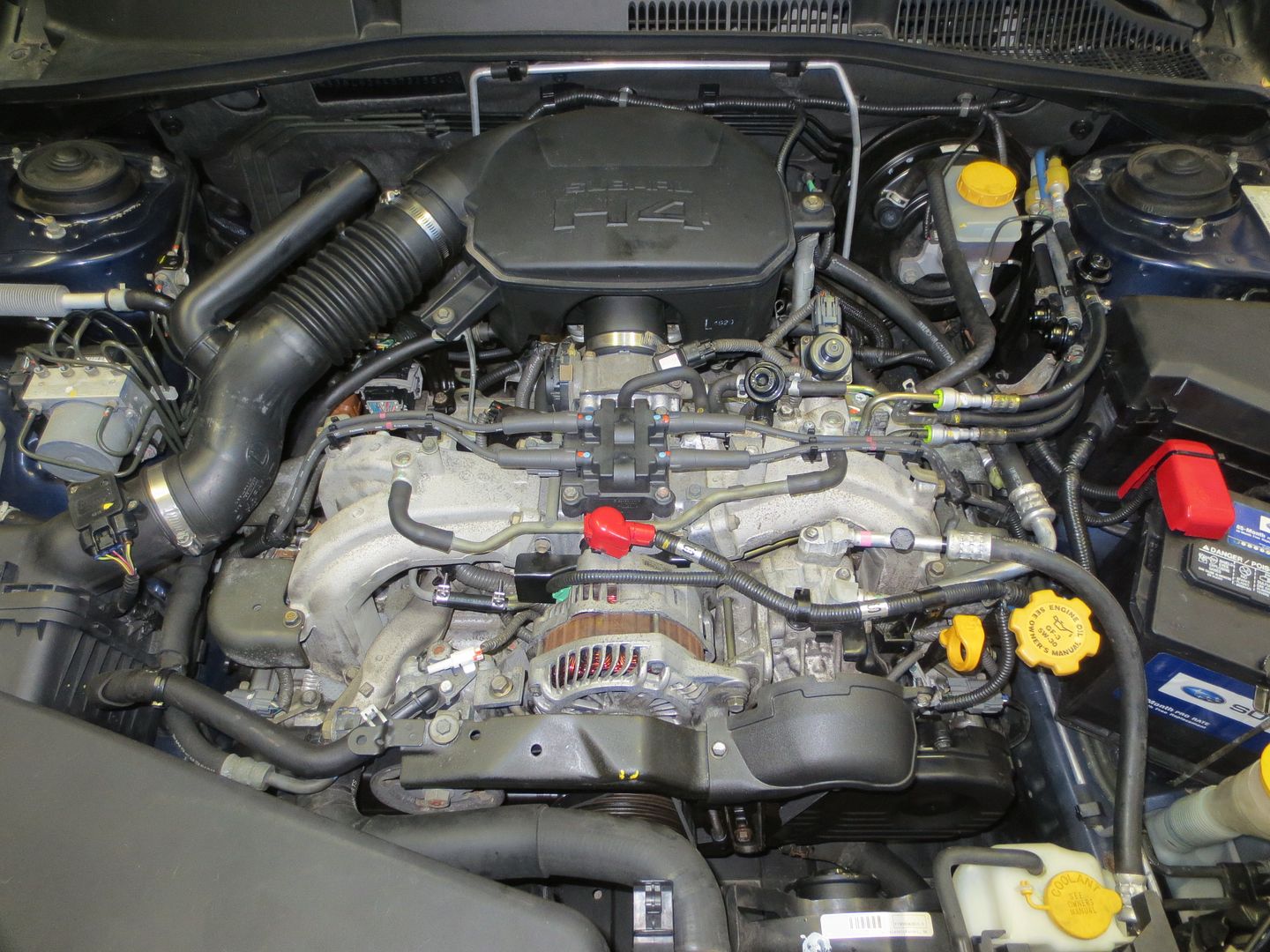

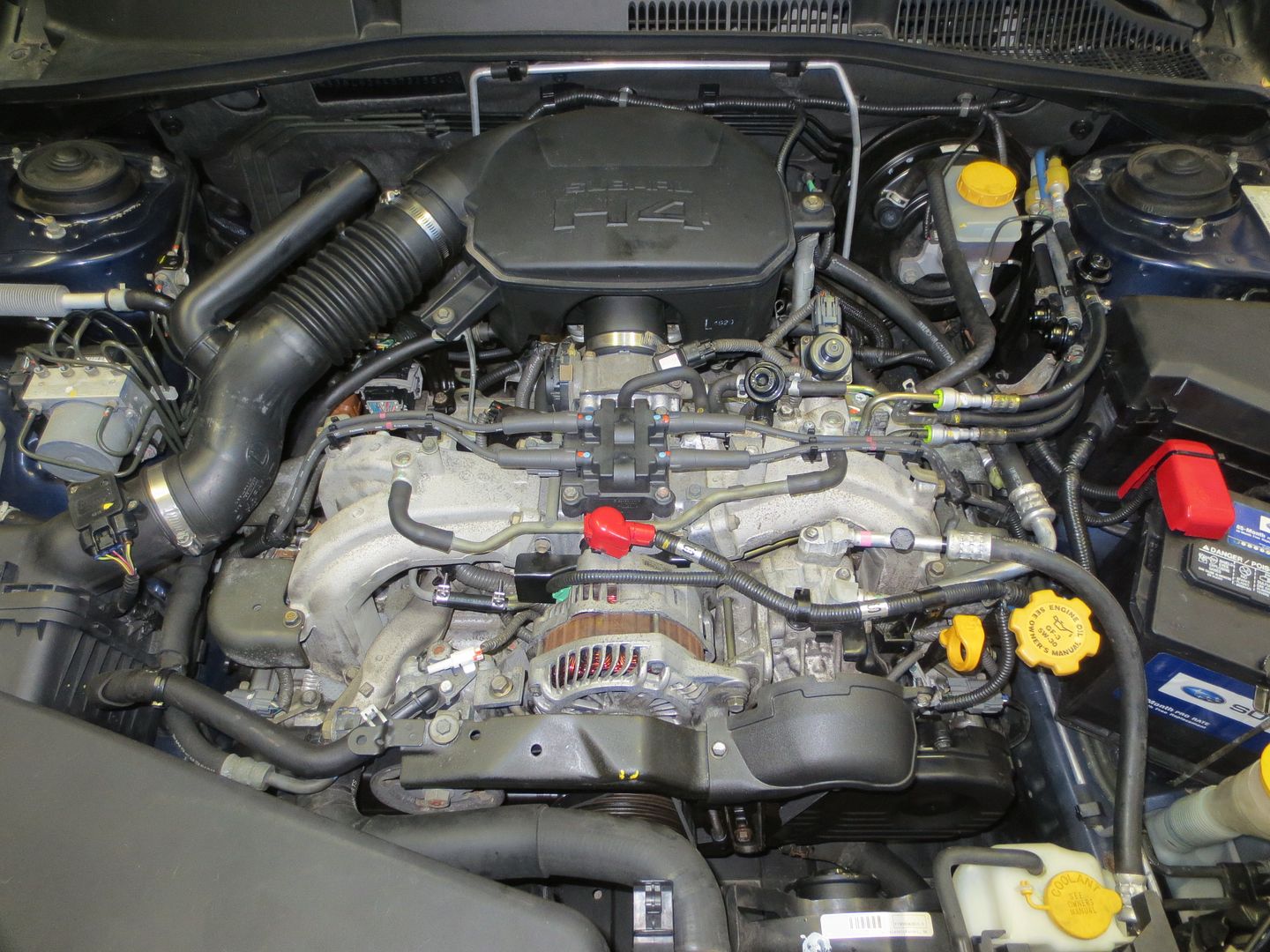

I just finished up an engine-out, head gasket/timing belt/valve adjustment on my 2005 Subaru Legacy 2.5i. It has the non-turbo EJ253 and 4EAT automatic. I had a little trouble lining up the engine and transmission, but finally got it in place and used the bolts to pull everything together. I attached the first bolt connecting the flex plate to the torque converter, but when I went to rotate the crank pulley to get to the next bolt hole, it was locked up solid. I pulled the engine back out and it's now on the stand. The engine turns over as it should, but I am unable to rotate the torque converter.

Googleing "Subaru Torque Converter" immediately told me that I was not the first one to do this. Apparently, it's very easy to pull the torque converter out a fraction of an inch when removing the engine. The shaft gets out of alignment and then jams back in the wrong place when you try to join the engine to the transmission again.

So...I understand what I've done, and I think I know what I need to do, but I've never messed with an automatic transmission before (and this will be the last time). I need to start by pulling out the torque converter and shafts.

Any advice from anyone who has done this before?

Next time make sure the torque converter is deeper than the flexplate extends from the bellhousing face (I use a finger gauge to check, it's not rocket science, it'll either clear with ease or be way off) and make sure the converter can move as you bolt the engine and trans together. This is all useless info NOW but useful for when you try to do it again.

Whether you borked the front pump or not, I can't say.

NGTD

SuperDork

11/2/14 7:56 a.m.

I did this when I replaced the engine in a 2007 Impreza that I flipped.

I re-seated the converter and it was fine. Just make sure it is fully seated and will spin easily before bolting the engine back up.

I cannot get the torque converter out. It's just supposed to slide out without fasteners, isn't it? There's no info on it in the shop manual.

Yes, it should just pull out. It's free-floating and only attaches to the flexplate.

