. They're rolled together during the assembly process with a special mildly abrasive orange goo, and the ring and pinion stay together until final assembly (and beyond.)

The diff lockup should occur when wheel speeds are 100-150 rpm apart, each one is checked on the line to ensure that is the case. Not really an ideal setup for a sporty application, but works well for the off-road types.

In a former life, I was a supervisor on the line where they were assembled.  Don't miss that work.

Don't miss that work.

From production manager to production editor... Living the life.

Thanks for the details, that's interesting stuff. I can see how they might be considered useful offroad, and I can see how it wouldn't be much use on the road.

I have an LSD in my Camaro donor - I think it's a clutch pack without weirdness. The original plan was to swap it into this housing. Looks like I'll stick with that plan then.

Another point, I can't say that they hold up to too much abuse. Or at least thats the case for the first one that I had. After mine failed, I popped the cover and watched all sorts of cool stuff fall out.

Keith wrote:

Thanks for the details, that's interesting stuff. I can see how they might be considered useful offroad, and I can see how it wouldn't be much use on the road.

Mmm, depends on how they are set up. In Volvo's, they are very gentle on engagement. You drive around with an open differential until you romp it, then you gently start spinning both tires unless you overcome the clutch pack.

I'm not disagreeing that the trucks are set up brutally (no personal experience), but the cars with the same unit are not so brutal.

Also, if you put oversize tires on, then get a flat and use the stock size spare it'll lock up at around 75 and try to yank you into the next lane. UT GEO field camp found that out the hard way one year, only lost a side mirror.