Curtis73 (Forum Supporter) said:

Oh, when you get to proper proportioning, hit me up. Swapping to rear discs without changing the brake proportion is a no-no. Discs take way more pressure than drums to offer the same braking, so just swapping to discs alone will throw about 90% of your braking to the front when you actually want closer to 70%. If your prop valve is one of the aluminum tetris-looking things under the master, it's pretty simple. If not, we'll have to get creative.

Confirmed: aluminum Tetris looking thing under the master.

While I have the solid axle knowledge base assembled, can we talk pinion angle for a bit? Here's how the 6l80 sits in there now. It is just unacceptable low, and leans extremely downhill.

It has room to go up, but it will never be flat. Should I just rebuild the mount as high as I can and deal with it?

Re: prop valve. Good to see the tetris block. We'll have to research it, but there is an easy mod to get more pressure to the rear discs after the swap. If your brakes follow the same basic engineering of most GM parts-bin brakes, you will end up taking that rubber cap off the end, taking the bolt off, and yanking out the plastic valve inside.

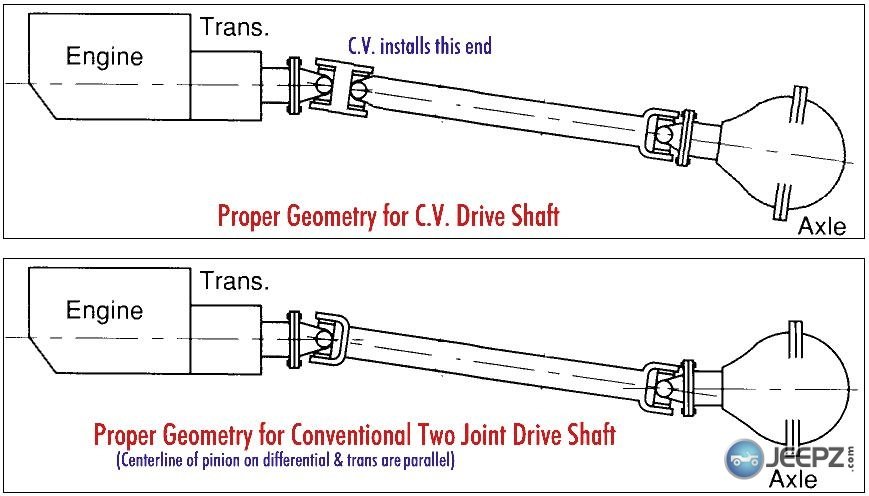

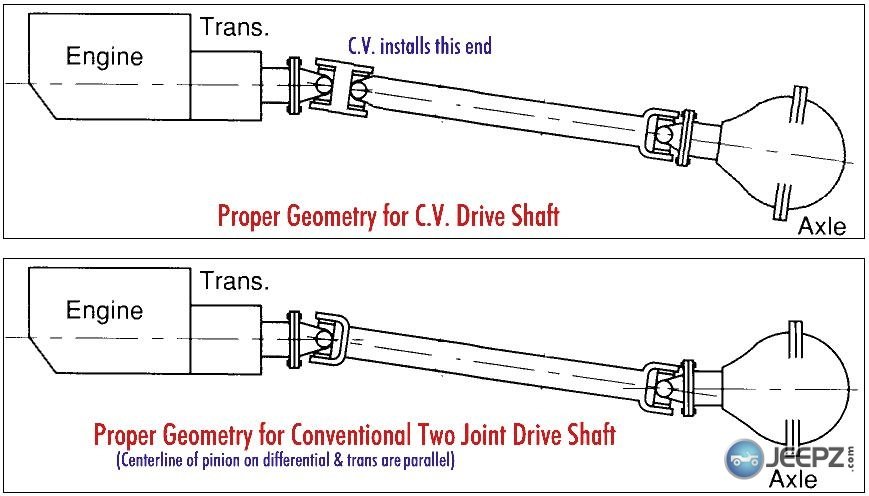

Re: pinion angle. Driveshaft angles need to be equal and opposite. If the output shaft points down 4 degrees, the pinion needs to angle up 4 degrees. That isn't the only important thing. You also need to have the combined angles within a certain range. That 4L80E is too low in my opinion, but I'm not there to see the math.

U-joint angles need to be within a range of about 1-4 degrees. Too little and the bearings don't rotate. Too much and they'll be over stressed. You may need to do some floor surgery to get it up high enough, but unfortunately it will be necessary if you can't get your angles right.

Take a peek at this.

The angle of A must be the same as C, and the difference of B to either of them should be 1-4 degrees.

