Would rotating a 5spd transmission the opposite direction be a quick way to destroy it?

I think I had an epiphany this morning. For the last 35 years or so if you wanted better gearing in a Fiat 850 you installed an aircooled VW transmission with a flipped ring gear so that it would provide 4 forward gears with the counter clockwise rotating Fiat motor. It hit me that the VW dasher, fox, quantum, audi 4000 transmission is externally very similar to the bug unit. By flipping it around and mounting it in the rear of the Fiat and turning it counter clockwise I would have 5 forward gears and and one reverse. I just cant decide if the tranny could take it for long. I know oil seals are directional so at least the input shaft seal should be replaced but all the other seals handle the reverse gear every now and then.

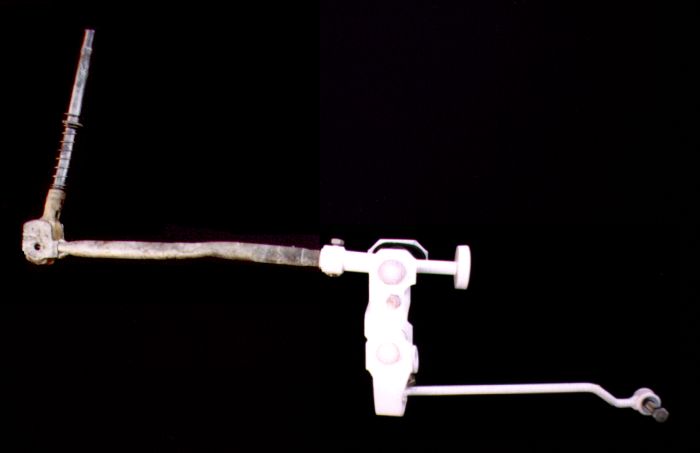

Fiat transaxle

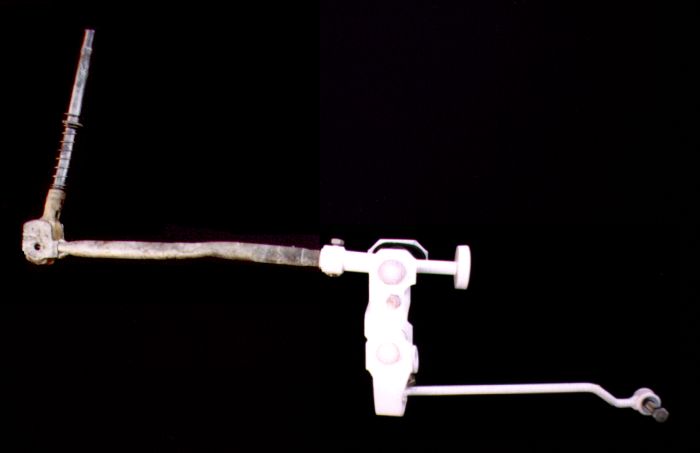

VW/Audi unit

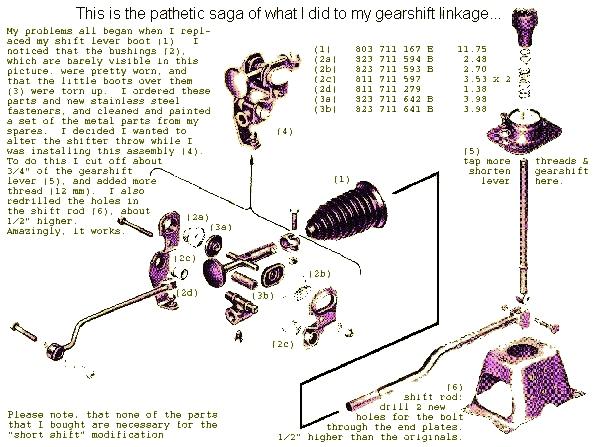

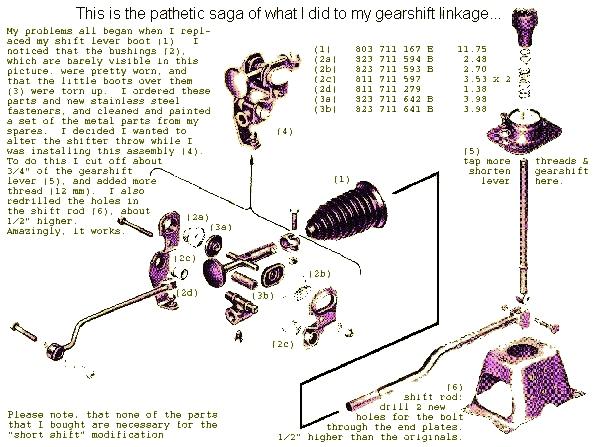

The output flanges are in approximatley the correct spot. Shift linkage would take some work but is not impossible and best of all these things are CHEAP. quite a few on car-part.com for under $200

Imagine a modern fully synchro'ed 5spd in this

IIRC that is how a Formula Vee works; result is a mid engined car with a tranny that used to be in a rear engined car...?

In a Formula Vee the transmission internals are still rotating in the "normal" direction i.e.the same direction as the crank, only the ring gear changes direction.If you look at the ring gear, it's merely rotated around to the opposite side of the pinion. It's still has the thrust between it and the pinion going in the original directions. Nothing is really reversed except the rotation of the axles, which is what you would have to do because the whole engine/trans assembly is simply installed backwards.

DeadSkunk wrote:

In a Formula Vee the transmission internals are still rotating in the "normal" direction i.e.the same direction as the crank, only the ring gear changes direction.If you look at the ring gear, it's merely rotated around to the opposite side of the pinion. It's still has the thrust between it and the pinion going in the original directions. Nothing is really reversed except the rotation of the axles, which is what you would have to do because the whole engine/trans assembly is simply installed backwards.

Now that you mention it...

D'oh!

Original question, would it hurt it?

engine mating could be an issue..you still want to run the 850 motor or plan on switching to VW/Audi power?

