I found myself filing out a keyway for a part for my Bridgeport Mill rebuild last night, and a realization hit me: My files are absolute garbage. I own one big square one that doesn't really have any teeth, as well as a set of tiny thread files. That's pretty much it.

So, here are my questions:

- What assortment of sizes/types of files should I have in the shop?

- What brand(s) should I look for, or are they all the same?

- What roughness/grit/etc. should I be buying?

Mr_Asa

PowerDork

7/28/21 8:11 a.m.

For a keyway, you want a keyway broach. They can be expensive. Enjoy that rabbit hole, they are a very interesting tool set.

For files there is an entire article worth of information out there. Coarseness levels, shapes, single-cut, double-cut, size, etc etc

I'll let someone else get a better response typed up as I am on my phone, but the most common ones I use are a big wide bastard file (technical name,) same width fine file, triangular in bastard and fine, and the little micro files that you get 5 to a pack and are big enough to not quite let you clean up a set of points with. All of mine are double-cut unless I'm working with aluminum, then I go single-cut and rub some chalk on the file face to prevent the aluminum from sticking.

Duke

MegaDork

7/28/21 8:13 a.m.

All I know is that you want an assortment of bastard files.

Trent

PowerDork

7/28/21 8:18 a.m.

A good sharp file is an amazing tool. A dull one is frustrating and leads to people thinking files are worthless.

Single cut mill bastard and a double cut mill bastard will be your main workhorses. Then collect the different sizes you think you will use.

Swiss pattern files are awesome but they aren't what you will keep next to you for a touch up on the lathe or a quick deburr.

Nicholson file quality is on the way back up. Almost to where it was 20 years ago.

If you wanted to sink tons of cash into it, Grobet Swiss made files are absolute jewels.

I used random junk files my whole life and then a couple of years ago I got a nice set of Simonds files. Wow what a difference.

I look forward to this article :)

In the first year of my apprenticeship we had to make 123 blocks, minus the holes, out of a chunk of hot rolled steel. It had to be within .002" in every dimension including squareness.

We were only allowed to use files.

I used to think it was a great way to teach you about files, but I think I missed the point. They were teaching patience.

In reply to Mr. Peabody :

I knew a metal working instructor that assigned similar projects to his first year students.

In reply to Tom Suddard :

I also have an assortment of round files.

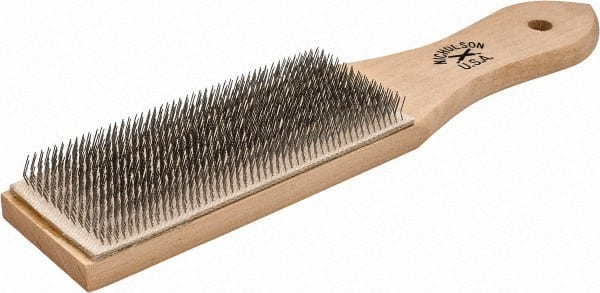

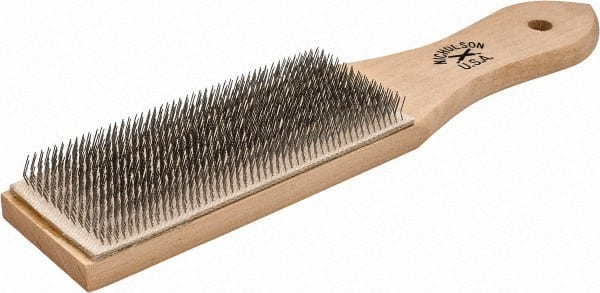

I was thinking the same thing in my garage last weekend as I struggled to deburr some mild steel with the crappy dull files I bought at Harbor Freight 10 years ago while building my LeMons car. They have been dull for a long time. I considered just buying the same set again; for under $10, I got a lot of use out of them, but I thought "nah, let's buy something better." I ended up ordering a Crescent Nicholson 22040HNNN General Purpose File Set (yeah, I prefer the molded handles) and a 21458 File Card. I have no formal training in machining or fabrication, so I'll let the more knowledgeable members of the hive here comment on how well I did, but this seemed like a decent step up in quality and a good alternative to buying more disposable junk to eventually throw in the garbage. The one thing missing from that set is a round file, which has come in handy for me a few times when I needed a drilled hole to be just slightly larger or a little bit oval-shaped.