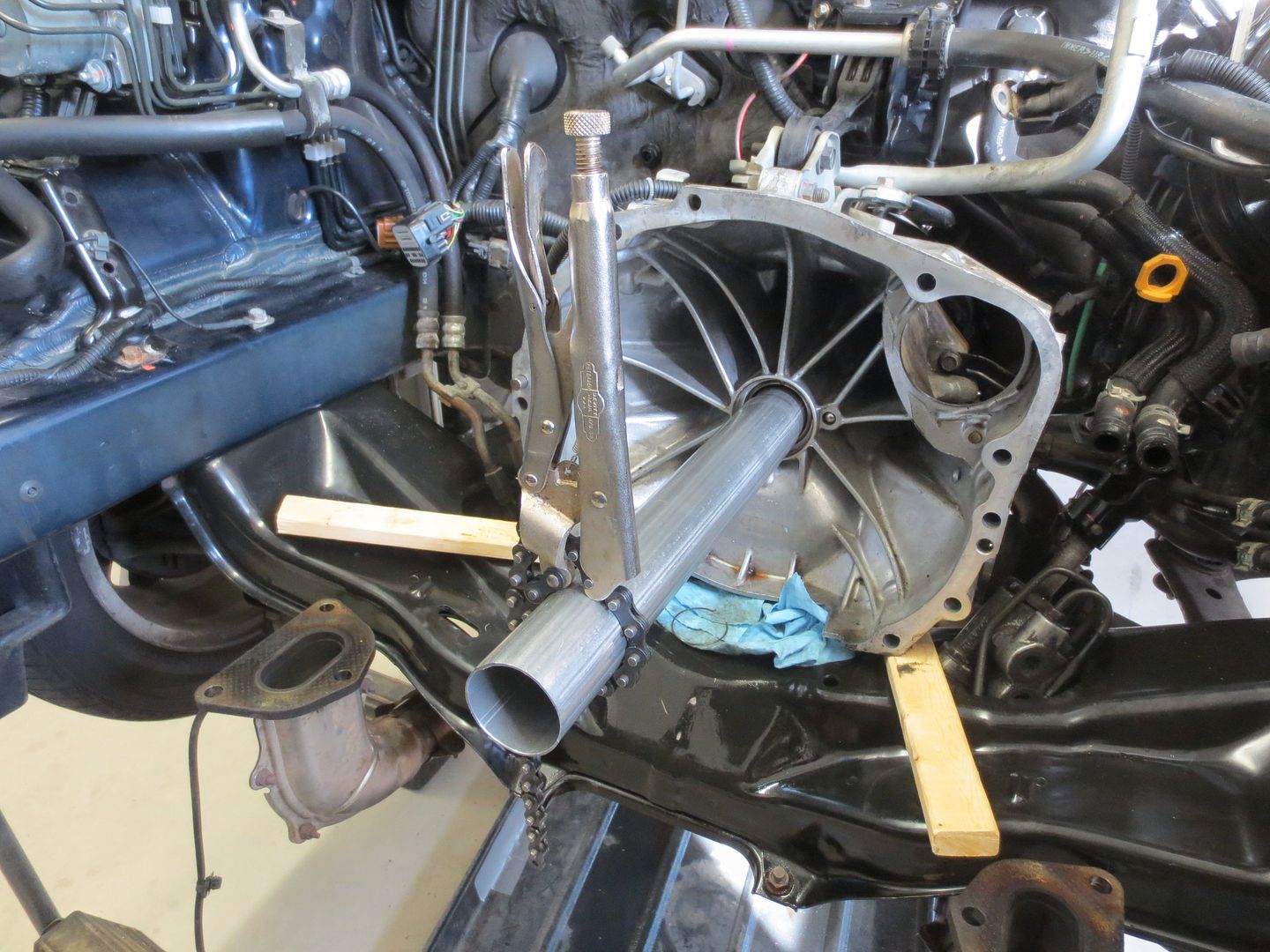

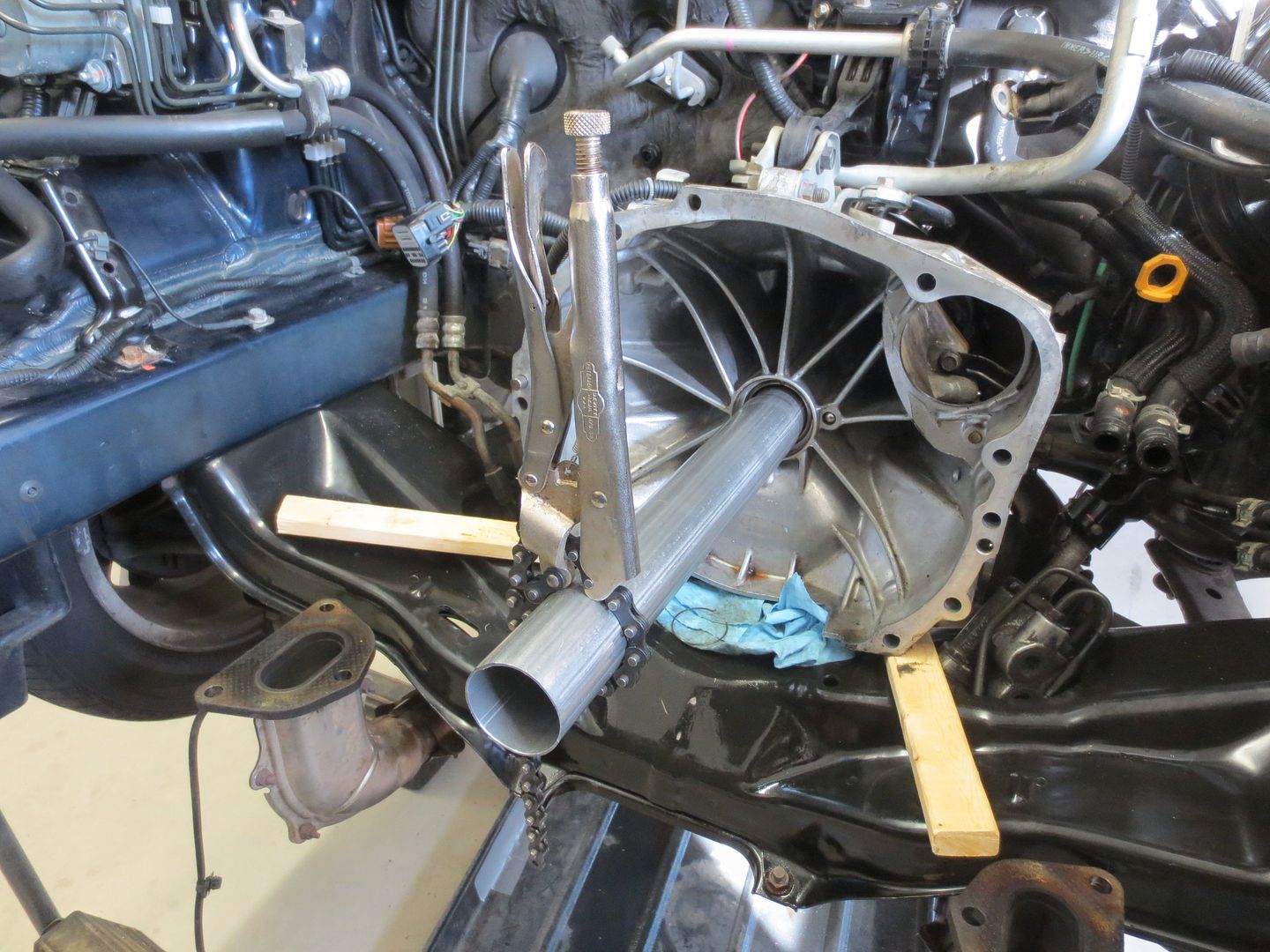

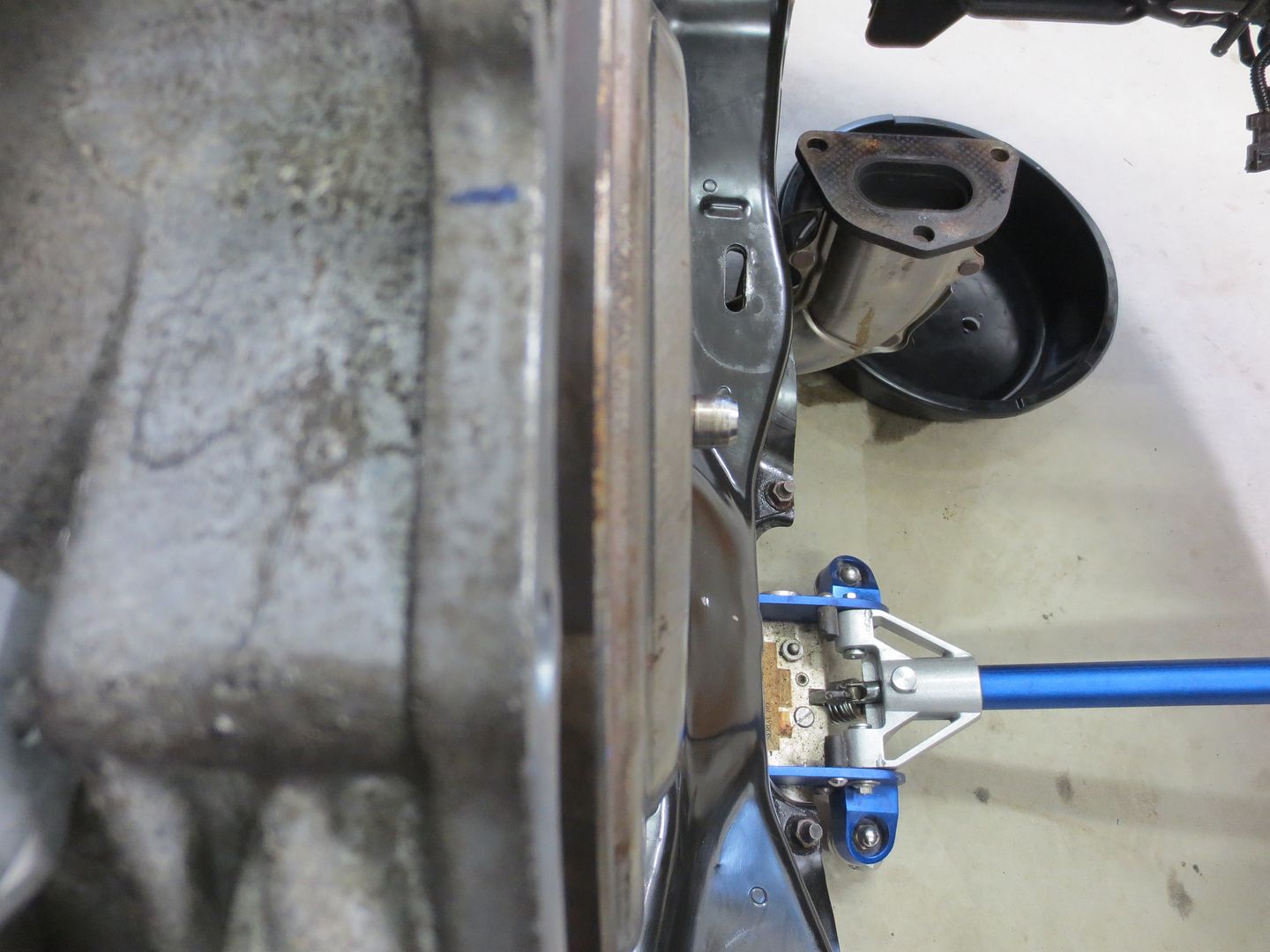

Torque converter and inner shaft are out. Now I need to get a piece of 1 7/8" exhaust pipe and make a Fornetti14 tool.

http://www.rs25.com/forums/f8/165059-correct-torque-converter-seating-depth-5.html

I made the tool, but the part absolutely refuses to come out. I'm pretty sure that the transmission has to come apart. Ugh...

Two things come time mind -

I'm pretty sure I needed that flat round plate at the end to twist & pull back on the pump shaft that was stuck inside. I think I had a pipe wrench on the end to turn & pull at the same time. It took me some time to fool with it, but it did pop out. When you are turning & pulling, try to pull straight out.

I also ground the end of the exhaust pipe tool so it would fit better into the transmission abyss.

I used a piece of tapered pipe, so no grinding was necessary, but it wasn't strong enough and it flared outward and rode up over the bumps when I twisted it.

I didn't try hammering on the tool.

You know, the more I think about it, I think the twisting wouldn't help at all.

It needs to come out of their straight and not while twisting.

I really need to take one of these apart in the salvage yard sometime.

It got jammed in straight, it probably needs to come out straight.

Kenny_McCormic wrote:

It got jammed in straight, it probably needs to come out straight.

Excellent point. I never thought of that.

I finally got it to come out.

I ended up making a second tool out of another piece of 1 7/8" exhaust pipe. I bought the first piece at Advance Auto. It was thin walled and too weak to hold it's shape. I bought another piece at Auto Zone and it was much heavier. I had to cut a deeper "L" shaped slot into and bend the ears down a little bit to get it to grab. Once I got it to hook on, I put the pipe wrench back on, gave it a few taps with a hammer and it started to come out.

