Hello,

Per my build here.......

97 S10 V8 swap

Specifics on the engine.

- 86 75K LG4 305

- .015 compressed HG

- Edelbrock 1406 AVS2 (choke removed and 8" step up springs all other parts untouched)

- Edelbrock single plane

- HEI

- Patriot Swap headers into a 2.5 y pipe merging to a 3 inch dump

- 10" Edelbrock Air cleaner

- Holley Mighty Mite FP

- Holley FPR (or Summit?)

Etc.

Truck has had even before the single plane and HG swap a bog on transition from cruise to WOT. I have a FPR and have to set to around 4.5 (sweet spot from my research). Initial timing is 14-15 BTDC and total is 34-35 (I need a dial back light to confirm timing). I have the 8" springs as per the manual I am supposed to use the closest spring I can to half of engine vac @ idle - so thats around 25-30 ergo the 8" spring. The air cleaner isnt the issue as even with the cleaner off it still happens. Acc pump is set to normal (middle slot on pump arm)

Please I need help. The truck is great to drive, but unless I slowly roll into the WOT (even then not always) it just stumbles it ass off.

My thoughts are........

- Actually see where the timing is. Get a dial back light and redo the initial and see what total actually is. Instead of assuming.

- Possible rejet? I have the kit, but would I lean or richen the secondary circuit?

Thanks and please HELP!

Tell me more about the bog. Is it just when you get into the secondaries that you have an issue? Is it responsive at part throttle? When it acts up does it actually slow down or does it just take a bit before anything happens?

I have never seen timing cause a bog. Usually if it's lean you will get loss of power and popping/backfire if it's severe and the bog is just rich. That can be accel or main or secondary, you need to do it in steps to not get lost. Borrowed wideband O2 can help a lot here.

In reply to APEowner :

Thank you. Any other time its responsive. Runs great! When the transition to WOT is made its most noticeable and sometimes rolling into it (in higher gears). It falls on its face. Slows down. You can power through it if you maintain a full pedal but its not happy?

Here is another tidbit. In first gear as it string it out. Its less likely to bog. Usually doesnt once warm. Its any other time. Even then its not a strong "oh E36 M3 here come the secondaries" sorta thing. Im thinking go the other way and jump my fp to 6? Change the ac pump arm to its richest setting?

In reply to Paul_VR6 (Forum Supporter) :

Thanks! Timing did help though. No popping or backfiring.

bonylad said:

In reply to APEowner :

Thank you. Any other time its responsive. Runs great! When the transition is made most noticeable when going hard WOT and sometimes rolling into it (in higher gears). It falls on its face. Slows down. You can power through it if you maintain a full pedal but its not happy?

