So, I got this crazy idea for my challenge car. It would be a lot of work, but 'going big or going home' is usually how my car projects work out, and this is turning out to be no different.

The idea is this:

- Cut away a significant portion of the body panels.

- Cut away some of the unibody.

- Replace where necessary with steel tube. Basically try to make a 'Luxo-cet' or an 'Exo-yacht'.

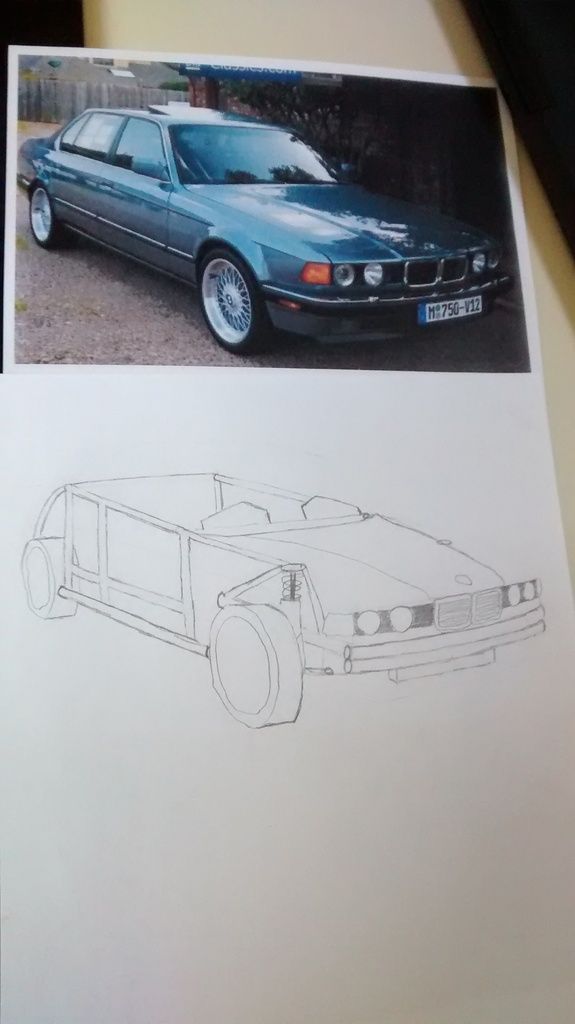

Pic of idea (PAD):

So, the question is: Round tube or Square tube?

I know round tube is easier to cut and shape (joints between tubes are much easier, mainly, and cue the jokes), but strength for strength, it is heavier. Is cost about the same between square and DOM? I would probably stay away from ERW or whatever.

I also have never built a cage or locost or exo car before, so my fab skills are currently low-ish. I have welded up a fully custom exhaust with straight tubes and mandrel bends, but this would be more intricate I imagine. Part of me wanting to do this is to learn though, that is a big part of the draw.

You have it backward there. Square is easier to work with, but heavier.

Jumper K. Balls wrote:

You have it backward there. Square is easier to work with, but heavier.

Yep, you 100% got me. Darn, and I read that like 3 times before I posted.

Doesn't part of the rules say that most of the bodywork must be intact? Do it anyway, because its rad, but realize you may be placed in the exhibition class.

tuna55

UltimaDork

5/13/15 10:25 a.m.

Appleseed wrote:

Doesn't part of the rules say that most of the bodywork must be intact? Do it anyway, because its rad, but realize you may be placed in the exhibition class.

I don't think the rules say that anymore, but I could be wrong.

http://grassrootsmotorsports.com/events/2015-challenge-rules/

Appleseed wrote:

Doesn't part of the rules say that most of the bodywork must be intact? Do it anyway, because its rad, but realize you may be placed in the exhibition class.

I see this:

"Appearance:

Cars should have a finished appearance. Use good sense and taste when you modify your car, as missing grilles, headlights, fenders, hoods and the like are generally unattractive. Cars that are ugly will be less likely to be featured in the magazine and other media. Please remove your front license plate and plate holder, as those things are ugly, too."

However, I think that rat rods, exocets, locosts, etc can be very finished/attractive if done right and good taste is used. I hope to qualify for that. I certainly don't plan to show up with an ugly car. If not, I'll be fine running exhibition.

