Ottobon

New Reader

9/20/18 2:47 a.m.

Without going into way way too much detail, as somebody who spends way too much time caring about engine sound, i wanted to ask:

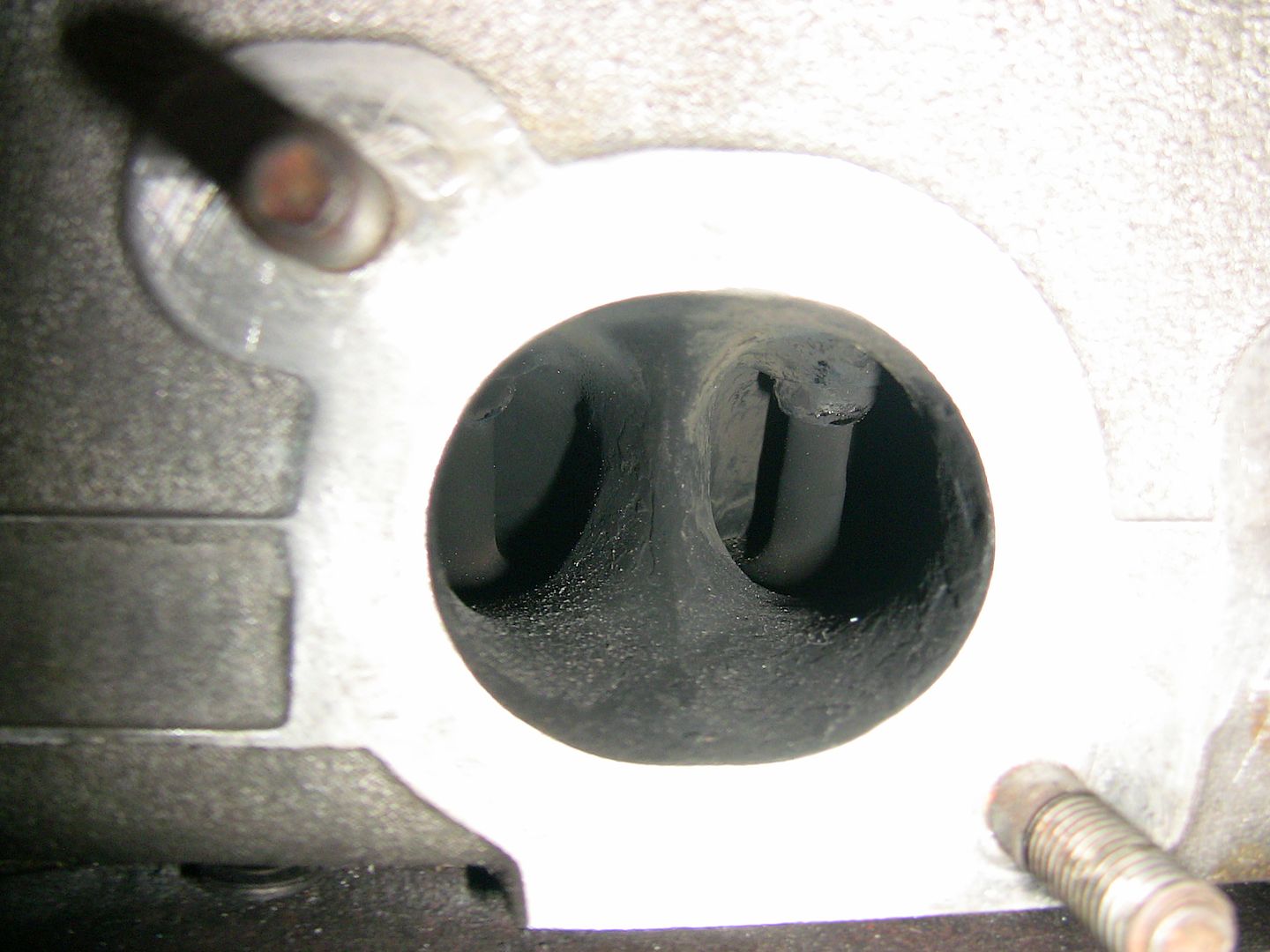

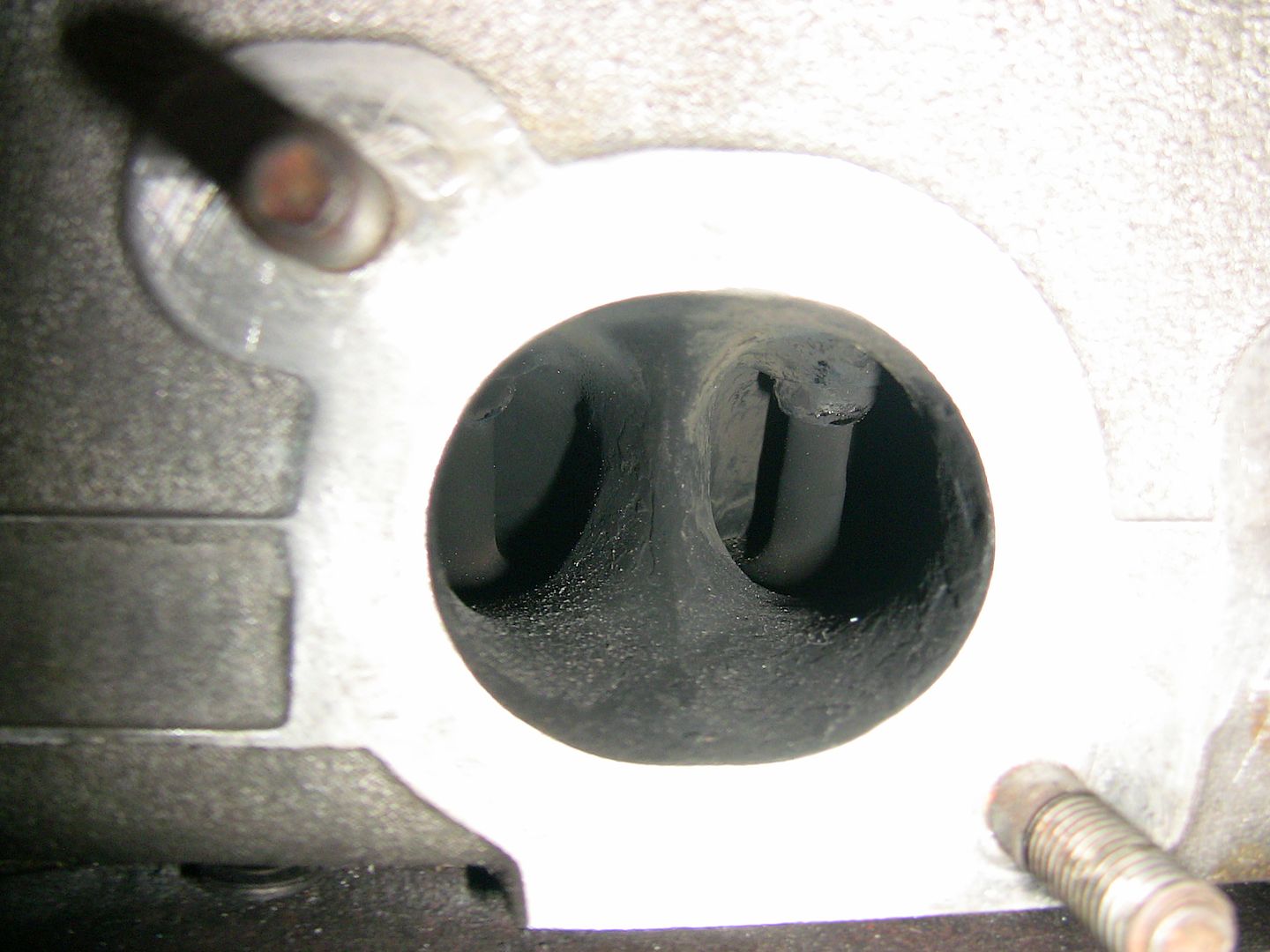

Is it possible to add material to exhaust port area (the merge in say a 4v per cylinder engine) without distorting the head itself, there are ofc many factors outside of this which relate to a engines sound (valve angle, intake vs exhaust valve diameter, header diameter vs main pipe etc), but this seems to be a huge one in regards to good sounding engine and given the requirement to fit engines in tight spaces and ignite catalytic converters many modern engines gouge out the merge between the 2 exhaust valves (most hondas, nissans, but many other modern engines as well), deadening a lot of the engines better sounds in what would otherwise be great engine series.

I suppose in some cases this could be used more for performance, less turbulence is always good, but ill be honest i only care about this because i slowly over time realized how it raped otherwise good engines of sounding better, that may seem weak given the nature of motorsports and that im on a motorsports forum but if it was possible to fix certain engines of this flaw by elongating and shaping a proper merge on engines where its cut-out nearly right after the valves i figured you guys would be the ones to ask. Is it even possible to tig-weld without warping the head?, or there any other potential material that can be added to exhaust port area to help with this?

Yeah... but sound is kind of a weird reason to do it. The OHV volvo guys chasing the last % weld up the exhaust port floor but the results are tarnished by the constant worry of warpage and the amount of work you have to do afterwards to get them perfect.

