Check this out. http://www.thetruthaboutcars.com/2013/07/the-new-waissi-engine-pistons-but-no-connecting-rods/

author says said:

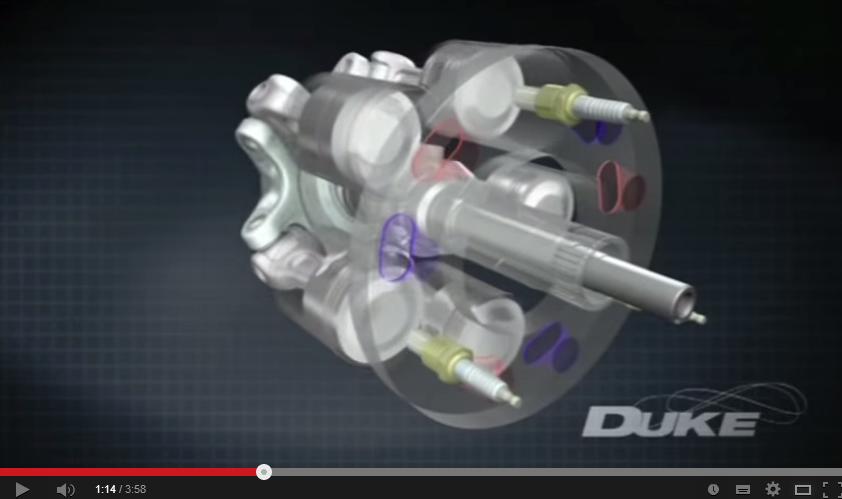

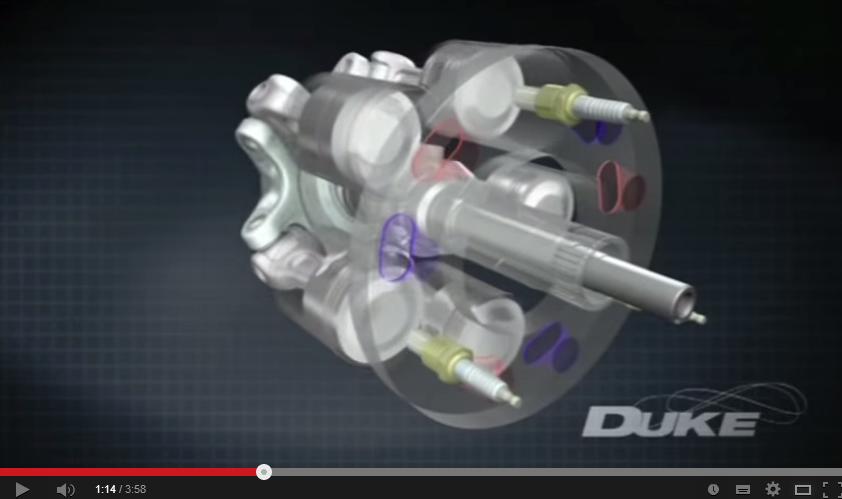

Waissi’s new engine is an opposed piston configuration that uses conventional head, valve and combustion chamber designs. What’s different is that the Waissi engine has no connecting rods between the pistons and the crankshaft. Instead, the pistons push directly on what Waissi calls a “crankdisk”. The engine’s output shaft has a large journal mounted eccentrically on the shaft, with a bearing ring that spins on the journal. The outside surface of the bearing ring fits into a landed grove at the bottom of the piston structure. When the piston is pushed down during the power stroke, the downward motion of the piston causes the crank to spin because of the offset as the bearing ring rolls under the piston landing. Each piston has an opposed twin which then spins the crank disk another 180 degrees to complete a revolution. The two pistons are attached to each other via steel rods, which keeps them timed properly. In his latest design, Waissi has replaced the rods with solid plates.

T.J.

UltimaDork

5/15/17 5:03 p.m.

Interesting idea. Not sure what problem it is trying to solve though.

T.J. wrote:

Interesting idea. Not sure what problem it is trying to solve though.

The problem of ICE engines sending ~2/3rds of the energy in our gas out the radiator.

I wonder what efficiency numbers this engine could get with Koenigsegg Freevalve heads on it.

T.J.

UltimaDork

5/15/17 6:12 p.m.

In reply to GameboyRMH:

I don't see that the connecting rods are a big source of thermal inefficiency. Please explain. Seems like more friction and not less to me with this setup.

EDIT: Ok, now I read the article that was attempted to be linked in the first post. So the crankshaft is essentially lobed like a camshaft and the sets of pistons are connected together with rods (or plates) that are not connecting rods. Still seems like a lot of friction as themagic crank disk spins across the bottom of each piston.

http://www.thetruthaboutcars.com/2013/08/waissi-engine-update-the-differences-between-waissi-and-bourke-engines/

what the heck. My links have sucked since I've came back around here.