Jewler's, Rat-Tail in all sizes, All different sizes, Isosceles triangle (not the real name, but super handy for re-instating threads), equilateral triangle (real name, again, unknown).

Like Jumper K said, a good sharp one is awesome. Additionally, when the metal is hot, a la blacksmithing, metal will come off extra quick.

Mr. Peabody said:

In the first year of my apprenticeship we had to make 123 blocks, minus the holes, out of a chunk of hot rolled steel. It had to be within .002" in every dimension including squareness.

We were only allowed to use files.

I used to think it was a great way to teach you about files, but I think I missed the point. They were teaching patience.

I worked with some engineers who were from India (and had Indian ME degrees). They had one class where they were given two plates of steel ~ 6" x 6" x 1.5" and one file. They had to use the file (and only the file) to make one plate into a "U" and one into a "T" and they had to fit together with no gap. And - whatever files they used were only one direction (push away from the user) - if you did a push / pull action (like all of us do) you had to start over with new steel. They had a whole semester to do it.

Really good files will have a plus and minus - on one hand they remove material quickly, on the other hand the shavings are razor sharp and will get caught in your clothes / skin / etc.

Do files have numbers on them like the "grit" number on sandpaper ?

any other numbers or markings we should look for ?

THANKS

Mr_Asa

PowerDork

7/28/21 12:38 p.m.

californiamilleghia said:

Do files have numbers on them like the "grit" number on sandpaper ?

any other numbers or markings we should look for ?

THANKS

I don't think they have individual markings, other than manufacturers. I'll have to check mine.

In general:

I use my file (singular) a lot. I should probably get some good ones.

I bought some Bahco files when I read on a bicycle frame building forum that the quality of Nicholson had gone down the tubes. Nice to hear they've rebounded.

To the extent I've used them, the Bahco seem nice, but I'm saying that from a perspective of no experience and a history of dead, cheap files.

I have an assortment of files. Probably the most used when machining is an 8 inch mill file. I keep one sitting next to the mill, and another next to the lathe. It will do 90% of what you want to do while standing at a machine. The second most used is a rat-tail file. Mostly used for cleaning up holes drilled in sheet metal. I think all of my files are Nicholson brand. They are reasonably priced and they work.

My small files are pretty much all diamond grit. They seem to cut better and don't clog up as quickly. I think I picked them up from the hammer store. I don't use them often.

It's also worth picking up a file card to keep your files clean.

In reply to Mr_Asa :

Hey, I am a big wide bastard

Tom1200

SuperDork

7/28/21 5:52 p.m.

I'm a two stroke guy so I have a selection of rat tail files. I still use them when porting stuff.

https://www.harryepstein.com in Kansas City usually has a good variety of quality files for sale, and their prices are usually good too.

Mr. Peabody said:

In the first year of my apprenticeship we had to make 123 blocks, minus the holes, out of a chunk of hot rolled steel. It had to be within .002" in every dimension including squareness.

We were only allowed to use files.

I used to think it was a great way to teach you about files, but I think I missed the point. They were teaching patience.

Henry Ford had his engineers, as their first task, make a steel ball of a certain diameter out of a square block, using nothing but files.

When they were done, they had to do it again with brass.

Once they completed those tasks, they were allowed to actually work on engineering automobiles.

The reason for this was so that the engineers could appreciate how time consuming high quality machine work could be. Time is expensive, tooling is expensive, close tolerances make for higher wasteage, so he wanted design that minimized the amount of machine work needed so they could crank out more products with less cost.

I have a bunch due to inherited tools, I need to do an audit for worn stuff soon and replace some.

This is fantastic info; thanks everybody! Time to go shopping....