Suprf1y

UltimaDork

1/30/20 8:08 a.m.

Our DD has end links that mount on the strut at the top and sway bar at the bottom, both with rod ends as I assume most cars are these days. We have a long, rough driveway, and live in the country where the roads are not the best. Because of that I have changed them almost yearly since we've owned the car. I've tried the better aftermarket and what are supposed to be the best aftermarket ones with little to no difference, and they all wear in the same place, on the rod end mounted to the strut. It makes sense because that end is seeing a lot of movement.

My question is, is there a functional difference between how they are now typically mounted, from the sway bar to the strut, and how they were traditionally mounted, from the sway bar to the control arm? It seems to me that, as long as they are mounted in the same plane (and not affect the rate) they should work the same, but it's not intuitive to me for some reason. I'm not seeing it.

You want ball joints, not spherical bearings. Is that from the factory?

Got a picture of the mount or even a hint as to what this vehicle is?

dps214

Reader

1/30/20 9:23 a.m.

Mounting them to the control arm most likely changes the motion ratio significantly and will affect the rate as a result.

Suprf1y

UltimaDork

1/30/20 10:59 a.m.

It's a Chevy Sonic, and I think the setup is the same as the Cruze, and as far as I know the Toyota Corolla is almost identical.

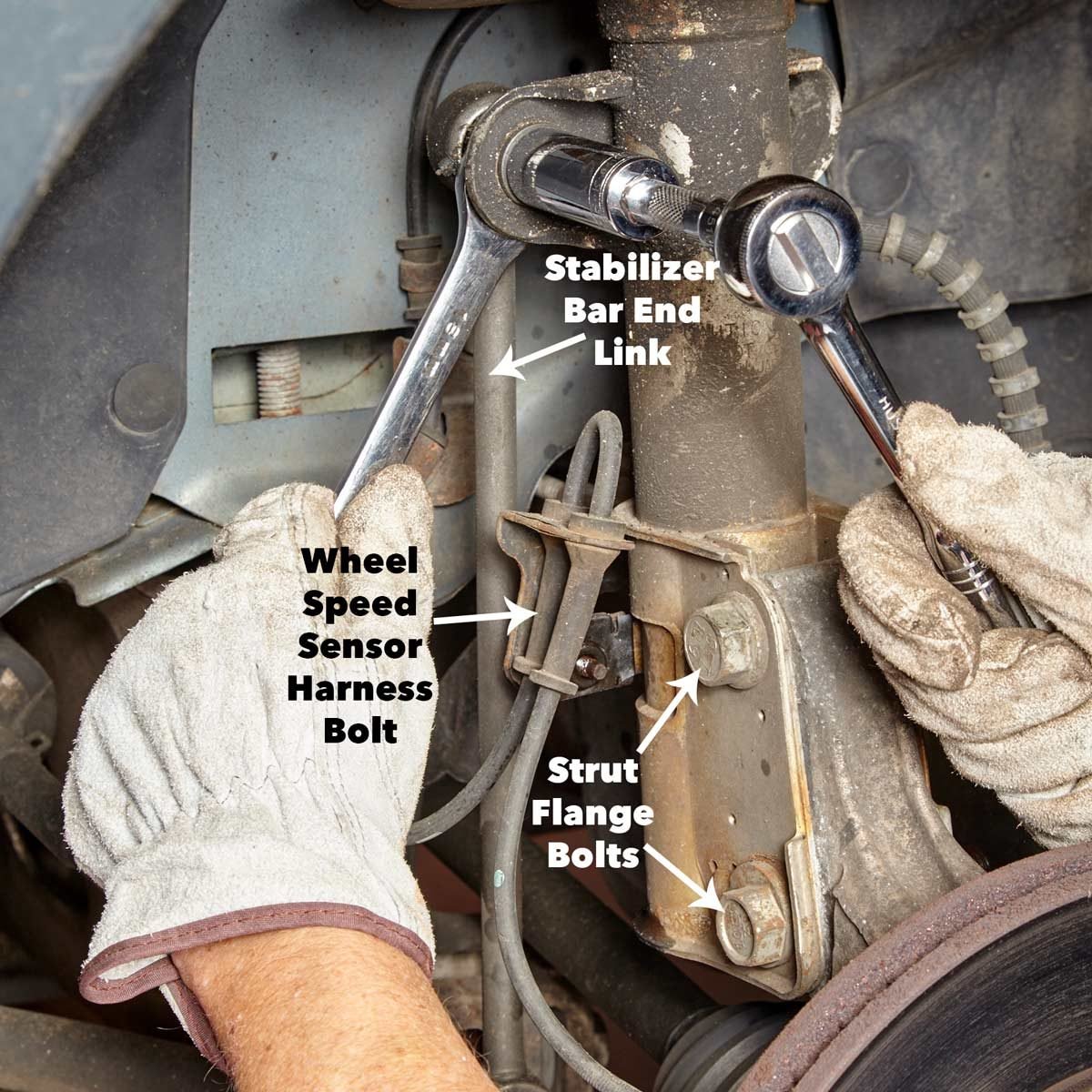

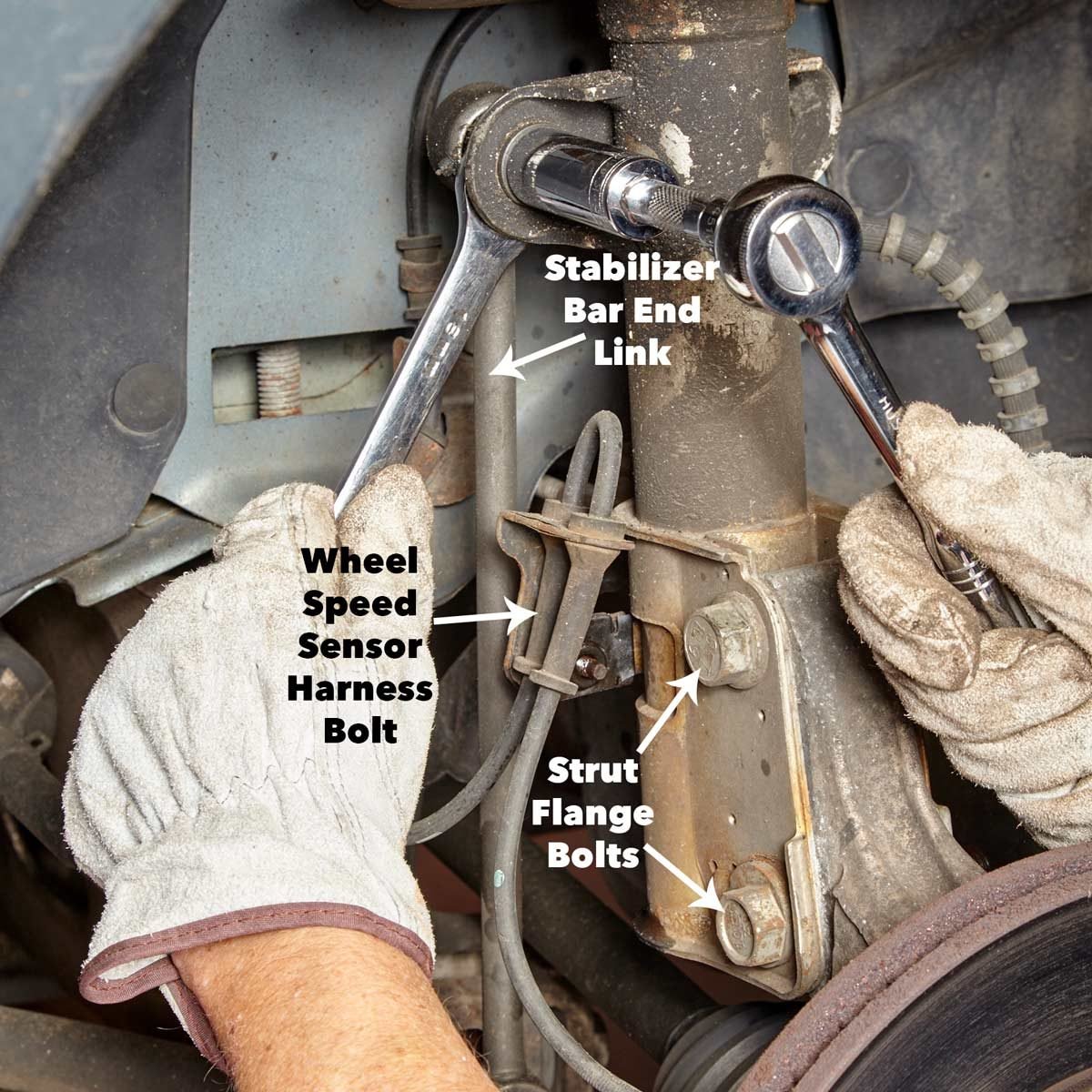

It's a lot like this

So this is what I'm struggling with. If it is attached to the strut as in the pic, does the wheel see the bar rate as 1:1, as I assume it does with the spring?

And if I mount it, instead, to the control arm, but in the same plane, or inline with the original mount, does the rate remain the same, or does it change based on the distance from the wheel? My assumption is that it does, but even though this kind of thing is normally pretty straightforward and intuitive, I'm not seeing it this time.

