I want/need to redrill the 4x114.3 hubs on my first gen RX7 GSL-SE to the more common 4x100. I've called a few machine shops in the SW CT area but so far all of them refuse to do this work.

Does anyone (relatively) nearby know of a shop that can re-drill me some hubs?

You could probably buy adapters for the same amount a machine shop would charge you (if you can find one). I have an $80 set of adapter/spacers in the Challenge car budget.

Are you trying automotive machine shops or real machine shops?

What kind of shops? If they're modern, CNC-only production shops, setting up to drill a 4-hole pattern, 4 times is a pain. And they're likely to be adverse to shouldering the liability.

I'd seek out a small "repair" machine shop or job shop. I do stuff like this all the time - but I'm officially retired from pay work. Beer jobs for friends only.

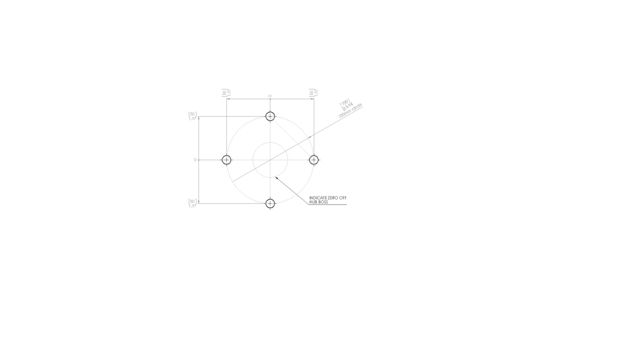

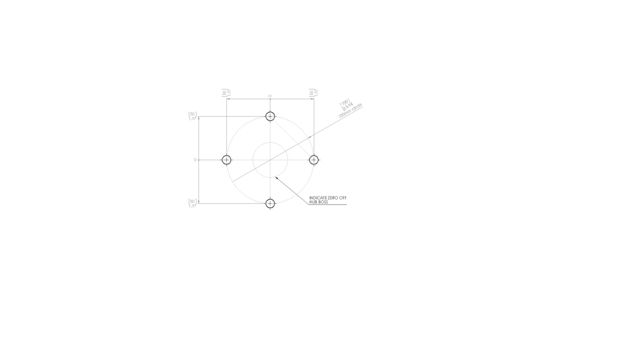

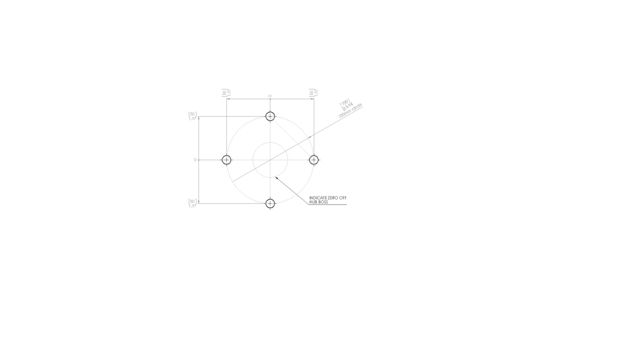

Here's a drawing that's what a machinist needs. Real machinists are binary; they make exactly what you tell them in the form of a drawing.

Yeah, with a car like that you should easily have the space to run adapters.

It's a liability issue. If they modify a part made by someone else and it fails they are afraid they would be sued and their right! Some friends ran into this issue a few weeks ago. Wanted a flywheel machined thinner. Beyond what would normally be within factory specs. No shop wanted to touch it. They did end up finding someone who had the equipment to do it and didn't have any issues with doing it.

In reply to jimbbski:

Again another automotive machine shop vs job shop issue.

114.3x4 is not exactly a rare fitment. Why do you want to change your's?

He probably saw a pretty wheel that he just has to have and it is 4x100.

Its darn near as common a pattern as 4x4.5 inches.

Thanks all. Glad to be on this forum.

maschinenbau, I don't want to run adapters because then I run into fender rubbing issues with a lot of wheels. My goal is to be able to use any wheel available for a Miata (essentially the same offset, different bolt pattern) as those tend to run cheap and/or are light and track-focused. For example, Enkei RPF1s only come in 4x100 for 14 and 15 inch diameters.

