Trent

PowerDork

9/25/22 11:56 a.m.

Let's start this off by saying, Yes I know this setup is no longer recommended and I know that modding the ecu for direct coil control is better. But this ecu is from when I built my Fiat a dozen years ago and I am not particularly interested in un-modifying the megasquirt and then re-modifying for a new layout when this worked awesome for me for many years.

What I have is a megasquirt 2 ecu on a version 3 board controlling an EDIS4 ignition system. This is on the 1330 BMC A series engine in my mini running a TBI setup.

On my last drive all went well until I hammered the throttle and the engine rocked back enough to pinch through the nylon vacuum line to the ecu. I limped the car back, realized what happened and rerouted a new vacuum line.

What is happening is the car starts up fine and if I give it any throttle the advance jumps up to 60°. This makes it idle at 3000+ RPM. Tunerstudio reports the timing is at 30° which is exactly what the timing table calls for at that RPM/MAP point. Timing light says 60°+.

If I disconnect the SAW wire and put the EDIS in limp mode it is dead solid at 10°. I can rip the throttle all I want and there is no movement via the timing light. This leads me to believe that my crank trigger setup is bueno. Swapping out the EDIS controller results in the same issue. Via the timing light I can watch it fire up and idle at 14°, as soon as I rev the motor it jumps way up and stays there. Turn the car off and on again and the same thing happens over and over

Current plan is to rerun the grounds and verify all is good with the PIP and SAW wires to the ECU. If that fails, what next?

Help me GRM

Can you post the tune file and a picture of how the board is modified?

Trent

PowerDork

9/25/22 3:29 p.m.

In reply to MadScientistMatt :

I will when I am back at the car tomorrow

What puzzles me is that the last dozen drives were fine. This problem is new.

Does this sound like a fairly major vacuum leak?

Trent

PowerDork

9/25/22 6:24 p.m.

In reply to Teh E36 M3 :

Very few places to have a vacuum leak. I have smoke tested it and found nothing. The MAP signal also indicates very high vacuum. Higher than startup actually since it is idling much higher with the throttle still at zero.

Pinching off the PCV hose (the only other source of air) has no effect.

I went through all of that before it occurred to me to check what was happening with timing

I'll bet you are measuring timing with a dial back light?

Most lights "dial back" feature will not function correctly on wasted spark ignitions.

Use a degree marked wheel and leave the knob at zero.

If it was really sparking at 60° it would be trying to disassemble the motor (making diesel noises).

In reply to bentwrench :

At idle, maybe not. When we used to bother installing flat tappet cams where I used to work, we'd crank the ignition timing up with a huge savage twist so that the engine would run cooler and maybe not burn the headers. Even ceramic headers will burn when they are trying to be orange as you free rev an engine at 2500 for twenty minutes with no airflow. 60 degrees would not be out of the question.

Trent

PowerDork

9/25/22 7:54 p.m.

In reply to bentwrench :

It is a dial timing light (snapon unit) that I used with no issue when I verified base timing and advance on first startup. It didn't have any trouble then. I will verify with a fancy Mac digital light tomorrow.

My tuner is adamant about verifying timing mark accuracy and advance before he lets a car roll onto the dyno, so I was pretty methodical.

kb58

UltraDork

9/25/22 8:04 p.m.

That's one of the hidden features of aftermarket ECUs. There's a big learning curve up front, and eventually you get completely familiar with it, get it running just right, so then there's no need to mess with it, so you move on to other things. When I sold Midlana, I realized that the great-running ECU tune hadn't been touched by me in six years. After sending the tunes to the new owner, I realized that if I'm asked to make adjustments, I won't remember how. Six years without messing with something is long enough (for me) to forget 97% of what I knew about it.

I forget now how the timing signal is sent down to the EDIS unit. If it is a simple square wave that increases in duty cycle to indicate more timing, I wonder if the transistor in the MS is sticking on. This would be a good job for a simple lab scope.

kb58

UltraDork

9/25/22 8:15 p.m.

Doubtful. Transistors tend to fail outright, either on or off, "sometimes" when hot, but not usually. More suspect would be intermittent wiring.

The EDIS signal is a "basic trigger" signal, one pulse for each cylinder.

Well, been doing this awhile and this is a new one.

I would try and get a hold of a scope and output test your spark out circuit.