As shown in the picture, it's 1:1 just like the strut. If you mount it to the control arm, the motion ratio is going to be determined by where it is on the arm- the closer it is to the balljoint, the closer to 1:1 it will be.

This is all assuming the bar is at the correct angle, stuff changes if its' arms are angled up or down too.

Suprf1y

UltimaDork

1/30/20 2:01 p.m.

I think you mean wheel rate, but it looks like I was on the right track. I already took it off the strut at the top and instead cut off the top (endlink) ball joint, threaded and mounted it, inverted to the contol arm, old school with rubbers from a Chev truck. It doesn't appear to be any different, but it's just a DD.

dps214

Reader

1/30/20 2:02 p.m.

To put some math to it: The motion ratio in the standard arrangement isn't quite 1:1 since the strut isn't exactly in line with the wheel arc and the link isn't quite in line with the strut, but both are pretty close. Overall the end link motion ratio is probably 0.95:1 or better. Dropping it to the control arm it'll most likely land somewhere in the middle of the arm, for a motion ratio of about 0.5:1. Since wheel rate = spring rate x MR^2 the effective rate of the bar at the wheel drops from around 90% of the bar's rate to around 30%, maybe 40% if you're lucky. Mounting the link to the control arm means it no longer has to articulate, so you can shift the attachment point out of plane towards the outer end of the arm to get a better motion ratio. But a) the link now being angled gives away some of the motion ratio you've gained and b) having the link out of plane isn't going to be great for durability which is the whole point of what you're looking to do.

Suprf1y

UltimaDork

1/30/20 2:09 p.m.

It's actually mounted reasonably close to the end of the control arm just behind the (wheel) ball joint and pretty much just below the original top mounting bracket on the strut, and still reasonably vertical. At least as much as you could expect from a traditional sway bar endlink arrangement with the rubbers at both ends. The way it looks now I would expect it to last the life of the vehicle.