OK, I know I should just deal with the inevitable. 1999 Sierra, trans needs to come out. I can't imagine I'll win the battle against 18 years and 280k miles but thought I would ask. I soaked them in Kroil today and won't be back to see it for three days. Is impact a good idea or a bad idea?

I like the judicious use of an impact, (short, quick bursts, off, on, off, on) maybe some heat from the torch.

You might be surprised at how easily they come off.

Also, if you need new hardware, spend the extra buck or two on OE stuff. It will fit and work so, so much better than aftermarket stuff.

Best way to get them out that ive tried is tighten them first before trying to remove them. It works on southern small block mopar.

Dusterbd13 wrote:

Best way to get them out that ive tried is tighten them first before trying to remove them. It works on southern small block mopar.

I'll second that. My success rate went way up when I started doing this.

I think the Chevs of the 90's bottom the nut out on a step in the stud, so tightening might not work in this case. Generally a good suggestion, though.

Sonic

SuperDork

3/12/17 5:24 p.m.

Heat them up nice and orange, I've been amazed at the crusty exhaust bolts I've been able to remove that way

Soak them. Heat them. Soak them again as they cool (make sure you have enough ventilation for the smoke). Then heat the ever loving crap out of them. And then hit them with an impact.

If that can't get them off, I doubt anything will.

They are undersized(imho) and impact will blow the heads off. Heat and a 3/8 ratchet is all i use on those

Sonic wrote:

Heat them up nice and orange, I've been amazed at the crusty exhaust bolts I've been able to remove that way

The good part is, if they are really bad, there's no threads below where the nuts are, so once you get it past three-four turns, it's off.

When they are only slightly rusty, you have a bunch of rust-filled threads that you have to graunch the nut past. This is where running a new nut over the threads first helps. But you're still going to want to get the nut orange, and stop trying to turn it once it sticks again, get it orange again before trying again.

This is one place where Chrysler did it right. The exhaust is held on with bolts, not studs. No threads in the exhaust manifold. Just cut the old bolts off, easy as pie.

NOHOME

PowerDork

3/13/17 6:13 a.m.

patgizz wrote:

They are undersized(imho) and impact will blow the heads off. Heat and a 3/8 ratchet is all i use on those

Are they similar to the tiny exhaust studs used on the Ford Modular engines? Good luck. Thread rust is the least of your problems, the rust attacks the nuts and there is nothing to grab with a socket.

Knurled wrote:

When they are only slightly rusty, you have a bunch of rust-filled threads that you have to graunch the nut past.

TIL:

graunch

/ɡrɔːntʃ/

verb

1.

(transitive) ( NZ) to crush or destroy

Exhaust studs in general suck! I once had to pull the head off of a BB Chevy just because someone (Not me) went gorilla on a couple of exhaust manifold studs and snapped them off. I do remember seeing a friend who at the time worked at a Midias Muffler shop take a torch and heat a broken manifold stud up and then hitting the cutting OX in and blowing out the stud with out doing much to the threads in the manifold. All it took was a tap to clean out the threads and it was good to go. The thing is I saw him do this a number of times and not just him getting lucky that one time.

NOHOME wrote:

patgizz wrote:

Are they similar to the tiny exhaust studs used on the Ford Modular engines? Good luck. Thread rust is the least of your problems, the rust attacks the nuts and there is nothing to grab with a socket.