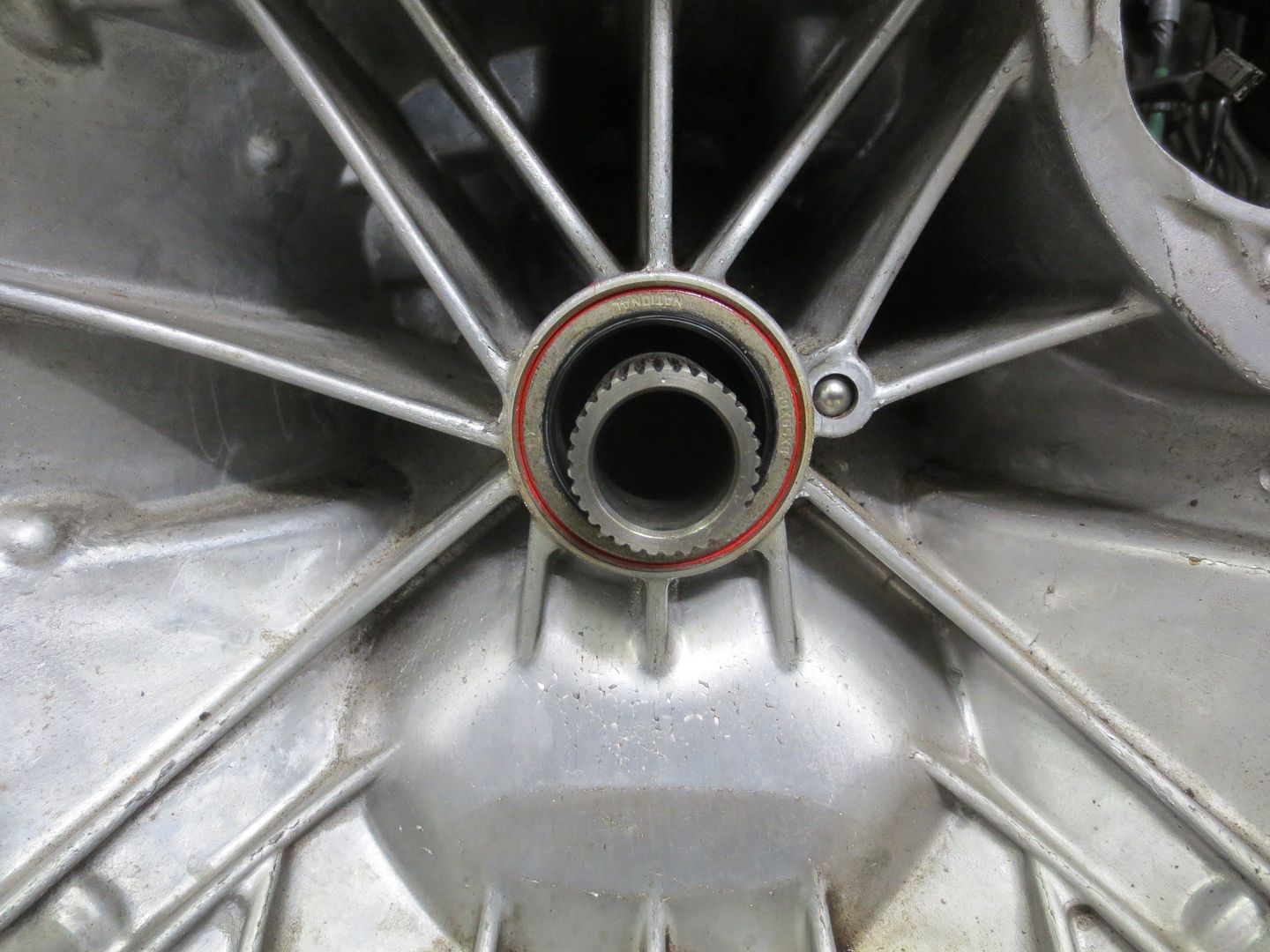

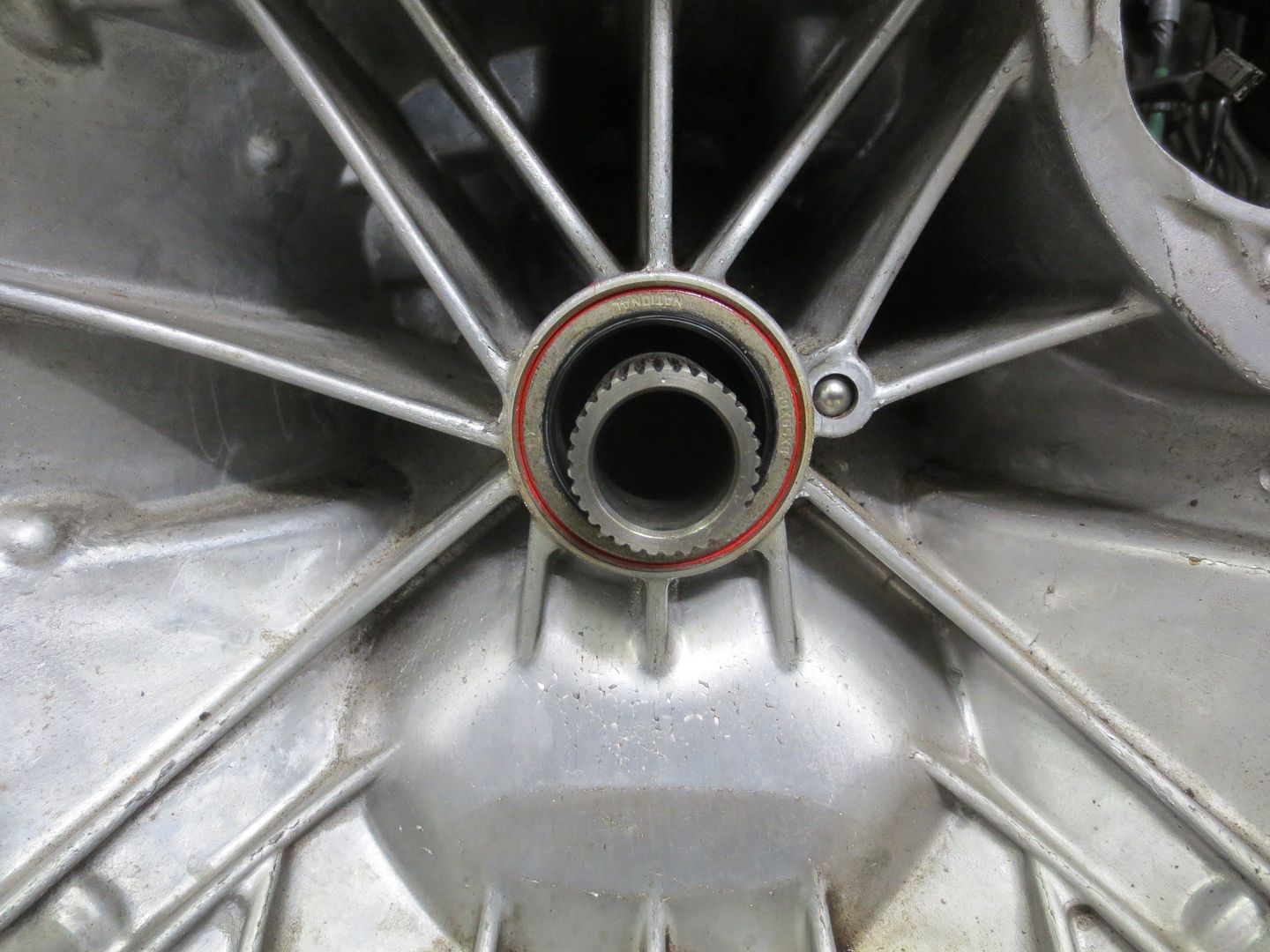

This is supposed to be round with two machined flats, not square.

A replacement should arrive by UPS tomorrow afternoon and I'll see if I can get everything back together.

Bottom line: I could not have saved this transmission without advice, photos and parts from Fornetti14.

Thank you.

NGTD

SuperDork

11/4/14 3:37 p.m.

GRM to the rescue!!

Again and again and again and . . . . . . .

The replacement shaft has arrived, courtesy of Fornetti14. It must be an updated version, as it has an extra oil seal at the far end. I measured them with the micrometer and they are within ten thousandths of an inch of one another, so I decided to go ahead and use it.