Seemed odd to me. Almost like trying to combine piston and rotary engines. It was just odd. Thought I would share.

GameboyRMH wrote:

T.J. wrote:

Interesting idea. Not sure what problem it is trying to solve though.

The problem of ICE engines sending ~2/3rds of the energy in our gas out the radiator.

I don't see this doing a dang thing about that. It looks like it still uses conventional combustion chamber shapes (which, to be frank, are already Really Good and hard to improve upon) and they still use piston rings.

I really wish I could find WHERE I saw this, but a sobering statistic is that about 1% of all manmade energy is spent on piston ring friction. Not 1% of all fuel burnt, 1% of energy from all sources...

The only advantage I see to this setup (and all others like it, this idea is nothin' new) is that it should shake a lot less because the piston accelerations near BDC and TDC are the same. With a connecting rod, the accelerations are different, leading to things like 4 cylinder engine shake.

I don't see this reducing friction or improving efficiency much. And in the pics showing how its less parts... those parts (assemblies) appear to be much more complicated than a piston or rod.

If you really wanted to reduce friction, use a ball bearing setup instead of oil bearings in the crank and rods. Just like a ball bearing turbo. I know I've seen this setup on a motorcycle before.

Knurled wrote:

The only advantage I see to this setup (and all others like it, this idea is nothin' new) is that it should shake a lot less because the piston accelerations near BDC and TDC are the same. With a connecting rod, the accelerations are different, leading to things like 4 cylinder engine shake.

I think as shown the accelerations would be the same. However, you could grind that center ring into a cam-like profile to change acceleration and dwell...

ProDarwin wrote:

If you really wanted to reduce friction, use a ball bearing setup instead of oil bearings in the crank and rods. Just like a ball bearing turbo. I know I've seen this setup on a motorcycle before.

If this worked, OEMs would be doing it already, reducing friction in the main/rod bearings is huge.

I dunno why it's so important for turbos, but they spin much faster than crankshafts, so that may be related.

ProDarwin wrote:

I think as shown the accelerations would be the same. However, you could grind that center ring into a cam-like profile to change acceleration and dwell...

Accelerations would be slightly better than a traditional rod because you're eliminating the side-to-side motion in the rod, but yeah.

author said:

...What’s different is that the Waissi engine has no connecting rods....The two pistons are attached to each other via steel rods...

So what makes this engine so special is that it doesn't have 'connecting' rods...It has 'attaching' rods.

codrus wrote:

ProDarwin wrote:

If you really wanted to reduce friction, use a ball bearing setup instead of oil bearings in the crank and rods. Just like a ball bearing turbo. I know I've seen this setup on a motorcycle before.

If this worked, OEMs would be doing it already, reducing friction in the main/rod bearings is huge.

Needle/ball bearings can't support as much load as a journal bearing. Their main advantage is that they don't need as much oil, which is great for a motorcycle engine that is a 2 stroke or has a plunger type oil pump that measures output in cups per minute.

Interestingly, roller lifters' main weakness is the needle bearings failing. With a decent cam, they need to be pulled and inspected every couple thousand miles. The latest thing is journal bearings to replace the rollers, and they seem to be lasting a lot longer.

Looks kind of like a variation on the DynaCam aero engine, which I've been seeing occasional pics of for years.

I'm going bet this engine will end up like all the other 'revolutionary' 'super efficient' 'longer lasting' 'game changing' internal combustion engine designs that come around every couple years. They usually never make it past a couple running prototypes, if they even make it that far. They are always cool to see but thats about it.

a few examples:

I'm not against new engine designs but personally i think we have a pretty good thing going with current engines. there are a few though that have made it past the design/prototype phase and into production vehicles, but we still always seem to go back to the standard ICE

You could convince me that due to the lack of fastening hardware, it has less rotating mass (I havent, and dont plan to read the article...not sure if its covered there). Less mass = less momentum to overcome = faster revs and faster return to idle. I could also see an engine like that being a good fit for something like low rpm use in agriculture or in a generator since you could theoretically make more HP at lower rpms due to reduced mass to spin.

Im not an engineer, but I did stay at a Holiday Inn last night...

also a roller bearing touching the Piston Base would be Very Minimal in creating Friction and also may only need a small Footprint to ride on and just One per Pair not One each. I like it, plus It's Opposed so smoooth operation Like Porsche or subi,or Corvair or VW Or Lycoming

OOOHH!! NR750.

I need to go did into the googles, but I kind of vaguely remember the race version of it was designed to make a 'V8' within the GP rules of the day?