So the two bolts I can find for this are too short to get through bulge in the floor pan for my civic. I've found a threaded eye "nut" but it's rates at 2700lbs, is that sufficient for this application? I can thread grade 8 hardware into it to get it any length.

http://www.saferacer.com/g-force-eye-bolt-50mm

This is the too short bolt in question.

bent eye bolts are a no-no.

It's solid, not bent, it's like an eye nut that you thread a bolt into.

I don't think you should be bolting that eye bolt to something hollow that would require a longer bolt. It should be used to sandwich solid sheet materials together only. I would not install it such that it was going through a hollow area of your floorpan. Back it up with both the included wide flange washer and ideally a ~6x6 welded in plate of 1/8 or thicker steel.

Pictures of your floorpan? We may be able to find a solution.

OG Racing.com has eye bolts that are longer (almost identical to in your original link), but also has backing plates that have nuts welded onto them specifically for this purpose.

SVreX

MegaDork

10/22/13 12:29 p.m.

I don't like extending the bolt at all. I wouldn't want my life dependent on the integrity of the internal threads of the "eye nut".

Get the right hardware for your application. Don't rig it.

I agree with nocones. Can you cut an access hole in the bottom of the pan to put the washer and nut so they are only sandwiching 1 layer of metal?

That eye bolt is not designed to rely on the shaft of the threads to avoid bending. It is designed for the seat of the ring to essentially be in direct contact with the floor, and sandwiched directly to the washer below (so it is not pulling the threads "sideways")

It's my understanding the the stock belt locations use the same thread pitch for the stock belt mountings. That may be an option for you.

If you are using a race seat, why not just fabricate a frame mount for the seats and belts. Many people do that.