When the vacuum line was broken, could it have sucked in a piece of the hose or other debris that is keeping things from working?

kb58 said:

Doubtful. Transistors tend to fail outright, either on or off, "sometimes" when hot, but not usually. More suspect would be intermittent wiring.

It's odd to be sure. My mind goes away from wiring because of how consistently it resets after powering the unit down, and locks high after being revved up.

I like the "check valved MAP" idea except that one would think it would be running dead lean if that were the case. Plus TS is reporting 30 degrees and actual is 60. Still, it's worth looking into because that was the last thing that was messed with.

I did look at the docs, and EDIS has a maximum of 59 degrees of timing, and the timing signal is a DECREASING square wave - more duty cycle means less timing. So a transistor failing to pull down makes sense. I would think that a hard wiring failure would have the timing drop to 10 degrees as the connection would be broken.

Very hmm.

Try using the fixed advance settings to lock the timing at several places - 10, 20, 30 degrees. Check at each point and see what the timing does

Trent

PowerDork

9/30/22 7:49 p.m.

I apologize for the delay. I took it upon myself to remove and inspect the wiring harness. I relocated the relay board and in doing so was able to shorten the run for the PIP and SAW wires hoping that there was some stray noise in that section that might have been an issue. It did nothing. The problem persists.

I can fire it up and as soon as I rev it over 3000 the timing jumps and the idle goes high. Disconnecting the SAW wire will pull the timing down to 10 degrees and the idle drops instantly.

