I thought polishing your pole just came naturally.

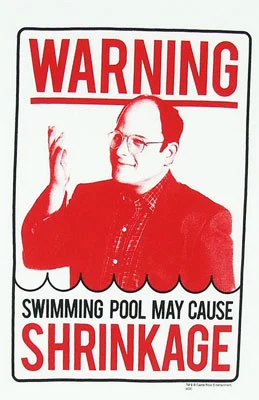

mndsm wrote: I hear a pole will shrink in the cold. Laws of thermodynamics and such.

Good idea. Do you have a pool?

bigdaddylee82 wrote: In reply to Wall-e: I legitimately thought this was going to be a Festivus thread.

No, unfortunately it's just that my pole has too much girth and I need to stuff it into two tight holes that are waiting for it.

Lathe or grind. This is not a time for polishing. Trying to polish or even grind with some sanding belts will take forever trying to remove .006.... Take it to a machine shop.

Have you tried rubbing it down with Kielbasa? Oh, you said polish, not Polish.

What you need is a machine called a Macoser (at least that's what we call them at work, which is probably a brand name rather than the technically correct term.) Basically it's a machine that has two sanding belts that revolve around the tube. With an aggressive belt, I'll bet you could take that .006" off in no more than a half dozen passes. Shouldn't be more than 5 minutes of work. Might wanna call a polishing shop and see if they might do it for cheap, or swing by and try to bribe one of their guys with beer.

Huckleberry wrote:bigdaddylee82 wrote: In reply to Wall-e: I legitimately thought this was going to be a Festivus thread.No, unfortunately it's just that my pole has too much girth and I need to stuff it into two tight holes that are waiting for it.

At the same time no less. That takes talemt.

Huckleberry wrote: In reply to fasted58: I could rent one of those for a couple bucks

Pipe machine doesn't spin all that fast. A 5" pneumatic grinder w/ a 36 grit disc oughta rough it in followed by finer grits to get the OD you need. If you built a gage from small piece of tubing w/ 2.495" (+ clearance) ID you wouldn't have to use calipers, sorta like a go-no-go gage. Keep at it till the gage slides end to end.

You'll need to log in to post.