Oldeskewltoy to the courtesy phone...

I know for cylinders there are some exotic and very expensive processes that can be used to add material, I didn't look into it further than that after I was given an idea of the cost.

Not for sound but for better flow and power many racers used to buy "tongue depressors" for the EX port on big block fords. Basically a exhaust manifold gasket that raised the floor of the ports. Haven't seen one in years. On the other side the 2.3 ford guys often mix oval and D port manifolds and heads but again flow not sound.

On the sound end. One of the comments I always get when i take my 1952 flat head Harley out is WOW it sounds just like a modern Harley.

maj75

HalfDork

9/20/18 4:35 p.m.

Years ago I found a site where the guy was making the ports of 4 cylinder motorcycle engines smaller. He had a bunch of flow data to justify his work. IIRC there is a velocity v volume that is optimal depending on the rpms and way the motor is used.

Aluminum heads can be built up with weld but what make you think that splitting siamesed exhaust ports would improve the sound? I don't know that it wouldn't but I also don't know why it would. I've always found engine sound to improve with improved flow and this seem contrary to me.

In reply to maj75 :

http://mototuneusa.com/homework.htm

He's not the only one, but one of the few that lay it all out there to read.

Vigo

UltimaDork

9/20/18 9:01 p.m.

I remember reading about and discussing a lot of this stuff with a head porter in the turbo mopar community who was also into fuel economy mods and trials ("races"). Looking at that link, it definitely looks like those bike head ports are an extreme example. They're goofy. I admit i don't know much about the sound aspect but i have heard a fair amount about using epoxy in head ports and it working out well.

Ottobon

New Reader

9/22/18 4:44 a.m.

In reply to APEowner :

Its very easy, i would just ask you as a human being who has a musical ear to some degree listen to great sounding engines and then look at the ports of less great sounding engines, not in tone of exhaust but in how muffled the noise itself is. A good contrary example of 2 good engines, one in a good state sound wise, one in bad state (but both performance kings from similar backround: japan) look at the ports of a Hayabusa 1.3 and a Nissan RB26.

Ignoring all that, even without looking at ports, listening to the same engine with different quality of headers it becomes extremely apparent how important the merge between the primaries in a header is in regards to sound, this translates even more so to the ports in a 4v+ engine (2 exhaust ports), a proper built race header vs and a header that just "dumps" the primaries is going to sound insanely different. Since one cannot change majority of cylinder head design, valve angle, valve size etc, the port is the next thing on the list in regards to how this all interacts....I've dug into this a bit, anything that interacts as a un-needed "pocket" of air does fairly terrible things so far as destroying sound, but more importantly probably hurts in regard to turbulence

Hayabusa

RB26

In this example if you can't reduce the entire exhaust port you could atleast smooth the transition, as in the RB26's case it literally just dumps both into 1 large chamber without care. Another modern example would be comparing most Yamaha designed heads (Toyota!) to Honda heads of modern era (excluding the F20/F22, which honda seemed to spare from this, but definitely including the K20 head)

Could and maybe should list 2 more extreme examples but felt important to maintain this effects with engines of good reputation. should show to some degree where the transition on one is a let down compared to the other, ofc there are a lot of variance between a RB26 and a Hayabusa engine, distinctly valve angle and ports approuch to this is a uncontrollable factor in regards to my question posed, however the part about port shaping and potentially adding material to smooth this tranisition is relevant. If one has to work with a shallow valve angle then not having said exhaust ports dump into a gauged out opening, creating a surface where said ports can merge better and in a less turbulent way is still valuable (probably from a performance perspectve, but if nothing else definitely from a acoustic one.)

I could write a guide to engine sounds excluding this if need be but i don't know where one would want that. Its all solid observation, but i wouldn't call it full on science, not going to pretend to be a acoustic engineer when i am not. In general intake vs exhaust valve propotions to eachother and displacement plays a huge part in tone, then header diamters vs exhaust after that. Quality of sound has more to do with how straight-through or unchanged the flow is in one way or another, which is why i brought up shaping exhaust ports to correspond bette in the cases they get gauged out early(usually in stock form, because its required they change direction and turn down to meet a catalytic converter as quick as possible.)

In reply to 44Dwarf :

I didn't realize they made modern Harleys. When did that start?

In reply to DeadSkunk :

Well they did just buy a large stake in ALTA used them to develop a E-bike now decided to go on there own....

But as you know my comment was more 2 side valve (flat head) sounding the same as 2 valve overhead models be it knuckle, iron, or Evo etc they all sound the same... Potato, potato.....