Curtis73 (Forum Supporter) said:

Yup, looks like an 8.5" 10 bolt. If the cover was almost perfectly round, that's what it is.

That is such a strange discovery since it is a 3/4.

The good news is that (since you mentioned your custom driveshaft anyway) the sky is the limit. The 8.5" will handle a fair amount of power, or a fair amount of trailer, but not both at the same time. Lots of guys put 500+ hp through them on sticky tires and they hold up, but the long, torquey dragging of a heavy trailer can't take tons of oomph at the same time. They are also slightly limited in how much axle weight they can carry. Adequate, but nothing to write home about.

There are plenty of truck 12-bolts out there with the 5-lug pattern, and they're cheap, but there is a reason. The pinion shaft on the truck 12-bolt uses the same as the 10-bolt, so they're not quite as beefy as a car 12-bolt. Still, it would solve the problem of the 8.5"... you would be able to give it plenty of twist, and plenty of trailer, and the bigger axle bearings would carry more weight.

Once you get to the 14-bolt, they are all 6 and 8 lug to the best of my knowledge. The brakes and axle tubes are very different so I can't imagine any parts-bin swaps to get back to 5-bolt.

If you're willing to go 6 or 8 lug, start shopping. If you find one of the 14bFF with the gov-lock differential, use the gov-lock's reputation as being terrible to negotiate the price down and then walk away the world's biggest winner. Gov-locks got a bad name because folks would stuff a truck 12-bolt under their 454-powered drag car, then wonder why they blew up when one slick got a little more traction than the other. For street, towing, and truck stuff, a gov-lock is a really sweet piece. I have pulled apart 14-bolt gov-locks with over 400k miles and the clutches look like new. Gov locks (in case you didn't know) work like an open diff until one wheel spins X amount faster than the other, then a little counterweight and clockspring engages the clutches. On 99% of the vehicles out there, that is a wonderful and reliable thing. In a 750-hp with slicks, they try to launch (a time when it's open), they mash the pedal and one tire breaks traction and spins to the moon before it gets to lock. Then it locks and big explosions happen. Instant bad reputation for something that was just a poor choice for the application.

not wanting to hijack ....Curtis what is the code for the gov-lock? I have recently purchased new to me a 2003 chevy 2500hd duramaxLB7/ZF6 and only one wheel hooks up is this a G-lock?

In reply to 759NRNG (Forum Partidario) :

should be g80 iirc

MrChaos said:

In reply to 759NRNG (Forum Partidario) :

should be g80 iirc

This code is not present in the glove box so here is the dilemma do a I do JY run for a G80 third member or will an Eaton TruLock be the the ticket for my diff?

The code for limited slip differential is G80, but that doesn't tell you what TYPE of LSD you have. RPO codes can be frustrating that way. G80 in a 92-97 B-body often meant a cone/auburn style. G80 in a 3/4 ton often was a gov lock. G80 in a G-body was often a clutch style.

They often follow certain years/bodies, but it isn't always a hard rule. I had a 73 B-body wagon with a gov lock, although I suspect it was added because I found no other documentation to suggest it was an LSD car. Strangely, that car also had the remarkably rare 10-bolt cover, 12-bolt axle.

759NRNG (Forum Partidario) said:

Curtis73 (Forum Supporter) said:

Yup, looks like an 8.5" 10 bolt. If the cover was almost perfectly round, that's what it is.

That is such a strange discovery since it is a 3/4.

The good news is that (since you mentioned your custom driveshaft anyway) the sky is the limit. The 8.5" will handle a fair amount of power, or a fair amount of trailer, but not both at the same time. Lots of guys put 500+ hp through them on sticky tires and they hold up, but the long, torquey dragging of a heavy trailer can't take tons of oomph at the same time. They are also slightly limited in how much axle weight they can carry. Adequate, but nothing to write home about.

There are plenty of truck 12-bolts out there with the 5-lug pattern, and they're cheap, but there is a reason. The pinion shaft on the truck 12-bolt uses the same as the 10-bolt, so they're not quite as beefy as a car 12-bolt. Still, it would solve the problem of the 8.5"... you would be able to give it plenty of twist, and plenty of trailer, and the bigger axle bearings would carry more weight.

Once you get to the 14-bolt, they are all 6 and 8 lug to the best of my knowledge. The brakes and axle tubes are very different so I can't imagine any parts-bin swaps to get back to 5-bolt.