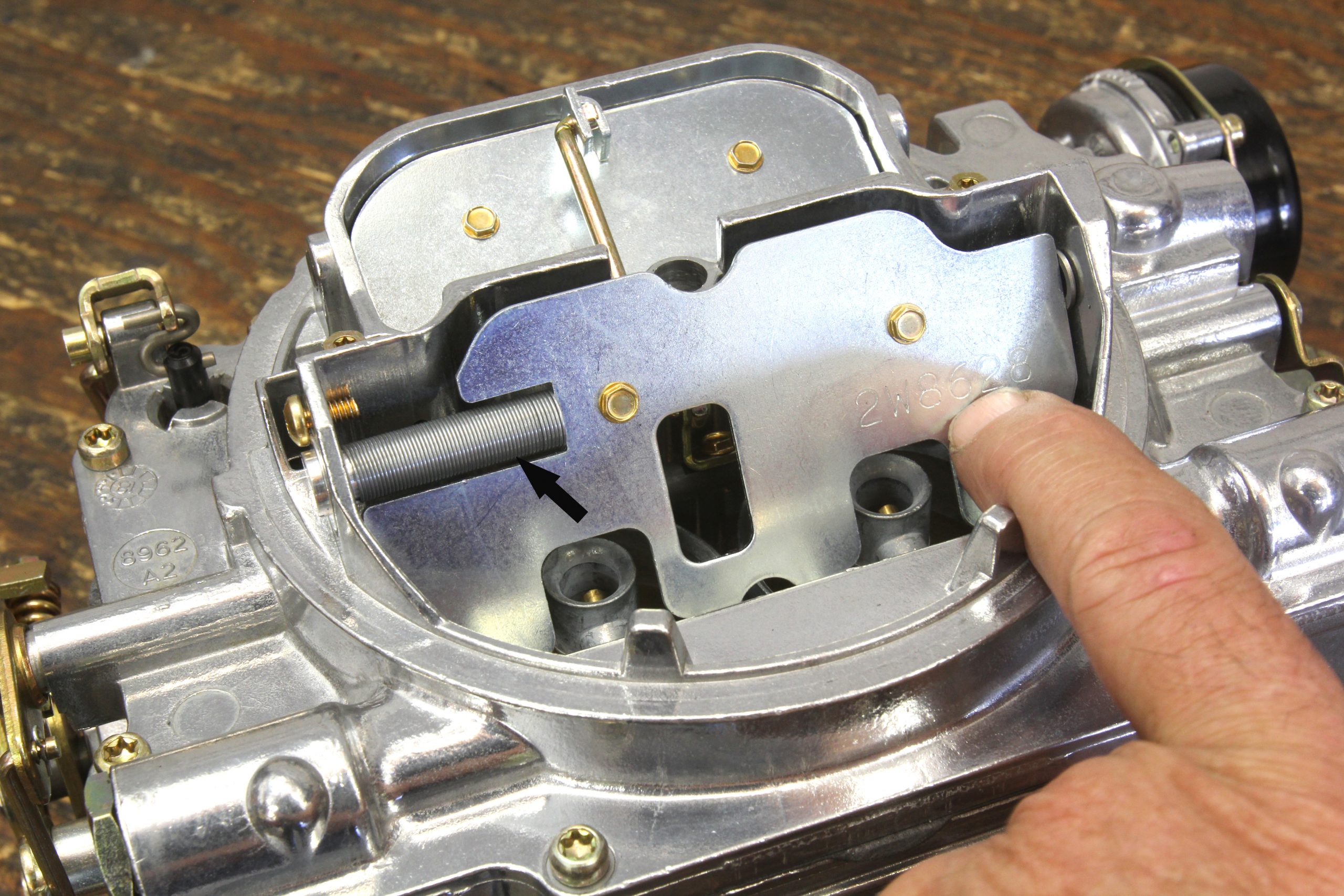

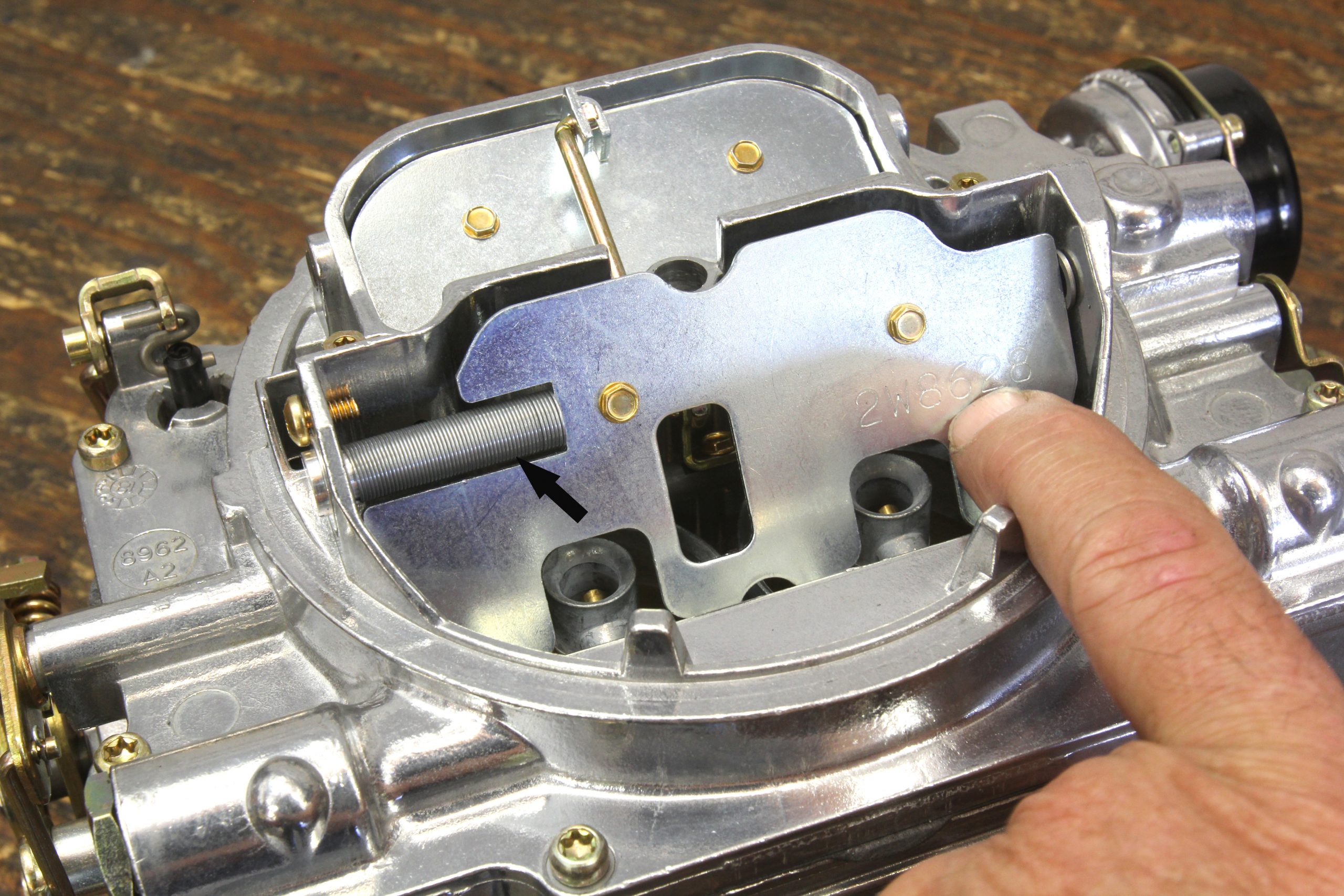

I'd try tightening up the spring on the air valve door. There's a picture of how to do that about 2/3 of the way down this -> Link page.