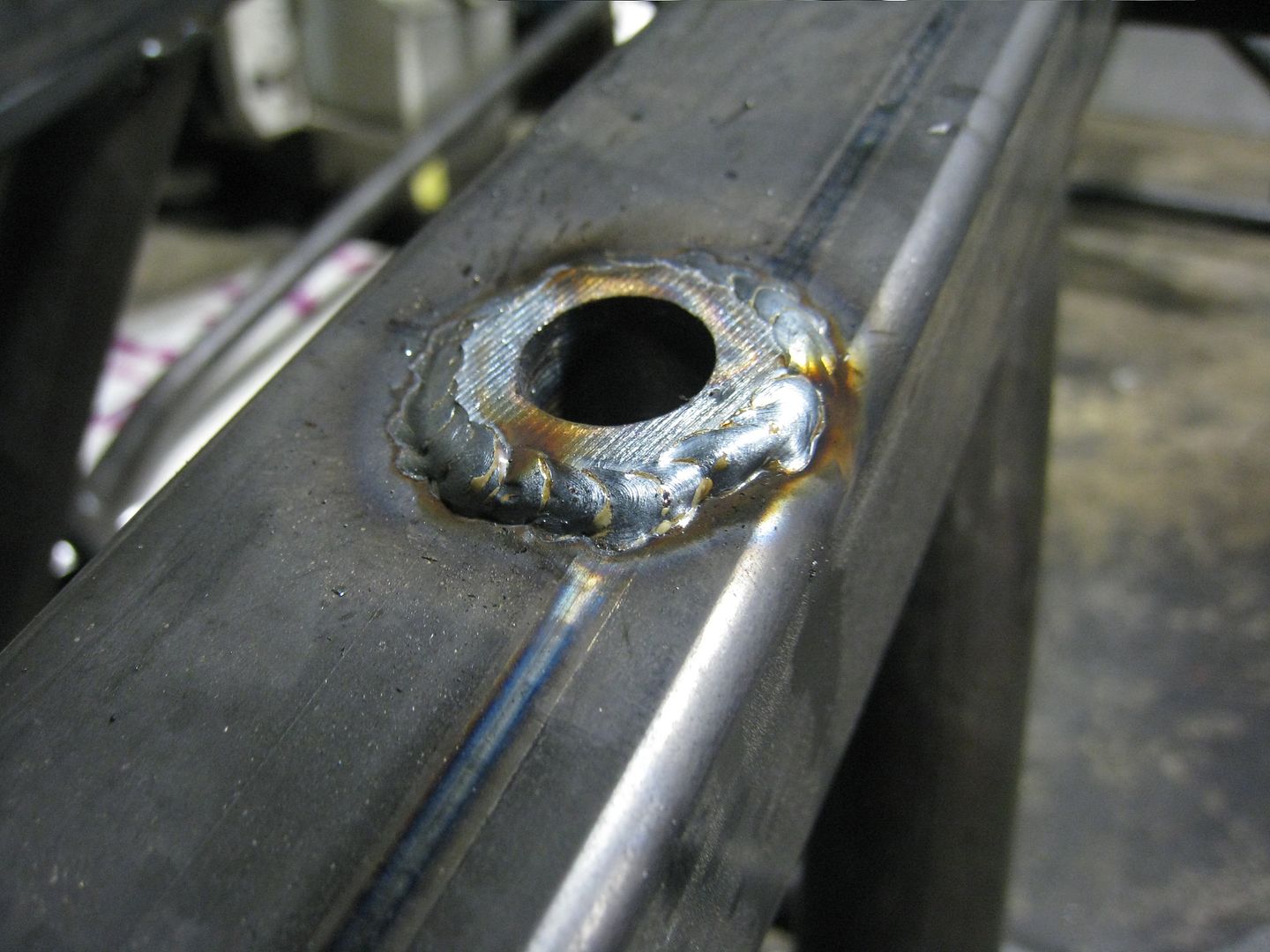

You say the 'bolt is too short for the bulge in the floorpan'. I hope you are referring to something which has an anti crush tube welded into it for the bolt to pass through, like this:

If you are referring to the stock seat mounts or similar which don't have a tube welded into them, I'd reconsider the mounting method.