The only way I could see it being an issue is if the transmission has an oil pump that is driven off the input shaft. If it is splash bathed, it should be fine

sobe_death wrote:

The only way I could see it being an issue is if the transmission has an oil pump that is driven off the input shaft. If it is splash bathed, it should be fine

I think most manuals are splashed lubricated.

For the most part they are just gears... But they are helical gears, which have end thrust... I guess the possibility exists that money could be saved by only using heavy enough thrust washers to deal with the loads for the life of the transmission on the side that gets the thrust in normal operation...

Meaning, when you spin the gears backwards, and they thrust the other way there may not be a surface designed to deal with that for long.

Though that is just trying to come up with something, washers are not terrible expensive and they could just as well use them on both sides...

Great idea! The only downside I can think of: the box has been run in one direction under load all its life. If you run it backwards it could be very noisy, at least for a while.

Noisier than the 40 year old factory box with bad number 2 synchros that keeps the revs at 4800rpm at 60mph?

Starting shopping today. It is worth the risk.

Are synchros directional?

ditchdigger wrote:

Are synchros directional?

They are usually just a cone clutch, so no.

See, they hold the bit that is attached to the shaft with those dog teeth, and just slide up on a taper on the gear to match the speeds.

See, they hold the bit that is attached to the shaft with those dog teeth, and just slide up on a taper on the gear to match the speeds.

Helical cut gears might have thrust bearings on the wrong end of the shafts if you spin them backwards with a load. That's the only thing I can think of.

So ditchdigger, there doesn't seem to be anyone on the board who's already tried this. You have the opportunity to go ahead and try this and become the "world reknowned expert" on the whole issue ! Keep us posted, especially if it doesn't work.

Keep us posted, especially if it doesn't work.

...especially if the failure is dramatic!

Good luck!

David

we love success stories... and we love dramatic failures even more! But.. why not search out a porsche 901 trans as used in the early 911s and 914s... those cannot be too expensive as most people upgrade to the more sturdy 911 trans that came out in the early 70s that did away with the dog leg first and gained a LOT of strangth and reliability

granny

New Reader

12/21/09 1:50 p.m.