The old damaged one is on the right

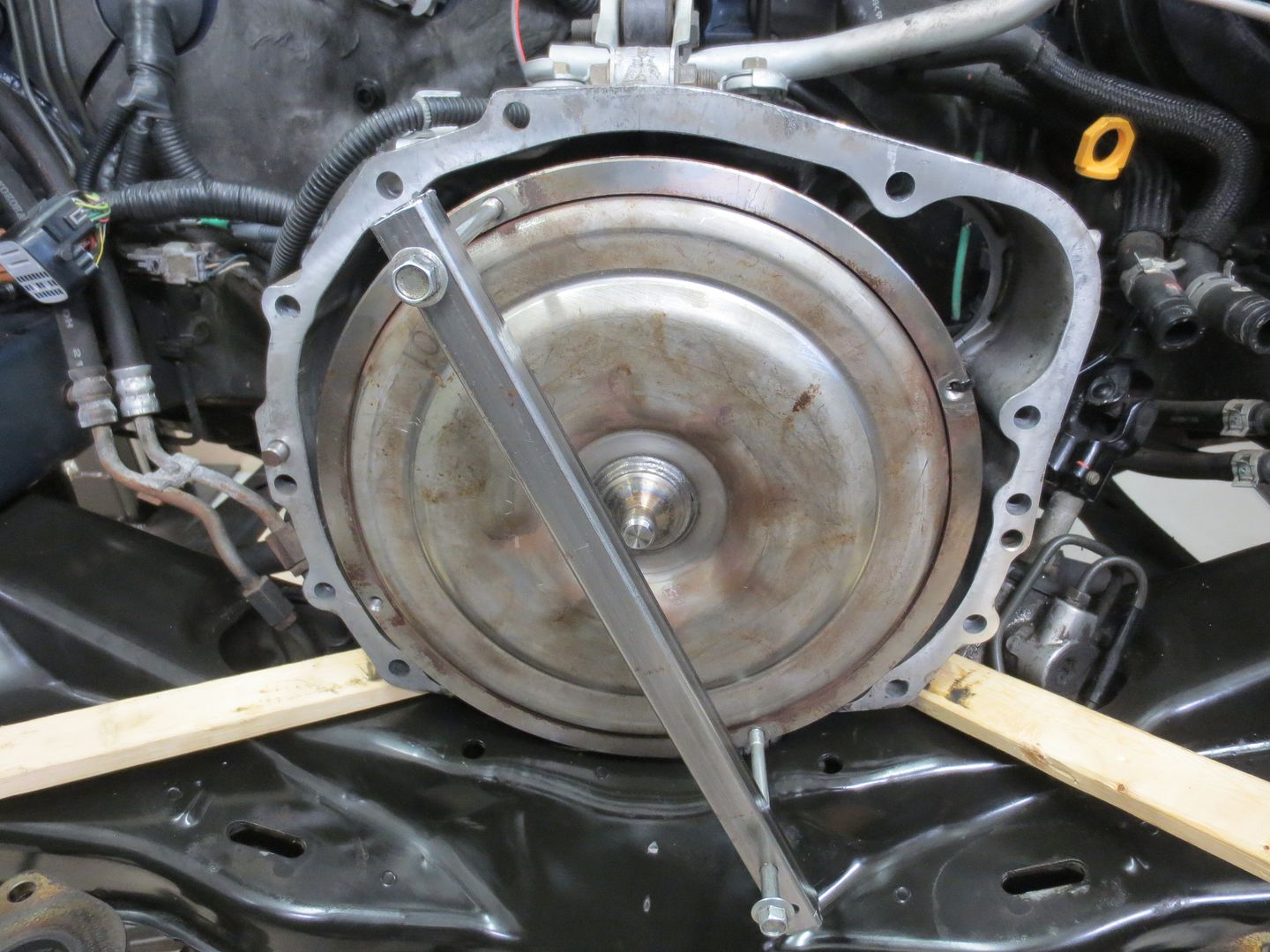

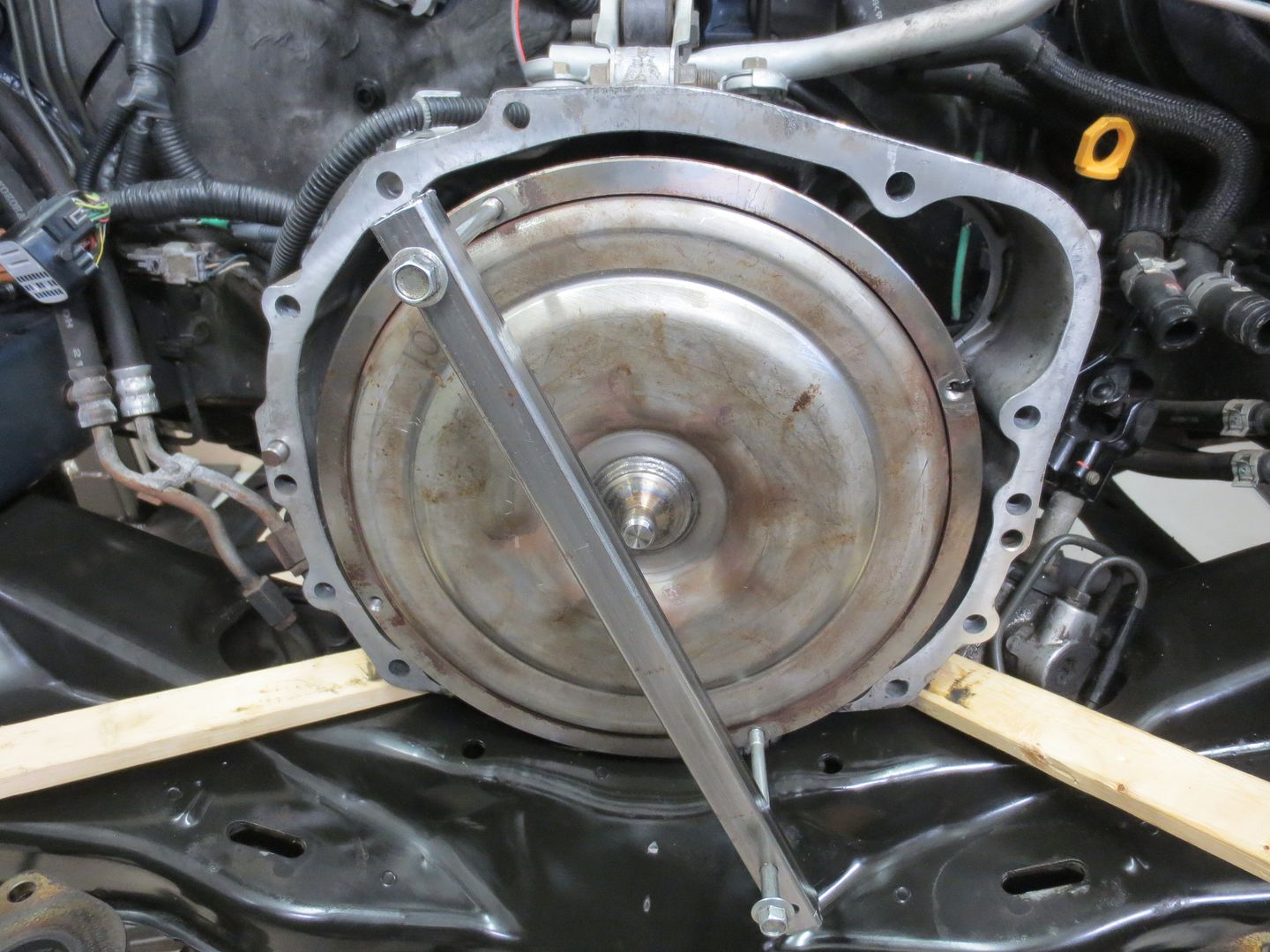

Torque converter and shafts ready to go back in.

New oil seal.

I added a handle when I was trying to remove it and it was helpful when it came time to reinstall it too.

If you're ever faced with this situation, slide the torque converter back in and turn it until it drops into place.

You are not done yet!

Then keep turning and pushing gently and it will drop in a little further.

You are not done yet!

Keep turning and wiggling and it will drop in a third time. I knew about this ahead of time, but I still thought I was done after the second step. It wasn't until I measured it that I knew that it wasn't fully seated. The Subaru shop manual says that it should be less than 8mm from the machined surface of the bell housing to the engine side of the torque converter. When mine was fully seated, it measured 3.1mm

This is how it looked after step 2

Once it dropped all the way in, I ran a cable tie through the torque converter, back through the starter hole and around the threaded stud for the starter. Once the engine and transmission were almost fully bolted together, I cut the cable tie and pulled it out through the starter hole.

If I ever remove the engine from a Subaru with automatic transmission again, I will add this cable tie as soon as the engine and transmission are separated.