If you're willing to go 6 or 8 lug, start shopping. If you find one of the 14bFF with the gov-lock differential, use the gov-lock's reputation as being terrible to negotiate the price down and then walk away the world's biggest winner. Gov-locks got a bad name because folks would stuff a truck 12-bolt under their 454-powered drag car, then wonder why they blew up when one slick got a little more traction than the other. For street, towing, and truck stuff, a gov-lock is a really sweet piece. I have pulled apart 14-bolt gov-locks with over 400k miles and the clutches look like new. Gov locks (in case you didn't know) work like an open diff until one wheel spins X amount faster than the other, then a little counterweight and clockspring engages the clutches. On 99% of the vehicles out there, that is a wonderful and reliable thing. In a 750-hp with slicks, they try to launch (a time when it's open), they mash the pedal and one tire breaks traction and spins to the moon before it gets to lock. Then it locks and big explosions happen. Instant bad reputation for something that was just a poor choice for the application.

not wanting to hijack ....Curtis what is the code for the gov-lock? I have recently purchased new to me a 2003 chevy 2500hd duramaxLB7/ZF6 and only one wheel hooks up is this a G-lock?

A properly operating gov-lock might slip one tire for 90 degrees of rotation before it engages the clutches, so it is either a busted G-lock or an open diff.

Rumors are all over the place that Dmax trucks all came with LSD and it just isn't true. Check for the G80 code in your glovebox. If you have the G80, then yours is likely broken. For the 11.5" axle used in the Dmax trucks, GM farmed out the gov-lock manufacturing to Eaton and they are known for failures if you push them or frequently "hoon" after lots of aftermarket mods.

The good news is, that same 11.5 AAM in your Dmax was used in Cummins trucks starting in 2003 and the Dodge version got a better, torsen-style LSD. Swap one from a Dodge Cummins and you're set. I think the only parts you would need are the correct bearings to make the Dodge diff fit the GM center.

Pinion angles do not have to be opposite. The important thing is angle to the driveshaft. You can have a trans at 5 degrees and a pinion at 1 degree if the relative angle to the driveshaft is 2 degrees for both. (A thing I had to do for a SBC-swapped Studebaker)

The key is the trans to driveshaft and driveshaft to pinion have to be the same angle regardless of "sign". Making the pinion and trans the same angle relative to the ground will guarantee this, but at high drivetrain angles, this can result in horrible U-joint angles, so you have to knock the pinion down the other way so the U-joint angles become sane.

Alternatively, you can make the pinion to driveshaft angle as straight as practical, and have a driveshaft shop splice a double-Cardan joint in at the front. Then the driveshaft to trans angle won't matter. I fixed a '69 Vette with a T56 this way, the T56 is huge and needed to be dropped down to fit, so the front U joint angle was like 5 degrees and the rear was zero. And the driveshaft is like two feet long in a C3...

In reply to Pete. (l33t FS) :

Disagree. This is only true if one of the U-joints is a CV joint. The point of keeping the pinion and trans at equal/parallel angles is to cancel the phased vibration. Altering one so they aren't equal induces pretty crazy vibes.

You can disagree, but I done did it, and fixed a horrible vibration in the process.

This was actually called out in a Mazda guide for RX-7 road racing. You have to make the U joints both angle the same way in order for the driveshaft to clear the floor., when heavily lowered with a stock tub. (Solid axle RX-7s, not those mongrel Johnny-come-latelys with IRS) U joint angles are VERY important when the driveshaft is spinning at 10,000rpm.

Curtis73 (Forum Supporter) said:

In reply to Pete. (l33t FS) :

Disagree. This is only true if one of the U-joints is a CV joint. The point of keeping the pinion and trans at equal/parallel angles is to cancel the phased vibration. Altering one so they aren't equal induces pretty crazy vibes.

So maybe the fabricator of this trans mount was shooting for that first graphic, because the pinion on the axle pointed up a pretty good bit, so maybe the trans is perfectly concentric with the rear shaft pinion now. Not sure. Will check

Axles are 30 spline. Any idea if this will match up to any newer setups?

A little RockAuto research:

for 1993 G20

for 2003 silverado 1500

I want to believe 3/8" is close enough, but I'm sure it's not.

Edit:

This is probably the ticket. 30.75, 30 spline, 5x5, but ouch! $230 a piece!

I have opted for (hopefully) the easiest and least time consuming option. I picked up a 10 bolt g80 center carrier out of a suburban and I'm planning to put it in the original axle and rebuild it. I will leave brakes alone, keep 5 lip, etc.

Before disassembly, I noticed that the axles had a bit of axial play in the carrier. Where does this come from? Is there swimming that needs to happen somewhere? Does this happen because worn wheel bearings? Is it something with the internal locker gears? Is it completely normal?