Okay, you got me, it's actually an F55 4-door, 'cause that's how uncool I am. Anybody been through timing cover replacement on a B38?

Anyhow, the core question is whether as I replace the timing cover (and the motor mount that the oil leak destroyed), is it worth buying the special BMW tool 2 357 900 (or the $65 knockoff) for guiding the seal onto the crank?

It seems like a stupid use of $65 for a (hopefully) one-time job, but it also seems like a great opportunity to save $65 only to have to buy another timing cover and do the whole job over again if it turns out that you are likely to berk the seal by just trying to slide the timing cover into place. I will happily cough up the money if it significantly improves the odds of not doing this again sooner than I ought to. Okay, "happily" might not be the correct word, but I'd love to know whether it's worth it.

I was disappointed nobody's done a model for 3D printing a similar tool, but I'm not going to try to figure out how when I wouldn't have dimensions 'til the DD is half-disassembled. Also a little concerned that it might be fussy to get that smooth enough to work nicely given the layer ridges' most obvious orientation, though a few minutes of manual smoothing might be nicer than the cost of the tool.

Okay, maybe if I put a B48 in the 2002 I'll get two uses out of it.

Aspen

HalfDork

10/3/22 2:50 p.m.

I can't say on the tool but am surprised that your B38 is leaking already.

In reply to Aspen :

I have no idea what's normal on "modern" cars. This is my third new-vehicle experience, and this is the first one I've kept for a while.

Seven years and 81k miles? I'd certainly be happier if it weren't leaking. And happier if it'd been obviously leaking when I did the crank balancer/pulley last year and was 80% of the way through this job in the process...

This thing was rock solid until that point, having only ever had a cracked spark plug insulator and a buzzy speaker in the first six years. Now I've got the timing cover, that leak killed the rubber in the torque link below that, and the top engine mount is dead as well.

I've bought tools more than once, and used them once, because the cost was a small percentage of what a mechanic would charge for the work.

Especially if it meant I wouldn't break something trying a work-around.

kb58

UltraDork

10/3/22 4:34 p.m.

My rule is: Buy it if it costs less than having someone else do the same work, because then you save money AND end up with a "free" tool.

In reply to jharry3 and kb58 :

I dig it; that aligns with my general tendency and makes a lot of sense.

I think I'm wrestling with some aversion as a long time BMW fan who's not stoked about their increasing DIY-hostility and other changes I find distasteful.

$65 for a tool to guide one seal on one engine (well, one engine family) is also a little ugly in terms of how general the functionality is (support a seal in transition onto a shaft) and how limited in use the specific tools is (B38 and B48?), but that doesn't change the practical calculus.

Thanks!

When it comes to MINI/BMW special tools, I've learned (sometimes the hard way...) BMW spec'd them for a reason. Are they always required? Maybe... maybe not. For example, I have a similar "seal protector" tool for installing the CV axles into the R50-53 transmission. I honestly don't know if any of the indie MINI wrenches I know use the tool, but it was in the manual... and the cars I was working on weren't mine... and the tool wasn't terribly expensive... so it's part of my collection.

When it comes to leaking oil, MINIs uphold the finest of British traditions. Especially the R53. It's almost heartwarming to read the F56 isn't immune either.

If that is a low tension seal (has no spring) like VWAG started using a ways back... you really do need a guide tool to keep the seal from getting damaged. They are more like stiff cup seals than lip seals and do not tolerate getting tweaked.

In reply to Ian F and Pete. (l33t FS) :

I've already ordered it, but I'm grateful for the confirmation (and education).

I was trying to figure out if there was some way to make a range of them for use across all applications of this type. Having a $65+ tool for every size of low tension seal you ever cross paths with sounds expensive. Does such a thing exist?

I don't actually know whether this is that type of seal yet, but contextually it sure seems likely.

The VWAG units I am familiar with generally came with a little plastic installer tool, just a thin little sheath to get the seal over the shaft it is sealing to, which will help you keep the seal from getting damaged but it does nothing to ensure that the seal gets installed perpendicular. The bores they pressed into all had positive stops, which is nice, but you would still need a way of pressing the seal in evenly so you don't bend it.

A lot of timing covers nowadays do NOT have a positive stop, you can push the seal in too far. I know the rear main seal in the R50 is like this, because I drove one in too far while trying to install it cowboy-style.

In reply to Pete. (l33t FS) :

In this case the seal is part of the timing cover and the tool seems to just be to stop you folding it back over on itself on the way on. New problems with multiple form factors! VWAG including the tool I like. BMW 0, VW 1, today. At least pressing evenly can be ad hoc'ed a bit more easily in many cases.

It feels like this is an application that could've been dandy to use an included $0.25 plastic guide with a little clever design. But I guess that's not the BMW way (nor is it the way of folks who install three of these a week, so there's that)...

Ozan2

New Reader

8/28/24 6:56 a.m.

In reply to Jesse Ransom :

Did u buy the special tool? U know the dimension of it to fit the seal properly on crankshaft?