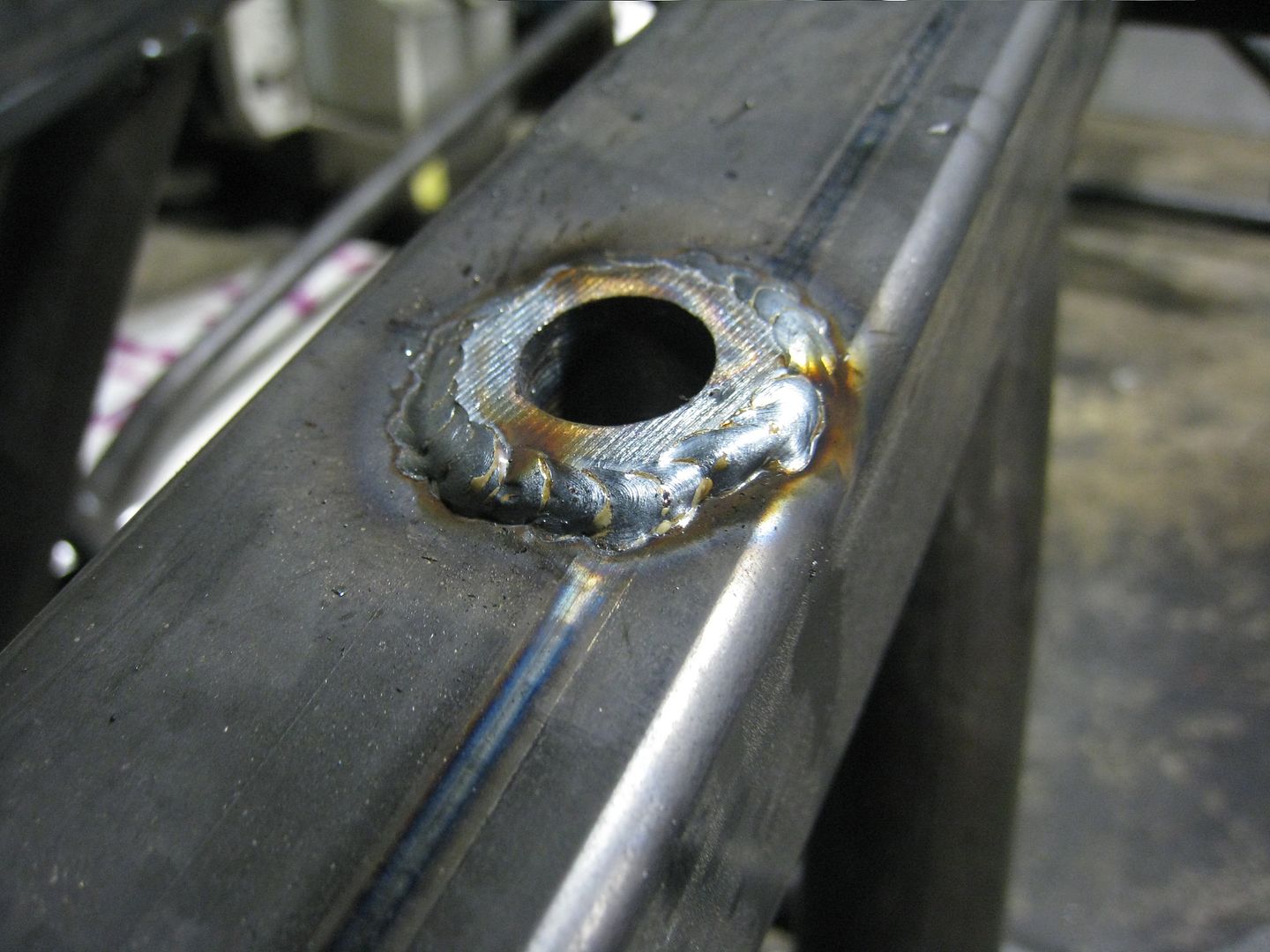

The "nut" in question.

I'm afraid to cut the "bulge" in the undercarriage. I suppose the car is caged so it's probably more structurally sound than it was before, regardless.

It runs along the exhaust tunnel beside the fuel/brake lines. I think I could take a hole saw to it to make an access hole and use the smaller length bolt. Does this seem like the best option to you guys?

And I have backing plates for all my mount points.

I'm using this

With a hole drilled directly into the floor pan with this on the bottom, and a massive thick round washer on the top side.

Is this incorrect?

If you're going through that piece you outlined it would need a sleeve welded in so that you wouldn't crush it. I'd personally look for another place, like higher up in the tunnel.

mazdeuce wrote:

If you're going through that piece you outlined it would need a sleeve welded in so that you wouldn't crush it. I'd personally look for another place, like higher up in the tunnel.

The consensus seems to be that I cut an access hole into it the bulge I think? The car is fully caged btw.

If it's fully caged, why not tie your belt mounts into the cage work?

In reply to sachilles:

No part of the cage runs along the center line of the car? I'm not sure where I would tie it in the for the hip belts?

http://daliracing.com/v666-5/catalog/x-images-more/harness-bars-install-diagram-Install4CWeb.jpg

I guess I need to take a second look at it all.... I'll take some pictures when I get home.

Is there a reason you can't use the stock belt mounts? Or failing that, move the mount up to the side of the tunnel?

Is there a reason you can't use the stock belt mounts? Or failing that, move the mount up to the side of the tunnel?

The only sturdy eye bolts I've found aren't threaded the same as the seat belt mounts. Maybe I'll figure out what they're threaded as and see if I can find an eyebolt for it. I went to fastenal and they only had E36 M3ty cast then tapped eye bolt pieces.

Does anyone have a source for them? I tried searching a few of my hardware haunts and none of them seemed to have any but the bent eye bolts.

Aren't these the same thread as every stock seatbelt since forever?

Eye Bolts

I hope so, I thought I tried it, but maybe not. That'll simplify everything.

I'll update when I get home.

devina

New Reader

10/22/13 9:45 p.m.

When I put the racing harness into my Integra (same bodystyle, I believe), I drilled a hole in the tunnel directly across from where the outer OEM seatbelt mount is located in the chassis.

Put a nice backup washer and you should be good. There is a nice reinforcement in the tunnel in this area.

I would not drill through that channel as that would weaken that feature in the chassis- probably would be fine but why weaken the tub at all...

DWNSHFT

HalfDork

10/23/13 12:32 a.m.

I'm not an engineer or anything, but if you're in a 30G impact (not a particularly hard hit) and you, your safety gear, and seat and belt all together weigh 200 pounds, you would load that bolt to 6000 pounds. So I would say that a 2700 pound rating is insufficient by a wide margin.

David

DWNSHFT wrote:

I'm not an engineer or anything, but if you're in a 30G impact (not a particularly hard hit) and you, your safety gear, and seat and belt all together weigh 200 pounds, you would load that bolt to 6000 pounds. So I would say that a 2700 pound rating is insufficient by a wide margin.

Presumably the seat has its own bolts holding it in? Also, the body & harness load is spread across all of the harness mounts, not concentrated in a single one. If you assume four straps taking most of the load (I wouldn't think much of it goes through the anti-sub strap), then that's 'only' 1500 pounds on that one bolt.

I agree on doing it the traditional way, though. Either find a different place to mount the eyebolt, or carve up the bulge on the floorplan and then reinforce around it (assuming class rules allow that).

IIRC all stock seat belts are SAE fine thread, even metric cars, some government requirement, that might be you problem finding something to fit?