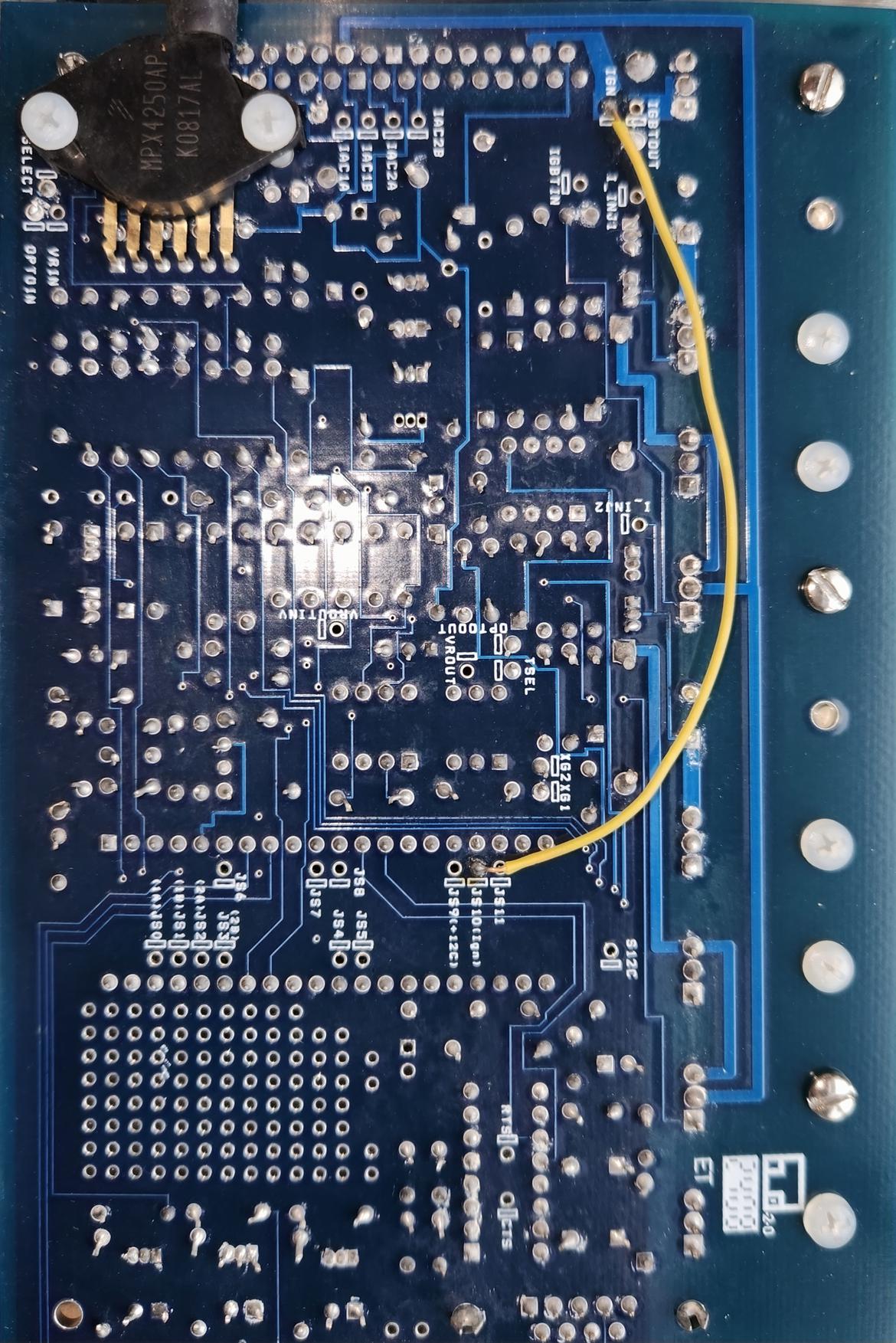

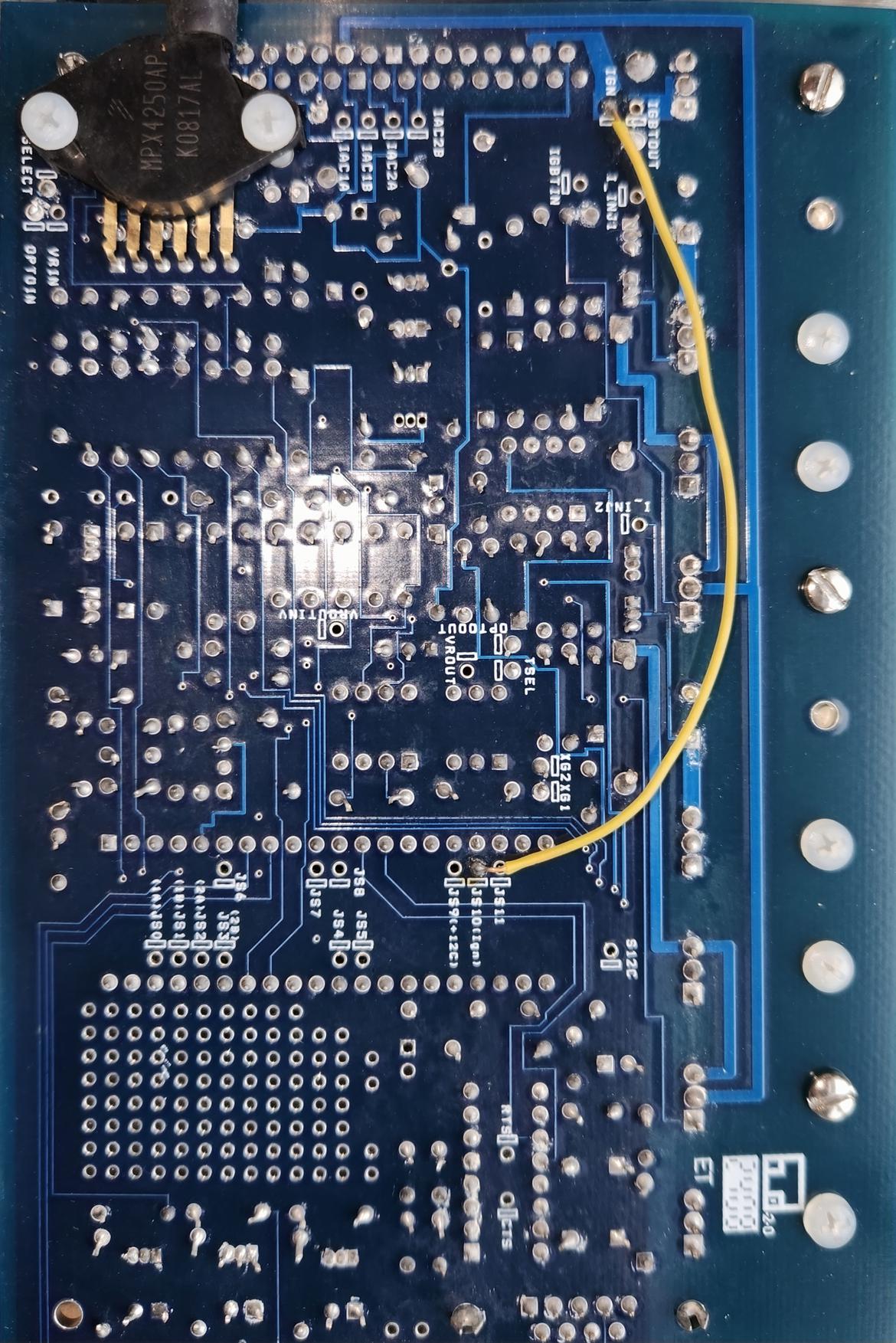

It is a V 3 board and I followed the procedure in the megamanual

- DB37 pin #36 to the SAW pin (#3) on the ignition module

- DB37 pin #24 to the PIP pin (#1) on the ignition module

- On the V3.0 main board:

