What happens when you give an 18 year old an old car with very little horsepower. Naturally they take it for a spin to see what its got and discover that they want to give it more power. In my case I was given a 1964 Chevrolet Nova 4 door, with a 250 cubic inch straight 6 cylinder.

I fixed it up and got it to the point that it was street legal and ran the way it was supposed to... mostly and took it the drag strip with my family. It ran an 11.69! .... in the eighth mile at 59.5 mph. For a worn out Chevrolet straight 6, that's pretty good, but I wanted more. Rather than taking the easy route and swap out the 6 for a V8, I decided I wanted to make the straight 6 go. So I talked to my dad and we decided that it would be cool to install a supercharger.

A friend of ours found a supercharger out of a Ford Thunderbird Supercoupe with an intercooler for $50 and then sold it to us. Then I machined a bunch of parts in my high school CNC shop to retrofit the supercharger to the Chevy straight 6.

I took a two barrel to four barrel adapter plate and cut it down and milled it to match the inlet tube in the super charger.

I also milled out a spacer to space the carburetor off of the back of the supercharger.

I currently plan to replace the current engine in the Nova with the 230 that came with the car. My dad thinks I'm crazy, but I think this will be a pretty awesome way to wake up the old 230. Tell me what you think. I'll keep you posted

Now that is cool. I can't wait to see the end result.

Dude, that is awesomely cool!

What are you running for a transmission?

I've been a bit bogged down by other things, but I've taken a similar approach to my first car, a '66 Dodge Dart with a slant six. Only instead of a blower and four barrel, it's a turbo and EFI. Good luck with this one, it looks like it's off to a good start!

awesome work.

i always wondered about using those t-bird turbos for a draw through carb setup.

I did something similar to a 70 Chevelle with the 250 I6. I turbocharged it using the setup off a 81 Turbo Firebird. It actually ran pretty decent considering the 5psi I was putting in it. I was scared the cast crank and pistons wouldn't stand much more than that. Still made enough power to smoke the clutch within a week of getting it running.

Way cool project, keep us updated.

This is great! your handle confuses me though...

This may be my new favorite thread.

Was the supercharger ready for the prom?

You & pop going to be around on Sunday afternoon? Erin & I might be out in your neighborhood.

EvanB wrote:

Now that is cool. I can't wait to see the end result.

Hopefully the result is another 11.69!

In the 1/4

Ok I am going to be the "wet blanket". By sucking the fuel through the supercharger will you wash out the grease from the back bearings in the supercharger? If this happens things will go wrong in a hurry. I don't know the answer to this but I would want conformation from some one that it is ok to pass fuel through an M90. I would give Eaton a call and ask them.

Ohya if you need help calculating the pulley size versus boost take a stroll over to here.

http://www.ehadesign.com/~dsmith/ENGINE_AIRFLOW.htm

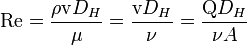

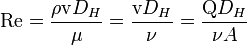

I made this spreadsheet so you can mathematically figure things out before I build things. Like pulley sizes and what not versus the motors capacity and what not. just fill in the data in the box's that have red numbers in them. The middle part has to do with air speed in the tubes as I was concerned about laminar flow characteristics of various tube sizes under various boos conditions and what the The Reynolds number was and if I was going to exceed the The Reynolds number that would result in turbulent air in the intake and this varried with boost / density of teh air in the intake. Not something you will probably need to worry about at the moment.

If you are really board here is the Reynolds Number calculation for tubes.

where:

D is the hydraulic diameter of the pipe; its characteristic travelled length, , (m).

Q is the volumetric flow rate (m3/s).

A is the pipe cross-sectional area (m²).

v is the mean velocity of the object relative to the fluid (SI units: m/s).

u is the dynamic viscosity of the fluid (Pa·s or N·s/m² or kg/(m·s)).

v is the kinematic viscosity ( (m²/s).

p is the density of the fluid (kg/m³).

patgizz wrote:

i always wondered about using those t-bird turbos for a draw through carb setup.

(off-topic alert) The original Ford 2.3T (ala Mustang GT Turbo, etc) was a 2.3 Lima with a turbo and a draw-through carb. To say it didn't work well would be an affront to humanity.

The later EFI versions turbochargers do not adhere well to fuel going through them, either. You really want to do blow-through for it to work.

Can a sealed gas-proof bearing be retrofitted?

Apparently the Toyota SC12 and SC14 superchargers had a coating on the rotors which didn't get along well with fuel.

It didn't stop the Mini guys from using them with good results though.

I'd say go for it. Like appleseed said, if it doesn't run a sealed bearing now (pretty unlikely) just swap it for a sealed unit.

IIrC, the same bearing number but use the suffix RS on the bearing number to get the sealed version.

Hey, I like where this is going!

(I'm currently looking into a megasquirt/turbocharged setup for my '66 250 inliner)

Rob_Mopar wrote:

Was the supercharger ready for the prom?  You & pop going to be around on Sunday afternoon? Erin & I might be out in your neighborhood.

You & pop going to be around on Sunday afternoon? Erin & I might be out in your neighborhood.

No the super charger wasn't ready for prom unfortunately..

We should be. Just give my dad a call before you stop in to make sure.

Kenny_McCormic wrote:

What are you running for a transmission?

please be a 3 on the tree

please be a 3 on the tree

please be a 3 on the tree

please be a 3 on the tree

regarding the bearings that everyone is so worried about- i thought these things were sealed and ran their own oil supply that no one knows they are supposed to change at some interval or another, which causes them to die a premature death from lack of maintenance. if that's the case, then what's the issue?

and even if the blower doesn't have it's own oil supply, i'd think they'd want them sealed up, anyways, due to not wanting to suck oil into the intake tract.. also, the seals on the bearings would have to be hardened against gas fumes due to the gas fumes that would be present in the blower when the engine is shut off..

singleslammer wrote:

This is great! your handle confuses me though...

It is a little contradictory isn't it?

In reply to novaderrik:

It was originally a 3 on the tree car, but someone converted it to an automatic.

In reply to bearing issue:

I'l have to look into that. I have to do a snout rebuild anyways.

![]()