Despite my best efforts I finally got around to installing the front suspension in the MS3 this past weekend with part's I've had laying around for two years. I knew there was a reason I bought all the different parts but it took me a bit to piece together why exactly I did things that way.

Anyway, Koni yellows don't have the hex at the top for a key they've got flats cut around the adjustment screw. The problem is the moment you add camber plates into the equation the pillow nut covers up the flats.

Like so:

I'm fairly certain I've hit full run out of the pillow nut to the strut but I'd really like to actually torque it for peace of mind.

The problem is that the piston rotates inside the strut body when I attempt to. I've already tried holding the adjustment screw (bad idea to get to 45 ft-lbs so I stopped) and taping the jaws of my Channellocks then using an old exercise band to grab the piston so not to mar it (still rotated). I'm planning on trying a rubber oil filter wrench tonight.

Anyone have a sweet trick stop the piston from rotating without manufacturing a screw down collar? (actually, I wonder if I can buy one).

Thanks.

Are you sure everything is installed correctly? That does not look like enough thread engagement to me, and if the top "hat" spacer is similar to most that I've seen, it's riding on the threads and will probably clank around.

In reply to ¯_(ツ)_/¯:

Yea I took it apart twice after I couldn't get it to torque the first or second time (or how I spent 4 hours installing front struts.) The pillow ball nut is threaded all the way through and goes through the pillow ball bearing to engage the strut. When the nut screws onto the onto the threaded portion of the piston without the camber plate it left about that much room. So I'm fairly confident that's how it's supposed to look.

Corksport's supplied instructions for stock shocks.

I suppose I could cut the flats off the pillow ball nut and use the thinner supplied Koni nut. That might give me enough room to hold the piston. I'd prefer not to though.

Can you weld a cap screw to the top of the strut so you can get the nut on still but able to put a allen wrench on it?

I would NOT be comfortable with that little thread engagement AT ALL.

Is there some spacer below the pillow block to the shoulder of the shaft?

(have an engineering degree, works in safety setting)

Normally you would use a impact on those. But not yet, it looks like the nut is not engaging enough threads, something isn't fitting up. Is that a self locking nut that just isn't threaded on all the way yet, or is the camber bearing assembly to thick?

In reply to MulletTruck:

Not really enough room inside the nut to get anything in there. The Koni 8mm flats very nearly contact the threads.

That said instead of cutting off the machined flats I might be able to drill them out to get a thin wall socket in there and use a crowsfoot... Guess I'll need to measure.

In reply to Apexcarver:

There's quite a bit of engagement. That was my first thought too hence why I took it apart again and again. We require at least four threads protruding in aviation so it made me nervous too. The pillow ball bearings are 3/4 of an inch thick + the flat and the machined flats on them. There's probably an inch of engagement at this point just no thread protrusion as you'd expect to see.

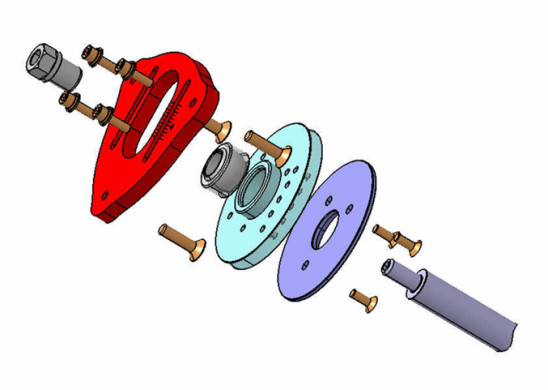

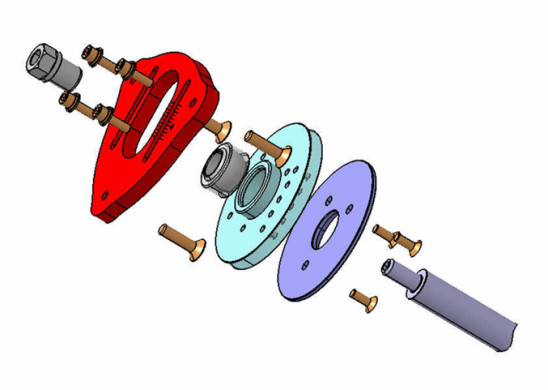

They look like this: just for the MS3 rather than the regular 3. You can see the bottom of the sleeve is threaded and how it extends through the pillow bearing with the flats up on top.