I ran a Dirt Late Model drivetrain in reverse rotation back in the late '80s / early 90s. It had a Mopar 440 for power that was mounted backwards and the early version had a remote mounted chev 3spd transmission (extended 18" input shaft driven off the crank snout). The transmission did not have any problems from spinning backwards. The 1st version used an upside down 8-3/4" rear, but the 2nd version shown below used a quickchange that had the centersection modified to put the ring gear on the other side of the pinion to comply with the reverse rotation. It also used a home built transmission with an internal clutch. This one even won a few features. It was all backyard engineering, but i would not hesitate to run either transmission backwards again if i needed to...

Granny you are my hero right now. That is AWESOME.

THAT. IS. AWESOME.

Reminds me of the chassis setups we used to run for RC dirt modifieds... but much harder to do with a 350 than an electric motor.

Toyman01 wrote:

Helical cut gears might have thrust bearings on the wrong end of the shafts if you spin them backwards with a load. That's the only thing I can think of.

Having had at least a few manual boxes apart, all of them I ever went into had the same size thrust washers on both ends of the countershaft which is where that would really become important. I never saw a 'directional' bearing on either end of a mainshaft with the lone exception of the double row 'thrust' bearing in a Porsche 901 box. That was more due to snap ring placement than anything else.

Granny, that is a helluva piece of engineering. Congratulations!

transmission located. Work to begin soon.

Bringing this one back from the dead.

So I bought a 4000S close ratio 5spd in december of '09 and started working out bolt patterns and got sidetracked by life in general. After a while I started listening to the naysayers that it wasn't going to work and kind of forgot about the audi trans under my bench.

Two weeks ago I got messaged on retrorides by a fellow in Romania who using translation software read my musings about how it might be possible and went and did it. He has been driving around for a year with an audi 4spd and was about to upgrade to a 5spd. He reports no strange noises or other oddities and that it works very well. However his shift pattern is backwards.

So I guess I am back onto this project. Gabi used euro market only Fiat flywheel and pressure plate with a VW polo clutch disc. I think I would like to adapt the Audi flywheel to my motor to take advantage of the much needed clutch upgrade.

So the next hurdle. How would you guys reverse the shift pattern?

The audi stuff

Reversing the fore and aft throw is easy but the side to side which is a twisting motion of the shift rod has me stumped.

I am thinking about perhaps converting the trans to cable shift some how.

Cable shift seems like it might be simpler overall.

Here's my dumbest-idea-in-the-world:

Find a tiny open differential. (1/4-scale R/C car? Bits from two hand-crank eggbeaters in homemade box?)

Mount that inline: Twist is reversed.

No, I don't have a clever idea for how to locate the reversing box housing while still allowing it to travel fore and aft...

Hey, I said it was dumb... Probably makes that cable shift project look better, though.

Cable shift and some type of translator mechanism.

ransom wrote:

Find a tiny open differential. (1/4-scale R/C car? Bits from two hand-crank eggbeaters in homemade box?)

Mount that inline: Twist is reversed.

Man you make a cableshift swap seem so easy!

It looks like it is just a shaft sticking out from the housing that needs to be pushed/pulled and twisted.

I just remembered I have a VW shifter and cables from the aborted VR6 rabbit project hanging on the wall! Result!

You know if this works, you'll be pretty awesome.

Oh and just to up the eVilness of this project:

The Audi Quattro transaxle uses the same case with an extension housing to drive the rear differential. Since you're using this in a rear engined car, your extension housing would be pointed towards the front. Also, for a factory limited slip, you can install a rear differential from an Audi V8 in the transaxle.

I believe the clutch spline on the Audi's are a pretty common Mopar/Ford spline. Seek out the GT-40 and Lamborghini replica folks for clutch disc ideas as they use these transaxles behind their V8's.

Also, I don't think you'd need a translation solution for the shifter if you went with a cable shifter. You'd merely have to run the cables from the opposite sides of the shifter to get the pattern corrected. I've heard from several folks that outboard motor control cables are great for home-made shifter cables and they obviously hold up to a certain amount of abuse, come in several lengths, etc. Just watch the cable routing to reduce the chances of binding and you should be good to go.

Good luck and may the eVil be with you

See, they hold the bit that is attached to the shaft with those dog teeth, and just slide up on a taper on the gear to match the speeds.

See, they hold the bit that is attached to the shaft with those dog teeth, and just slide up on a taper on the gear to match the speeds.