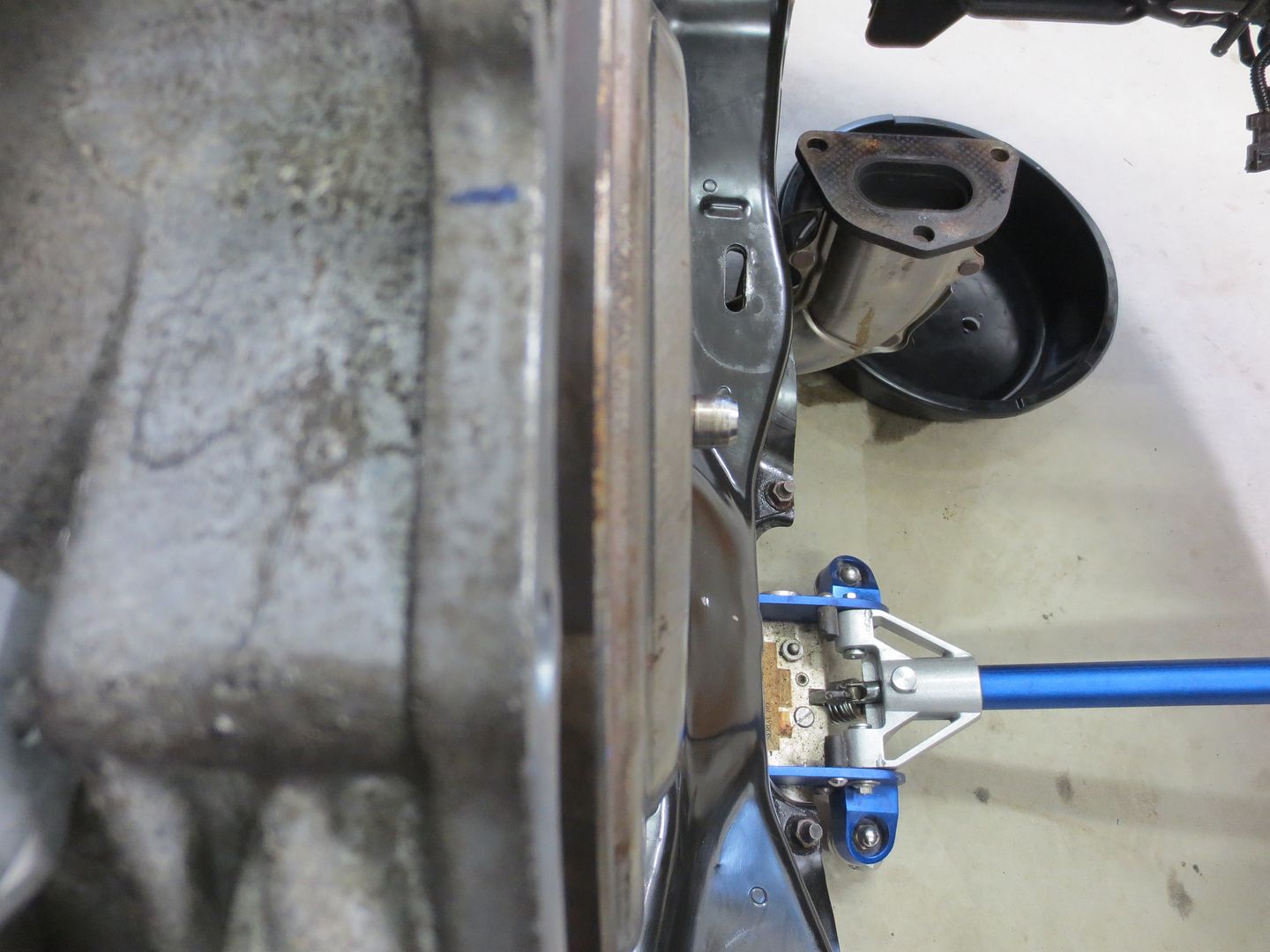

The engine and transmission are now bolted together. The motor mounts gave me a little bit of trouble before they would line up with the frame, but once I removed the bolt from the dog bone transmission mount, they dropped right in.

How did you damage that shaft thing? Go from round to square?

The torque converter was only out by a fraction of an inch, but it was clocked wrong. I wrecked it when I tightened the engine to transmission bolts that last bit. It's only the last 3/16" that's squared off. Two sides of the square are machined flats.

When you pull these engines, you have to lift it to clear the motor mounts, loosen the engine to transmission bolts, then put a jack stand under the transmission and lower the lift a bit to get the engine and transmission to separate. You end up dealing with a weird angle and it makes it tricky to line everything back up again. The engine housing has a tendency to grab the torque converter as they come apart.

Once I created the problem, I did a search and discovered that it happens all the time. Unfortunately, I had no reason to search for that info until after E36 M3 got bad. There were no warnings in the factory shop manual or the Haynes book. I'm fairly certain that nobody has ever done it twice.

Always always make sure the torque converter is more engaged than the flexplate sticks out.

Knurled wrote:

Always always make sure the torque converter is more engaged than the flexplate sticks out.

On everything. Its happened with every make and model of automatic at some point. At least with the Scooby, you don't have to buy a new pump, which is what happens with most of them.

Finally making some progress. It was a good day in the garage.

Just got back from a victory lap around town. New head gaskets, timing belt, pulleys, water pump, valve adjustment, etc... No leaks or funny noises, no signs of any transmission issues.

It's been a long week...

In reply to Woody:

There is nothing better than a victory lap after thrashing on a car for a week. Congrats!

It's alive! Still going to sell it?

I'll drive it for a few weeks to make sure that no issues pop up, but I do need to sell it. The fleet is a little heavy right now and I'll have no place to put the snow with an extra car in the way. My truck and my daughter's Honda are parked outside full time, so there's no room for this one.