In reply to N Sperlo:

Okay, I will jump in this debate again....

Can you solder an O2 wire?

I was told you can't solder due to the "vent" for the O2 sensor being the wire itself. I was also told that the "wire" is steel and therefore can't be soldered.

It seems weird to me, but that is what I have found.

Rob R.

In reply to wvumtnbkr:

Seems as if your 6 wasn't very good at determining that the O2 sensor failed. If it had, they usually ignore a known bad signal.

If it's bad, and can't tell- odd things can happen. But if the system is throwing a bad O2 MIL, well...

wvumtnbkr wrote:

In reply to N Sperlo:

Okay, I will jump in this debate again....

Can you solder an O2 wire?

I was told you can't solder due to the "vent" for the O2 sensor being the wire itself. I was also told that the "wire" is steel and therefore can't be soldered.

It seems weird to me, but that is what I have found.

Rob R.

No, you should not solder on O2 sensor wires. It is the path for reference air, as wierd as that sounds. Better than the air around the sensor, since it's more likely to have environmental issues plugging the hole up. But the sensor works comparing the partial pressure of o2 across it, which is why there needs to be a source. WB sensors actually move the air- not much, but it still moves.

In reply to wvumtnbkr:

Worked fine for me. Never had a problem with it. What's the proper way? Butt connectors?

wvumtnbkr wrote:

In reply to Giant Purple Snorklewacker:

Isn't he looking for the upstream one?

You can buy all four for just over $200. They all cost between $50 and $80 each for any car if you can splice 3 wires yourself. All you lose is the OE connector (which often you can just reuse if you can massage the pins out to solder).

alfadriver wrote:

No, you should not solder on O2 sensor wires. It is the path for reference air, as wierd as that sounds.

Bosch sensors have the spade connectors soldered on from the factory. They don't have terminals on the sensor - they have a 3 wire harness that protrudes for 6-8" though so you are just mating it to the vehicle harness upstream. I suppose you could use a crimp to splice them but I have never had any issue with using Denso or Bosch sensors with my own pigtails on any application. I can't imagine using solder 6" upstream on the wire would effect any reference air to the sensor.

Interesting factoid for future reference though in case I get one that does only have posts on it.

EDIT: I just went and looked - the Bosch sensor on my shelf (E46 325iX application) has a male/female connector included and crimps in the box. The wire leading away from the vehicle side of the connector is copper strand.

The universal Bosch O2 sensor I bought for my RX7 had a crimp fitting. It specifically said not to solder it. Just crimp it and add heat shrink.

The point is that the air travels between the insulation and the wire until it gets to the stock connector. This helps keep the air path clean and debris free. Debris and grime is why most newer O2 sensors don't use a vent on the body of the O2 sensor (the old ones did).

Air actually travels up that 6-8" Soldering it closed CAN make bad ju-ju.

Rob R.

Learn somethin new every day...

+1 learned that too. I wonder how many people with EFI'd offroad rigs that wade through muck don't know that.

My V6 Liberty had 4 O2 sensors, 2 upstream just before the cat.

Improper use of an RTV, where it can get drawn into the intake or blown into the exhaust can cause O2 failure.

Giant Purple Snorklewacker wrote:

Partsgeek says it's a $52 problem - which is more inline with what I'm accustomed to be paying for BMW O2s.

http://www.partsgeek.com/gbproducts/DC/18535-05169344.html?utm_source=google&utm_medium=ff&utm_content=DN&utm_campaign=PartsGeek+Google+Base&utm_term=2005-2006+Toyota+Tacoma+Oxygen+Sensor+Denso+Downstream+Left+05-06+Toyota+Oxygen+Sensor&gclid=CI25xKW66LYCFYHe4AodmWEASg

Wrong one. I need the upstream sensor. It was a $151 problem.

