So the rear suspension in an Opel Kadett is pretty much like the rear of an 80s Camaro; it's a solid rear axle on coil springs with a torque arm out the front located by a pair of trailing arms, one on each side. and a panhard rod.

For one particular project I would like to raise the car 4-6" with respect to the axle, and I will be swapping in a different rear axle at the same time.

Assuming that I like the current geometry just fine, am I better off incorporating the vertical displacement into the brackets on the axle and using the stock pickups on the body or building the new axle as a duplicate of the stock one and spacing the springs and mounting points down from the body? Maybe a combination of the two, where the torque arm front mount gets spaced down but the trailing arm, panhard rod, and spring mounts on the body stay the same with the axle brackets for them moving?

And, lastly, has anyone seen a torque arm suspension used for a solid axle in the front of a 4wd truck? Just looking at options.

If you want to lift by moving suspension attachment points, it's better to move the mounts on the body. If you move the mounts on the axle, your axle will have more leverage against the suspension members and it will be extremely difficult or impossible to make them beefy enough to compensate.

I would agree with gameboy. And axel wrap would become much more difficult to control. My guess is you will need a longer driveshaft too with more robust u joints.

Torque arm up front is similar geometry wise to radius arms. Lift more and it will jack the body more under accel(assuming 4wd).

Also leaf springs with a traction bar will be similar too.

