kcbhiw

Reader

8/13/09 10:46 p.m.

Recently, I assembled a new 2001 era engine for the CSP Miata. 224 miles later at it's first auto-x, the #4 rod bearing spun at the end of the second run (many thanks to DILYSIdave for the tow!!).

The only items reused were the block, crank, and rods on the bottom end. The head, camshafts, and valves were the only used bits on the top. All re-used parts were machined, clearanced, and cleaned by a noteworthy engine shop. I performed the overall assembly myself and double checked rod and main clearances with plasti-gauge during the assembly and all checked out mid-tolerance.. The oil and filter were changed at 66 miles to remove any left-over machining debris. There was some metal on the magnetic drain plug, but not enough to raise any flags.

On to the oddities....throughout it's short lifespan, there was a light sound emanating near the #3/#4 area that varied with engine speed that sounded like lifter noise. I assumed that the lifter (shim) clearances weren't set properly at the shop. I later checked these during the postmortem to find them within tolerance. Furthermore, oil pressure during a 50-ish MPH cruise was hovering just below 90 PSI with the engine at operating temp.

Upon disassembly, I noticed heavy wear on the #4 and #5 main bearings as well as significant piston skirt to cylinder wall contact as well as some abnormal wear on the #2 rod bearings. My assumption is that there was a partial blockage somewhere in an oil passage leading to overall failure. Fortunately, all of the cam journals survived and are currently usable. I followed Flyin' Miata's break-in procedure and never noticed anything odd other than the points previously stated. Other than this, I'm at a complete loss.

Thoughts?

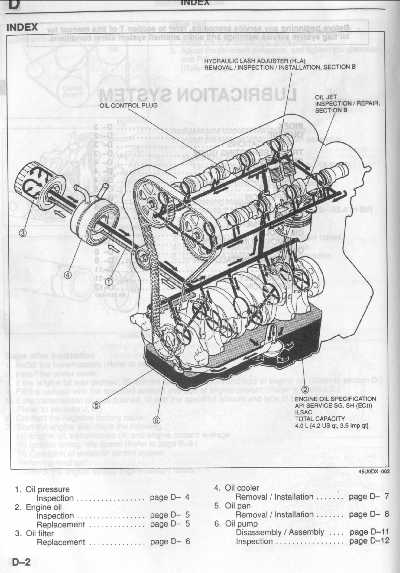

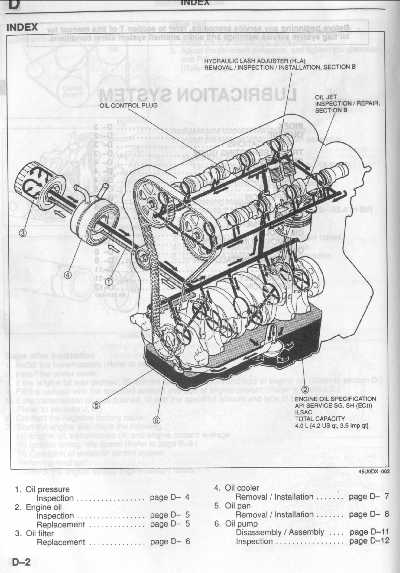

1-4, left to right:

2 rod bearing was significantly scarred:

4 and 5 mains weren't so good either:

Kramer

Reader

8/14/09 8:40 a.m.

That seems like crazy-high oil pressure to me...

I bet the #4 bearings were put in backwards or upside down

kcbhiw said:

rthermore, oil pressure during a 50-ish MPH cruise was hovering just below 90 PSI with the engine at operating temp.

That's crazy high, higher than what I believe the pressure relief valve blows at(60ish). I think you're on the right track with a blocked passage downstream of oil pressure sensor.

as well as significant piston skirt to cylinder wall contact

Sounds like the piston squiters weren't working either, I believe they open around 40psi. Definitely check ALL your oil passages, and your oil pump(I had a 911 that wouldn't make OP due to a dirty relief piston seal)

John Brown wrote:

I bet the #4 bearings were put in backwards or upside down

Would that explain the scoring on the others? I see how it would raise the pressure by blocking the hole - but it seems like something was starving the others too like a piece of casting or something on the positive side of the pump. I don't really know my way around the inside of a Miata mill though so... just speculating.

It would if the bearing was blocking or reducing oil flow through the rest of the system. It would explain the high oil pressure as well.

It may not be #4 as well. I just guessed because the damage was worse there.

tpwalsh

New Reader

8/14/09 9:47 a.m.

In reply to John Brown:

I wouldn't think it would spike the pressure past the blow off point though?

The 90PSI on a hot motor oil pressure does seem high. The 'lines' in the other damaged bearings indicate metal or other particles. Of course, that could have come from the #4 rod. Chicken/egg, egg/chicken...

I think I would look very carefully at all the oil passageways, particularly the crank's cross drillings. Oil feeds from the pump into the oil gallery and this goes to each of the mains. From there it goes through the crank's cross drillings to feed the rod bearings.

The oil passage alignment is critical and that's why there's locating tabs on the bearings, it would be real hard to put a bearing in backwards because as soon as you torqued the caps the crank would lock up. About the only way to do that wrong and not lock the crank on assembly would be to put the main bearings in upside down (plain half on top, grooved/drilled half on the bottom). If that were the case the motor probably wouldn't have lasted 5 minutes and ALL the rods would show heavy damage.

About the oil squirters: somebody correct me if I'm wrong, but doesn't this motor have the squirters as part of the rod, i.e a hole drilled in the rod pointing up? If so there's no relief valve or etc.

Another REAL long shot: by chance are you running a remote oil filter mount? If so, if the hoses are connected backwards the oil pressure goes off the charts and the volume is much reduced (remarked the voice of experience... ).

).

Reply: tpwalsh:

No but definitely before it. Once the oil stopped flowing past it wouldn't efficiently supply oil to either side of the obstruction.

tpwalsh

New Reader

8/14/09 10:23 a.m.

no the oil squirters hang out above the crank, but below the cylinders, and point up.

kcbhiw

Reader

8/14/09 11:50 p.m.

The bearings were installed correctly. Furthermore, all of the bolt/nut torques yielded normal results on disassembly.

Thanks all for the insight! I agree that everything points to a blockage somewhere. The machine shop is willing to accept the parts in attempt to determine the cause.

In the mean time, I've acquired a 70k mile short block to accept the abuse I plan to give it. It'll get me through nationals and the rest of the local season.

Something I learned a long time ago: oil galleries are drilled or cast into blocks, head etc and generally have Allen head pipe plugs or small expansion ('freeze') plugs at the ends. It's worthwhile, particularly on a block that's been hot tanked, to remove those plugs, use carb cleaner or similar and a set of those 'gun cleaning' brushes to thoroughly scrub the passages. 'Hot tanking' won't clean those passages and the caustic soaps can dissolve residues which then collect in the passages.

If you can't get the plugs out, use a long piece of copper tubing with spray bomb carb cleaner or etc and get anywhere/everywhere you can. Use several cans and keep flushing till it comes out clear. Then use compressed air to blow them out. I have seen some nasty goop come out of them, mixed with stuff like flakes of paint, metal fuzz, etc.

I'd check the oil pressure relief valve in the pump as well as the thrust bearing. Those two seem to cause most of the non-structural failures of Miata motors.

kcbhiw

Reader

8/15/09 10:40 a.m.

Good points, Jensenman, I'll check 'em out.

The thrust bearings are the only bearings that didn't have a mark on them, hehe. I'll take the oil pump further and check out the PRV.