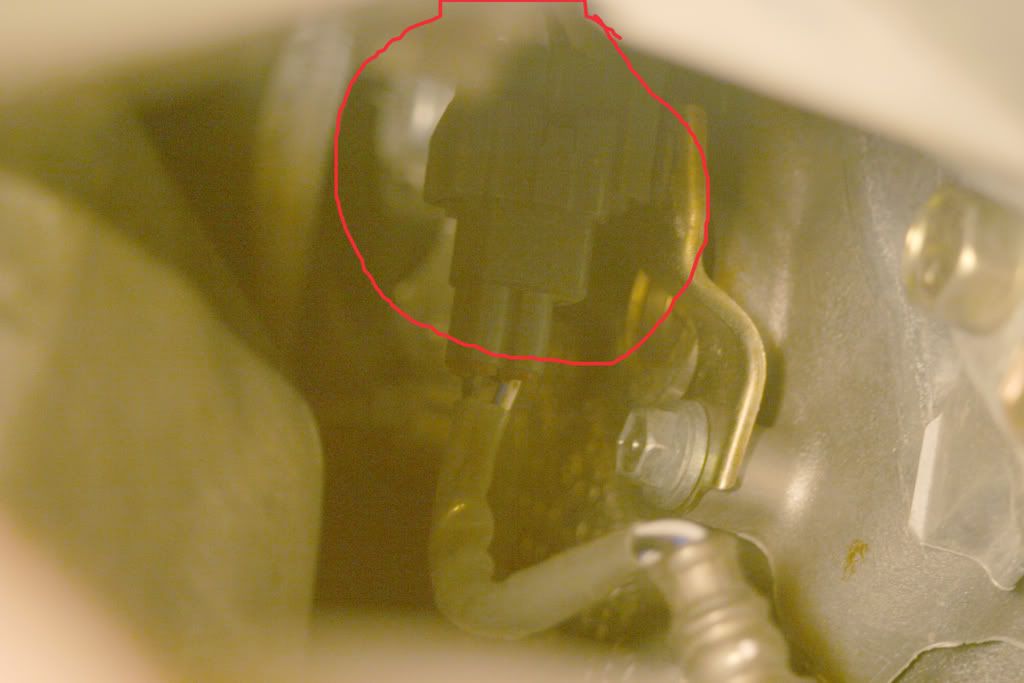

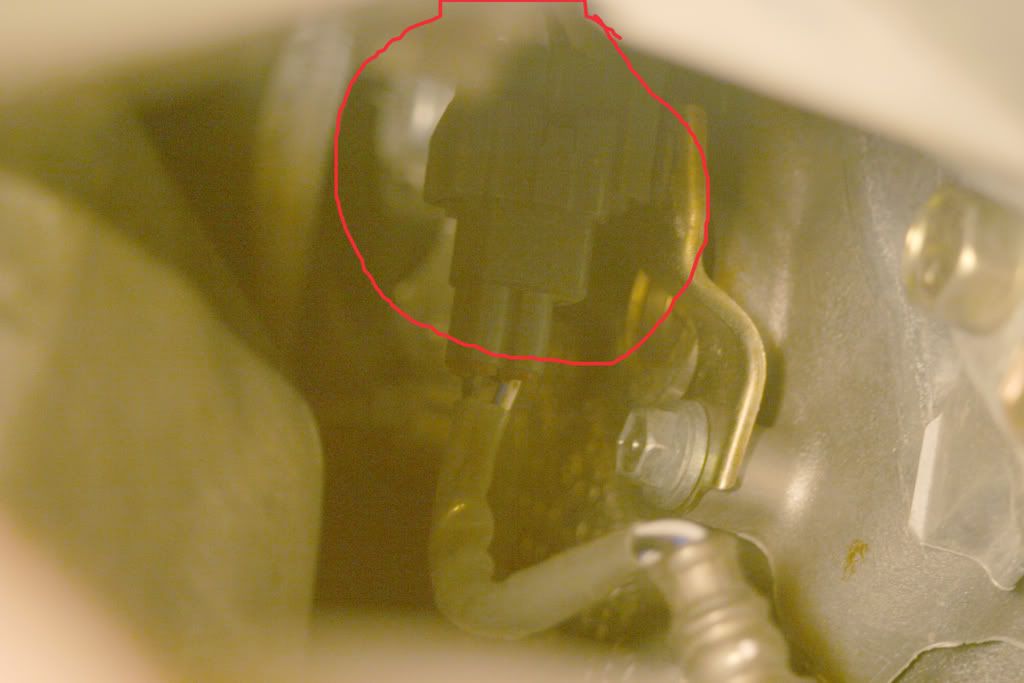

On a related note, I haven't attempted to get the old sensor out of the manifold yet, but I can't even unplug the berkeleying connector.

Hotlink:

Remove the connector from the bracket first. Then it should come apart. Honda and Toyota are both bad for that... fight it and fight it, but slide the connector off of its holder and then it will slide apart and make you look like an idiot.

As regards O2s... Bosch generic O2s tend to be junk. Have seen so many of them bad out of the box that there's no point in using them.

Not that it matters for this application since it's not a narrowband.

The things the OEs test for on O2s is mind-boggling. They look at things like lag time, time spent rich vs. time spent lean, the time it takes to cross the threshold, etc. Probably 11 different ways that it won't like the sensor aside from "dead lean all the time".

That's not mine in the photo. It doesn't slide onto the bracket, it clips into the hole. I'm not even sure if I can get anything behind it.

Jerry wrote:

Noob question- so what are the ramifications if a certain hypothetical individual ignored the bad O2 sensor warning? Like for a really long time?

We just had an Audi in at work that had O2 sensor code CEL ignored long enough that the only way to get the CEL to go away was to replace all four O2 sensors and the ECU.

Also, when my 9000 had a bad upstream O2 it was getting ~14MPG.