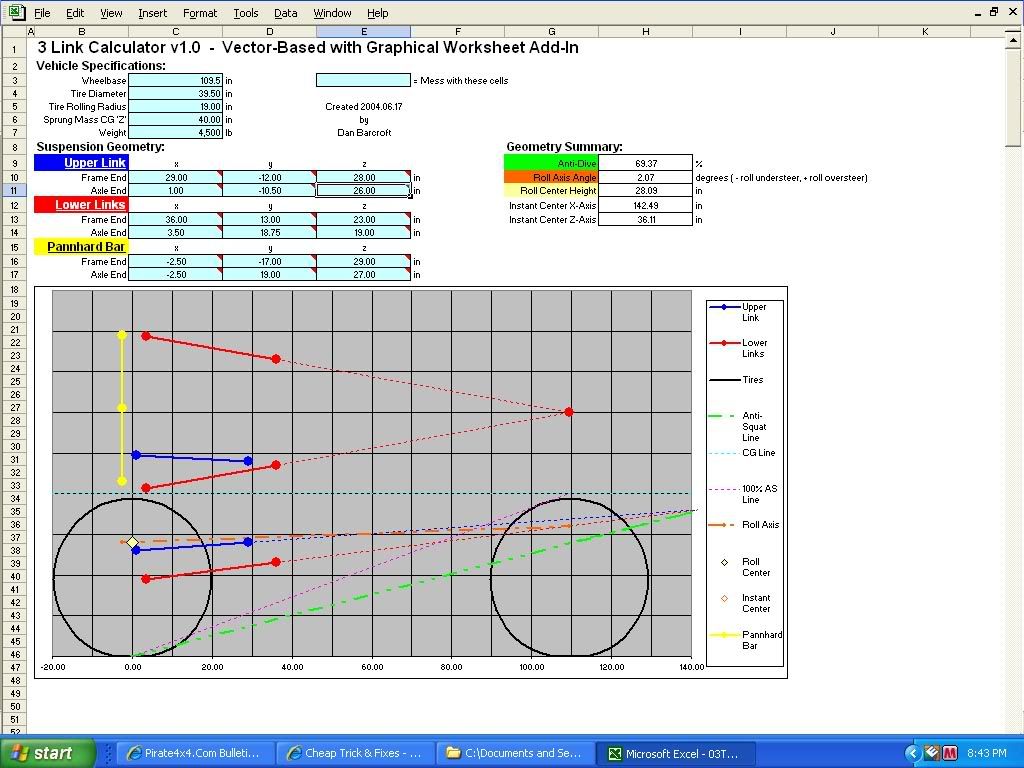

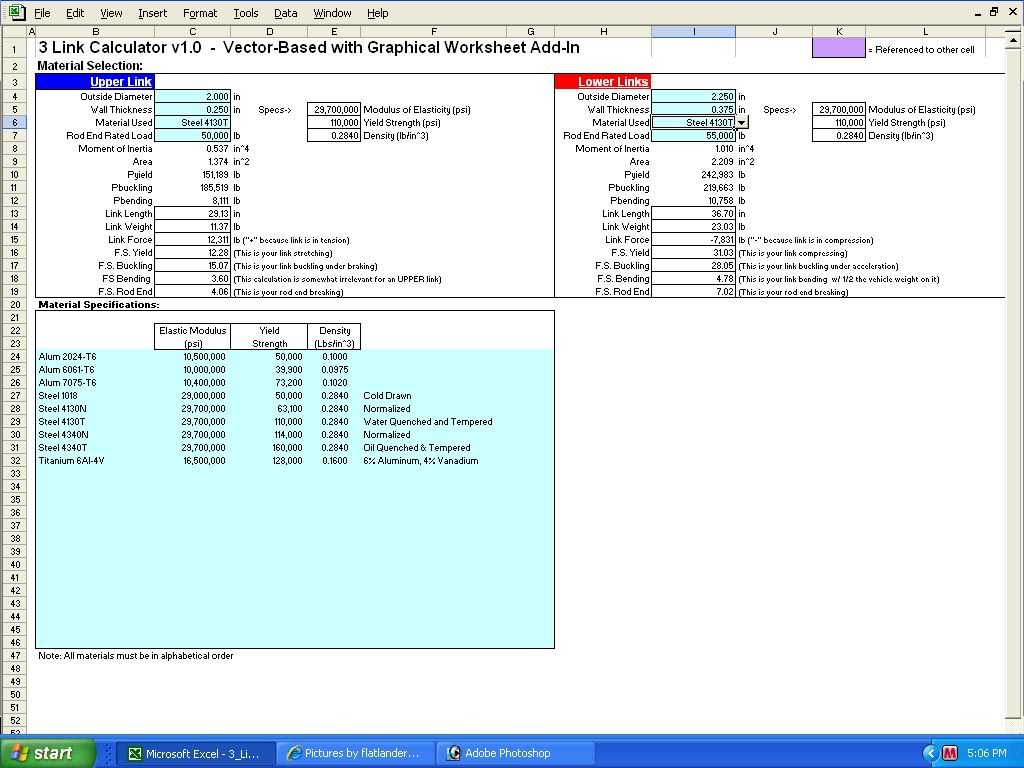

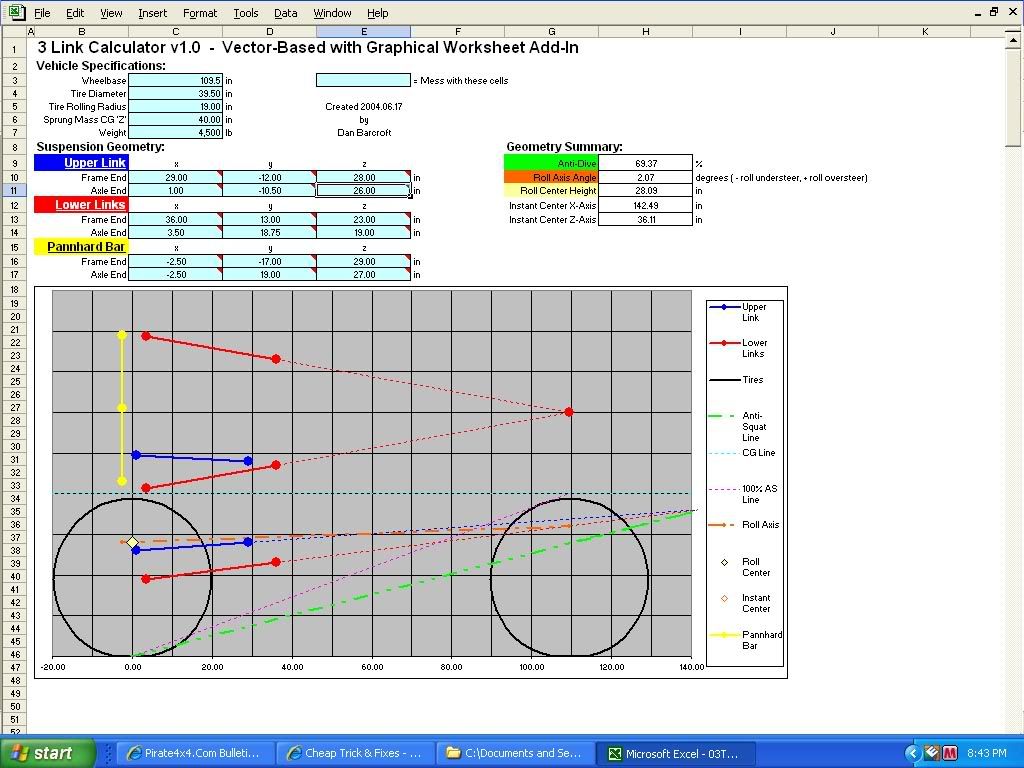

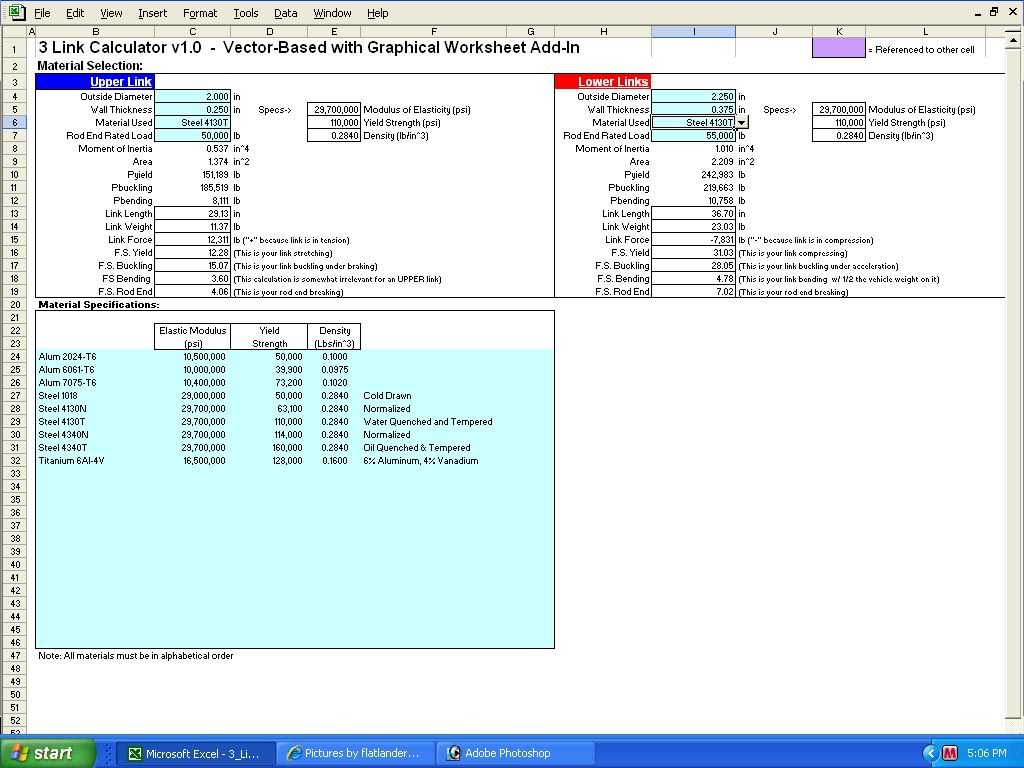

Some terms to get familiar with will be wheel recession and anti-squat/anti-dive.

Moving brackets up on the axle will have the same problem that unimog axles have: TONS of force on the brackets and links. Unimog axles have drop housings at the wheels so the wheels are about 6in below axle center or so.

The correct answer is to mount longer control arms further up the frame to keep similar geometry, plus more consistent geometry for a given range of travel.

Check Pirate4x4 for stuff about link suspensions and whatnot.

What kind of rear suspension exactly? 4 link with panhard? 3 link with panhard? Two radius arms and a panhard?

I spent a lot of time calculating the 3 link with panhard front on this, plus used a 4 link rear calculator to simulate my traction bar with leaf springs to keep it daily drivable. On 40s. I did 10k miles on it like this:

The rear suspension is not a typical (3,4,5,whatever)-link. The torque arm effectively makes the axle like a large capital "T" with the wheels at the ends of the top and the bottom attached to the car.

Imagine having one ladder bar in the center of an axle, handling all the brake and acceleration torque forces for the axle and then add a pair of parallel links, one on each side to locate the axle fore and aft and a panhard rod to locate it side to side. That's what I am talking about.

Currently the panhard rod and trailing links attach to the axles through brackets on the axles at about 5" below the axle centerline. I'd like to attach them much closer to axle centerline, which should if anything reduce any weird forces on them and let me use the current mounts in the unibody and factory rods and links.

I think the torque arm front mount should stay roughly the same with respect to the axle to keep the squat and lift roughly the same, which means moving the pivot point down off the bottom of the unibody by the amount of the lift.

I'll probably just build it and see how it rides.

You could keep a tq arm setup, but for longer travel I think you'll want to bring the control arm mounts farther forward on the unibody (longer arms), and to prevent bind ditch what I assume is a big rubber tq arm mount for a shackle.

Yeah using longer arms and moving the mounts forward would be a far better solution overall than just moving the mounts downward. Just moving them down could work well enough for a gently-driven street cruiser, but if you're going offroad you'll really want those longer arms.