Further, I had a set of 4x114.3 and 4x100 dual drill aftermarket wheels, but I broke one, and they're NLA; I was only able to pick one up in 4x100 and 4x108. If I redrill in 4x100, I can continue to use this set. Pricing out a new set of wheels and mounting tires versus redrilling the hubs seems to favor drilling the hubs. And I need to change the front wheel bearings anyway, so now's as good a time as any to pull off the hubs. Adapters would push the wheels out way too far. My alternative is to pawn off this mismatched set to someone with a Miata.

chiodos- I went onto google maps and called every shop I could find in about an hour radius.

motomoron- Am I correct in assuming that small "repair" machine shops don't have an online presence? Other than word of mouth (I've located one that might be able to help in PA through friend of a friend), how can I find a good small machine shop more locally?

Also, thanks for the picture, but I can't read it. It's too compressed. It would be good to know what the machinist needs so as to not ruffle any feathers.

jimbbski- I would gladly sign a waiver for this if it saved me the trouble of having to use a far away shop.

iceracer- I'm also considering redrilling to a 5 lug pattern so I can fit twenty-fo's with spinners.

The_Jed

PowerDork

4/20/16 6:44 p.m.

motomoron wrote:

What kind of shops? If they're modern, CNC-only production shops, setting up to drill a 4-hole pattern, 4 times is a pain. And they're likely to be adverse to shouldering the liability.

I'd seek out a small "repair" machine shop or job shop. I do stuff like this all the time - but I'm officially retired from pay work. Beer jobs for friends only.

Here's a drawing that's what a machinist needs. Real machinists are binary; they make exactly what you tell them in the form of a drawing.

You're thinking of an operator. Setting aside any potential liability issues, any machinist could have that job done in a few minutes. With no print.

Even cnc as he said would be too hard...just a g70, a g83 and a line of code, indicated, cycle start and done!

Are there any wheel repair shops in the area? If they can weld a split wheel back together, a new hole pattern should be child's play.

In reply to HappyAndy:

Im curious what kind of equipment wheel repair shops have. Only wheel dude we have local is mobile with a 20ft trailer behind a diesel.

WatanabeWannabe wrote: how can I find a good small machine shop more locally?

Maybe look in the Yellow Pages?

Vigo

PowerDork

4/20/16 9:18 p.m.

I only did it once, but i did it myself with the help of a friend. The basic idea was i centered a rotor with the proper bolt pattern over the hub with a hubcentric ring like you would use to center a wheel. I then used 'transfer punches' that fit the lug hole of the rotor tightly to make a center punch hole in the hub. I then drilled up to the proper press-fit diameter of the lug studs and installed them. It was not a heavy car but i did take it over 100mph and autocross it.

Find someone with a Bridgeport mill in their garage..

http://www.jalopyjournal.com/forum/threads/drill-guides-to-change-wheel-lug-patterns.659626/

i bought my bolt pattern change drill guide from him. my datsun has a ford 4.25" pattern rear hub and i'm going to change it to match the front. his jig is very nicely made and it comes with bits. i emailed him, told him the pattern i had and the one i wanted to go to and i had a setup within a week.

Don't you need to redrill the rotors as well?

Including any replacements?

Yeah, I'd look at adapters or ensuring I can use off the shelf rotors without needing to redrill them every time you replace them.

Try Mikes Automotive machine shop in Beacon Falls.

I miss running machines. If I lived close, I'd bang it out in no time.

skierd

SuperDork

4/20/16 11:44 p.m.

Maybe search eBay and forums for a 4th wheel instead?

Or, order the 4th wheel and sell as a set of 4x100 wheels and get yourself something that fits.

Stefan (Not Bruce) wrote:

Don't you need to redrill the rotors as well?

Including any replacements?

Yeah, I'd look at adapters or ensuring I can use off the shelf rotors without needing to redrill them every time you replace them.

Dig around on the right parts pages and you can maybe find a hub/bearing combination to make it a bolt on affair.. I once found a combination of parts to put 12" x 1.25" 80's Chevy/GMC pickup brake rotors on a Chevette because I was bored one night..

It's actually not that simple. Some hubs aren't machined flat on the backside and have thinned areas between the stock lugs...you're not going to want to drill and tap those (or press in studs). Narrower pattern may also cause interference issues.

It's also not as simple as writing a program. You have to hold the hub in the milling machine (not exactly throwing a square chunk of metal in a vise) and indicate....set up time would be a lot more than running the program.