Progress has been made.

Waterpump, FMS, timing belt kit, RMS all changed. Maintenance = DONE.

I pulled the plug from behind the exhaust cam and was pleased to find the cam had the receptacles for the CAS. So that has been fitted.

Butterflies have been pulled out of the intake. I need to tap and seal the hole for the butterfly shaft next. Going to use a 10mm x 1.25 bolt. (No pic.)

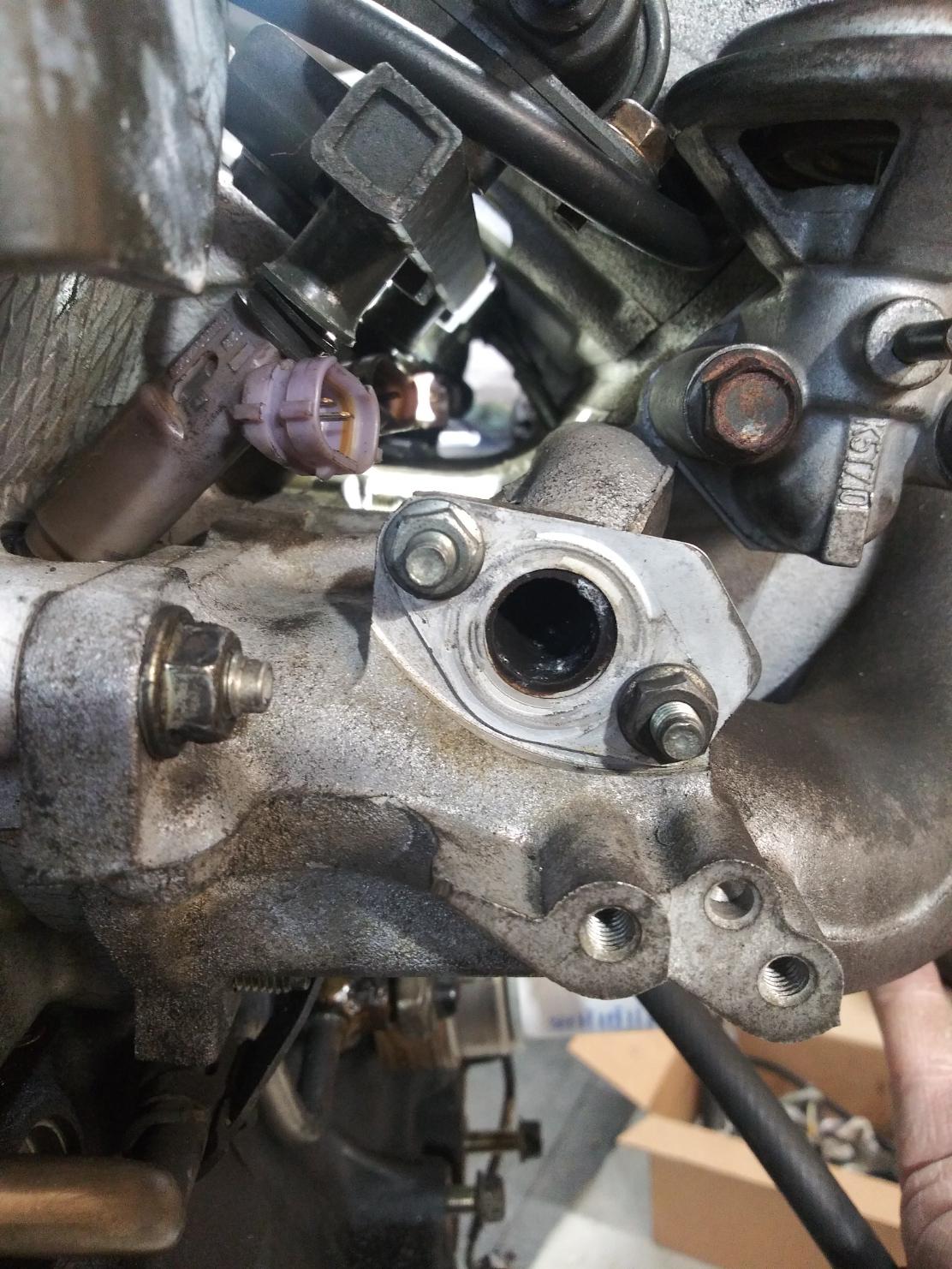

EGR valve swapped (may need to clearance a bit, but seems to sit flush):

EGR Differences ('97 on left, '02 on right). I did this so I could use the '97 harness and not modify the EGR connector.

Now here is where I would like some feedback as to whether what I have done will work or I'll die in a huge fireball. Everywhere I have looked said I need to use a '99 fuel rail and FPR from an NA. I didn't like that answer. So I do what I do and tinkered and made the '97 fuel rail fit.

Original Fuel Rail:

Modified Fuel Rail:

1. Gently manipulated fuel feed pipe to clear '02 intake.

2. Rotated FPR 180 deg. It is sealed via O-rings and easily rotated.

3. Removed hangers for fuel return line.

Not marked: Ovaled mounting holes with modified spacers to maintain proper angle on '02 fuel injectors.

FPR Vacuum line nipple had to be bent slightly downward for clearance.

Test fit:

It fits very well! My only concern is some a slight angle at the fuel rail to injector interface, but it is an o-ring seal so some angle can probably be tolerated. I'll be sure to pressure test carefully before any driving.

EGR to FPR clearances are tight, but there is enough slop to get more clearance than shown in the picture. Bending of the FPR vacuum nipple down gave some more clearance as well.

So hopefully This will allow me to keep using most of the stock '97 ECU wiring. Next will be figuring out the wiring. My dad is painting the valve cover for me so the top will look nice at least :)

Let me know what you think! Thanks!