And like this with stock shocks (stolen):

Is it just a simple flat on the bottom of that top nut? If so I'd see what it looks like using the nut supplied with the Konis with a washer under it.

In reply to ¯_(ツ)_/¯:

It's not. It's a threaded sleeve that extends through the pillow bearing sitting flush with the bottom of the pillow bearing and has machined flats on the top of it. If I blow it apart again for modification I'll take pictures. The simple Koni nut is very low profile. These provide quite a bit more engagement.

In reply to The0retical:

OH!

If threaded all the way through, I think that's a lot less scary than what most of us thought we were seeing. I've had good luck grabbing the strut shaft by wrapping an old serpentine belt or chunk of inner tube around it a few times and grabbing that with vice grips in similar situations (adjustable HotBits, for example, have no provision for keeping the shaft from spinning).

I didnt realize there was a threaded sleeve beneath the flats of the nut. I dont care for the design, but my concern is much reduced.

Toebra

Reader

2/13/17 1:26 p.m.

That long threaded nut is the same setup on my Bilstein coilovers, sort of shaped like an inverted top hat. No way to grab the top of it, so you have to grab the shaft to keep it from spinning and tighten the nut with an impact wrench. Still don't have a very good way to keep the shaft from spinning.

Blue loctite would not be a bad idea for that top nut.

In reply to Toebra:

At least it isn't just me although I sure felt like it when I went looking for the issue. Impacts make me leery for installing things when I have a specific torque called out, but I tend to be a bit of pansy in that respect. If that'll do it I guess I have an excuse to buy one now.

84FSP

Dork

2/13/17 8:13 p.m.

Impact for the win. Learned this years ago the hard way with that puny hex head on the top of VW Bilsteins.

RedGT

HalfDork

2/13/17 9:08 p.m.

I wouldn't tell you to hit the top of a Koni with an impact...but better tightening than loosening I guess. Definitely don't use it to loosen for removal later on.

Miatas have the same issue on Koni installations - no flats or hex holding available and in some cases an extended nut like yours too. I hold the shaft with a section of heater hose folded over 4-6 times plus vice grips.

That top nut on most struts, the only way to actually tighten it is with a impact wrench.

With a air impact, you could adjust the air pressure, to avoid breaking anything.

I think once it is fairly snug, you might be able to then use a torque wrench.

But if there are enough threads engaged, I have just hammered that nut with the impact.

I don't recommend it if it can be avoided but an impact with the air turned down or a torque stick if you have a set is probably the only way to do this one. edit: Or put a wrench you don't love on it and hit the end of the wrench with a hammer until the nut has moved a satisfactory amount.

With a lathe (or patient and skilled die grinder work) you might be able to open up the ID of the hex section of the nut big enough for a socket without weakening it too much. The hex end of the nut isn't really doing anything, so if it's kept strong enough to be torqued to spec and removed there's enough meat on that end.

BrokenYugo wrote:

I don't recommend it if it can be avoided but an impact with the air turned down or a torque stick if you have a set is probably the only way to do this one. edit: Or put a wrench you don't love on it and hit the end of the wrench with a hammer until the nut has moved a satisfactory amount.

Since I don't have an impact and torque stick set so I did the latter of the two suggestions last night. 19mm wrench and tap with a 16oz ball peen until it rotated about 3 flats. Then ghetto torque stripe (sharpie on the steel surface so I can clean it off with alcohol when I do get a torque stick). I'll probably regret that when I go to take them off but that's the way it goes.

I was able to hold the strut with a strap wrench and get my torque wrench to click at 10ft-lbs but not any higher. Thanks for everyone's help.