It's a bit lean, and wind down the secondary air door s[pring to slow it down a bit.

In reply to APEowner :

Thank you! Will do.

EDIT - I dont have that part. It was removed. This hesitation occured before removal of the choke assembly. Issue was still present before hand.

Get a wideband. It makes tuning a carb so easy it's almost cheating. I have that same carb on my 357 in my C10.

What happens to your vacuum when you go wot? Does it go to 0? That carb might be too big for your 305.

In reply to Streetwiseguy :

Wind it down? Are you referring to what APEowner refers to? Do you think I would be better off either

- increasing base fuel pressure (though I feel this could affect overall driveability)?

- one size larger secondary jetting?

If i understand the metering rods, they really affect the primary circuit of the carb. Secondary is metered by the jets. Is this correct?

bonylad said:

In reply to APEowner :

Thank you! Will do.

EDIT - I dont have that part. It was removed. This hesitation occured before removal of the choke assembly. Issue was still present before hand.

It's OK to remove the choke (although I don't know why you'd want to) but the air door is critical to the operation of those carbs. They don't have an accelerator pump on the secondaries and instead rely on the air door to open at a rate that prevents a stumble. The air door is shown below

What is your vacuum reading at idle. I bet your metering rod springs are way to light. Take the engine vacuum at idle in in/mg divide by two and use that step up spring.

In reply to Patientzero :

Its only a 600 CFM. I suppose so? Yeah I would love a wideband, though I want to see if I can get this right like the old farts did. By touch, feel, and smell. Sounds dumb I know, but for THIS truck I dont want to rely on new tech, rather old tech like it was done.

In reply to wearymicrobe :

Its around 25-30 depending on RPM. As of now I have the highest spring. 8"

In reply to APEowner :

So the possibilty is the bog I had before hand was maybe something else? Now it may be this? Worst case I can go back and install it. I still have all the parts. MMMMMMMMmmmmmmm good thought. Thanks!

So maybe install that air door first before I go fiddling with the carb?

OMG. This makes sense. The bog as mentioned is there at lower engine speeds. Now that I think of it. Thats why when I am revving it out in first, the engine speed is high enough to not need it, or rather its not making a huge difference. At speeds where I am in 2nd or 3rd, the speed isnt high enough and as such the bog is there because

"The Edelbrock carburetor does not use these squirters, as you noticed. The idea behind the air valve door is to gradually open to create enough air velocity past the secondary boosters to create a sufficient signal to begin to pull fuel from the boosters into the engine."

Wow........I feel stupid.

The 1406 is not an AVS2.

1406 has a weighted secondary air door located under the boosters.

AVS2 has a spring loaded secondary air door located above the boosters.

I use a single 1406 on a street/strip 9.36:1 solid roller 251/261/114LCA 355sbc with 2 stages of nitrous. Manual trans, it sees 9k on occasion. Tuned with a wide band.

Primary jets .092, 6857 rods on pink 7" springs.

Secondary jets .101, I have several secondary air doors that have had their weights drilled and some that have had weight added, in the end i'm using stock weights but removed the small tubes from the secondary cluster.

Accel squirters .036", linkage in #3 hole.

Despite the low compression, it's very responsive NA and gets 20mpg without an overdrive.

In reply to weedburner :

Perfect timing. I just realized its a 1905 AVS2! Thank you! Regardless I am reinstalling the parts now. Still trying to remember how it all goes.....linkage wise.

Thanks!

bonylad said:

In reply to APEowner :

So the possibilty is the bog I had before hand was maybe something else? Now it may be this? Worst case I can go back and install it. I still have all the parts. MMMMMMMMmmmmmmm good thought. Thanks!

So maybe install that air door first before I go fiddling with the carb?

OMG. This makes sense. The bog as mentioned is there at lower engine speeds. Now that I think of it. Thats why when I am revving it out in first, the engine speed is high enough to not need it, or rather its not making a huge difference. At speeds where I am in 2nd or 3rd, the speed isnt high enough and as such the bog is there because

"The Edelbrock carburetor does not use these squirters, as you noticed. The idea behind the air valve door is to gradually open to create enough air velocity past the secondary boosters to create a sufficient signal to begin to pull fuel from the boosters into the engine."

Wow........I feel stupid.

It could be that the initial problem was that the air door needed to be tightened. When you put that back together make sure that the screws the hold the plate to the shaft are secure. I've never taken the air door off one of those but most throttle and choke plate screws are staked at the factory. If you don't have a way to do that I'd at least Loctite them. Having one fall out and go through the engine will make you sad.

In reply to APEowner :

Yep. I have considered that as well. I had forgot how it all went together and somehow have lost a screw. I figured it all out last night and need to finish putting it together tonight. Little dap on the screws backed out and then tightened should do it. Will report!