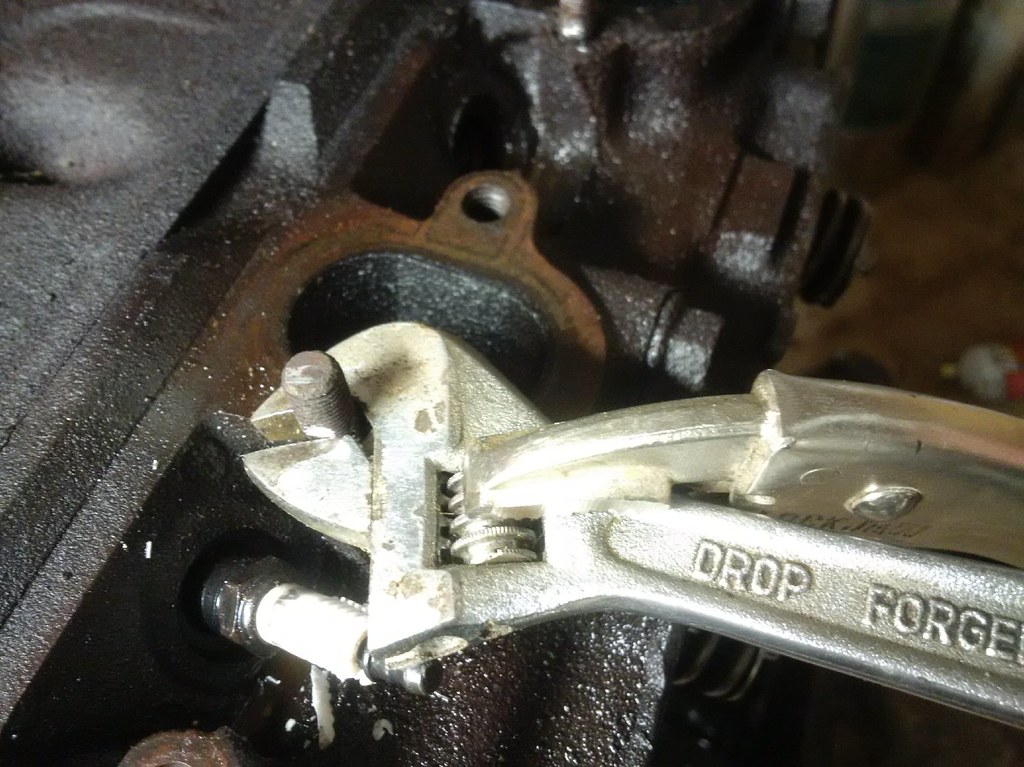

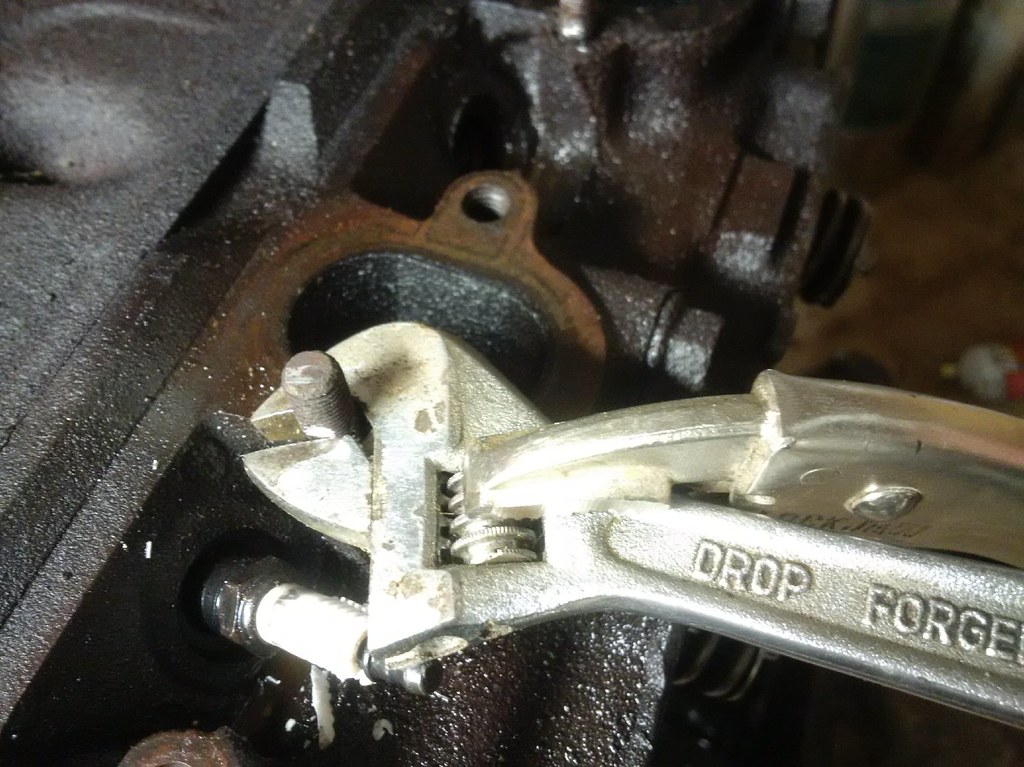

This is how I did it on a Big Block Ford (same issue):

Will a typical small bottle propane torch generate enough heat or do I need something more angry?

Sonic

SuperDork

3/16/17 6:18 a.m.

Much more angry, propane will never be hot enough. I have a small kit like this for the rare times I need it

http://m.homedepot.com/p/Bernzomatic-WK5500-Brazing-Torch-Kit-361487/300055608

Take it to your friendly neighborhood muffler shop and ask them to replace the gasket for you. They deal with the mess every day and it's worth the $75 to drink coffee and surf the internet while the job gets done.

Life lesson from the air cooled VW crowd: If you use brass or copper nuts they will be easier to disassemble next time.

A small bottle of map gas is what you need. I have a torch for mine that has about four feet of hose on it so getting the torch in to tight spaces is easy. I have had it about thirty years way easier than luging out the ox/acc rig. In fact the map gas torch I have is a big reason why I got rid of my tanks. It wont cut anything but is dam good at getting things good and red hot.

I have an older version of this.

Ok I misinterpreted. The studs aren't undersized on your truck, but the manifold to head bolts are. Chances are you have a few with missing heads right now.

Either way, get them red hot. Somehow i managed to get them all off when i changed out the 5.3 in the snaab but it had 1/3 the miles and was from a no winter climate. I did hammer on them with the impact and a 6 point socket. The studs themselves are strong, it's the nuts that are weak and love to round off especially if you try and use a 12 point socket

Another option is to hit the nuts and studs with phosphoric acid, they sell it as rust dissolver. Works great, havent ever tried it on exhaust studs though.

+1 on phosphoric acid, loc-tite markets theirs as "naval jelly." If you're not in a hurry you just slather it on and let it sit, the longer the better. After that, heat plus ratchet.

I have never tried it, but I watched a video that made it look easy: Heat it up glowing red (not super hot cherry red) and then melt a candle on it. Supposedly the paraffin wicks into the threads very well.

Naval jelly is garbage, get the liquid stuff rust dissolver. If you use naval jelly get the aluminum one, it is stronger.

Like Curtis said, I took an engine building class and the prof used the oxy/settlin to remove a galley plug or something, heat up red put wax on and thing comes out easy.

If you really flooded them they might just come out cold after soaking a few days. I pulled an old Y pipe once where one side snapped off both studs and the other came right off, both sides got soaked for days, and then I think torched (propane, just smoking hot), hit with oil again, and removal by hand attempted with a socket. The difference was the easy side was much easier to hit with the can of PB blaster and got a more effective initial application.