I'm a fan of round tube for everything that needs to be bent or joined w/o a gusset and only really use square tube for things that need a flat mounting surface like seat brackets, steering supports, brake pedal boxes, engine frames/mounts and so on.

Personal preference and path of least resistance engineering more than any other reason.

Sonic

SuperDork

5/13/15 11:15 a.m.

I've thought about making a "super duper 7" by taking a full frame car like a p71, taking away the body, shortening it a bit, adding basic sides, fenders and lights, a seat and belts, and seeing how it would do at the challenge. Seems easier than dealing with a unibody car

square tube will be alot easier but round tube will look better if you leave exposed cage

SVreX

MegaDork

5/13/15 12:17 p.m.

Appleseed wrote:

Doesn't part of the rules say that most of the bodywork must be intact? Do it anyway, because its rad, but realize you may be placed in the exhibition class.

NO!. The rules don't say that.

I wish that rumor would go away and SOMEBODY would take advantage of the rules opportunities that now exist!

Read 'em, guys! Even Per Schroder said it would be really interesting to see how much people exploit them when he saw the new set of rules.

So far, absolutely nothing. We all fail.

The best I can say is that I have a car underway that is being built to take advantage of the new rules.

Unfortunately, its a slow build.

I only said that to make sure it fit the rules. Since it does, I say have at it. I want this to work.

SVreX

MegaDork

5/13/15 12:53 p.m.

In reply to Appleseed:

Wasn't picking on you.

I am just amazed how much opportunity exists in the current rules that NOBODY is noticing.

My secret weirdo wish is to narrow the body of a RWD coupe while keeping the track the same. Imaging an open wheel Camaro or FC RX-7?

tuna55

UltimaDork

5/13/15 1:41 p.m.

I have some good ideas, but I lack the dollars and garage space at the moment. You'll see it someday.

Every tube frame race car that I've seen and a few that I've worked on all contained both round, square, and even some rectangular steel tubes. Both of the two Roush built Trans Am race cars that I worked on the most surrounded the driver with a cage made with round DOM tubing. The main frame rails that formed the base of the cage were square tubing. The entire frame both forward of the fire wall and behind the driver was made with square tubing.

Square tubing is stiffer if the load paths are in the same plane of either one of the two sides of the tubing but not as much if the load is at an angle. Round tubing has the same stiffness at all angles which is why it's used in a roll cage. You can never predict how a crash will load the cage.

Appleseed wrote:

My secret weirdo wish is to narrow the body of a RWD coupe while keeping the track the same. Imaging an open wheel Camaro or FC RX-7?

Or, an open wheel 750iL? hehe

Also, I seem to be reading the rules that you can recoup 1008 dollars no matter your purchase price. Therefore, you really could get a lot of budget going with the right car... Can someone confirm or deny?

jimbbski wrote:

Every tube frame race car that I've seen and a few that I've worked on all contained both round, square, and even some rectangular steel tubes. Both of the two Roush built Trans Am race cars that I worked on the most surrounded the driver with a cage made with round DOM tubing. The main frame rails that formed the base of the cage were square tubing. The entire frame both forward of the fire wall and behind the driver was made with square tubing.

Square tubing is stiffer if the load paths are in the same plane of either one of the two sides of the tubing but not as much if the load is at an angle. Round tubing has the same stiffness at all angles which is why it's used in a roll cage. You can never predict how a crash will load the cage.

Thanks, that makes sense. I'm not planning on going full tube frame (maybe on my second try, ha), really just taking out some unibody and then reinforcing that area if I think I took out something structural.

I hope to leave the unibody frame rails, firewalls (actually keep basically all unibody that touches the 'interior compartment'), and mounting points for engine, trans, and suspension. I want the engine bay to be visible and look good though, so I know there will be some work to do working around the strut towers.

SVreX

MegaDork

5/14/15 9:10 a.m.

rcutclif wrote:

(actually keep basically all unibody that touches the 'interior compartment')

Ummm... except the roof, right?

That's the most important part (structurally) to a unibody.

Your idea is missing something very important.

SVreX

MegaDork

5/14/15 9:19 a.m.

In reply to rcutclif:

You don't need to start deciding what shape of tube to use until you begin with an idea that won't fold in half the first time you try to move forward.

