I have been doing some fiberglassing and I need to cut it to size. Not sure what the best tool to do the job is. I have a cordless dremal I have tried to use but the battery sucks and I don't seem to make much progress. I got an email today from harbor freight for a pneumatic die grinder only $10.

Not sure if that would really work given the size of the fiberglass piece I am working on. Any suggestions?

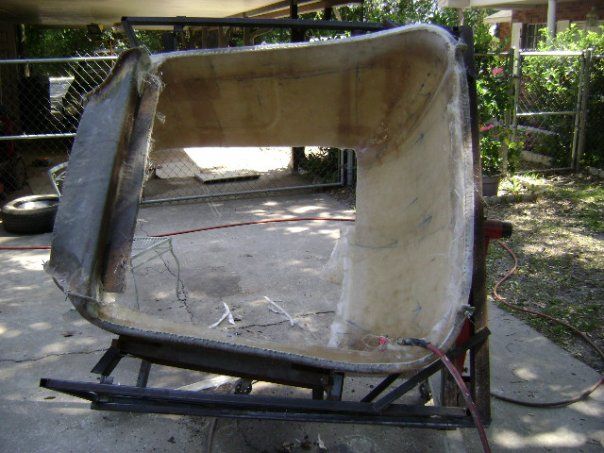

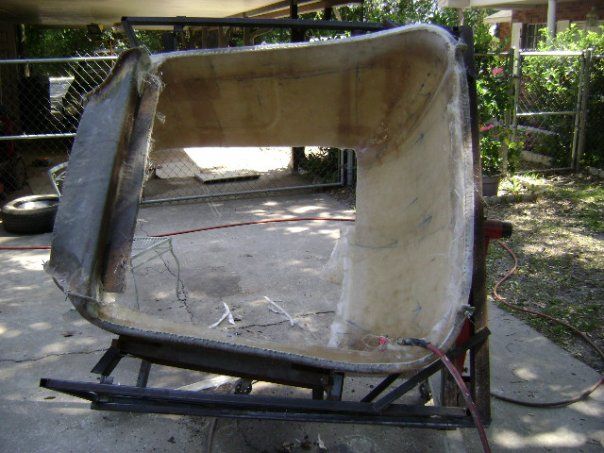

Here is what I am working on. Shorty Center Console for NB Miata

PHeller

UltraDork

9/27/12 11:04 a.m.

Angle grinder and a good mask.

Maybe one of those multi-tools that vibrates its way through things?

What about the $20 electric 3" wheel cut off die grinder from HF?

http://www.amazon.com/Black-Decker-RTX-6-3-Speed-Accessories/dp/B0001GUDRI/ref=sr_1_1?ie=UTF8&qid=1348761798&sr=8-1&keywords=Black+a%26+Decker+RTX

Ditch the battery powered tool and ditch Dremel's rather spotty reliability. BTW, the Dremel stands and tools work with the B&D rotary tool.

Otherwise, maybe try a coping saw?

oldtin

SuperDork

9/27/12 11:21 a.m.

Start with a decent mask and long sleeves. I use a grinder with cutoff wheel. For finer fitting a pneumatic die grinder or angle grinder with 2" sanding discs. The big grinder makes quick work of it, but things can go bad in a hurry too.

In reply to oldtin:

It easy to fix fiberglass in the event of cutting a little too much. There always plenty of resin and fiber to lay down.

The best tool for accuray is the oscillating type tool. The model makers (scale wind tunnel models) I know use them for carbom. The cordless versions out there would be acceptable for a home user...They don't make much in the way of a mess and the kerf is very small (1/32").

For speed and mess, go with the cutoff wheel. The resin may get a little sticky though.

jhaas

HalfDork

9/27/12 4:24 p.m.

THIS

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

JThw8

UberDork

9/27/12 5:11 p.m.

jhaas wrote:

THIS

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

Agreed, I use one of these or a set of hand held metal shears to trim it and then a grinder to finish the edge.

jhaas wrote:

THIS

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

I tried one of those. I'm going with Suck. Oh, it would cut through, but the blades lasted for zip. Might have got a foot or two before the teeth on the hack saw blades were totally gone.

A Sawsall type tool with metal cutting blades worked best for me.

I used to make my own T-Bucket hot rod bodies and other assorted fiberglass parts. I would always use a cut-off wheel grinder to trim everything before I removed them from the mold. I found that anything that oscilates or reciprocates, such as a saw, could sometimes cause the gel coat to crack.

JThw8

UberDork

9/27/12 9:16 p.m.

Dr. Hess wrote:

jhaas wrote:

THIS

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

I tried one of those. I'm going with Suck. Oh, it would cut through, but the blades lasted for zip. Might have got a foot or two before the teeth on the hack saw blades were totally gone.

A Sawsall type tool with metal cutting blades worked best for me.

Get better blades. Hell Im using Harbor Freight blades and I could cut fiberglass forever and not burn out a blade. I can use them on sheetmetal and cut a car in half on the same blade. You got some bum blades or you have something else weird going on.

Dr. Hess wrote:

jhaas wrote:

THIS

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

http://www.northerntool.com/shop/tools/category_air-tools+air-saws

I tried one of those. I'm going with Suck. Oh, it would cut through, but the blades lasted for zip. Might have got a foot or two before the teeth on the hack saw blades were totally gone.

A Sawsall type tool with metal cutting blades worked best for me.

The quality of blades for there saws vary quite a bit. The HF, Northern Tools, etc. are all chinese junk. If you can find made in USA bi-metal blades they will cut for quite a bit longer. I would still only use this saw for fine cutting and a sawzall for the long straight cuts.

pneumatic die grinder and thinnest quality wafer disc you can get

+1 for cutoff wheel. That's what's recommended for cutting CF, reciprocating/oscillating saws can cause delamination and scissor-type tools can cause cracks (especially if you try to snip through a small CF tube).

GameboyRMH wrote:

+1 for cutoff wheel. That's what's recommended for cutting CF, reciprocating/oscillating saws can cause delamination and scissor-type tools can cause cracks (especially if you try to snip through a small CF tube).

Agreed. Been my experience as well. A thin wheel cuts best.

This is what I think I am going to get. And for $10 if it stinks it not much of a loss, I can always find some use for it.