iansane said:

Also, is there a build thread for this thing? That's one of my favorite gen civics and I've always thought an LS powerplant would be fantastic.

I don't have a build thread. Got a few pictures on my phone, but it really isn't anything special. I hacked apart the front sub-frame wide enough to fit the GM bell housing, but made sure I wasn't removing any mounting. I never even dropped the sub frame. I need to box all of it back in and re-torque the mounting bolts, still.

Then I went to town with a cut off wheel on a 4 1/2" grinder to open up the firewall. Trying to keep anything that I could. Probably cut a lot more than I needed to, but I initially was going to keep the truck intake. I ended up coming across a slightly damaged ls3 intake with fuel rail and injectors.

I stayed between the unibody 'rails' and opened up the location for the transmission. The ar5's shifter is about 2 inches forward from where the factory Honda one was positioned. After I got the transmission where I wanted it I spent some time mocking up the backend. All I've got there is just a late 80's Ranger 8.8. The carrier/center section is offset to one side on them. So, I lopped off what I had to on the long side to reuse another short axle. Did it on a rickety wood bench on jack stands. Used a cut off wheel to make both cuts, hand beveled it with the same grinder and a flap disk, and then tacked it up and tig'd it together. I also welded the axle tubes into the center section with some 309L. Not sure if it was needed, but I came across a few posts where it was recommended. I think the overall axle length axle flange face to axle flange face was 54 and some odd inches all said and done. It was about 8 inches too short, so I've got quite the adapter plate and spacer setup going on at the moment. Went around my ass to get to my elbow. That's what I get for flying with some track width number I'd assumed was close after adjusting for OE wheel offset. I did use some silicon-bronze filler to hold the spider gears together... I'd never had the chance to run the stuff, but man it's fun to braze with the ol' tig. Looks really nice, too.

The rear axle is mounted with some S-10 triangulated 4-link kit I'd first purchased off of Maxxxpeeding Rods? Wild experience with them. I never got the full kit, not even after they'd repeatedly resent individual parts. The box looked like it was used for target practice when I got it. Someone spent more money on tape then I'd spent on the kit trying to seal it back up. I found another one of the identical kits on eBay for cheaper yet. It came complete at least. I half followed some instruction sheet for the legitimate kit that these people had copied. I'm sure it'll need some components moved or light adjustments, but it seems to go up and down without binding and keeps the pinion angle consistent throughout the range of motion that the Honda will ever see. I was actually able to mount the rear struts directly to the lower arm bracket on the axle. I modified the strut mounting slightly, but I think it'll do what it needs to for now. To make space for the axle I dropped the fuel tank and cut about half of the spare tire well out. That includes the lower control arm cross bar. I don't think it'll really matter that the stamped and spot welded in unibody cross bar is gone, but I guess I'll find that out, too. I was able to use the factory Honda brake lines. Even the rubber ones. Just got some adapters and built a couple of little jumper tubes. Nothing fancy. I'm sure I can have someone build me a braid ss line in the future.

There's a machinist here in town that has a few stacks of old driveshafts laying around. I was able to eyeball an aluminum one with the right u-joints. It's not quite long enough, but it feels solid even without the rear suspension compressed. No play in the slip yoke into the output of the transmission. I need to swing back up there and see if he has another shaft a little longer...

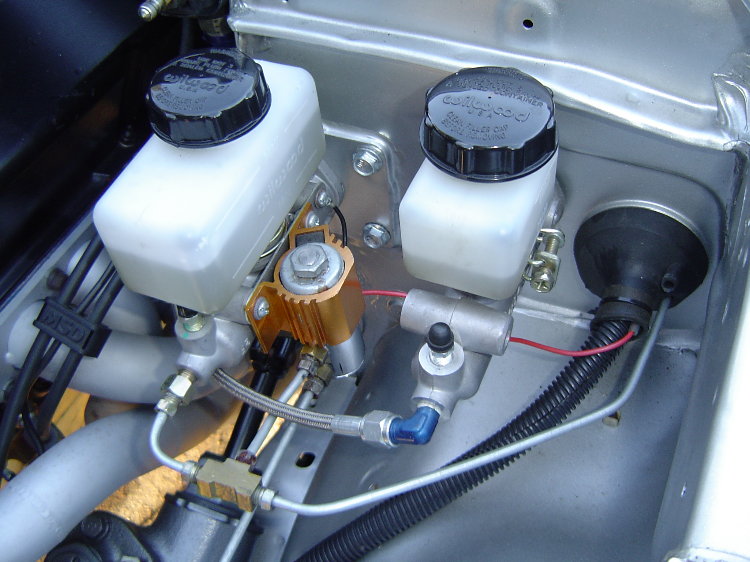

The fuel system isn't anything special, either. I managed to stuff a wally 450 into the Honda's factory sending unit, but upgraded all of the in-tank wires. Which reminds me I need to build myself a fuel pump rewire kit... I just extended the Honda's fuel pump power wiring. I need to do it with the level sender, too. I plan on retaining as many of the factory gauges as possible. The tank is sittings in the trunk as of right now. It's plumbed to regulator I found on Speedway. Used some field attachable 3/8" fuel line kit from Amazon.

Up front got kinda weird. I was able to swap the front knuckles side to side. That moved the outer tie rod mounting to the front. Which also required a completely different steering rack, but I found a way to reverse the Honda one. I wouldn't recommend it, but I think it's going to be solid. I need to get my tie rod situation figured out, but I think I'm onto something now that I understand tie rod angle should be parallel to lower control arm. At least close, or you create a crazy bump steer situation. Installing the tie rod into the bottom instead of the top has put me very. I was able to flip the castle nut and grab a couple of threads. I promise I won't drive it on a public rode like this haha.

The steering shaft needed extended. I chopped the splined section off of the steering rack and put it back into the end of the shaft where it originally was at the firewall. Bought myself a Dewalt universal joint, A couple of 1/2" ID PTO shaft bearing kits with the mounting block and wedge ring, found some old 1/2" drive extensions I never use, and melted it all together with hardwire. Doesn't look great, but I haven't been able to twist it apart yet.

The radiator was another Amazon special. 2.5x19x31 is what I believe it is. Came with fans and shroud. I converted it to a dual-pass? Inlet and outlet are on the same side and I split the tank... Seems to cool just fine idling in the garage. Don't have the fans hooked up yet, but I'll use the E38's outputs to control the Honda's relays. Should work fine... Took some more cutoff wheels to make space for it, but it fits. I've got the heater core lines looped for now, too. I'd like to have A/C and heat, but I know there ain't space for a compressor. I see that there are 12v options out there, tho.

The exhaust manifolds are flipped sides. Built a cross over/y-pipe that comes back over the steering rack and under the starter. Kinda sloppy, but it doesn't leak. I did cut the flanges off of the nasty oem manifolds and replaced them with the more common 3-bolt style.

It was a pain to get the truck throttle body and water pump to work with the car intake manifold. I ended up slipping the truck manifold gaskets under the car manifold. It seems to seal up, and I think I found spacer plates that are meant for this exact thing. We'll see if it pans out. I'm concerned with the job the machine shop did and installing the Melling sleeves. They weren't too confident in their work...

Sorry for the long message! I wanted a Miata, but didn't want to pay Miata prices. I think I've done worse...