- use the 'Hall sensor circuit' (step #50.a in the assembly guide) - jumper D1 and D2,

- jumper OPTOIN to TACHSELECT on the bottom side of the PCB, near the DB37 connector, opposite the heat sink,

- jumper TSEL to OPTOOUT on the bottom side of the PCB, near the center.

- jumper JS10 to IGN (this uses the processor port for the SAW signal directly),

- jumper XG1 to XG2 on the bottom side of the PCB, near the 40 pin socket

Matt I can email you the tune if you would be so kind as to take a look and find what silly mistake I have made. The timing and fuel tables are still off since the car hasn't made it to the dyno yet.

I almost feel silly still looking for just noise, but I think you said wires are shielded and the shield isn't grounded, while the MM page I'm looking at has the shield connected to EDIS-4 unit pin 7 (and presumably thus to ground)

bentwrench said:

The EDIS signal is a "basic trigger" signal, one pulse for each cylinder.

That is incorrect.

The SAW pulsewidth from the ECU is loaded into the EDIS to determine timing, and then used for subsequent spark events for all cylinders.

The SAW signal must be refreshed again within every 5 cylinder events, else the EDIS sees it as an ECU failure and goes into 'limp home' mode, ie 10 BTDC.

You should beg/borrow/steal a scope and monitor the SAW pulsewidths from your Megasquirt at various throttle openings. You should check the TPS signal at the same time, and be sure your timing map has not been altered somehow.

Ford EDIS technical information (dainst.com)

See 'Spark Angle Word Calculation' for details on how SAW pulsewidth sets the advance.

You can get usable USB scopes for under $100 USD, very useful for troubleshooting ECU issues.

I recently scored a single channel DS211 standalone scope for $29.

In ignition settings, js10 selected as spark out and not d14, right?

put a thread on msextra w the tune and link us

In reply to clshore :

I was talking about the PIP basic trigger signal signal not the saw.

The best way to utilize this setup is to throw away the EDIS module and hook up everything directly to the MS.

And use a smart wasted spark coil.

In reply to bentwrench :

Fat it depends. I mean, the EDIS is not perfect, but it does have a good measure of failproofness.

In reply to bentwrench :

The PIP signal is generated by the EDIS and sent to the ECM.

The EDIS processes the VR signal from the crankshaft timing wheel, detecting each tooth,

as well as detecting and synchronizing with the 'missing tooth' that indicates he start of each crank rotation.

Each EDIS module is hard programmed for the number of cylinders in the intended application. By knowing the number of cylinders, it knows how many teeth are between each cylinder on the crank wheel. When the number of teeth required passes the VR sensor, the EDIS module emits the PIP signal to the ECU.

The PIP corresponds to each cylinder firing event, and is used by the ECM to derive RPM, used to calculate the SAW and injector pulsewidth from the fuel and ignition tables, and on ECM featuring SEFI, to synchronize the fuel injector pulses to RPM.

The SAW cannot be sent to the EDIS during a cylinder firing event, so the PIP is also used to synchronize the ECM when sending SAW to the EDIS.

The EDIS reduces a nice 36-1 crank position signal down to a per cylinder signal like a 57 chev.

A 36-1 wheel provides a much more accurate signal for the ECU to use to calculate spark timing than a per cylinder signal.

EDIS sucks and is lame, it's only attraction is the "easy button". 1960's technology.

If you are going to roll your own, it does not make sense to chain yourself to a black box.

Points are reliable.

In reply to bentwrench :

The nice thing is that it makes a solid square wave that does not require screwing around with pots to make the MS happy.

This is my my Megasquirted car has an MSD. Solid signal from its tach output with no issues.

This is also why I only do Pro box installs for anything that needs to read a crank signal, its circuitry is a lot better.

I hear what you are saying about the timing accuracy, but I'll take the robustness over the theoretical timing accuracy issues. (I only say theoretical because I never had an issue with timing drift or lag when using GM DIS modules, which work similarly)