I realize you've never built a roll cage, and your drawing is a first rough pass, but you have made a giant "U" shape out of the car when you cut the roof, and drawn no triangulation at all, either fore- aft nor diagonally corner-corner.

I am concerned you will put a lot of effort into something that you are very disappointed in.

You need to work a little harder on the drawings and consider the design like a roll cage long before you worry about the tubing shape.

SVreX wrote:

rcutclif wrote:

(actually keep basically all unibody that touches the 'interior compartment')

Ummm... except the roof, right?

That's the most important part (structurally) to a unibody.

Your idea is missing something very important.

Yes, except the roof. Ha. You guys are so detail-oriented! I do think your statement about 'most' important part of a unibody is a bit of a stretch, but I see that it is an important part.

That's why I'm planning to have those bars front to back at basically window level. I'm hoping that helps substitute for the roof (actually, the load path should be much more straight through the bars in compression, which is NOT something you can say about a roof). I could even run a third in the center of the car if really necessary, but id rather not.

SVreX wrote:

In reply to rcutclif:

You don't need to start deciding what shape of tube to use until you begin with an idea that won't fold in half the first time you try to move forward.

I realize you've never built a roll cage, and your drawing is a first rough pass, but you have made a giant "U" shape out of the car when you cut the roof, and drawn no triangulation at all, either fore- aft nor diagonally corner-corner.

I am concerned you will put a lot of effort into something that you are very disappointed in.

You need to work a little harder on the drawings and consider the design like a roll cage long before you worry about the tubing shape.

thanks for your concern. I'm sure you will help me quite a bit along my journey.

However, I know there are LOTS of unibody convertibles out there, some are even sporty... cough, cough, cough, miata, cough, cough, and they still even have real doors, and no diagonal bracing through the middle of the passenger compartment. Now, I know they were designed that way, and engineering a car is no small feat, so I'm not saying it's easy.

I still believe: no roof /= failure, and if I give up the idea of having real doors, then I should have a giant advantage that automotive engineers don't realistically get to leverage.

Let me see if I can clarify my original question:

If you have designed or built your own locost / exo car / dune buggy / whatever, did you primarily use round tube or square tube? If you were to do it again, would you change your mind? Does the easy of use of square tube outweigh the looks, "lightness", or strength in less-than-predictable loading of round tube?

Many have answered already, and thank you all for that.

SVreX

MegaDork

5/14/15 10:19 a.m.

rcutclif wrote:

That's why I'm planning to have those bars front to back at basically window level. I'm hoping that helps substitute for the roof (actually, the load path should be much more straight through the bars in compression, which is NOT something you can say about a roof). I could even run a third in the center of the car if really necessary, but id rather not.

There is no triangulation in that "truss". The top bar won't do much- all 3 of the vertical bars can lay over together when stress is applied at either end.

Even a roof has a little triangulation. That's why "A" pillars lean back, and "C" pillars lean forward. Both have "gussets" designed into both the top and bottom attachments.

Plus, the roof ties the car diagonally. The front right is connected to the rear left via the roof.

SVreX

MegaDork

5/14/15 10:26 a.m.

rcutclif wrote:

However, I know there are LOTS of unibody convertibles out there, some are even sporty... cough, cough, cough, miata, cough, cough, and they still even have real doors, and no diagonal bracing through the middle of the passenger compartment. Now, I know they were designed that way, and engineering a car is no small feat, so I'm not saying it's easy.

ALL convertibles (unibody or not) have heavier frames than their counterparts with roofs.

Check the curb weights. A Fox body Mustang coupe weighs LESS than a Fox body Mustang convertible, not more.

That's because the rigidity is designed into the frame/ floorpan of a convertible. Essentially, it's heavier/ stronger to act like a bridge from the front wheels to the rear.

You've got no bridge if you cut the roof from a unibody.

Look at Exocets. Look at Locosts. Look at Atoms. All have truss design triangulation both vertically (in the side design/ construction), AND corner-to-corner (through the roll cage design).

I am not saying it can't be done. It can, and I'd like to see you succeed.

But it can't be done the way you are approaching it.

I'm having deja vu with that proposed 3 wheel kit car thread.