In reply to Ozan2 :

I did buy the tool. I'll try to get some dimensions soon.

Ozan2

New Reader

8/28/24 4:05 p.m.

In reply to Jesse Ransom :

Please reply here, dimensions and any useful information(ex: TIS file, how the shaft seal should come(inside or outside) with the lip, use of any black RTV silicone, neccesary to drain oil from sump(i still have gauge at half).

Bought aftermarket cover(made by NTY) for my b38 because started to make oil mist around and i see a few droplets.

Ozan2

New Reader

8/29/24 1:37 p.m.

In reply to Jesse Ransom :

?

In reply to Ozan2 :

Sorry, it's been a hectic couple of days.

Ozan2

New Reader

9/2/24 12:56 p.m.

In reply to Jesse Ransom :

please

I believe this is the manual I got, and its been very useful, and contains things like callouts for the correct sealant etc and all the related steps (a given procedure is generally described across several parts of the manual in terms of prerequisites and so on): https://www.ebay.com/itm/387342583908

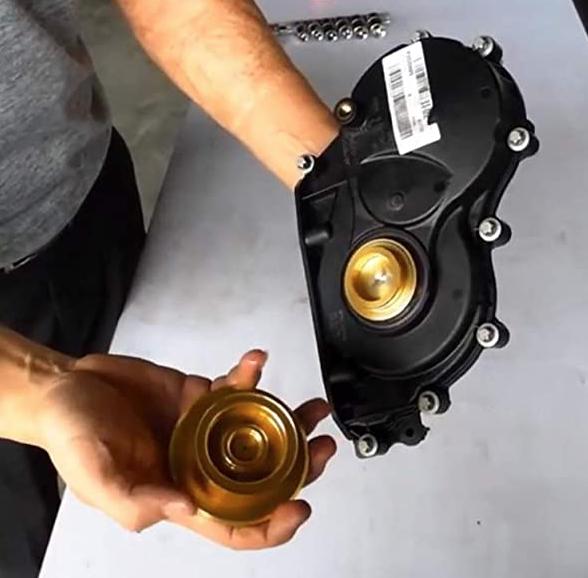

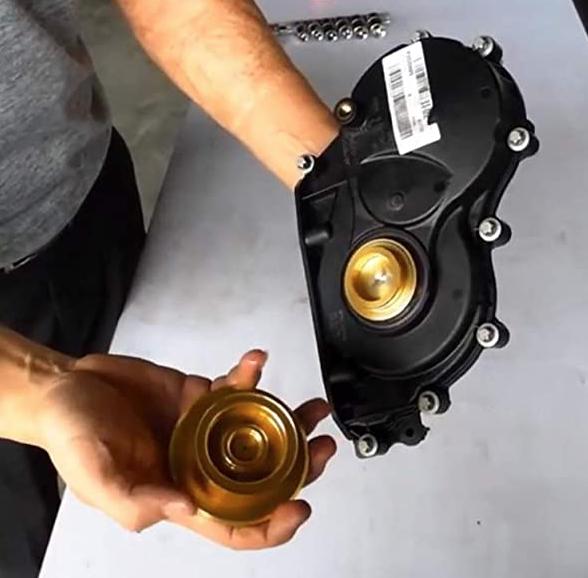

I don't suspect I could get a reliable measurement, but I expect that little flange around the perimeter of the part on the right is important for "handing off" the seal from the tool to the crank. If you don't have that flange to match the chamfer on the crank, it would probably be easy for the seal to catch and get flipped. Similarly, I measured the tool at 52.5mm; if you took that 52mm measurement off the crank, the small increase in size on the tool is probably important again to help with that handoff. I don't think this tool could be 3D printed, or at least not by filament without post-processing or perhaps being clever with orientation because the most natural orientation would put a bunch of ridges right where they'll interfere with smooth seal sliding. All that to say that even with a 3D printer and all the dimensions sitting right here, if I had it to do over I'd still buy the tool.

Ozan2

New Reader

9/4/24 4:57 p.m.

Thanks for dimensions.

I went to my car with vernier caliper and i start to measure and imagine. took the spare part, checked the outer lip the gap between outer lip until seal etc. I made the project and printed succesfully the tool.

The problem with this special tool is that i don't find it in my country and i must wait at least 1 week for delivery.

The special tool made by plastic is what i needed and of course i made it a few mm larger than crankshaft to help the seal slide when i remove the special tool.

Ozan2

New Reader

9/4/24 6:35 p.m.

In reply to Jesse Ransom :

Thanks for support! Everything ok, used the car 150 miles starting from low rpm until hell yeah. Zero leakage.

I put black RTV silicone(not loctite 5970) in corners where the oil pan and engine casing meets.

Very important to all DIY to clean the surface properly with brake cleaner and something which doesn't make scratches on metal. U will find burnt O-ring on metal and also oil residues.

Scratching the metal won't hurt a darn thing. Wire brush, Scotchbrite pad (handheld not power tool), it's all good.

In reply to Ozan2 :

Congratulations, nicely done!